SolidWorks® 2011 Assemblies Bible®

Table of Contents

Part I: Introducing Assembly Basics

Chapter 1: Understanding Assemblies

Understanding the Purpose of Assemblies

Identifying types of assemblies

Creating an alternative to multiple assemblies

Creating Assembly Templates

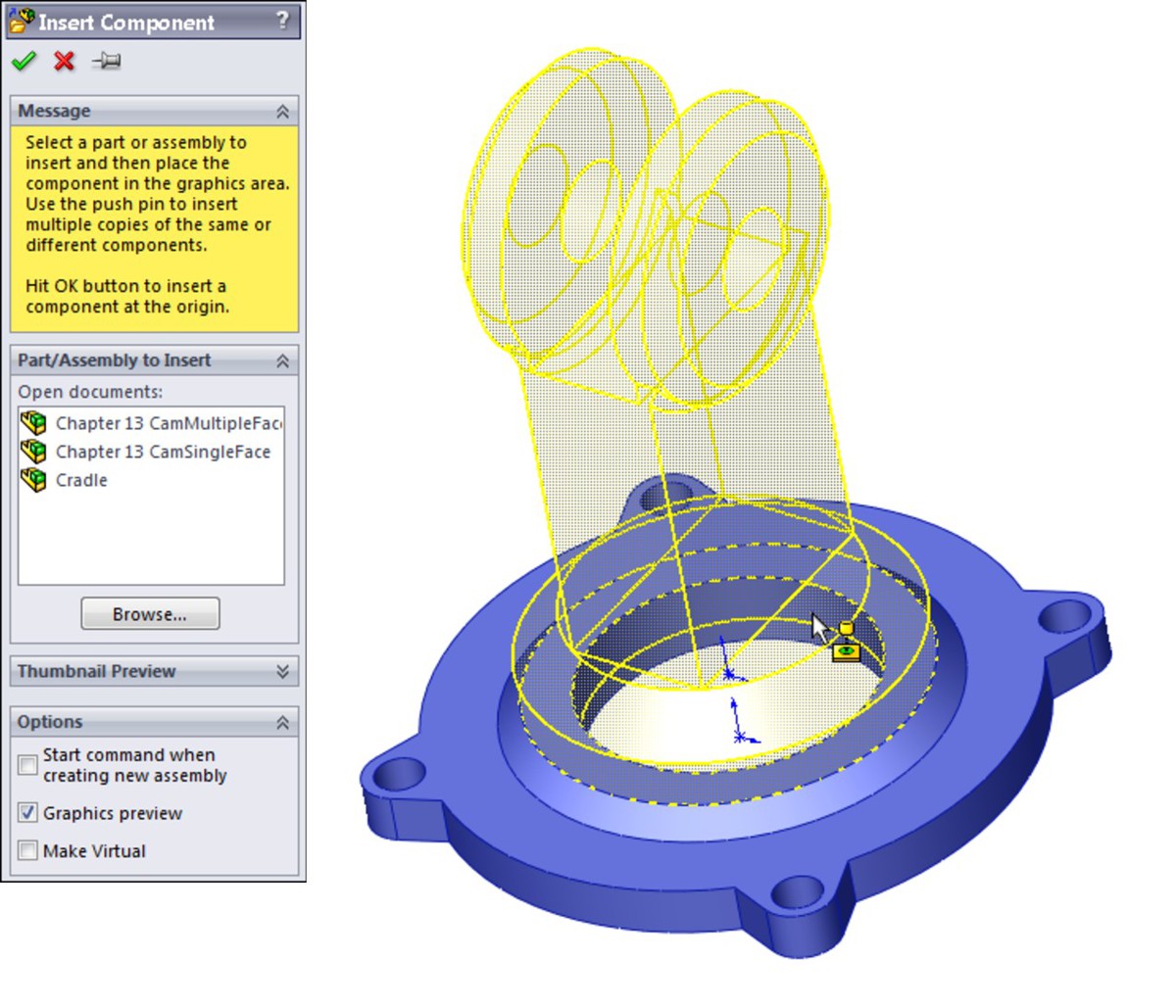

Putting Parts into Assemblies

Understanding External References

Referencing external files in-context

Referencing external files from a part

Summary

Chapter 2: Navigating the Assembly Interface

Identifying Elements of the SolidWorks Assembly Interface

Using the CommandManager and toolbars

Introducing the assembly tools

Using the Heads-Up View toolbar

Using the Shortcut “S” toolbar

Working in the assembly FeatureManager

Working with multiple document windows

Managing open windows

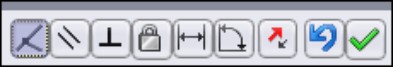

Understanding the Interface for Moving and Mating

Using the Move Component interface

Using the Mate interface

Summary

Chapter 3: Visualizing Assemblies

Manipulating the View

Using arrow keys

Using the middle mouse button

Clicking the triad

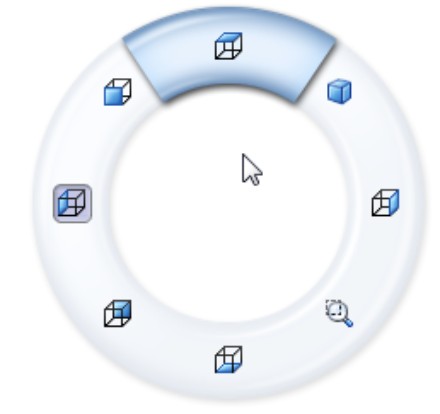

Using mouse gestures

Using the Magnifying Glass

Investing in a 3D mouse device

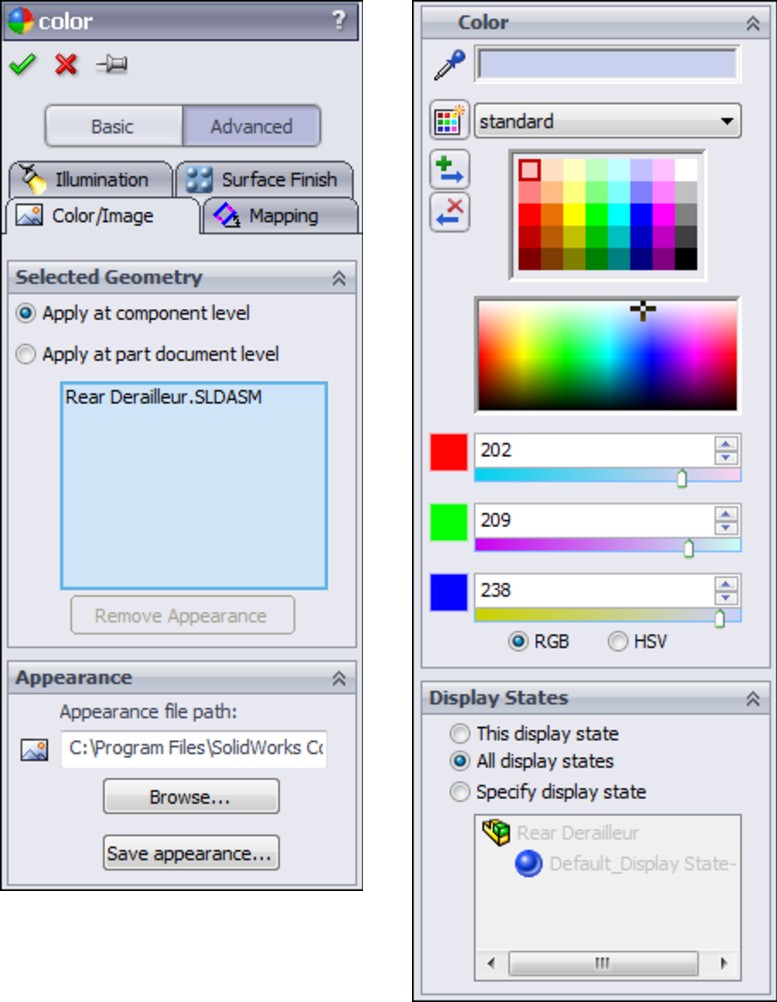

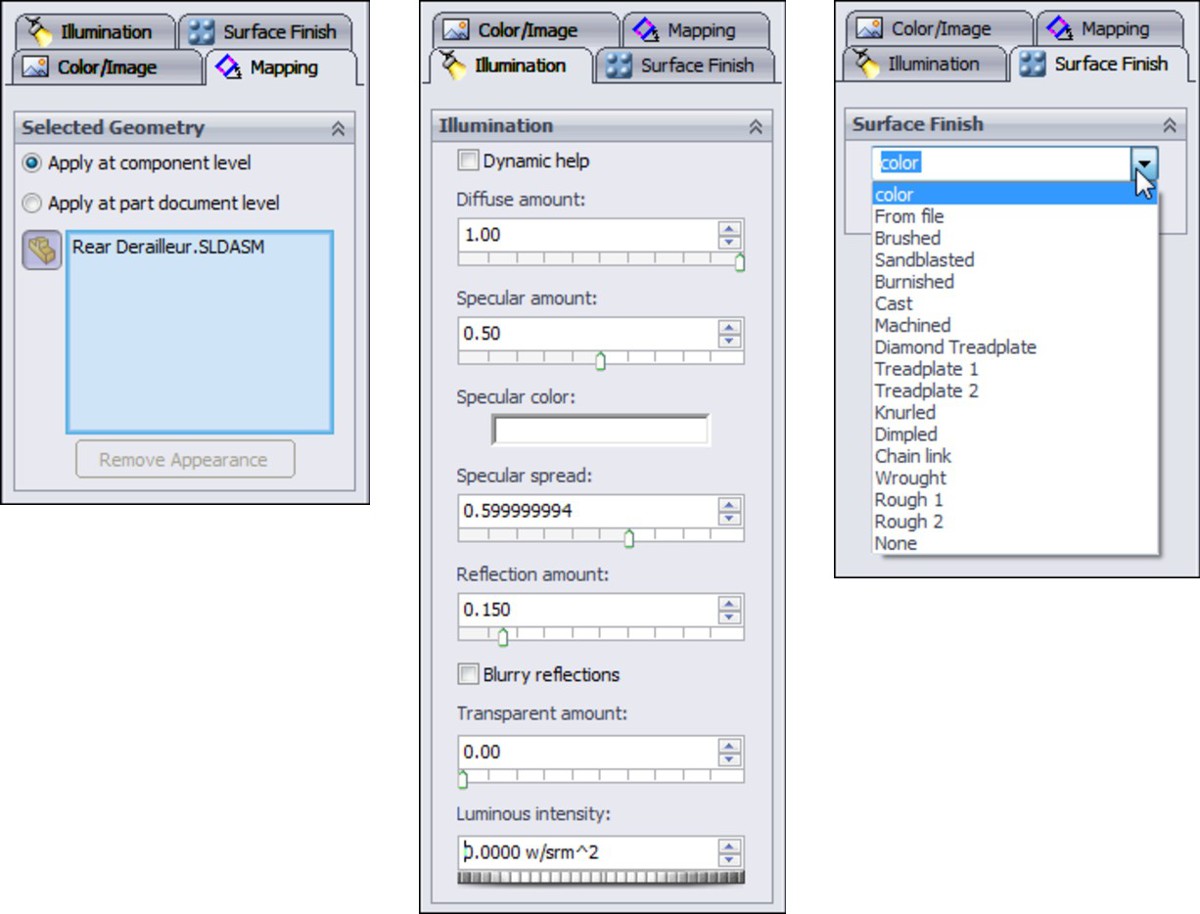

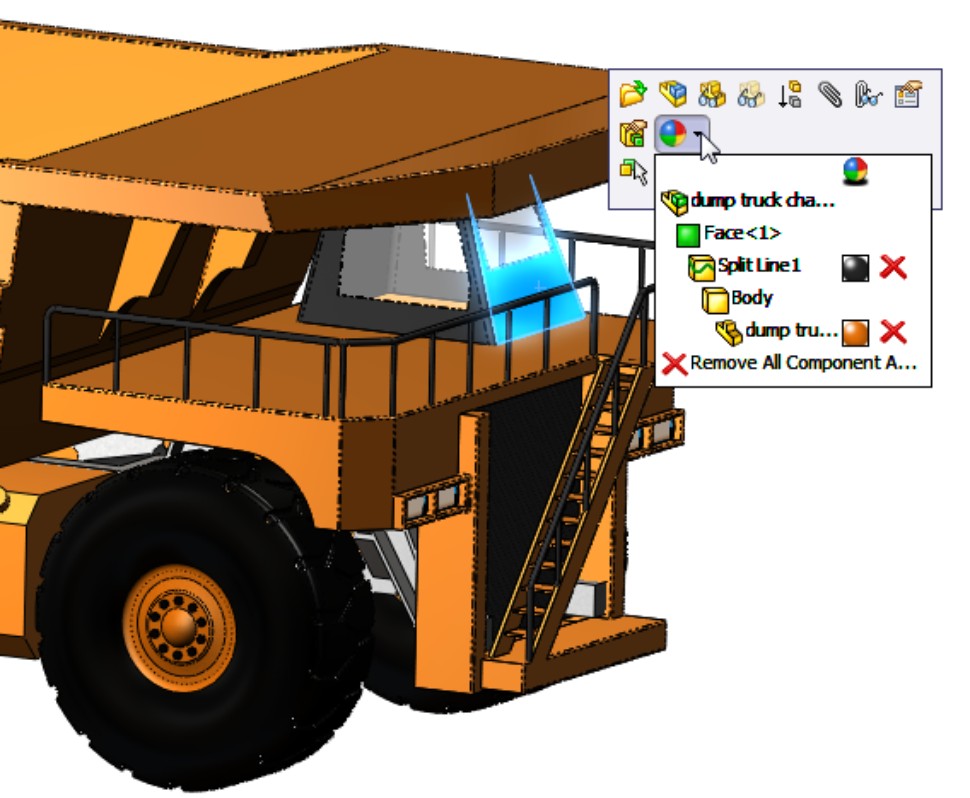

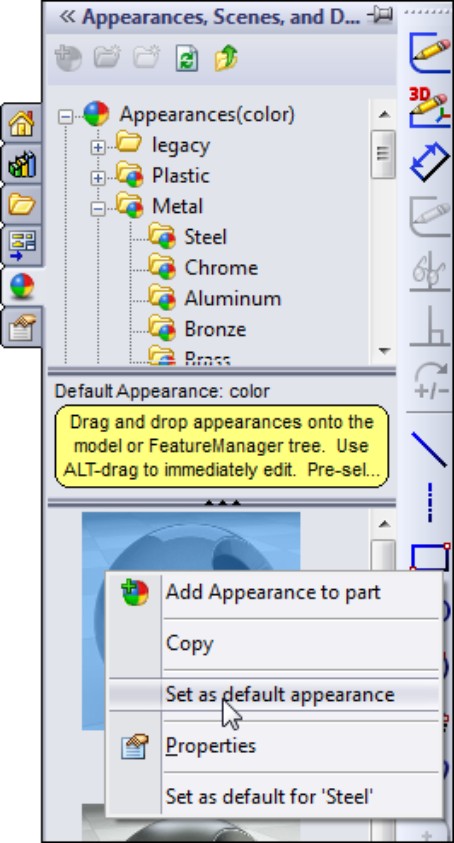

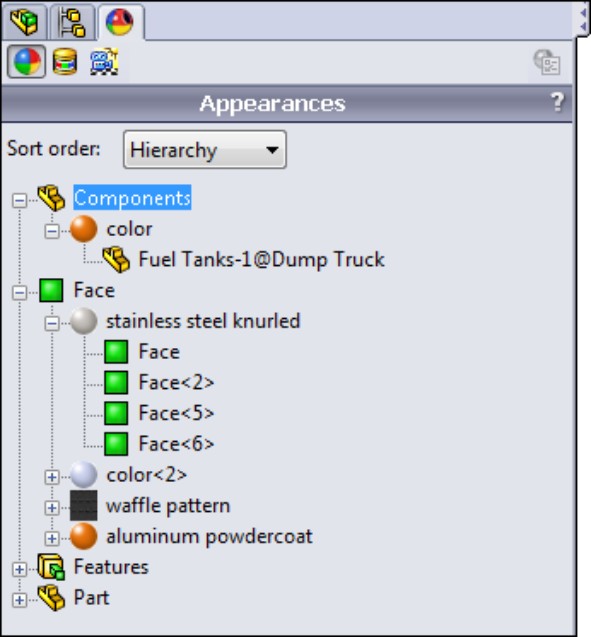

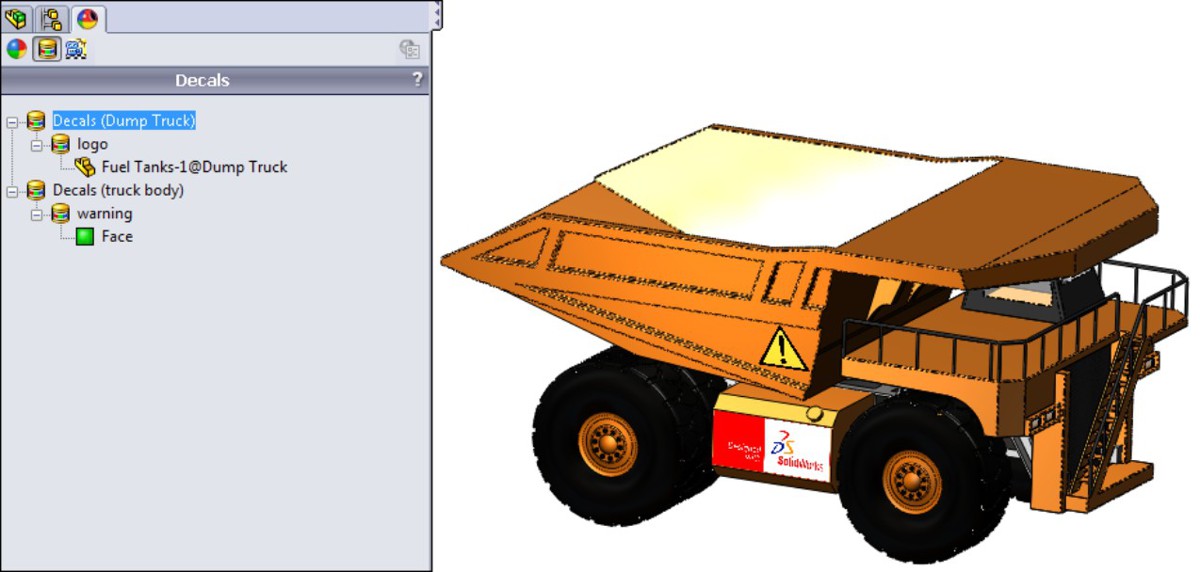

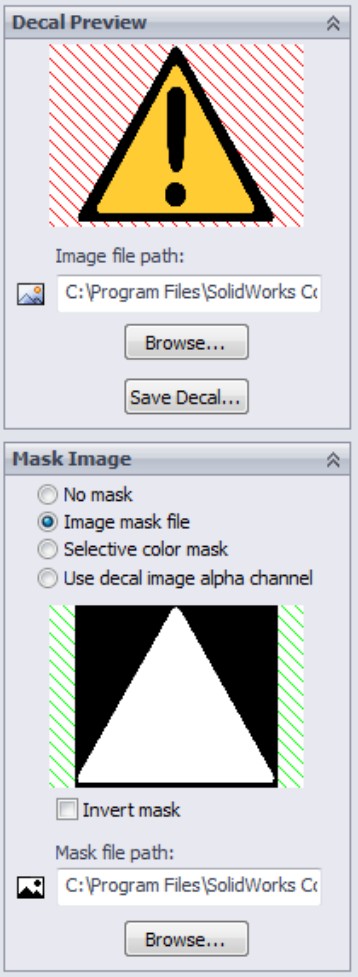

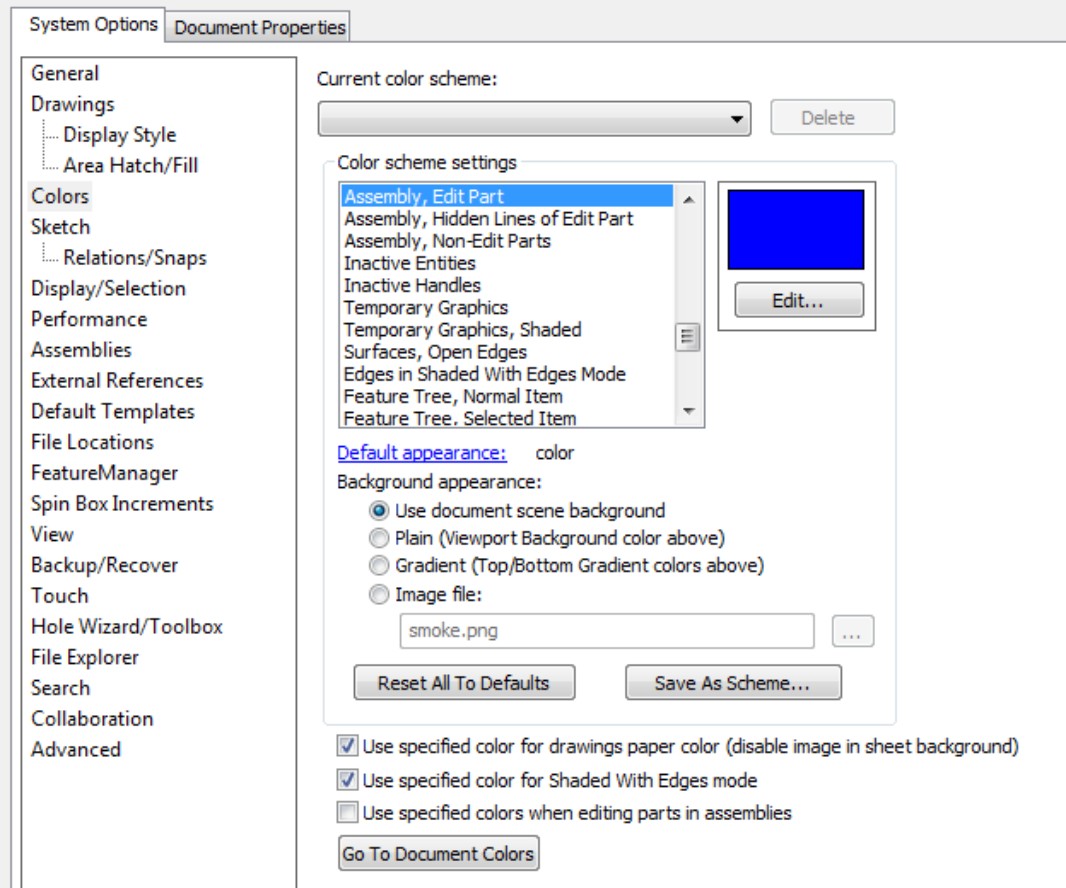

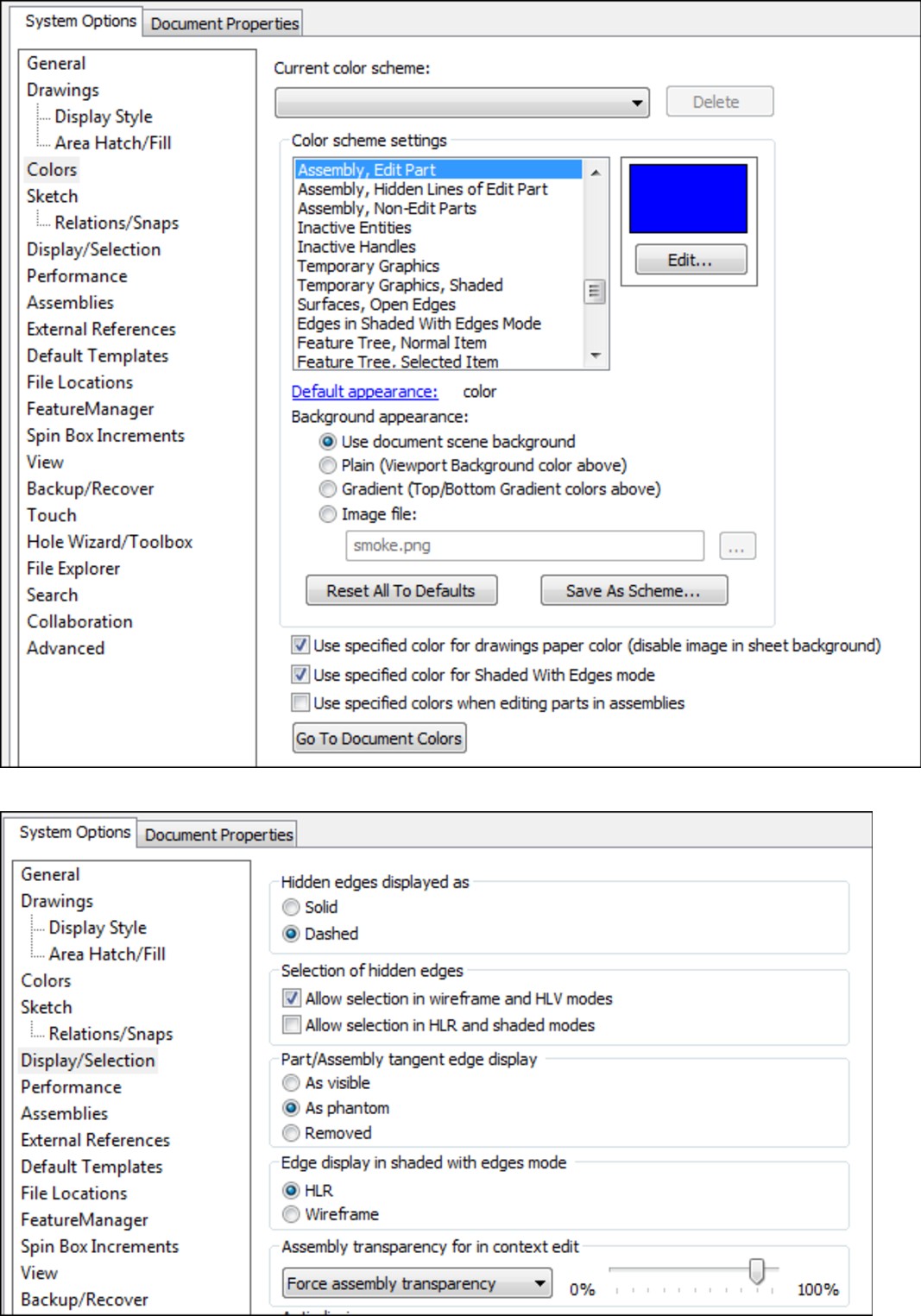

Controlling Appearances

Removing appearances and overrides

Using the Display Pane

Using the DisplayManager

Using Display States

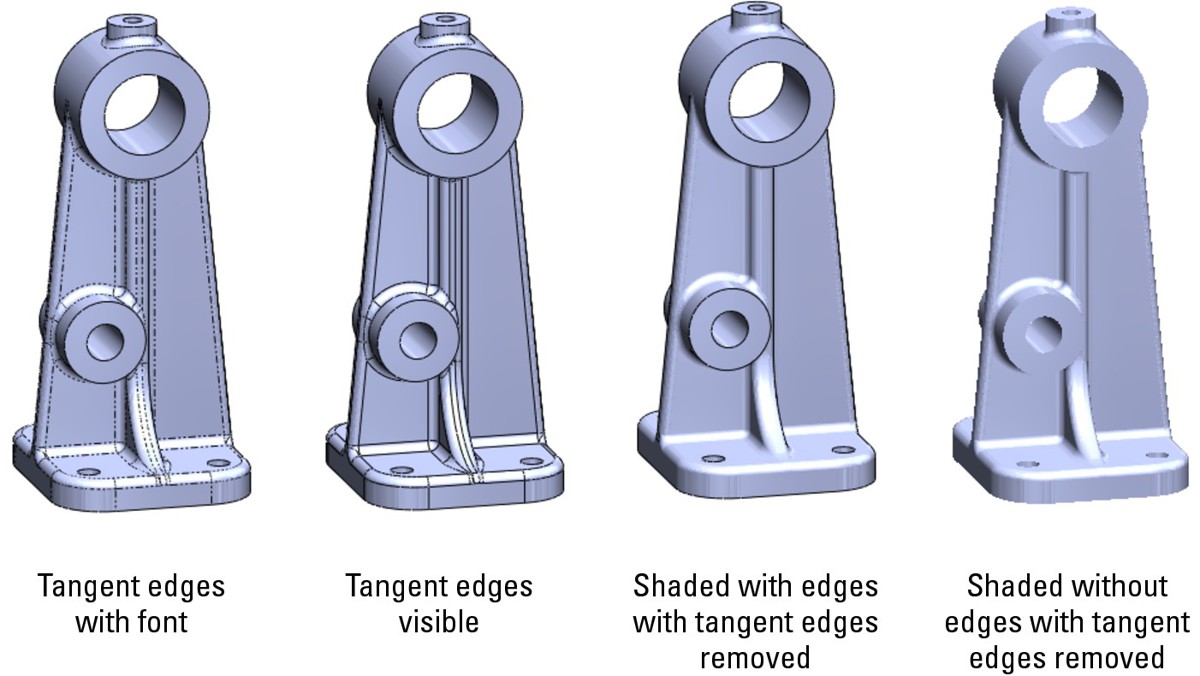

Using Edge and Wireframe Settings

Making the case for shaded with edge display

Using tangent edge display

Using Assembly Visualization

Tutorial: Using Assembly Visualization

Summary

Part II: Working with Assemblies

Chapter 4: Building Efficient Assemblies

Identifying the Elements of an Assembly

Understanding standard reference geometry items

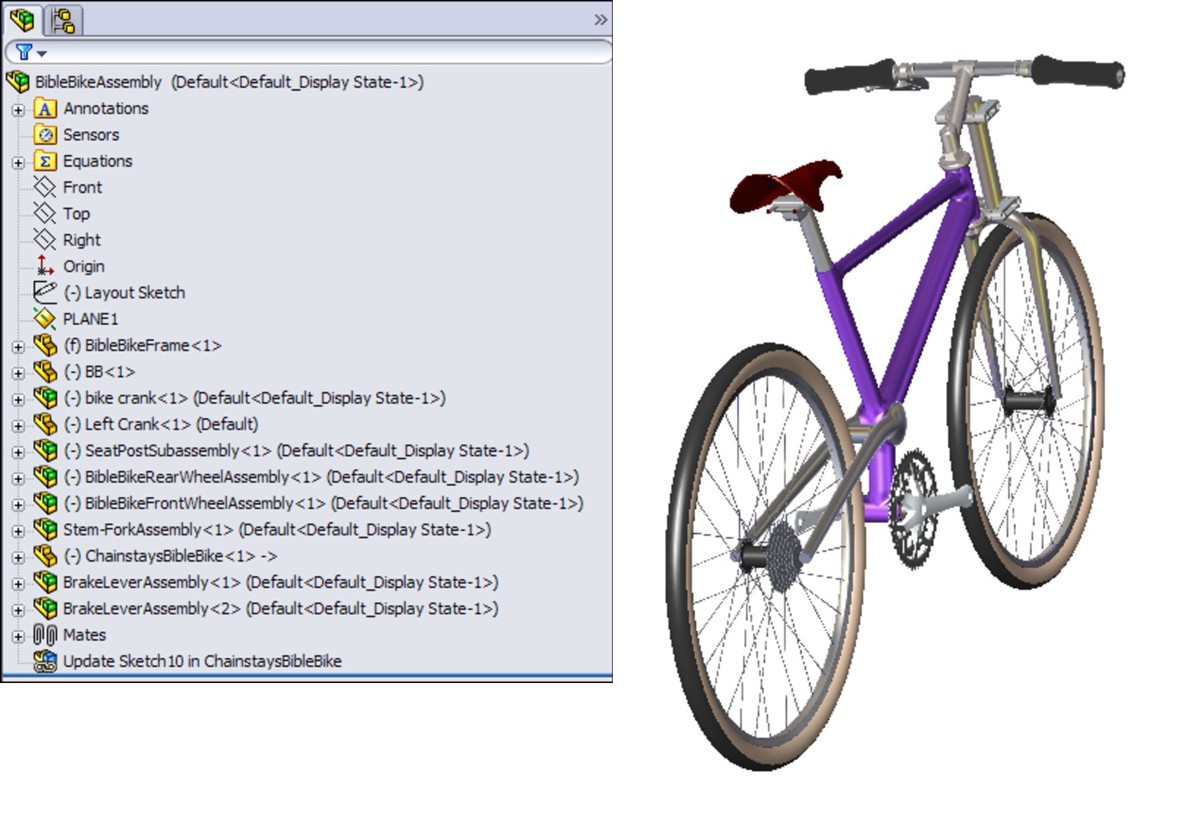

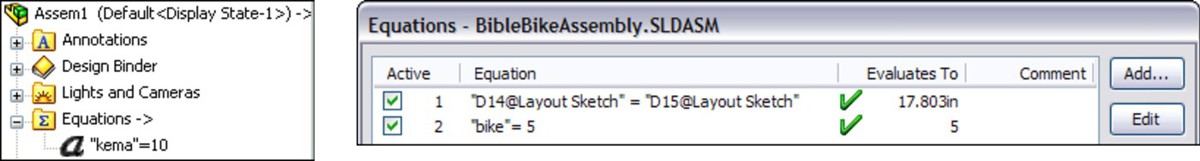

Working with assembly equations

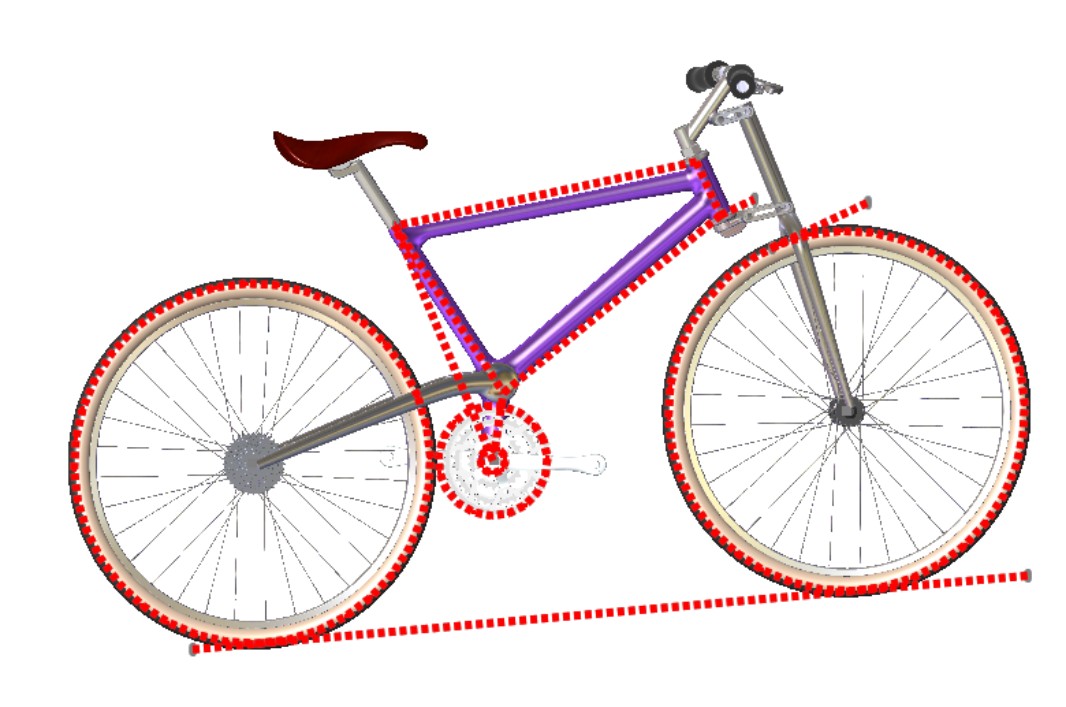

Using an assembly layout sketch

Working with virtual components

Creating assembly reference geometry

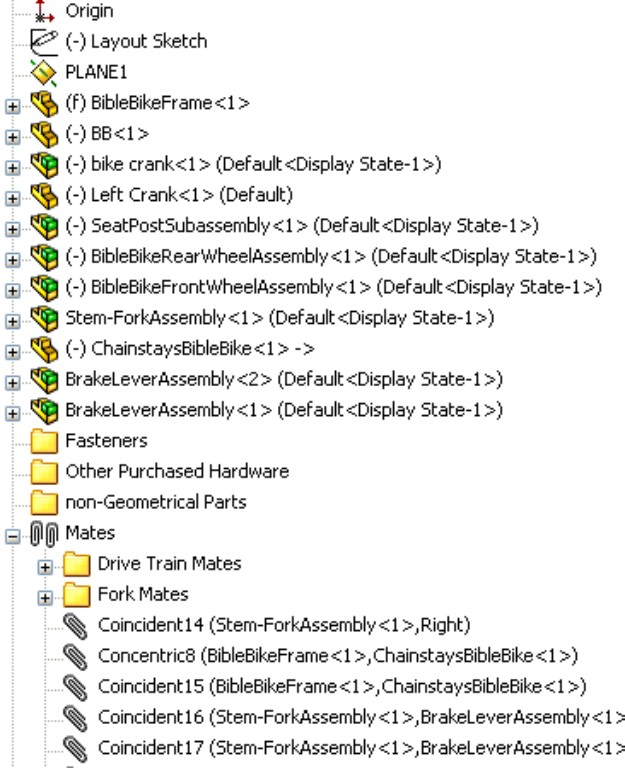

Comparing history-based and non-history-based portions of the assembly tree

Understanding parts and subassemblies

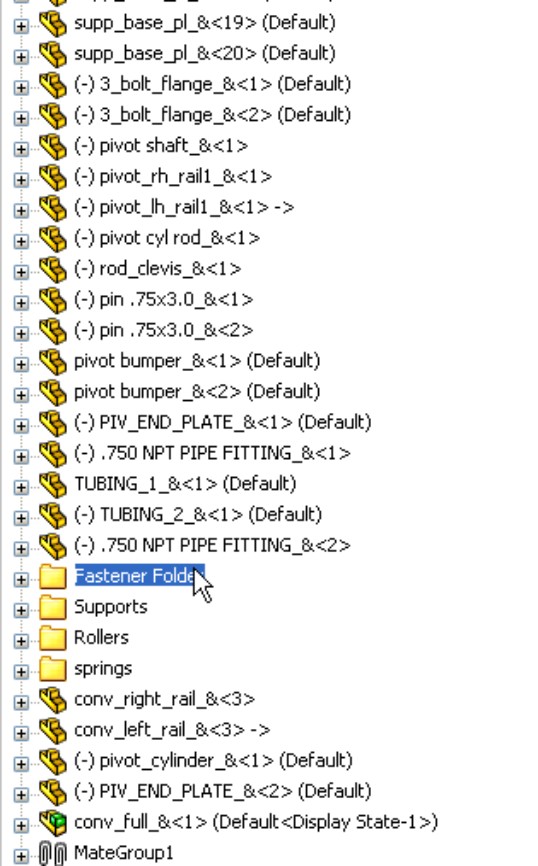

Creating folders

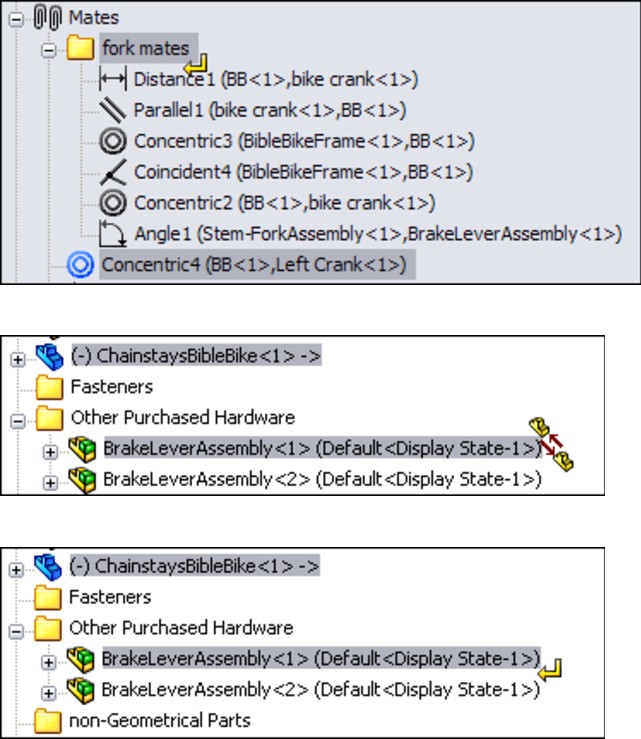

Organizing mates

Applying assembly features

Using component patterns and mirror components

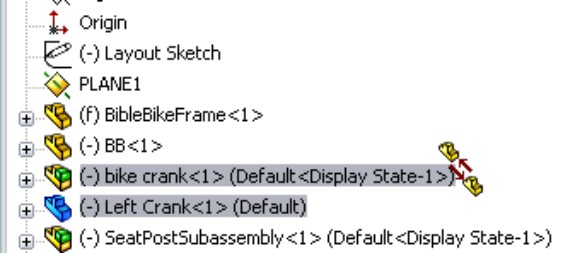

Looking at in-context reference Update Holders

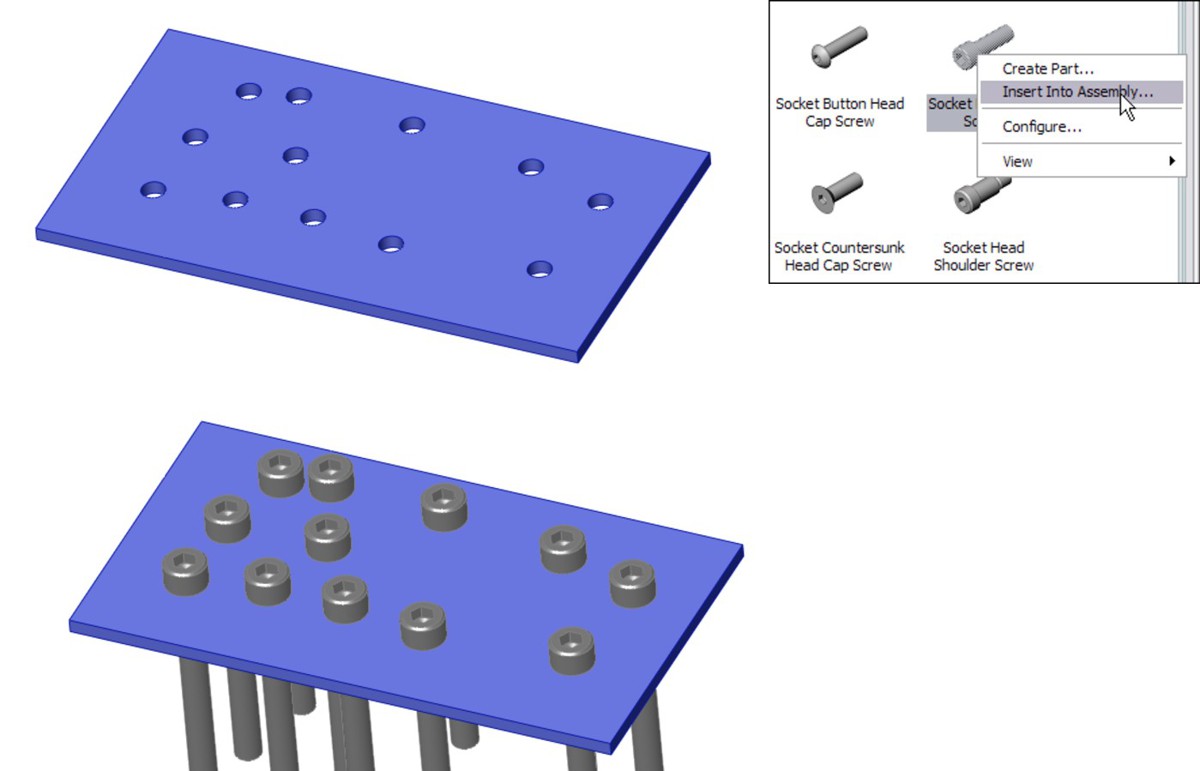

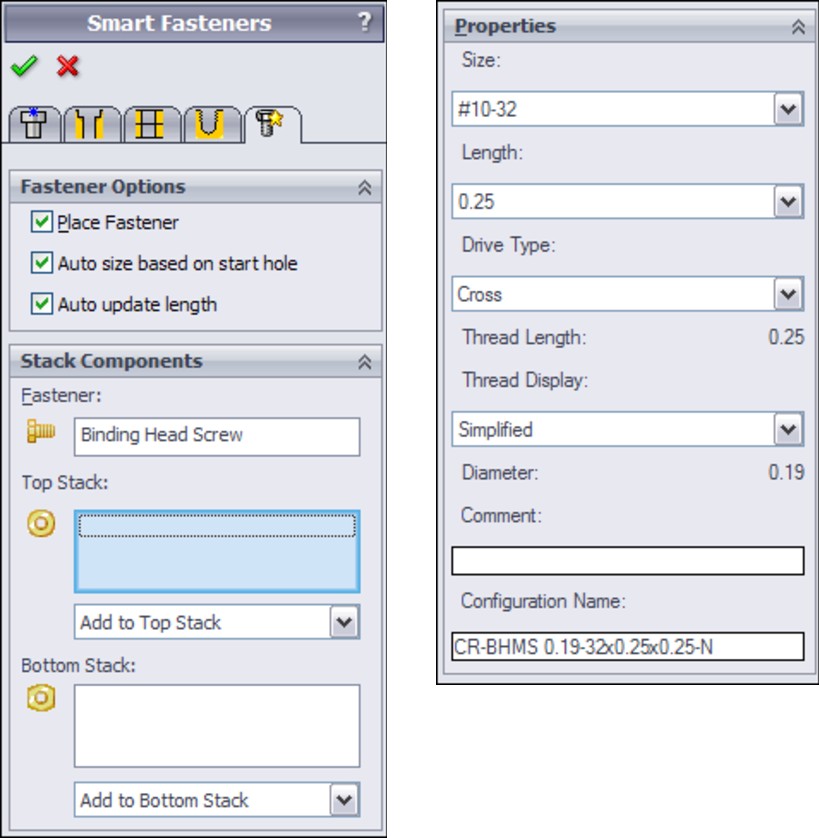

Using Smart Fasteners

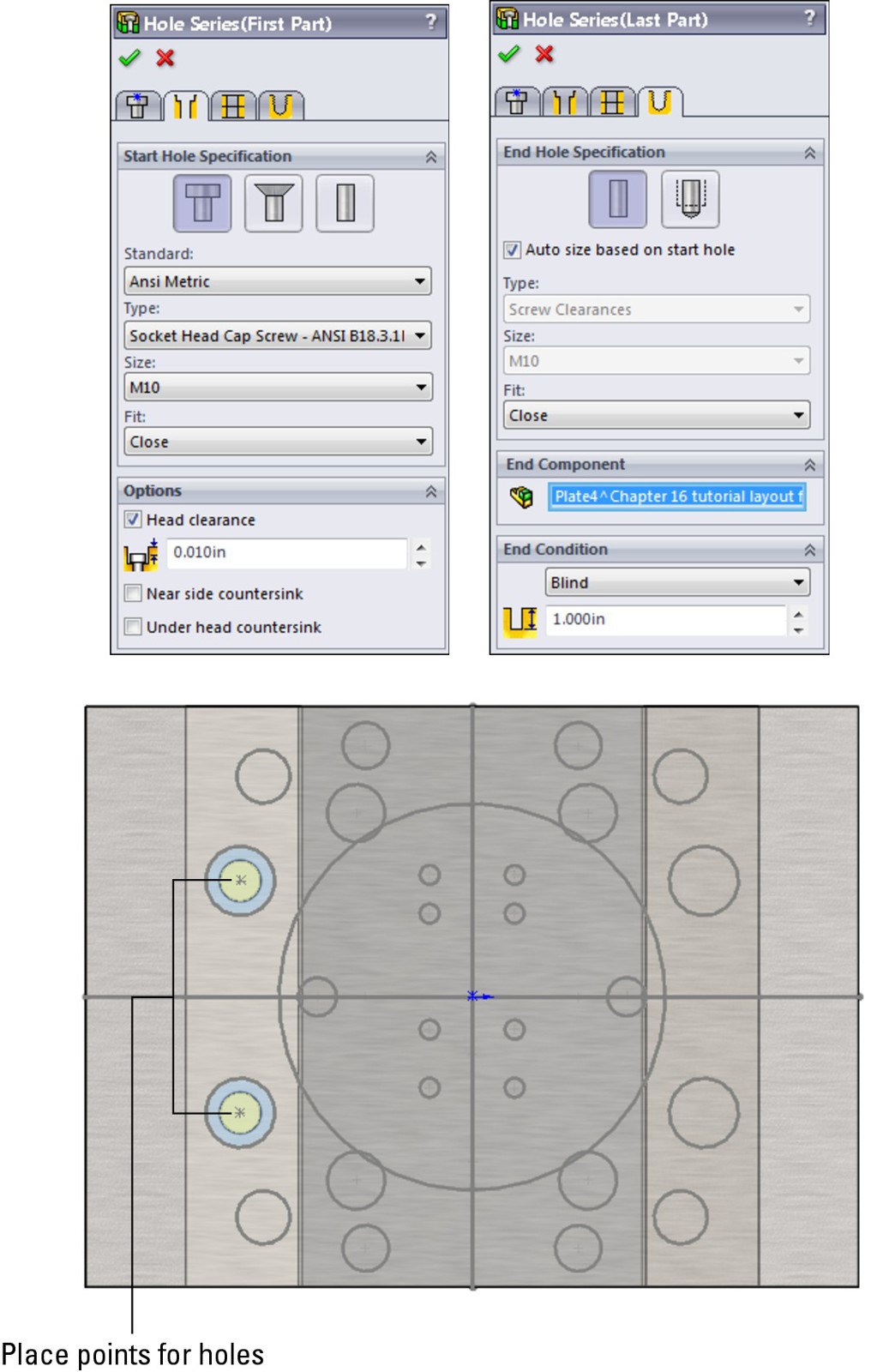

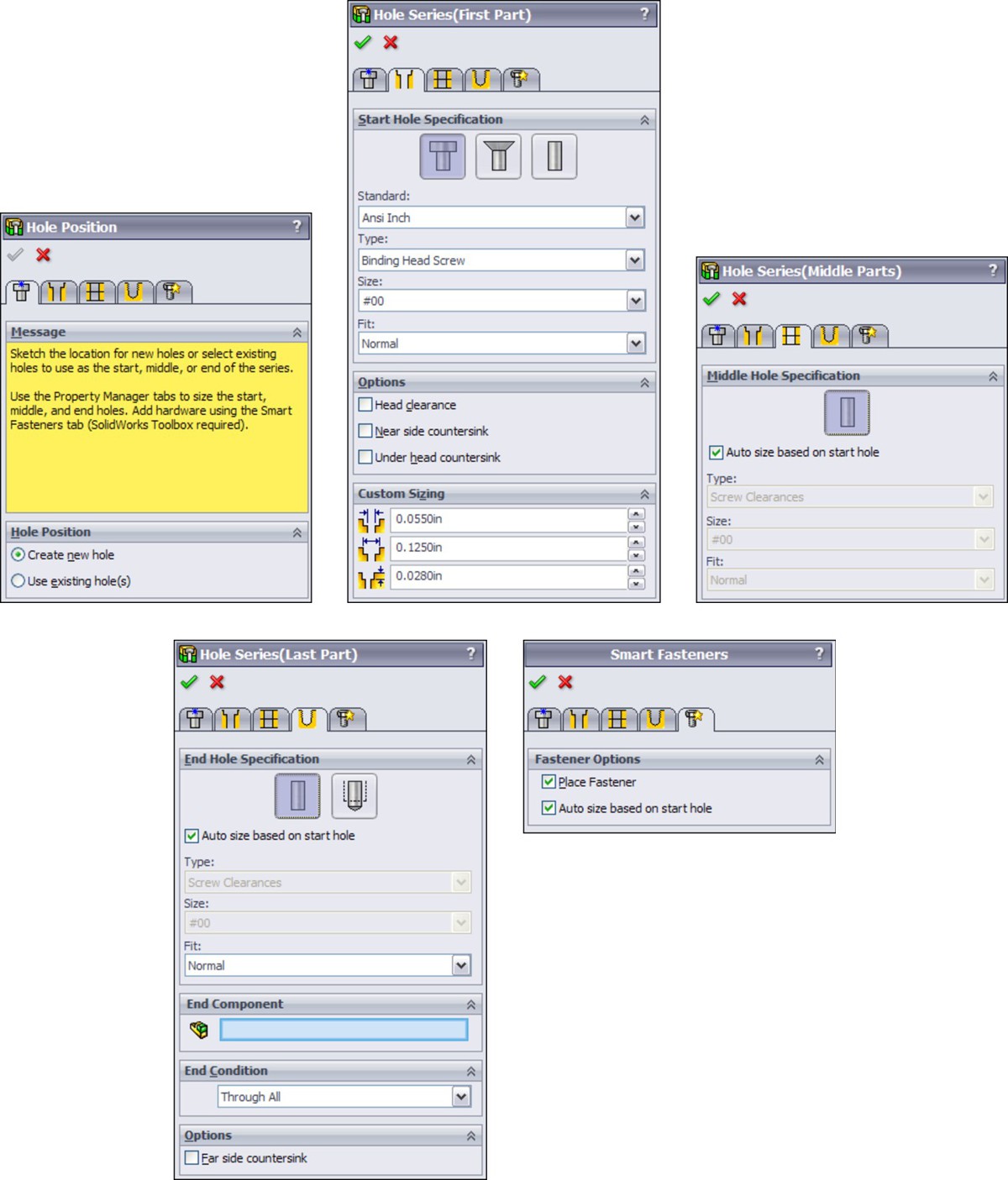

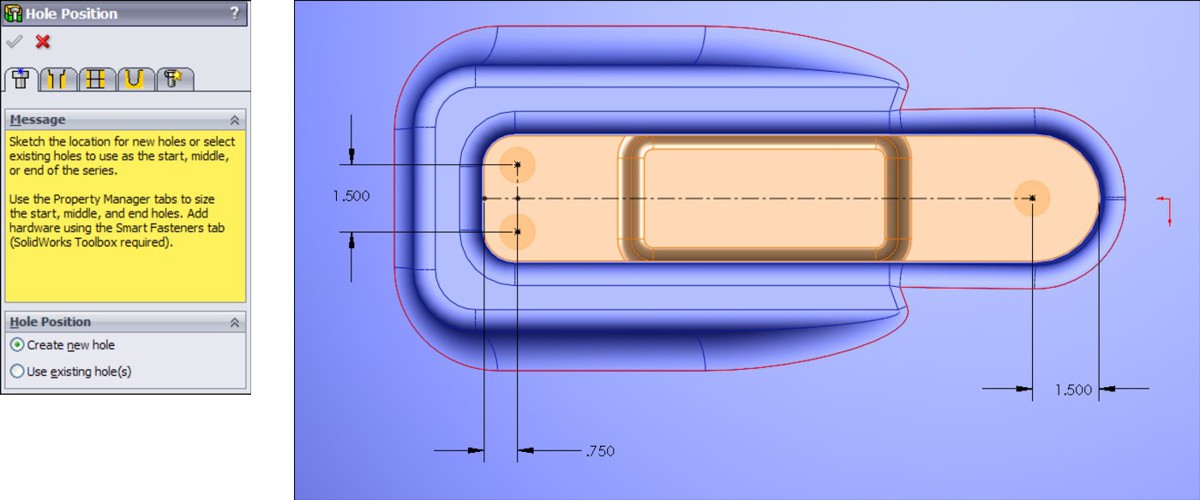

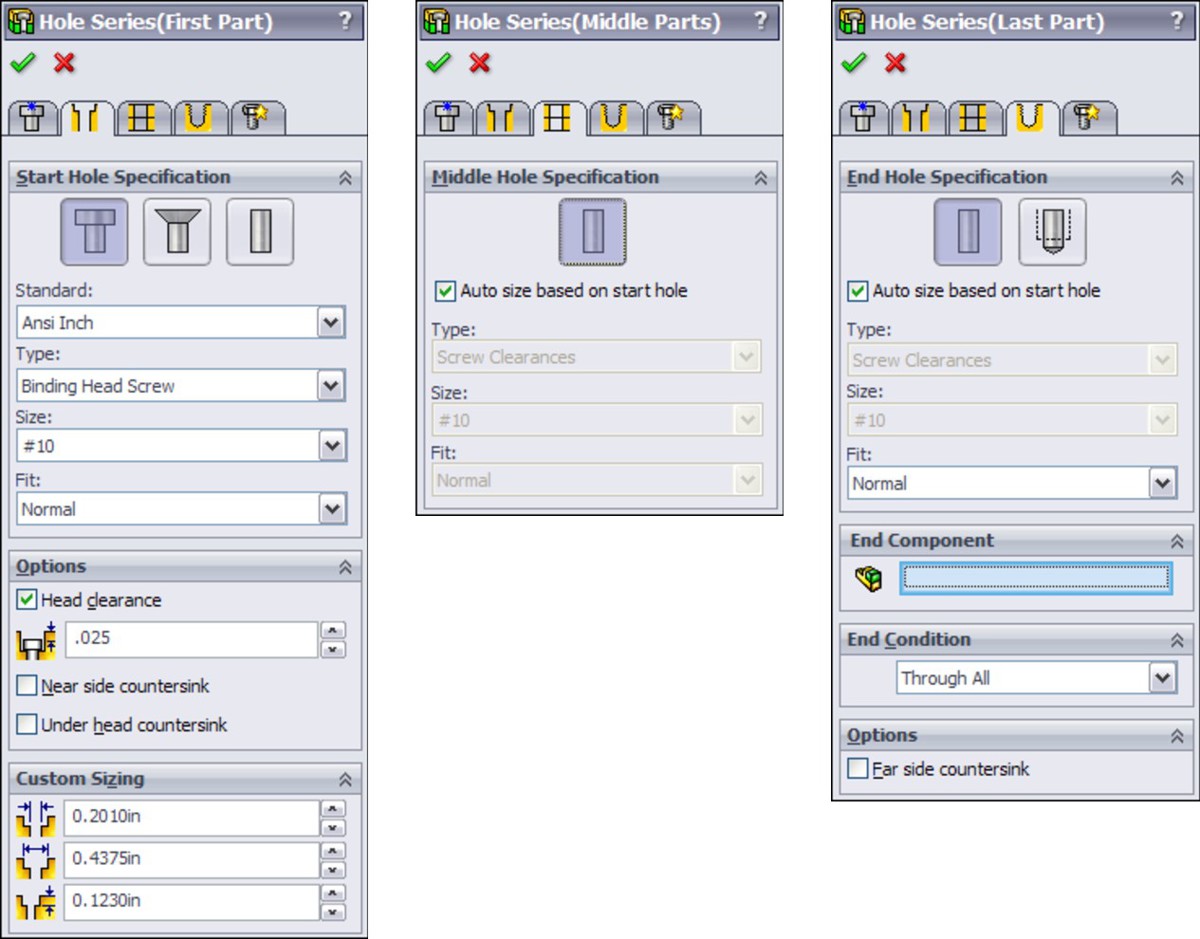

Applying the Hole Series

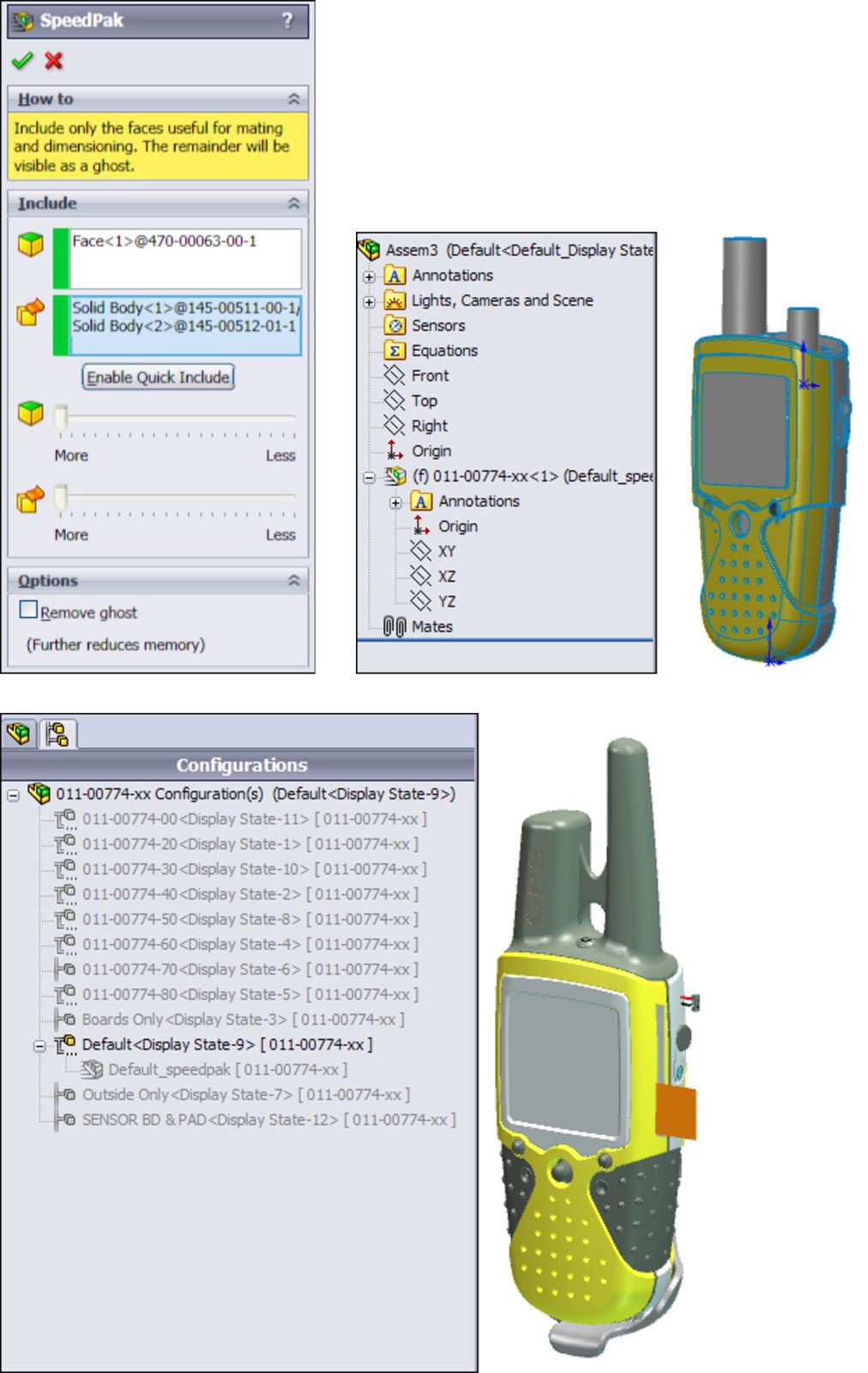

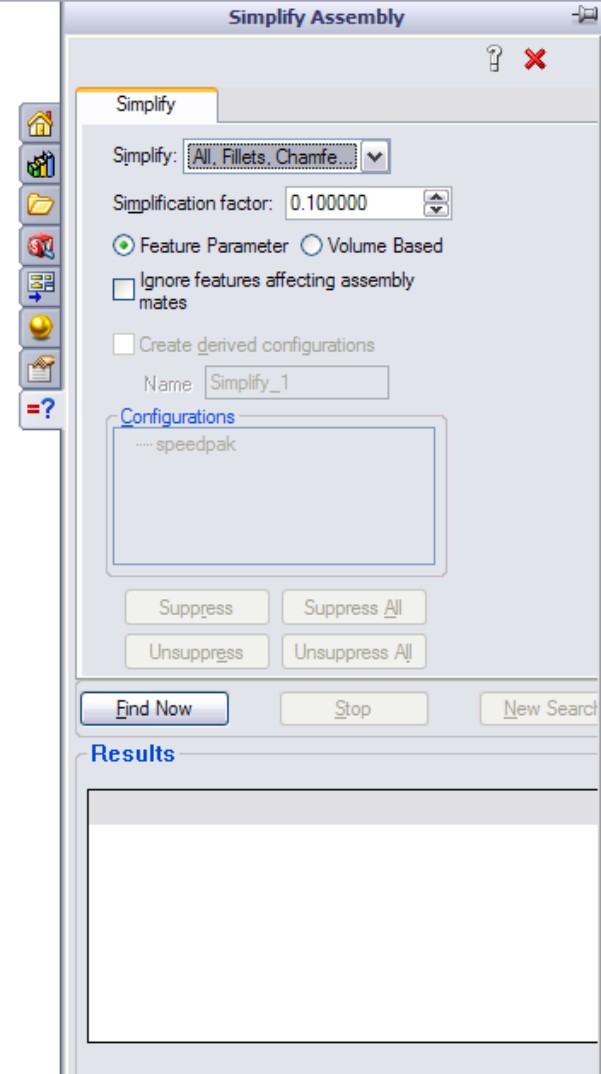

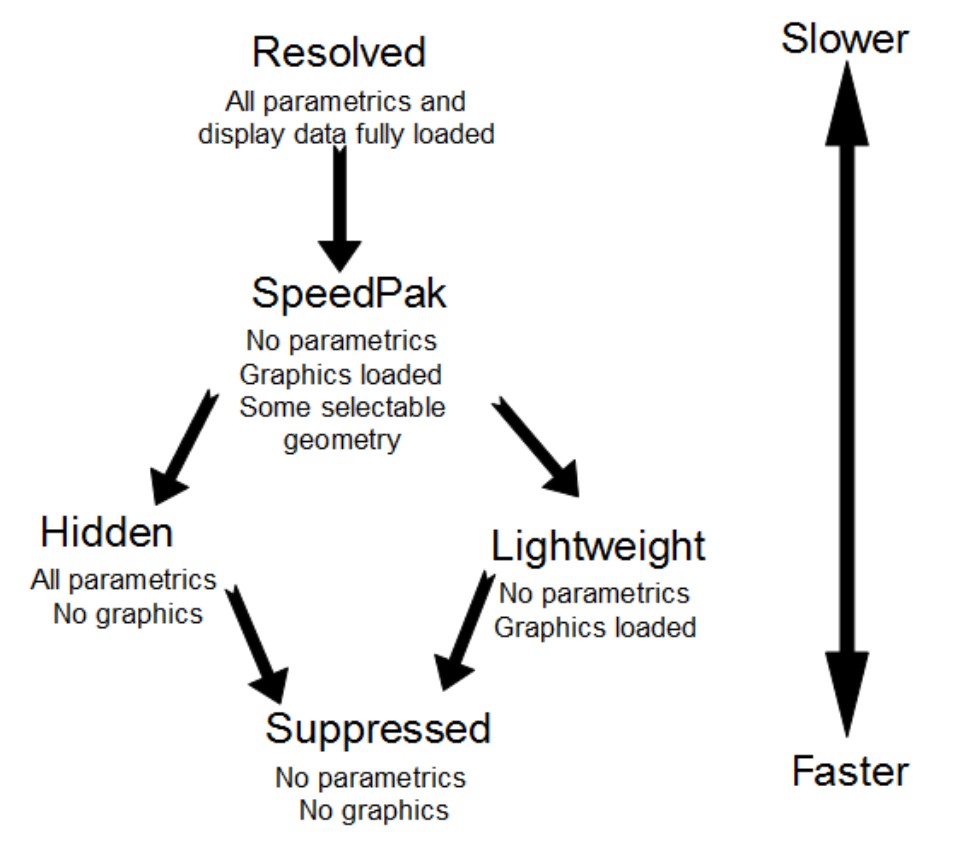

Using SpeedPaks

Using ghosts

Sharing self-contained data

Using SpeedPaks with drawings

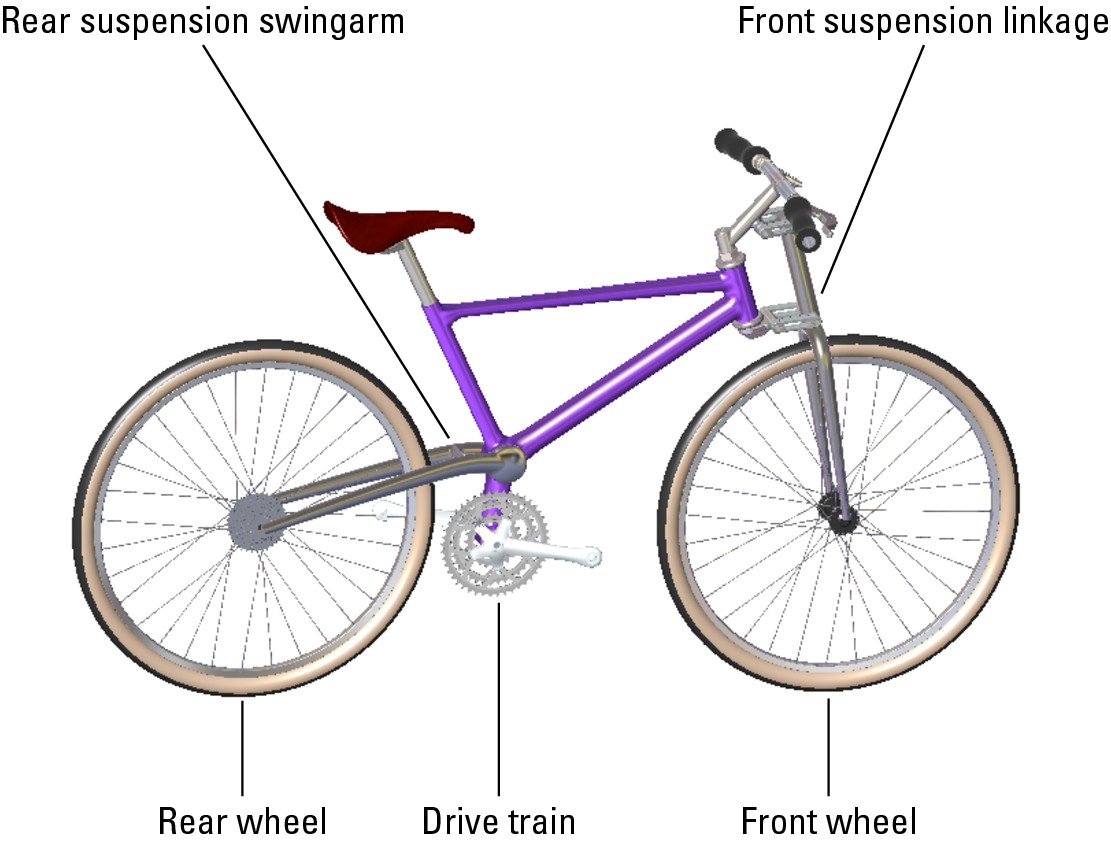

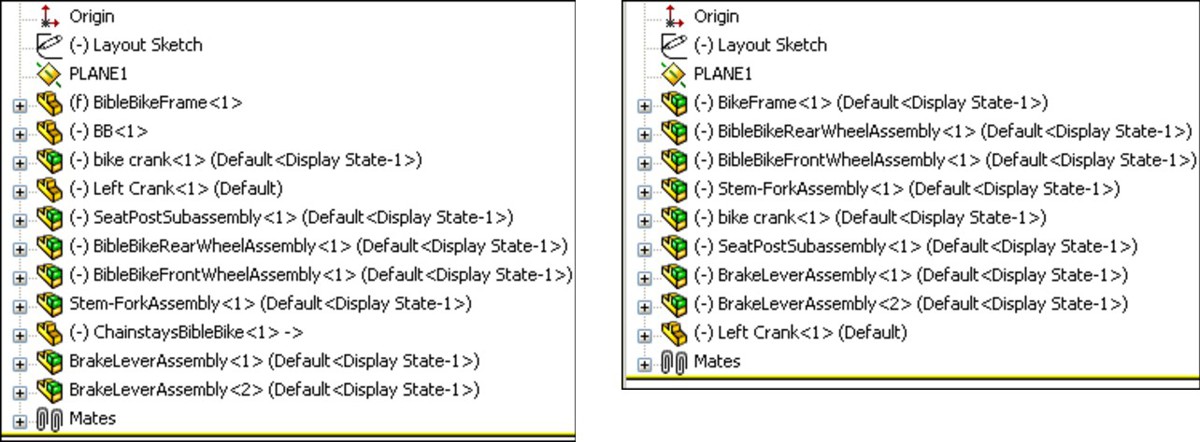

Using Subassemblies

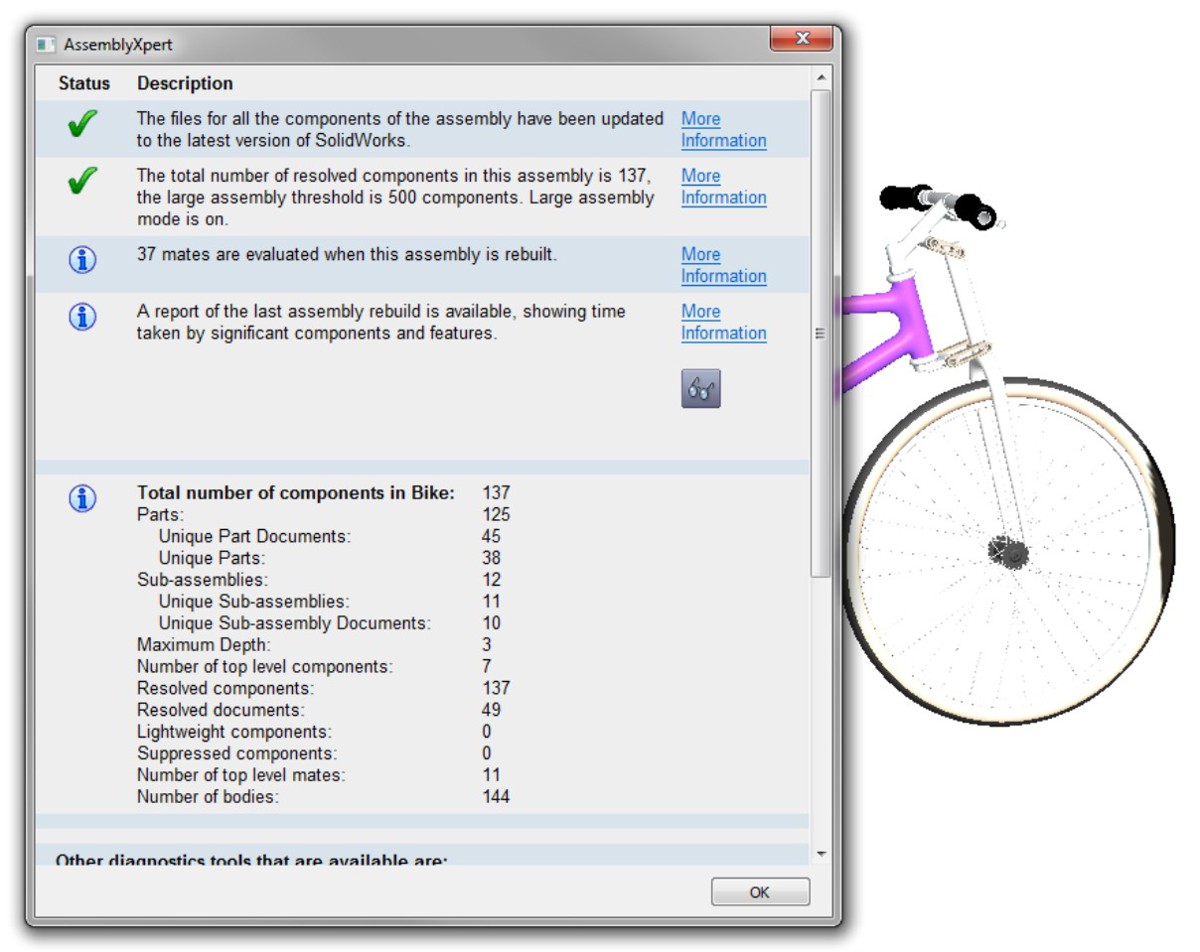

Creating subassemblies from existing parts

Organizing for performance

Organizing for the Bill of Materials

Grouping subassemblies by relative motion

Organizing groups of purchased components

Depicting an assembly process

Patterning considerations

Using Folders

Creating folders in the FeatureManager

Adding items to existing folders

Reordering items in the tree

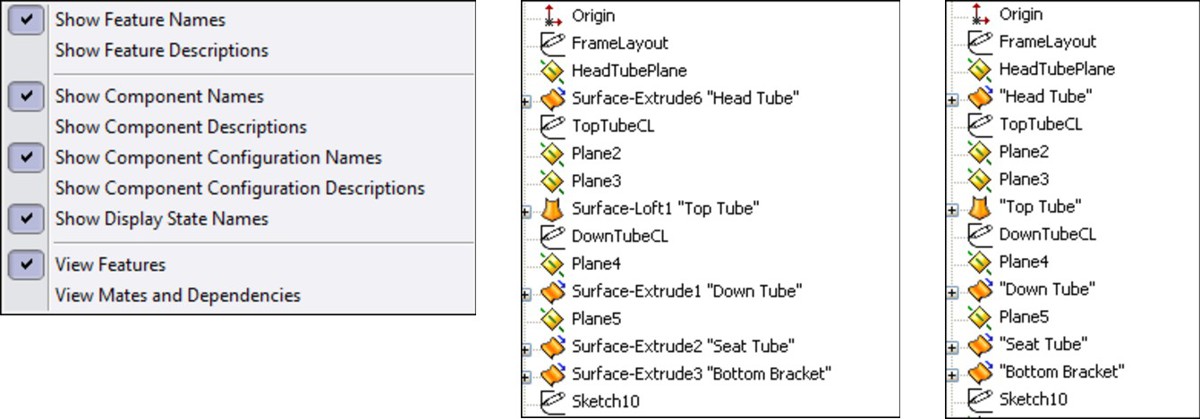

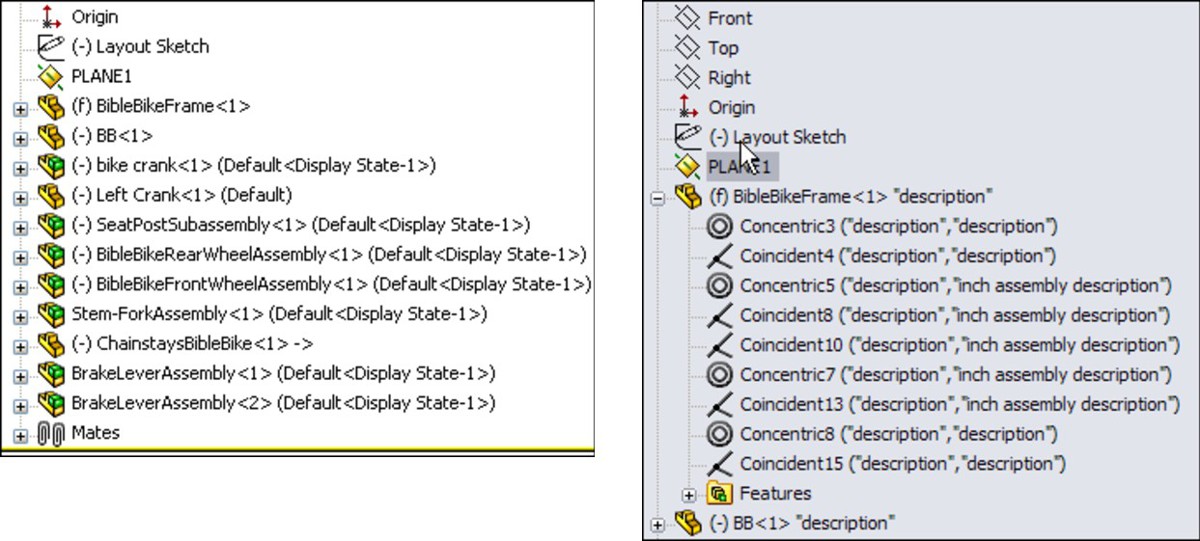

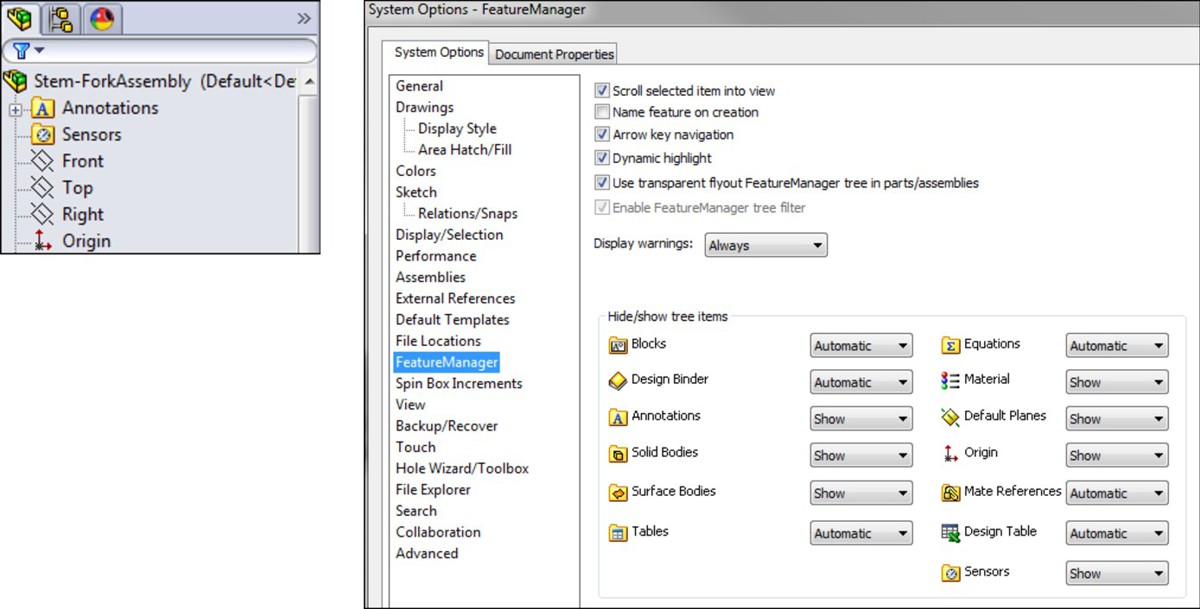

Working with Tree Display Options

Showing feature names and descriptions

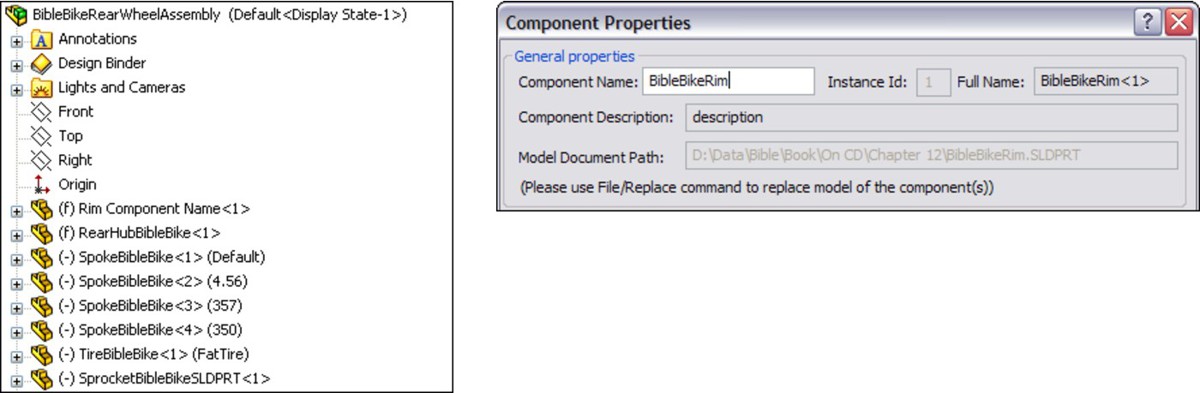

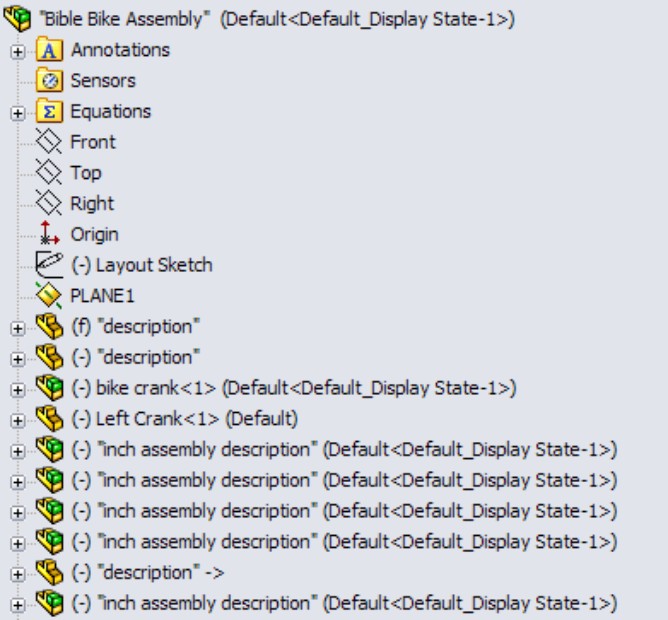

Showing component and config names and descriptions

Using names other than the part filename in the assembly FeatureManager

Using Component Reference per Instance

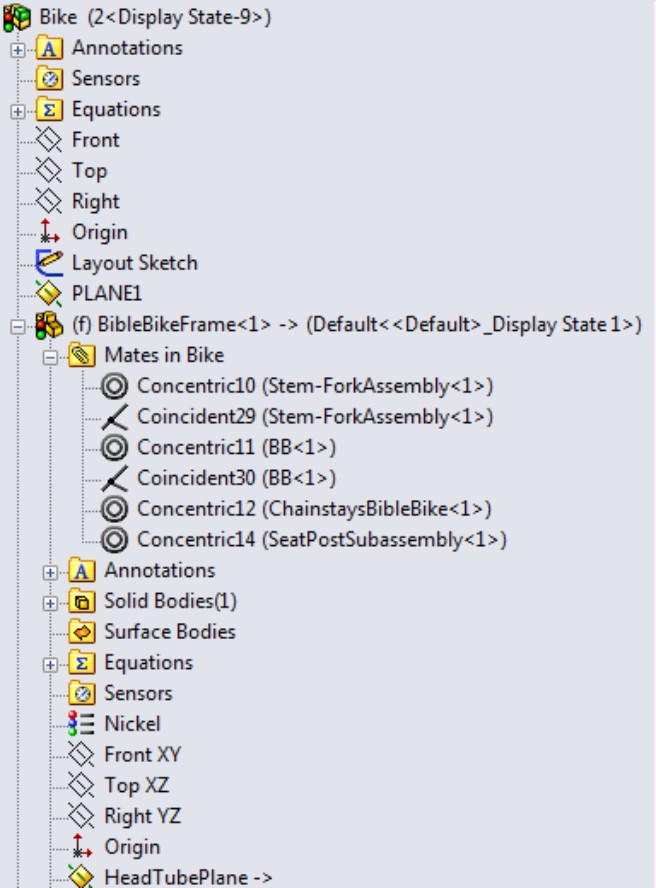

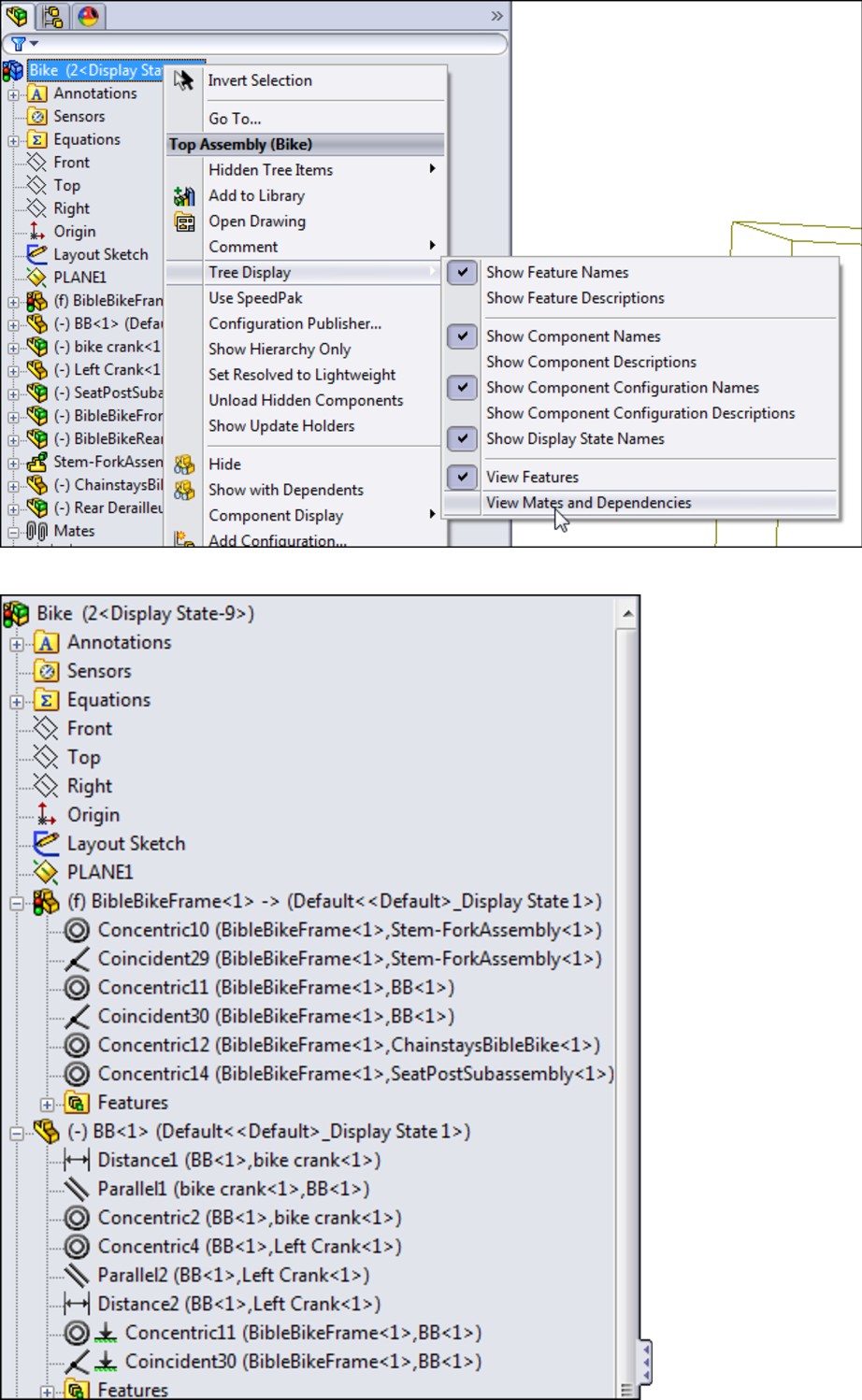

Viewing features, mates, and dependencies

Working with Assembly Tools

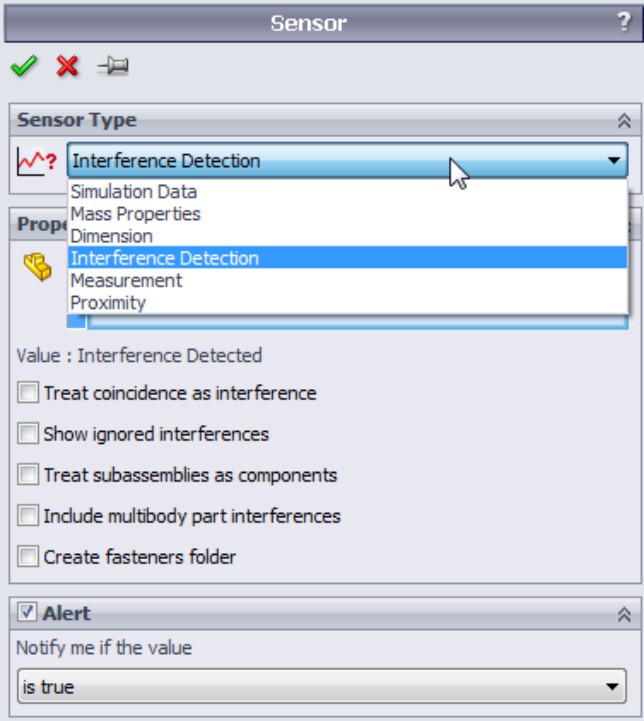

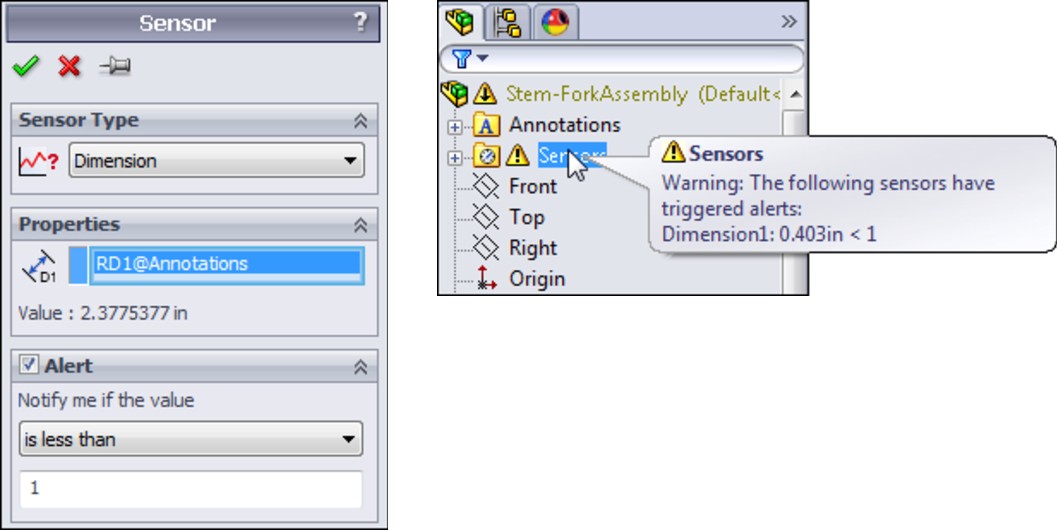

Using Sensors

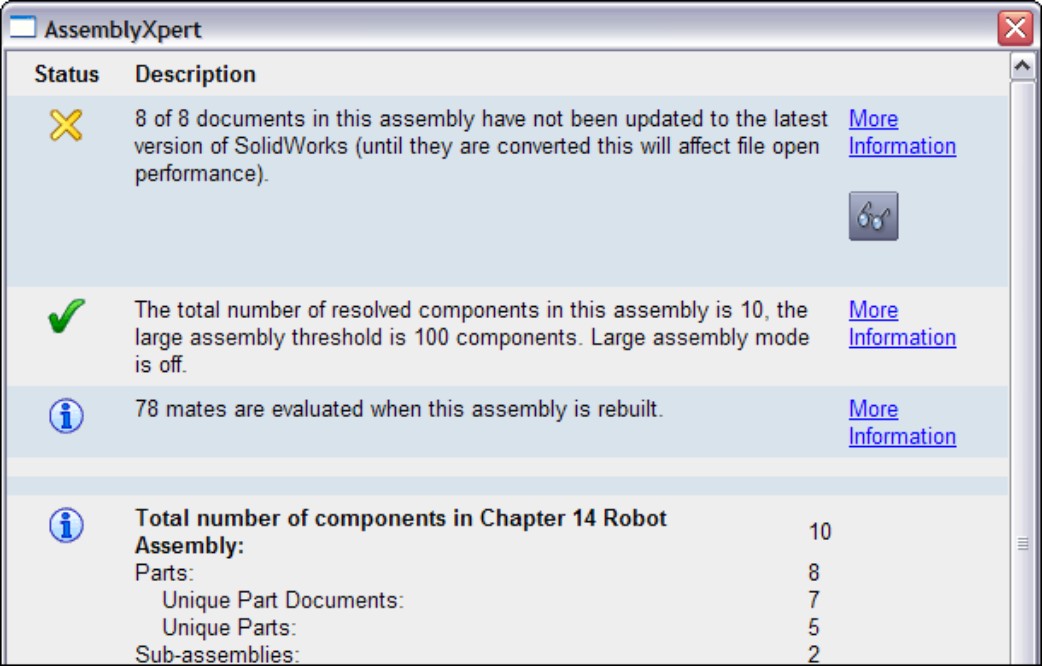

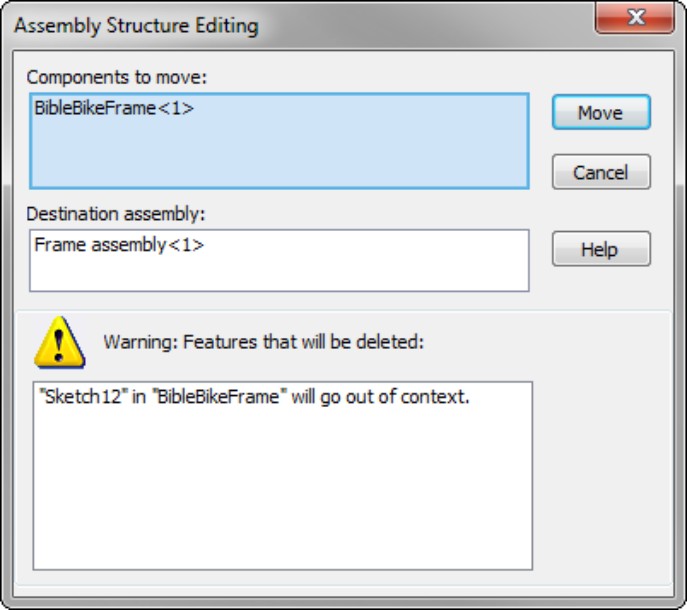

Using the AssemblyXpert

Tutorial: Arranging Assemblies

Tutorial: Managing the FeatureManager

Summary

Chapter 5: Getting More from Mates

Applying Mates

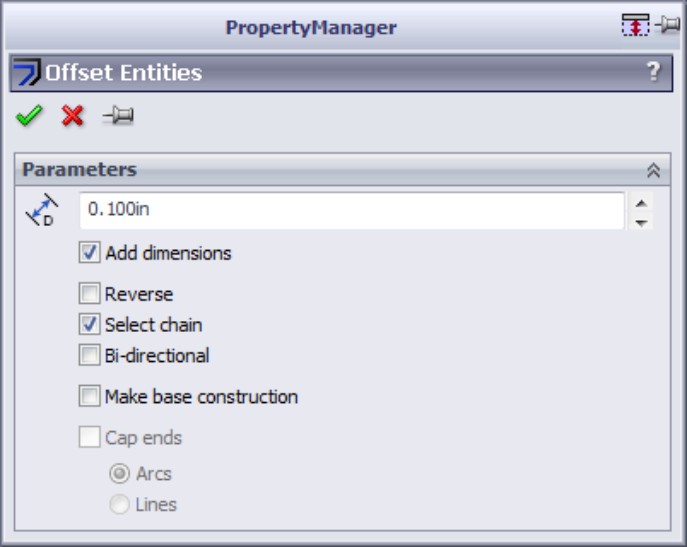

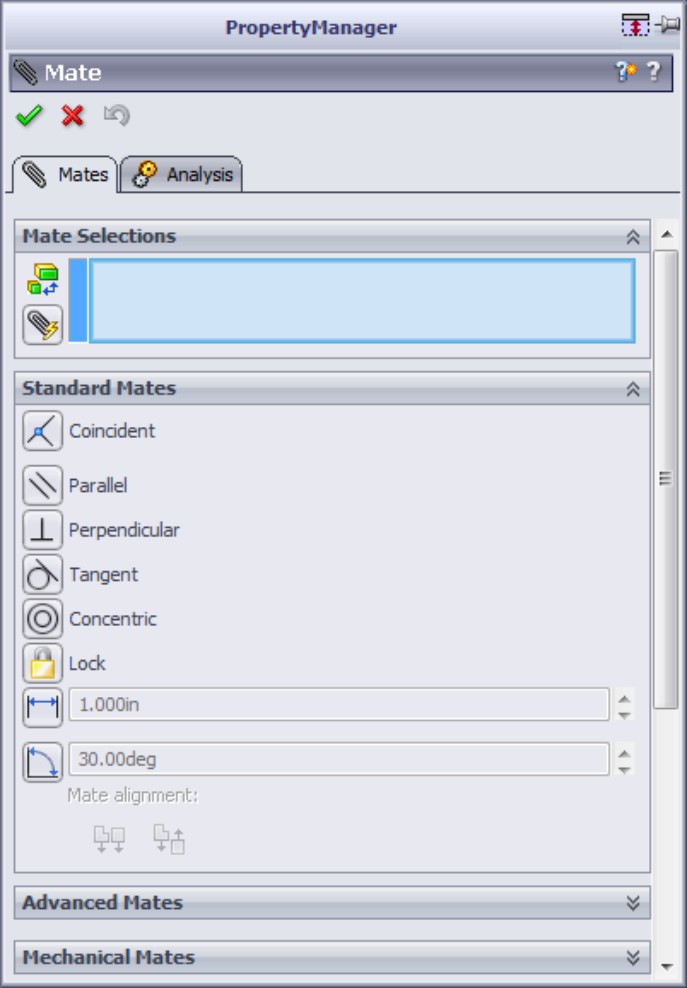

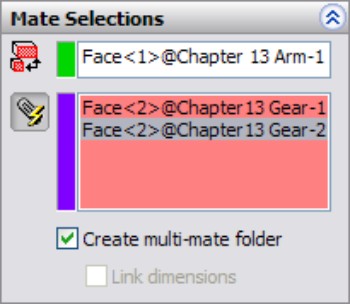

Mating through the Mate PropertyManager

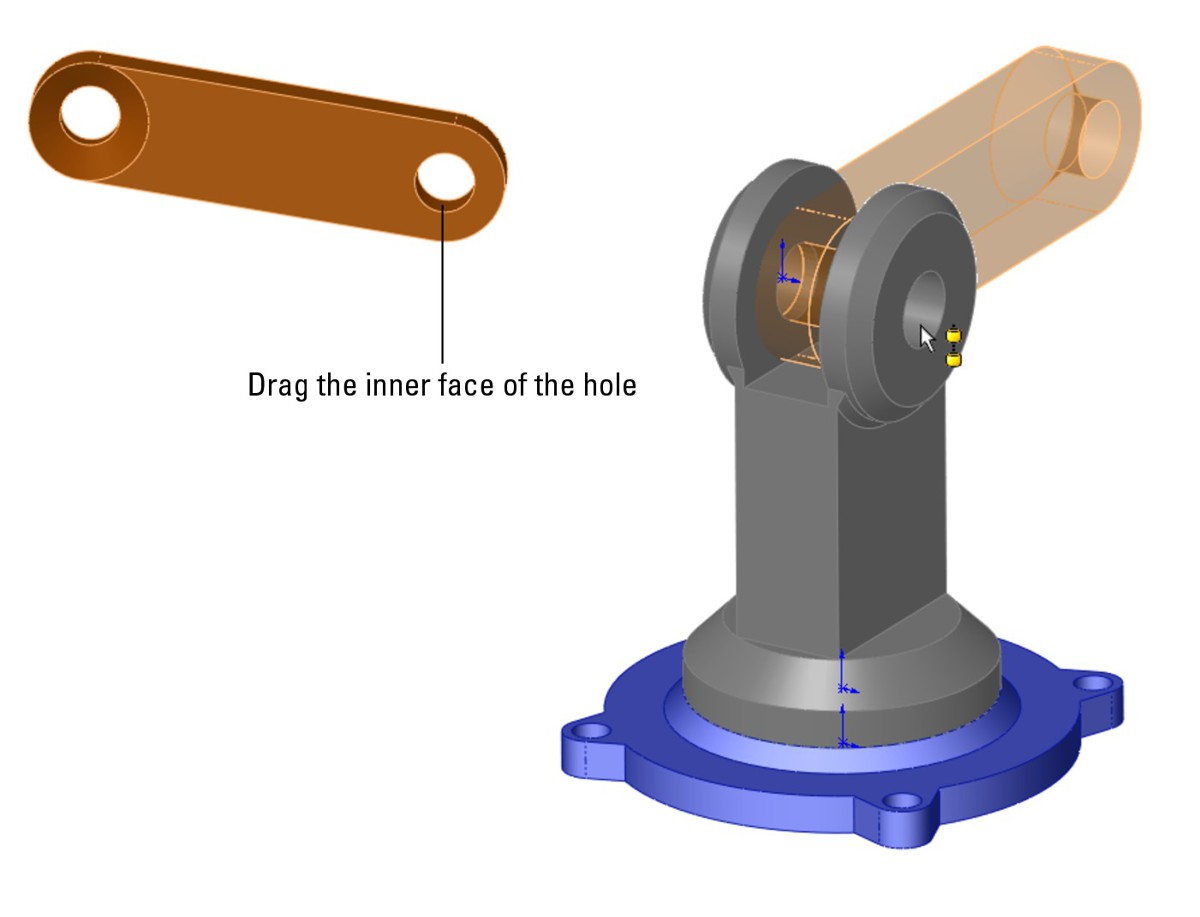

Taking advantage of SmartMates

Mating with macros

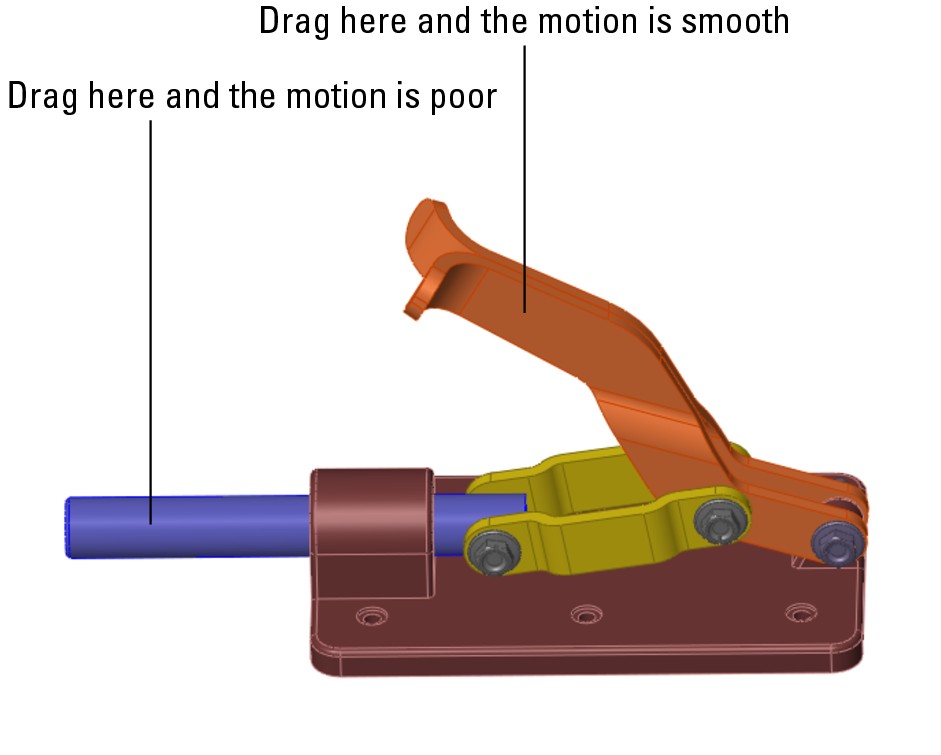

Mating for Motion

Analyzing degree of freedom

Setting up successful motion

Working with Advanced and Mechanical Mate Types

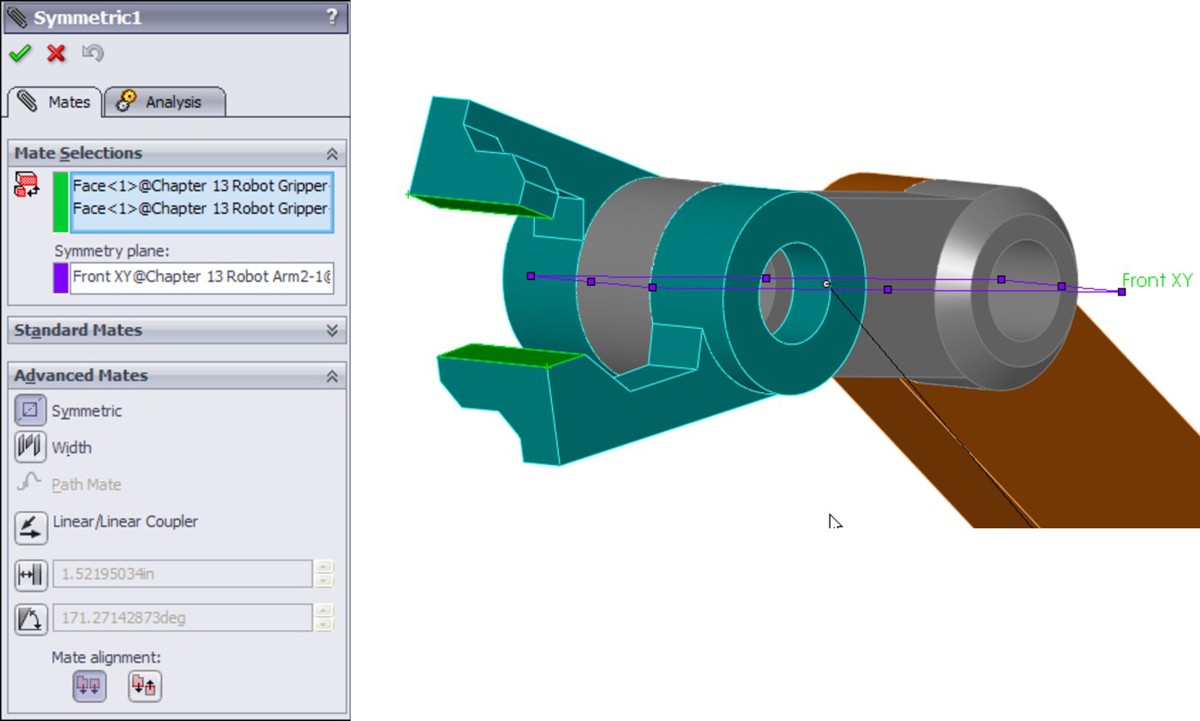

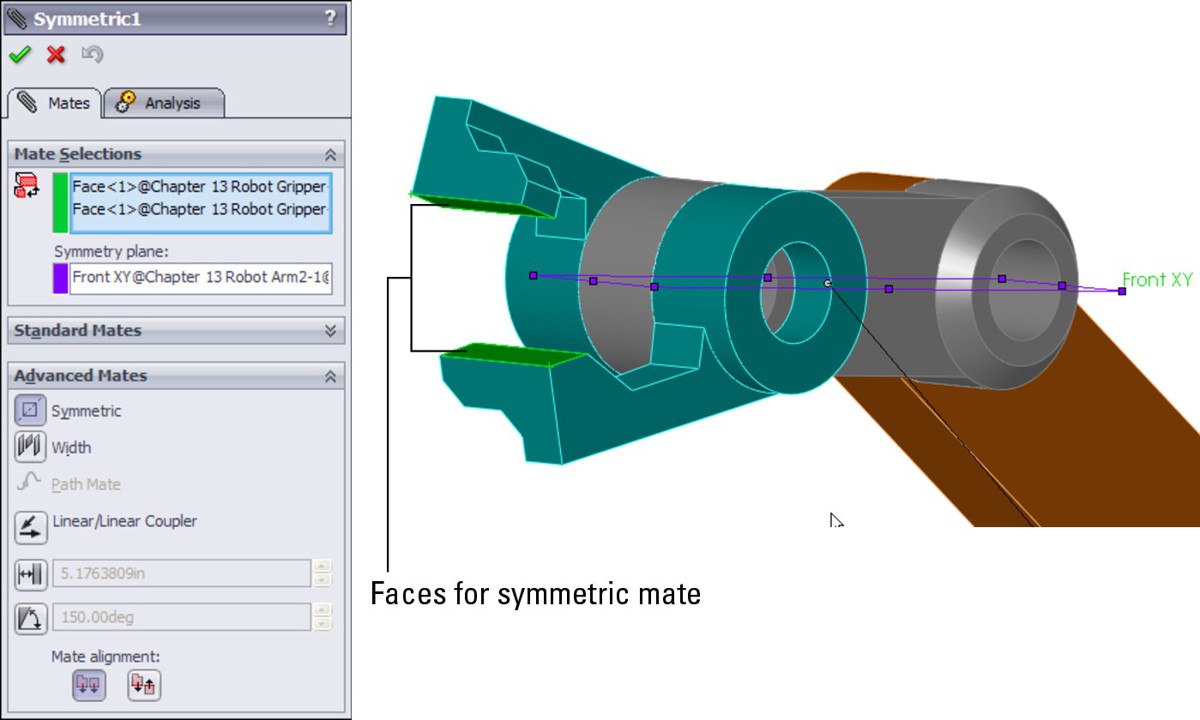

Symmetric mate

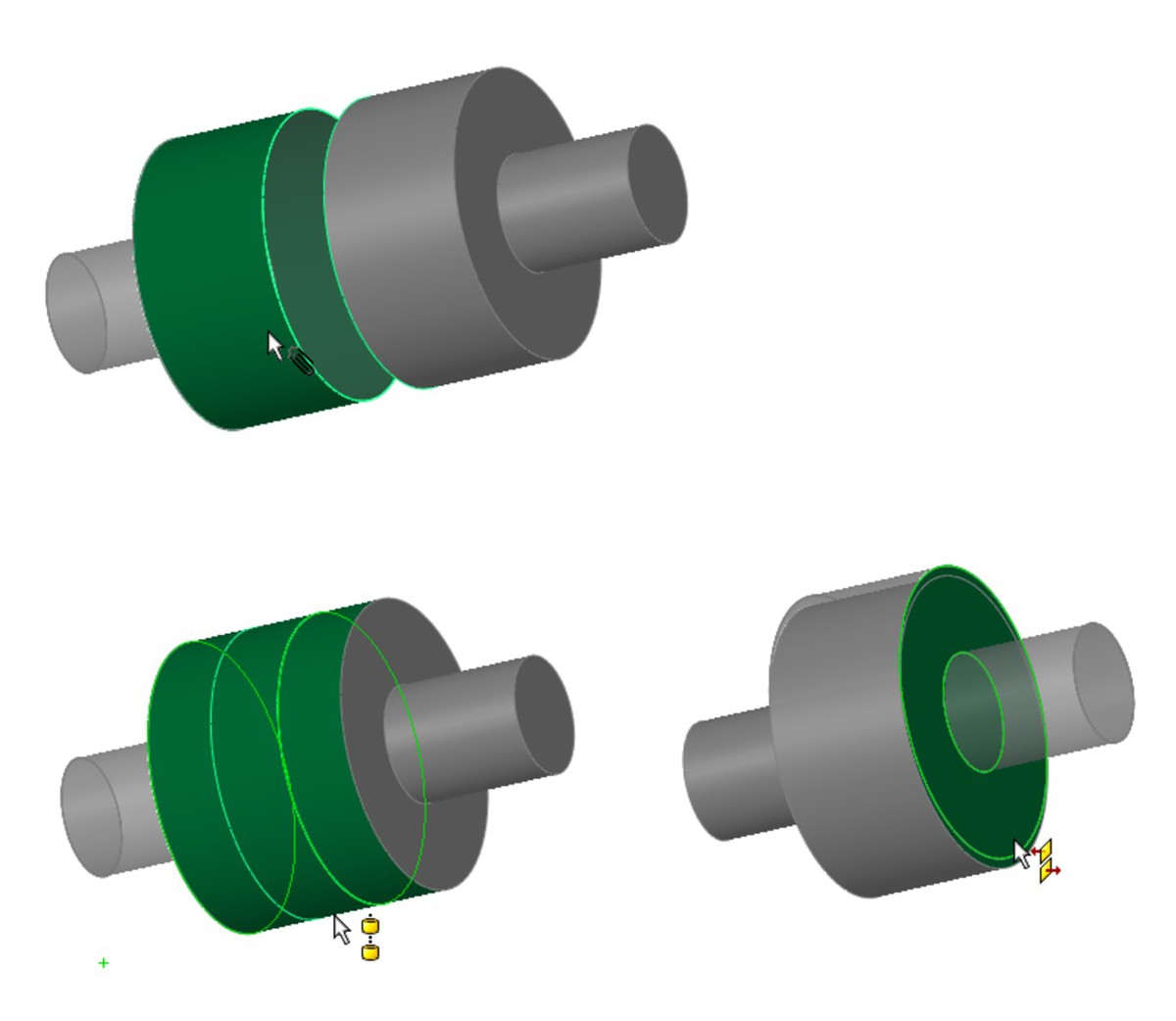

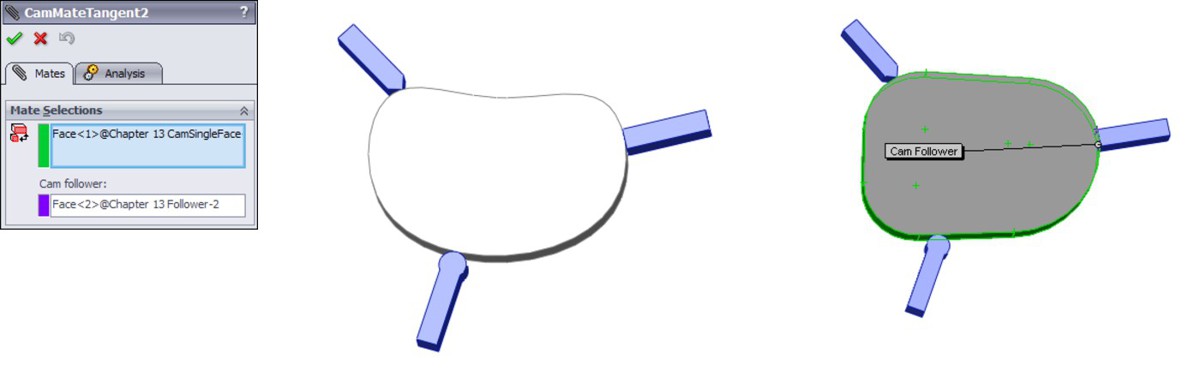

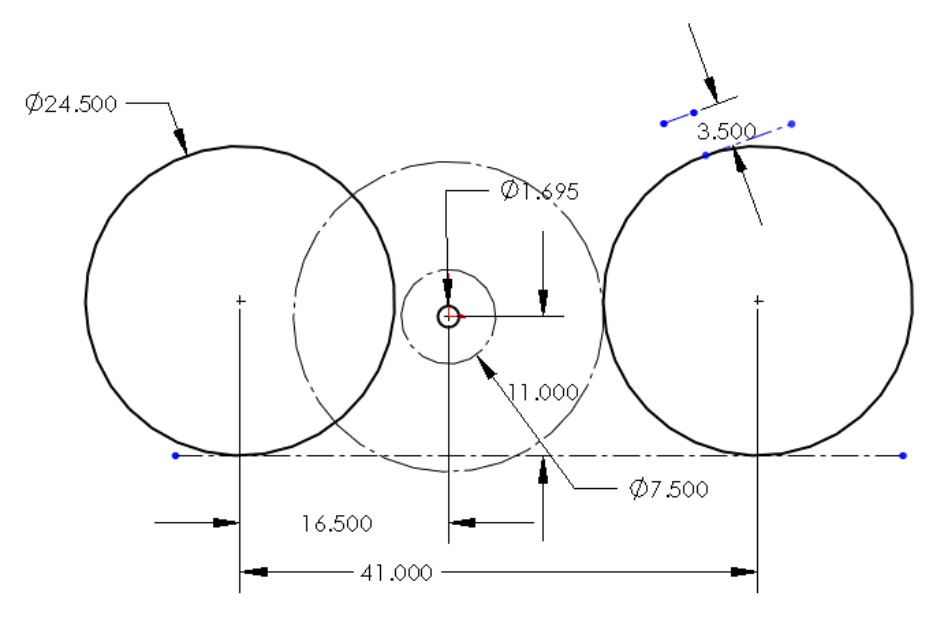

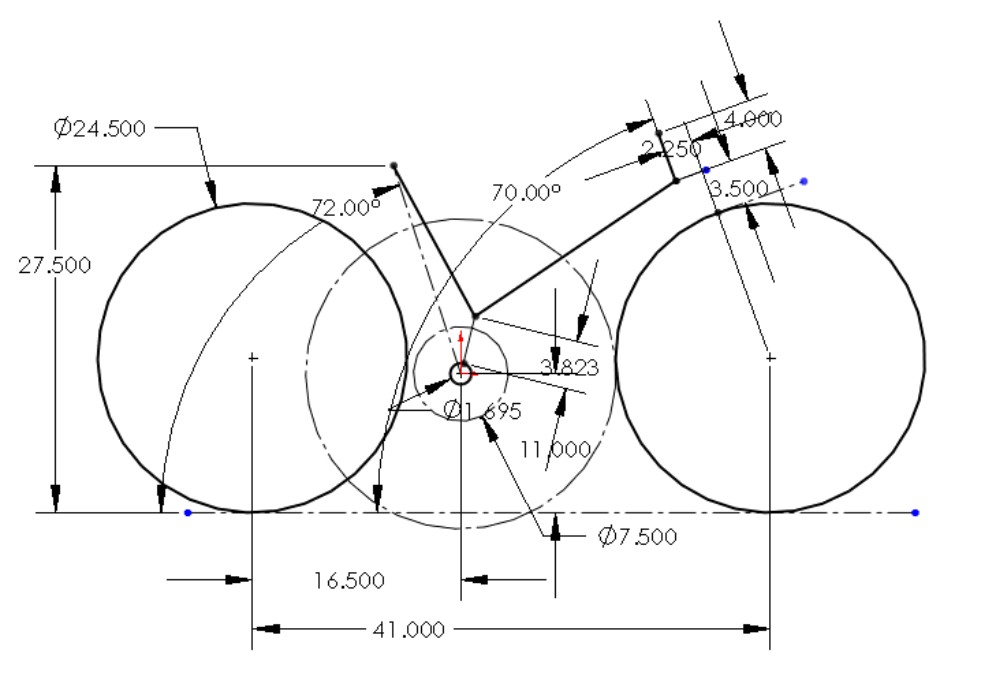

Cam mate

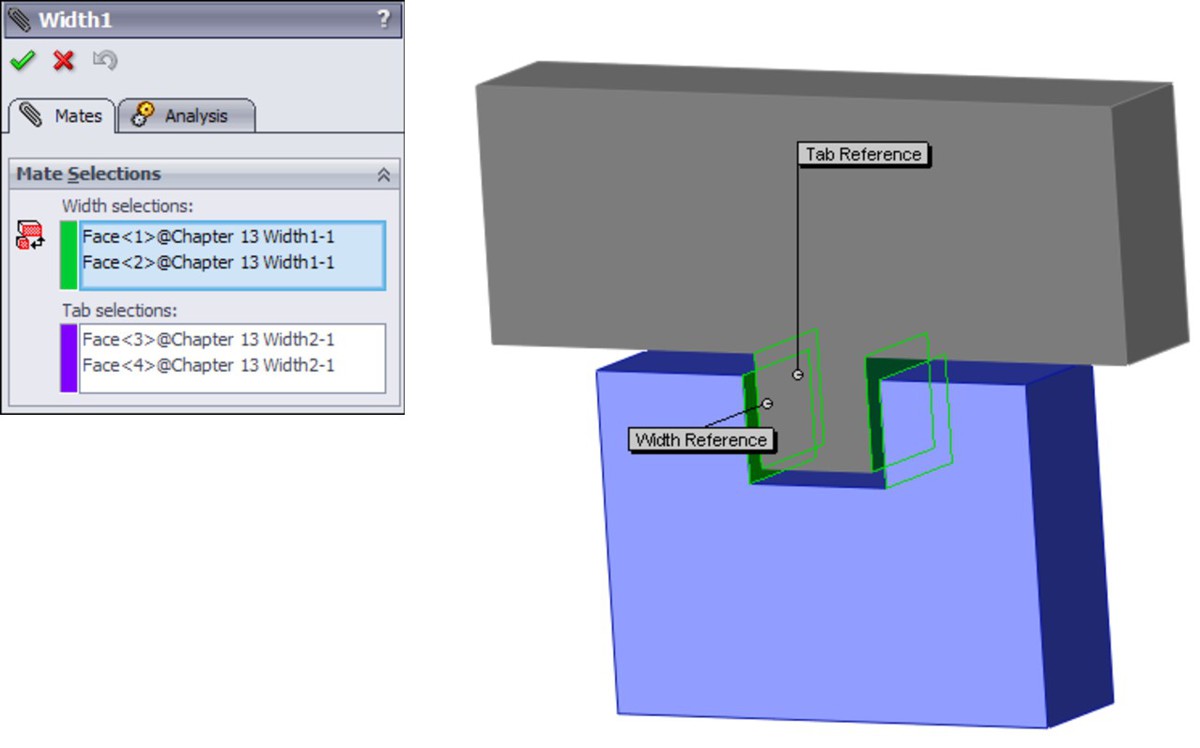

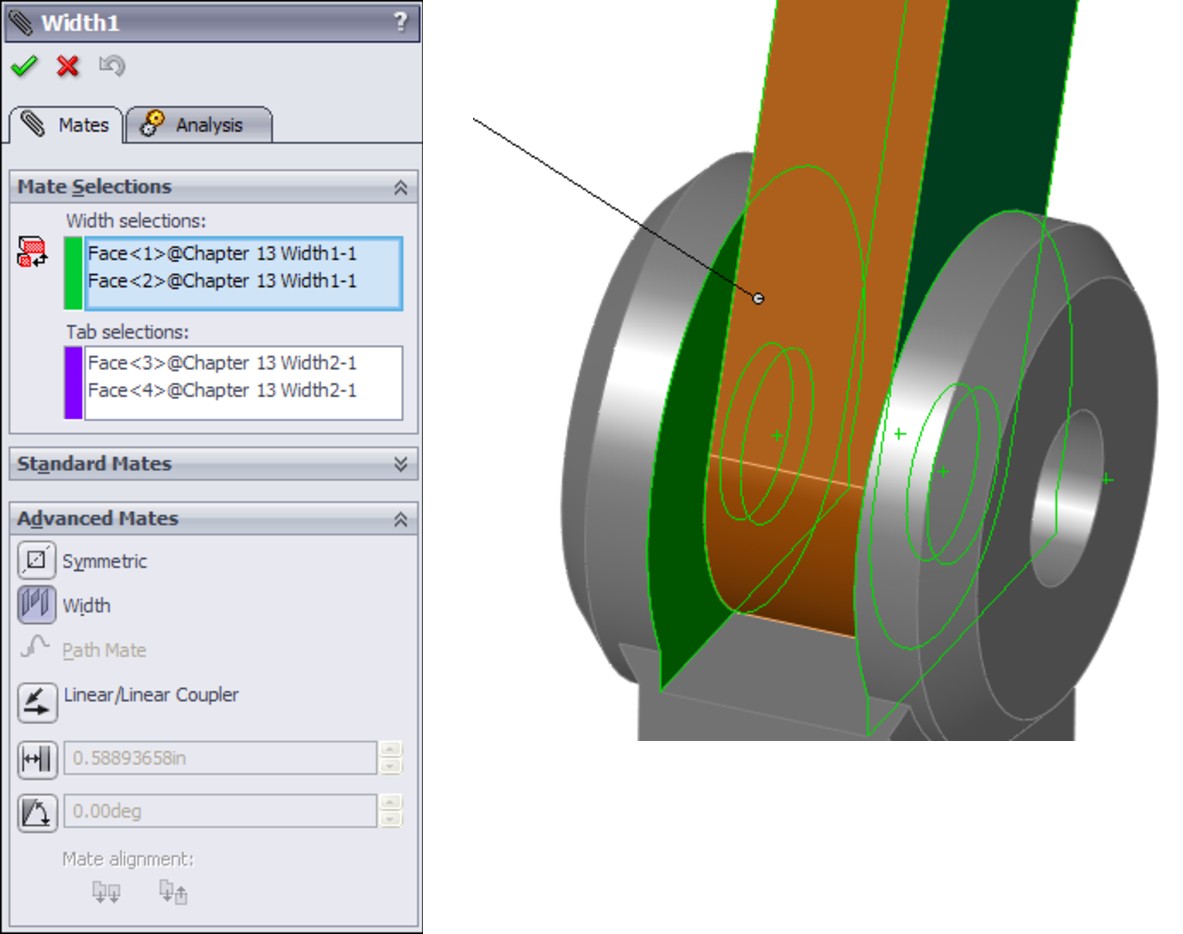

Width mate

Gear mate

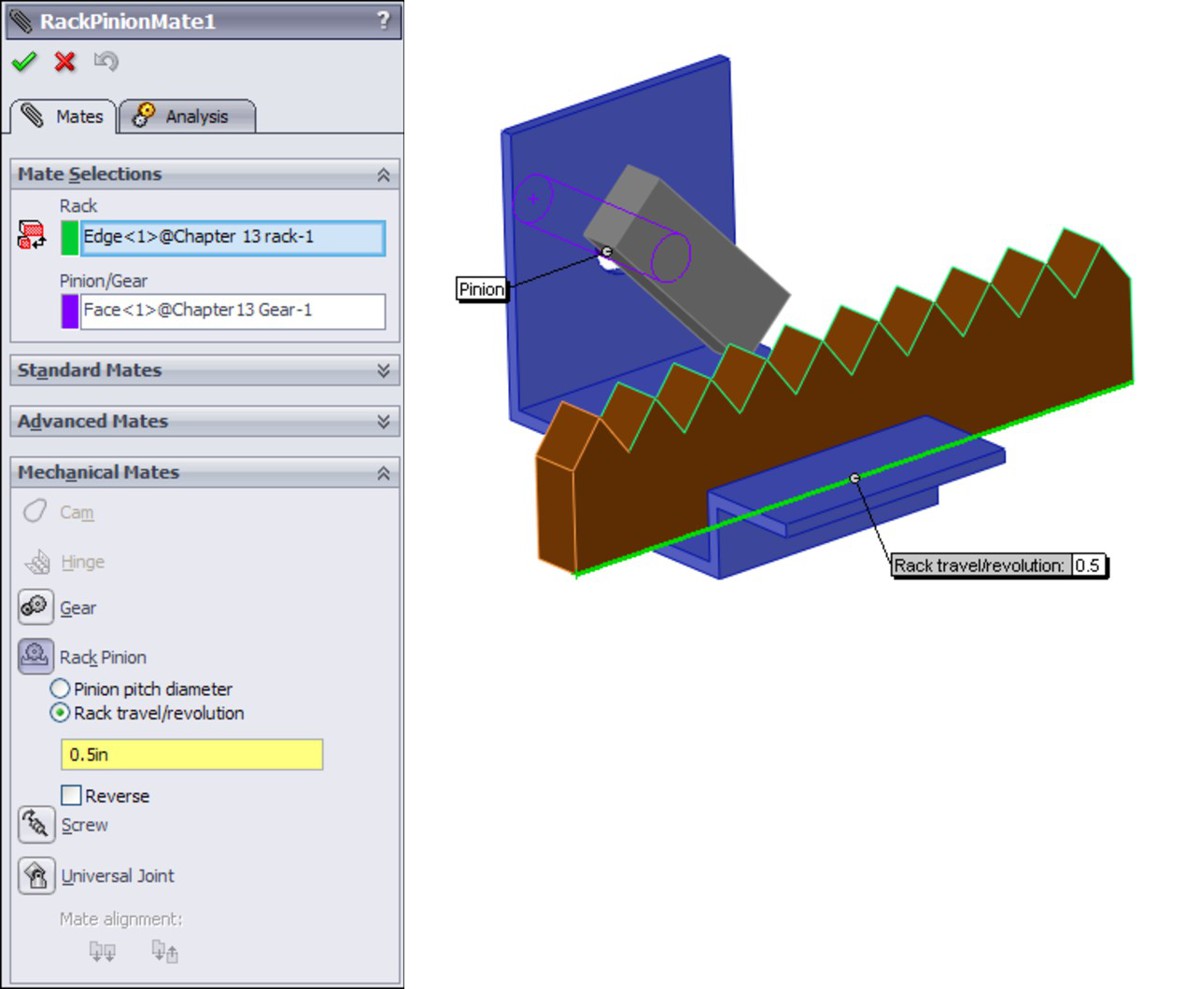

Rack and Pinion mate

Limit mates

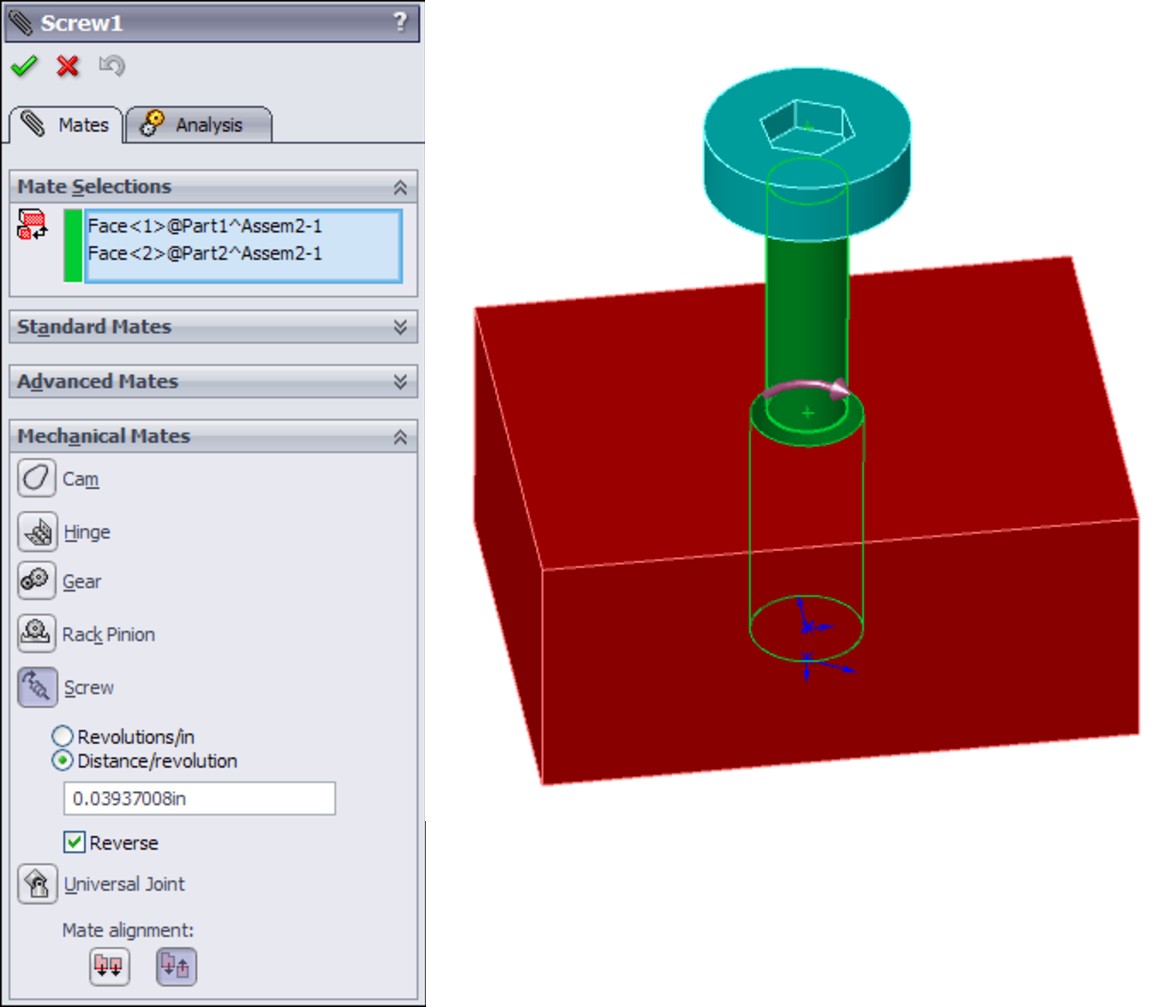

Screw mate

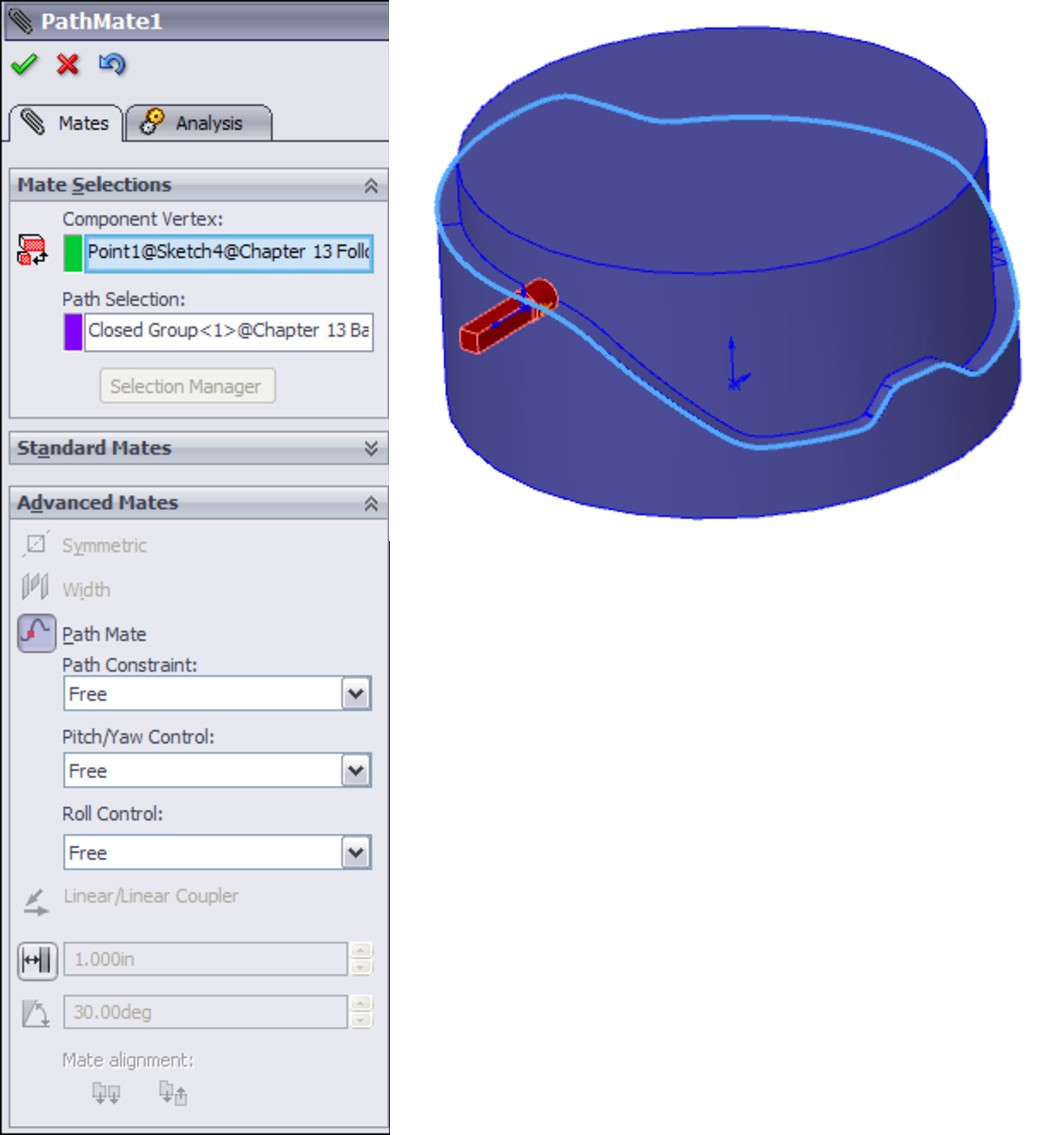

Path mate

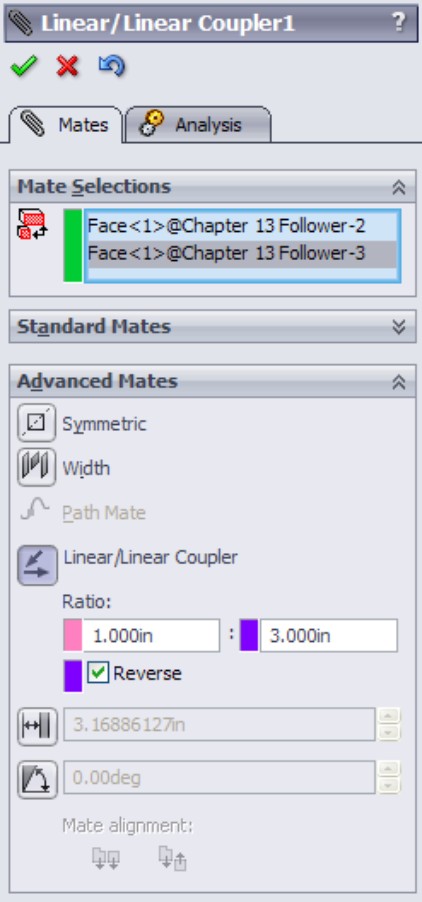

Linear Coupler mate

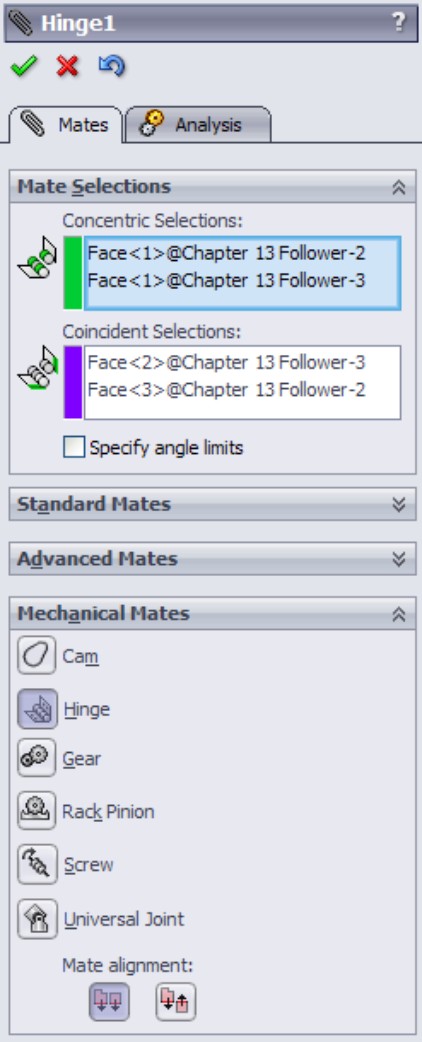

Hinge mate

Belt/Chain

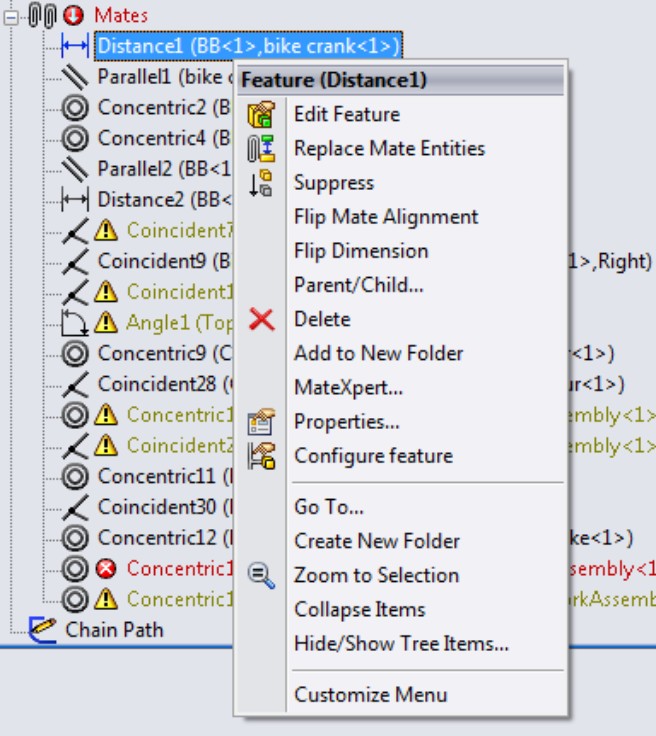

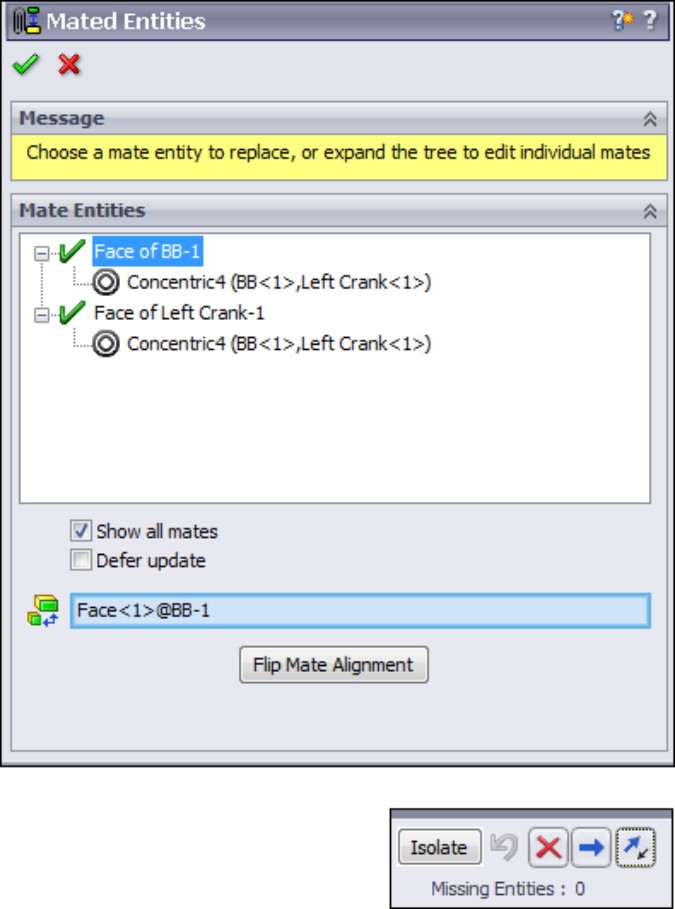

Editing and Troubleshooting

Editing existing mates

Troubleshooting assembly mates

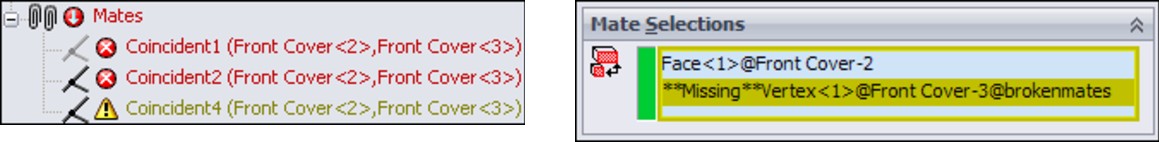

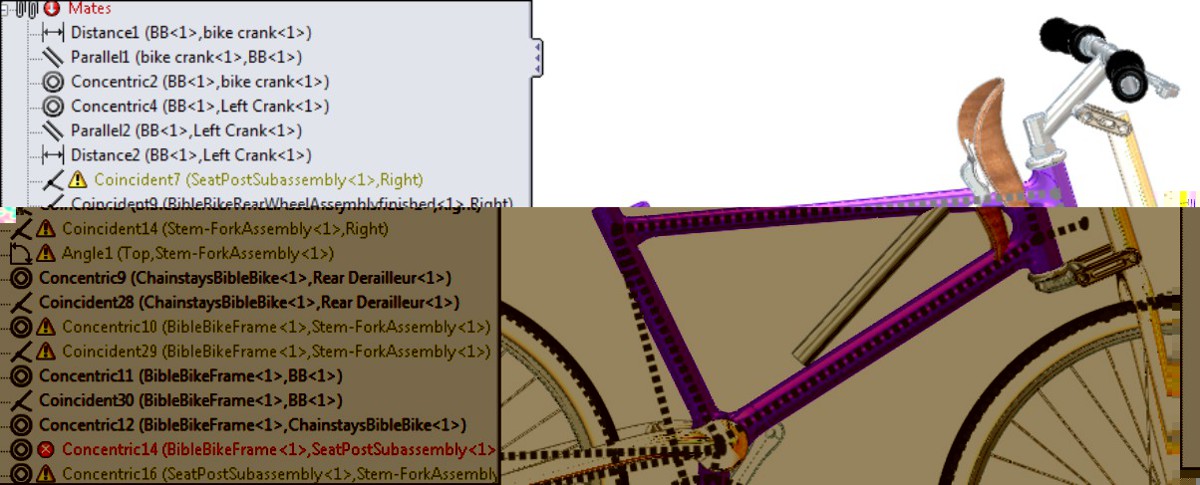

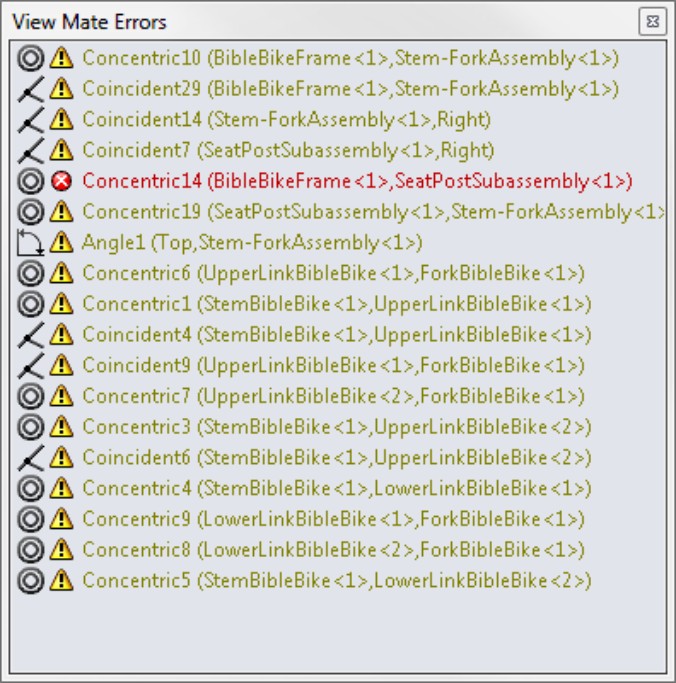

Troubleshooting warnings and errors

Examining Mate Options

Reviewing Mate Best Practices

Tutorial: Mating for Success

Summary

Chapter 6: Working with Assembly Sketches and Layouts

Looking at the Techniques

Using the assembly layout sketch

Using master model

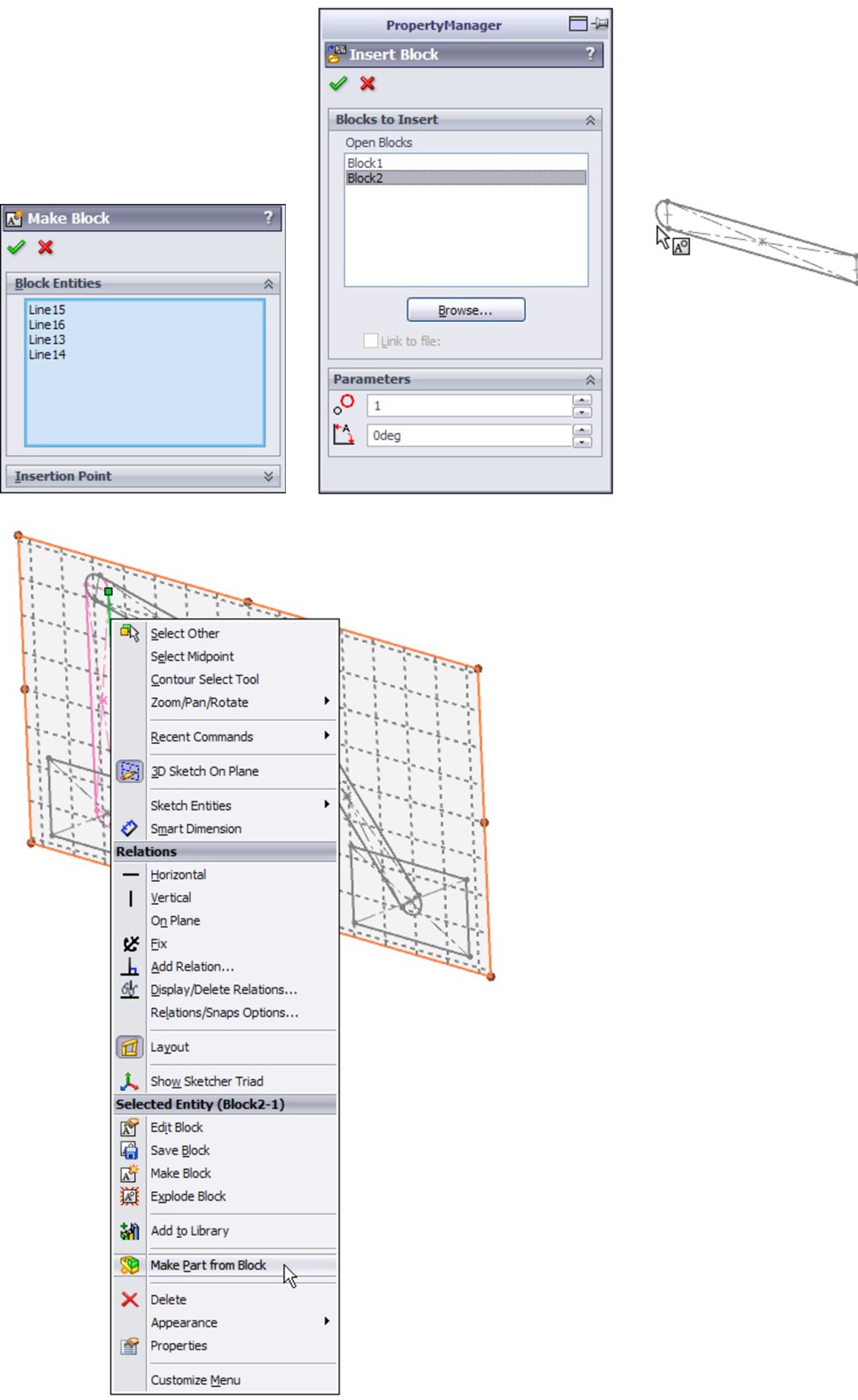

Using the Layout Feature

Using the Layout workflow

Working with virtual components

Balancing advantages and limitations

Tutorial: Working with a Layout

Summary

Chapter 7: Using Assembly Tools

Placing Parts without Mates

Using the Move Component options

Using the For Positioning Only option

Building parts in place

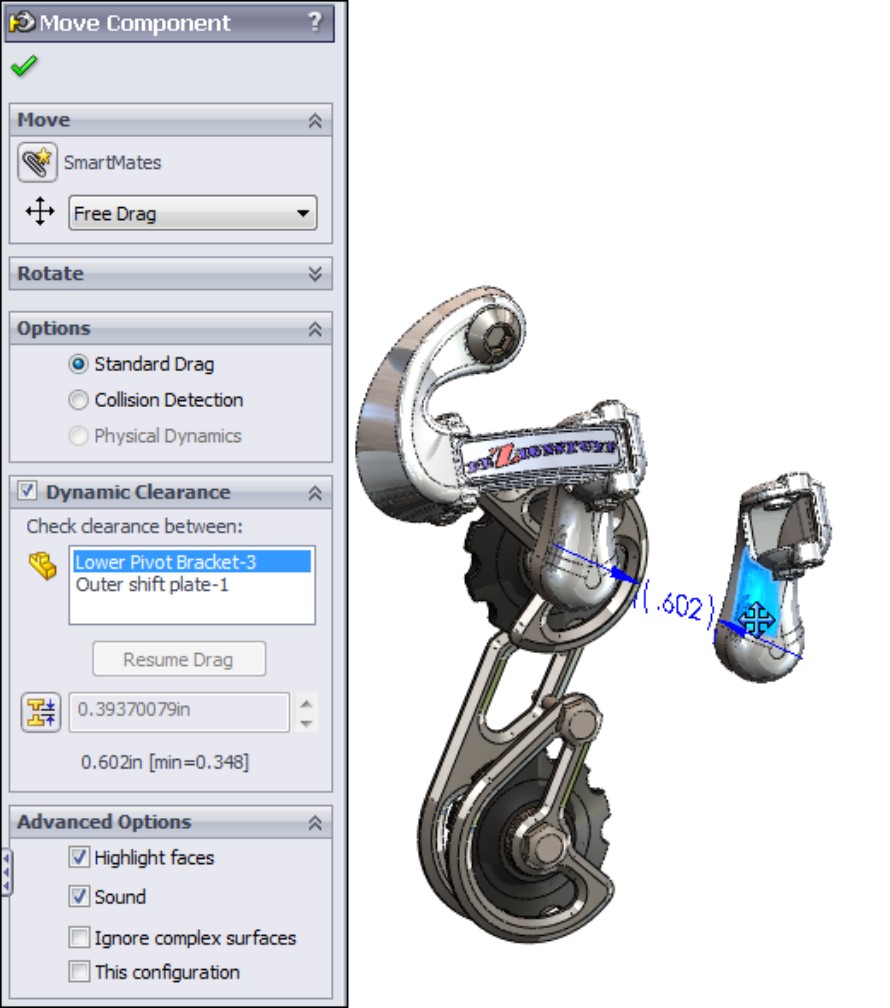

Using Proximity Tools

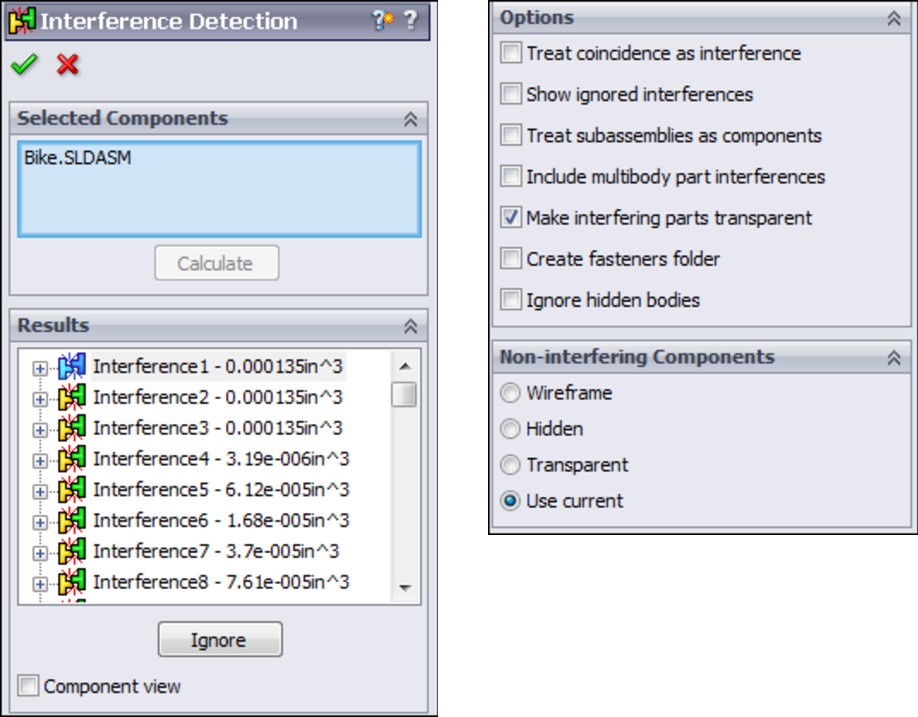

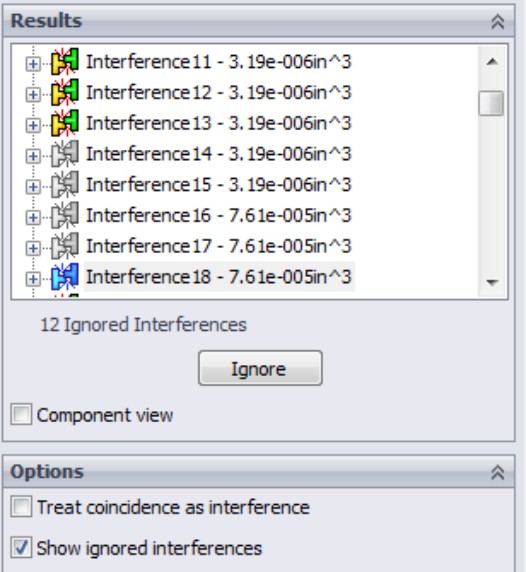

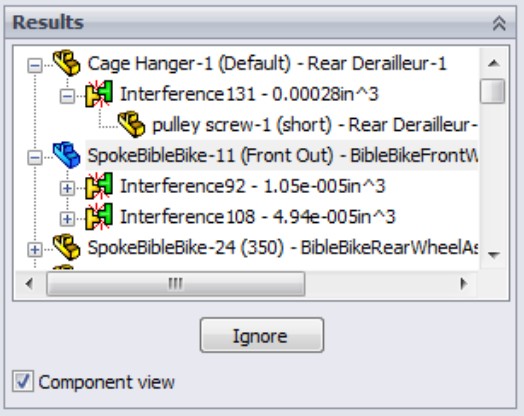

Using Interference Detection

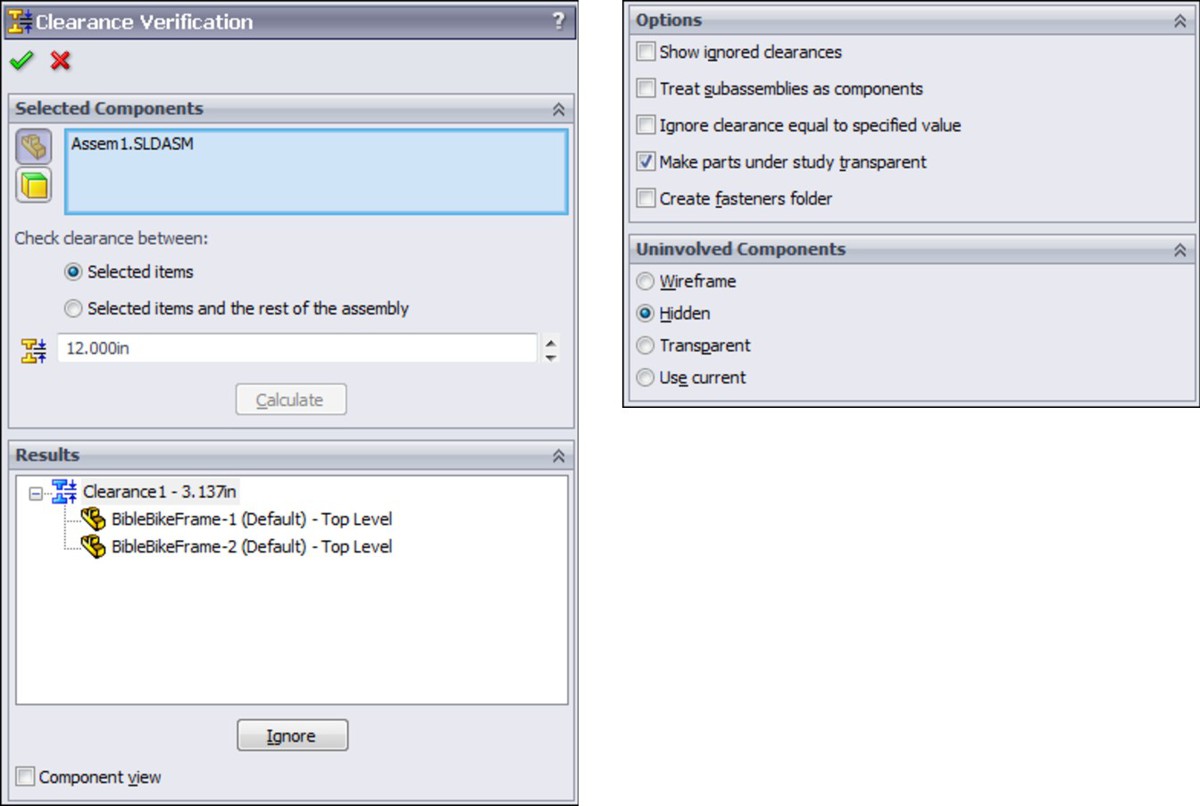

Working with Clearance Verification

Using Dynamic Clearance

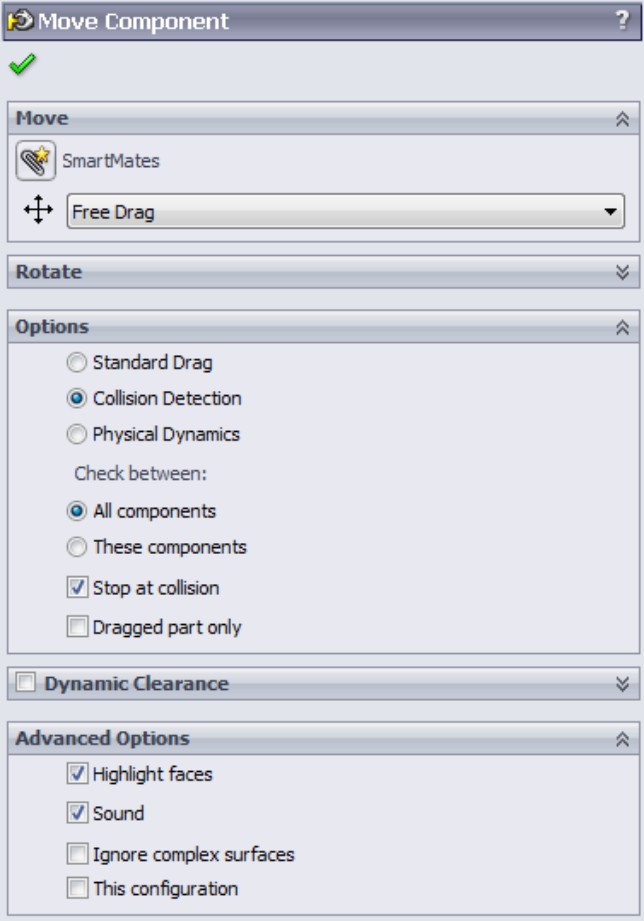

Working with Collision Detection

Using Physical Dynamics

Using Sensors

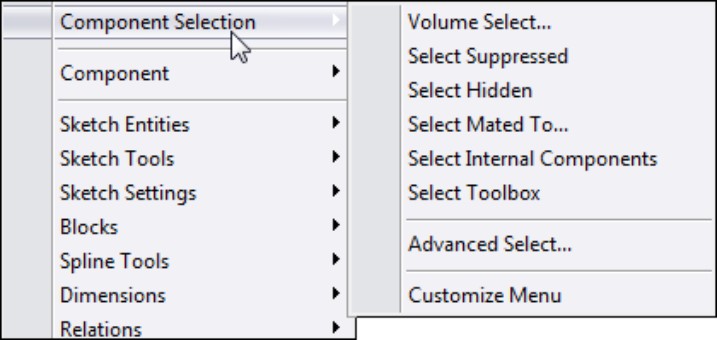

Selecting Components

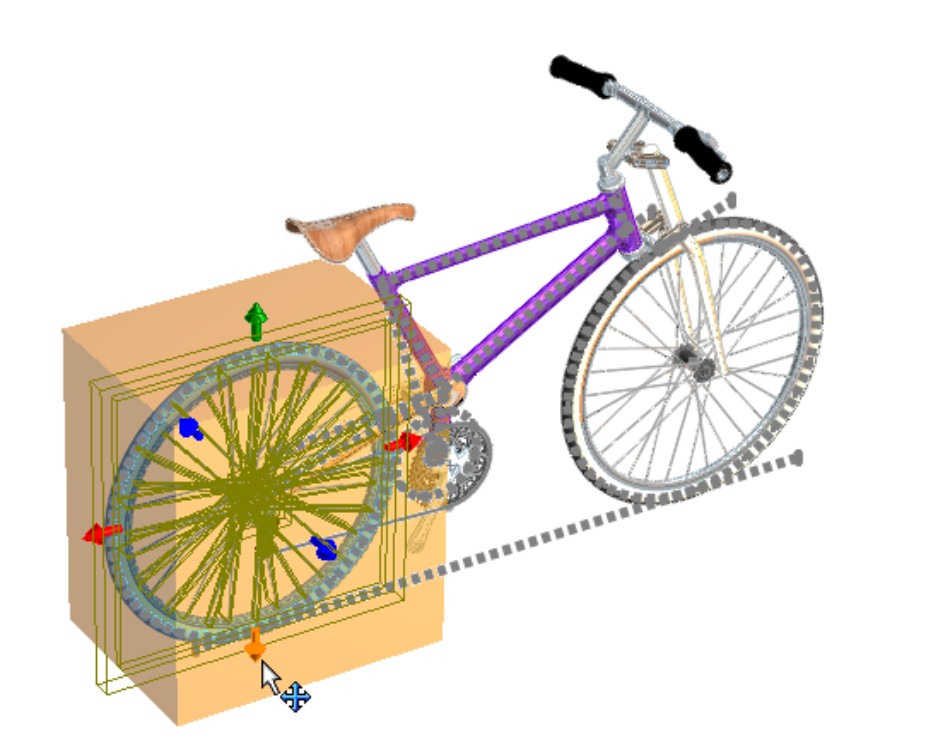

Selecting with a volume

Selecting suppressed components

Choosing hidden components

Selecting parts mated to another part

Selecting internal components

Choosing Toolbox parts

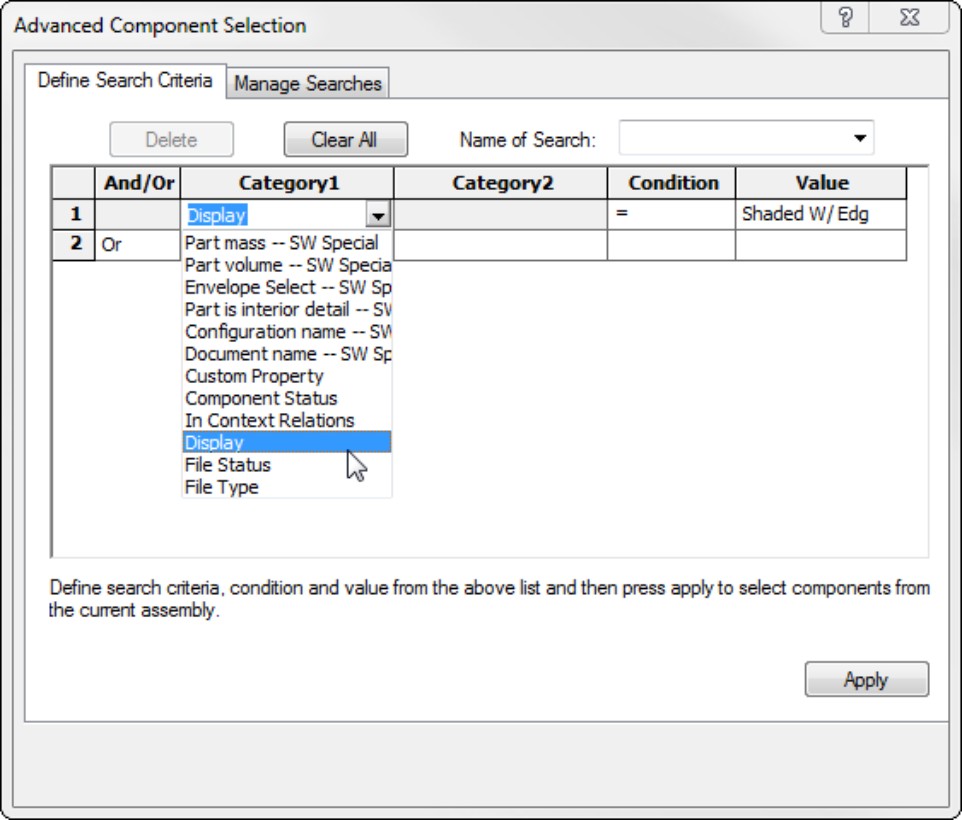

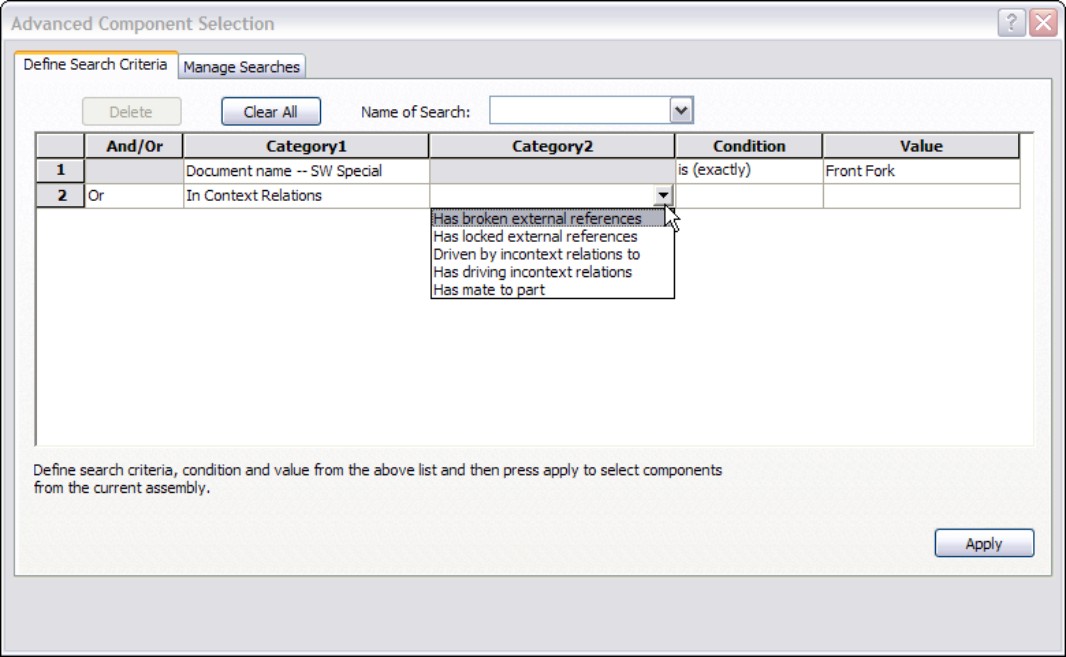

Using the Advanced Select options

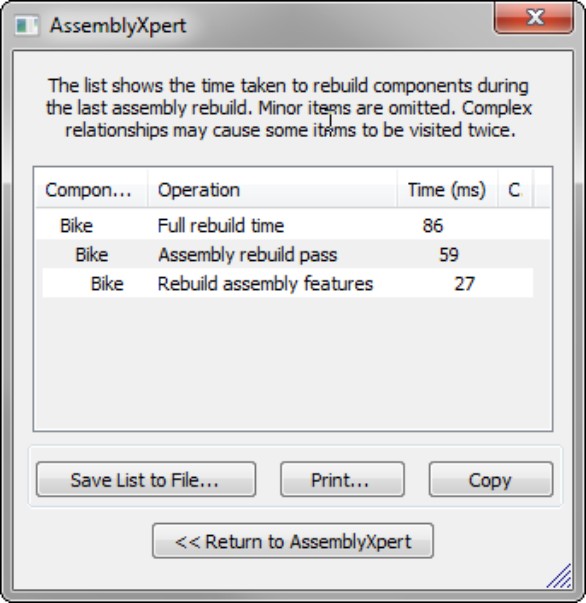

Reading AssemblyXpert Results

Using Defeature

Using the Hole Alignment Tool

Working with Large Assemblies

Using special techniques to improve large assembly performance

Using special tools to improve large assembly performance

Summary

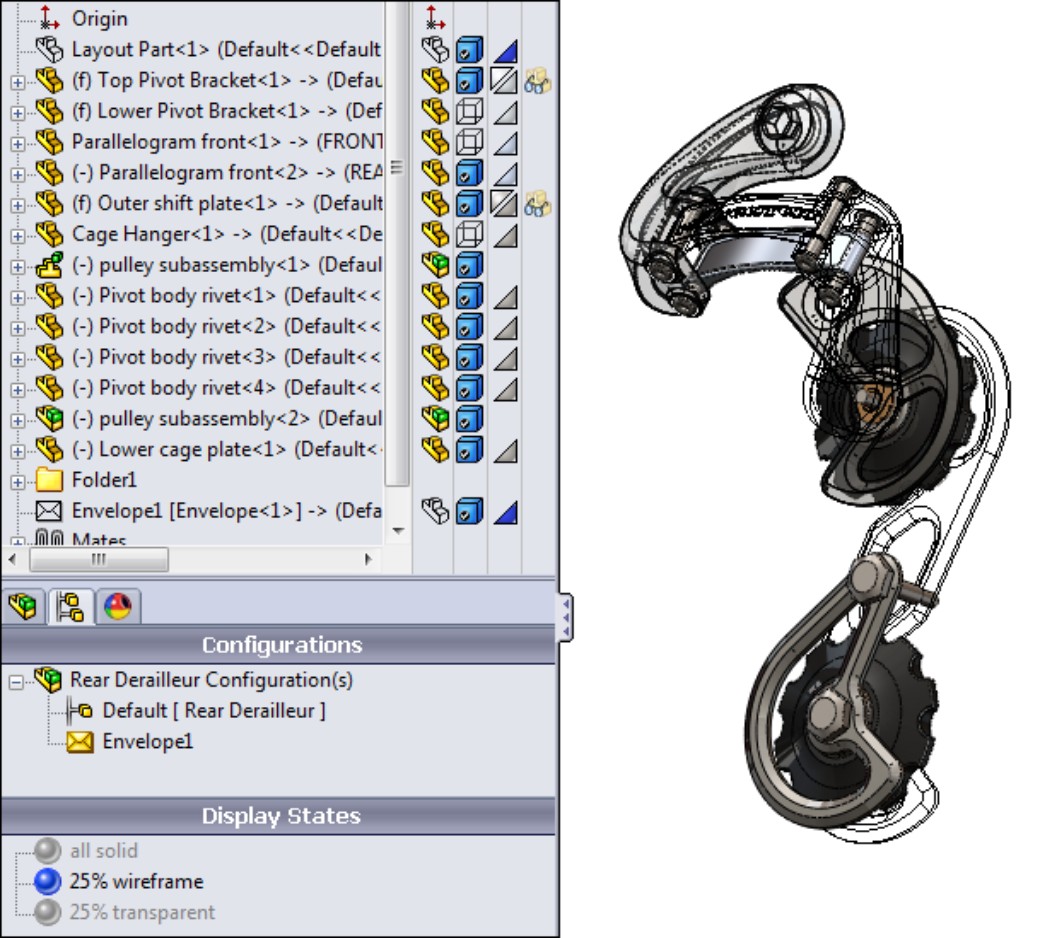

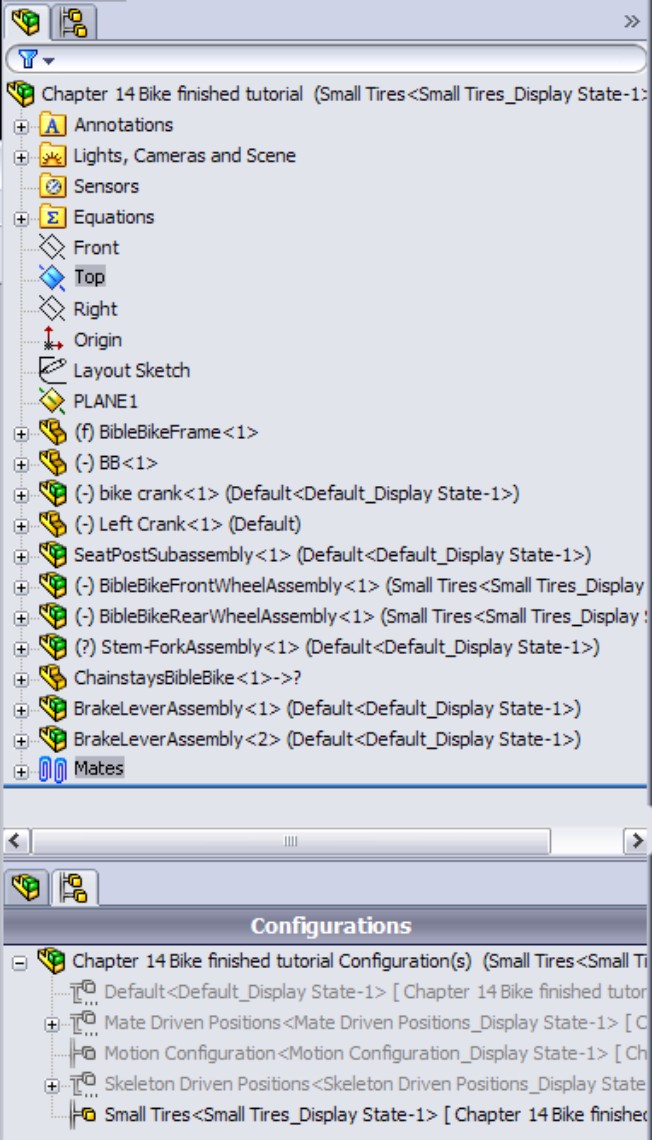

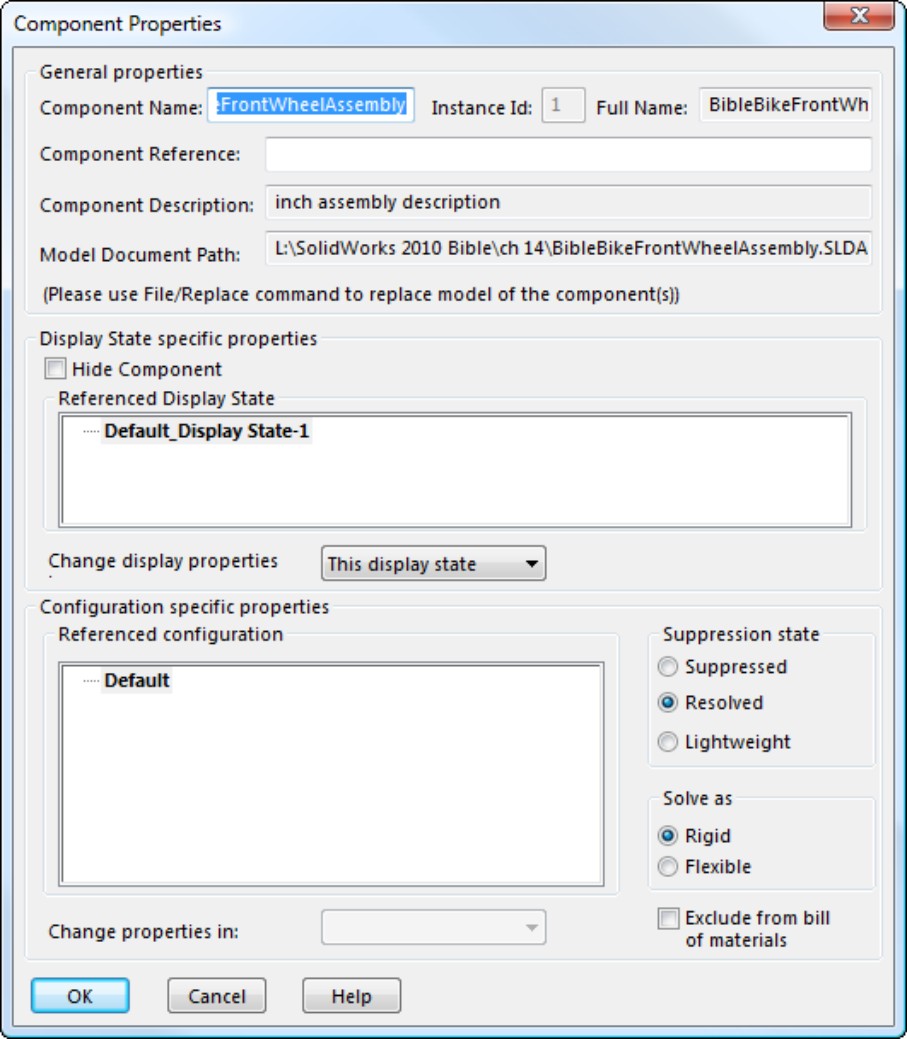

Chapter 8: Controlling Assembly Configurations and Display States

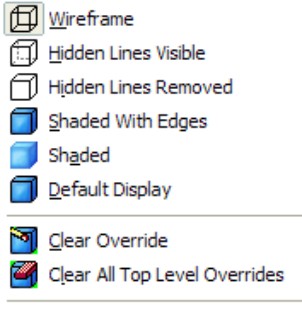

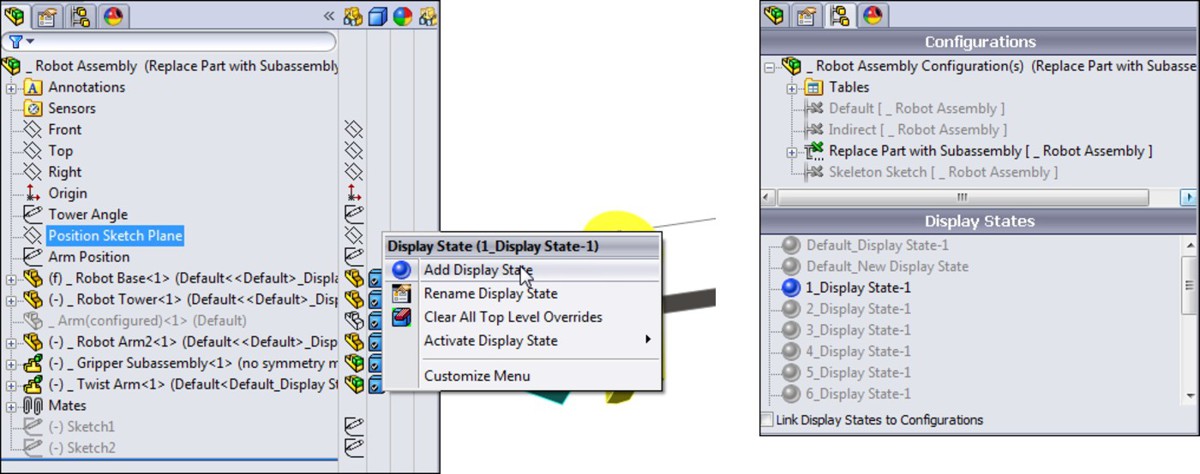

Using Display States

Controlling display states and configurations

Using display states with drawings

Using part display states in parts

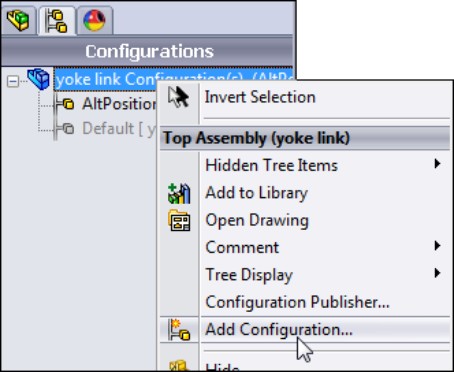

Understanding Assembly Configurations

Applying configurations for performance

Using configurations for positions

Applying configurations for product variations

Using design tables for assembly configurations

Working with Modify Configurations and the Configuration Publisher

Looking at assembly configuration dos and don'ts

Tutorial: Working with Assembly Configurations

Summary

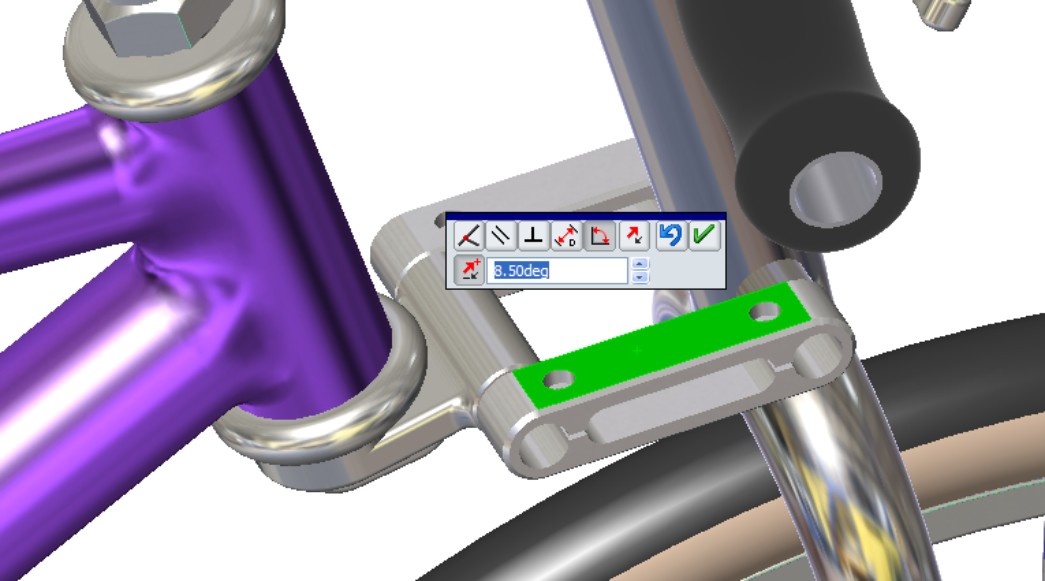

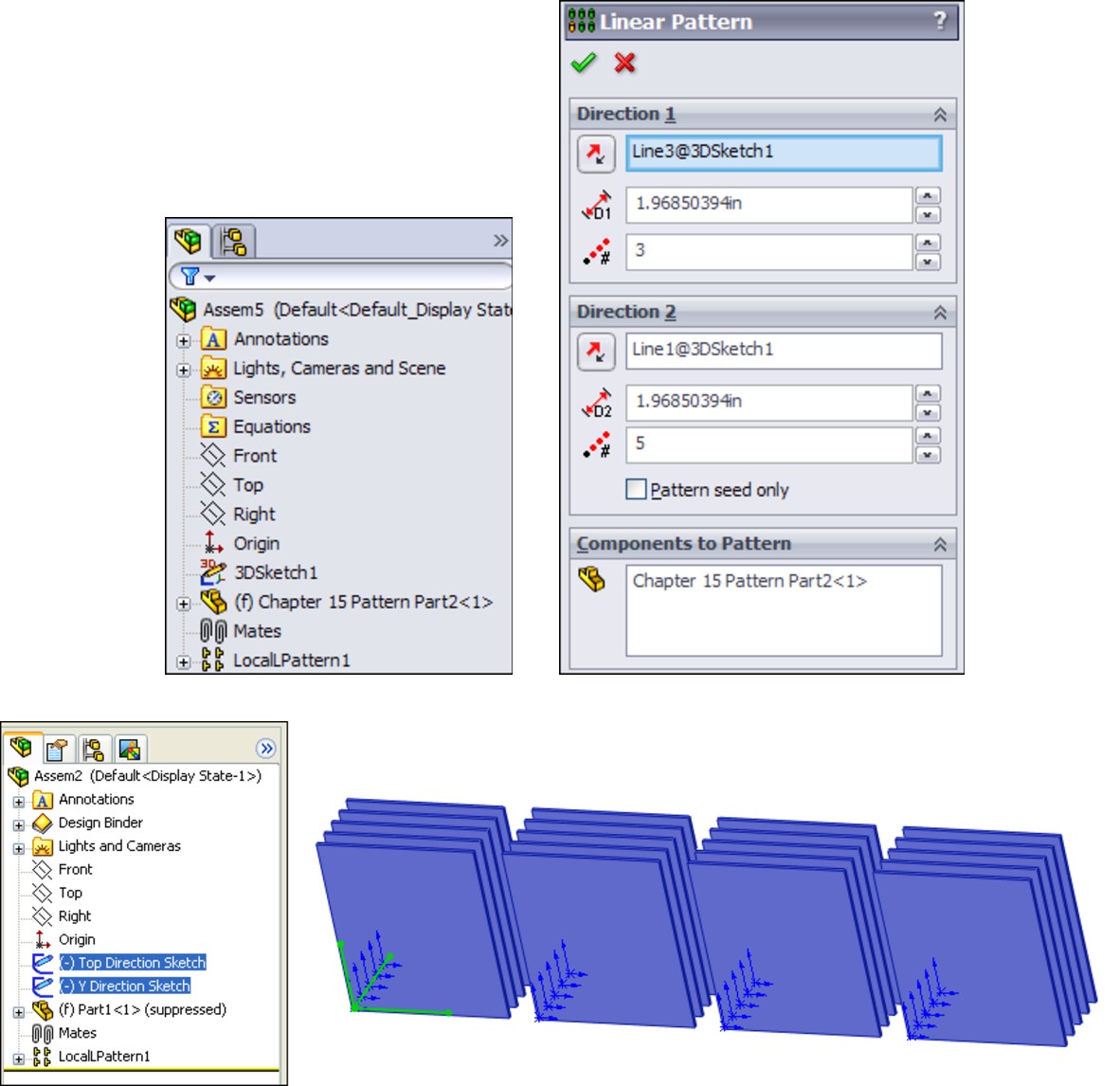

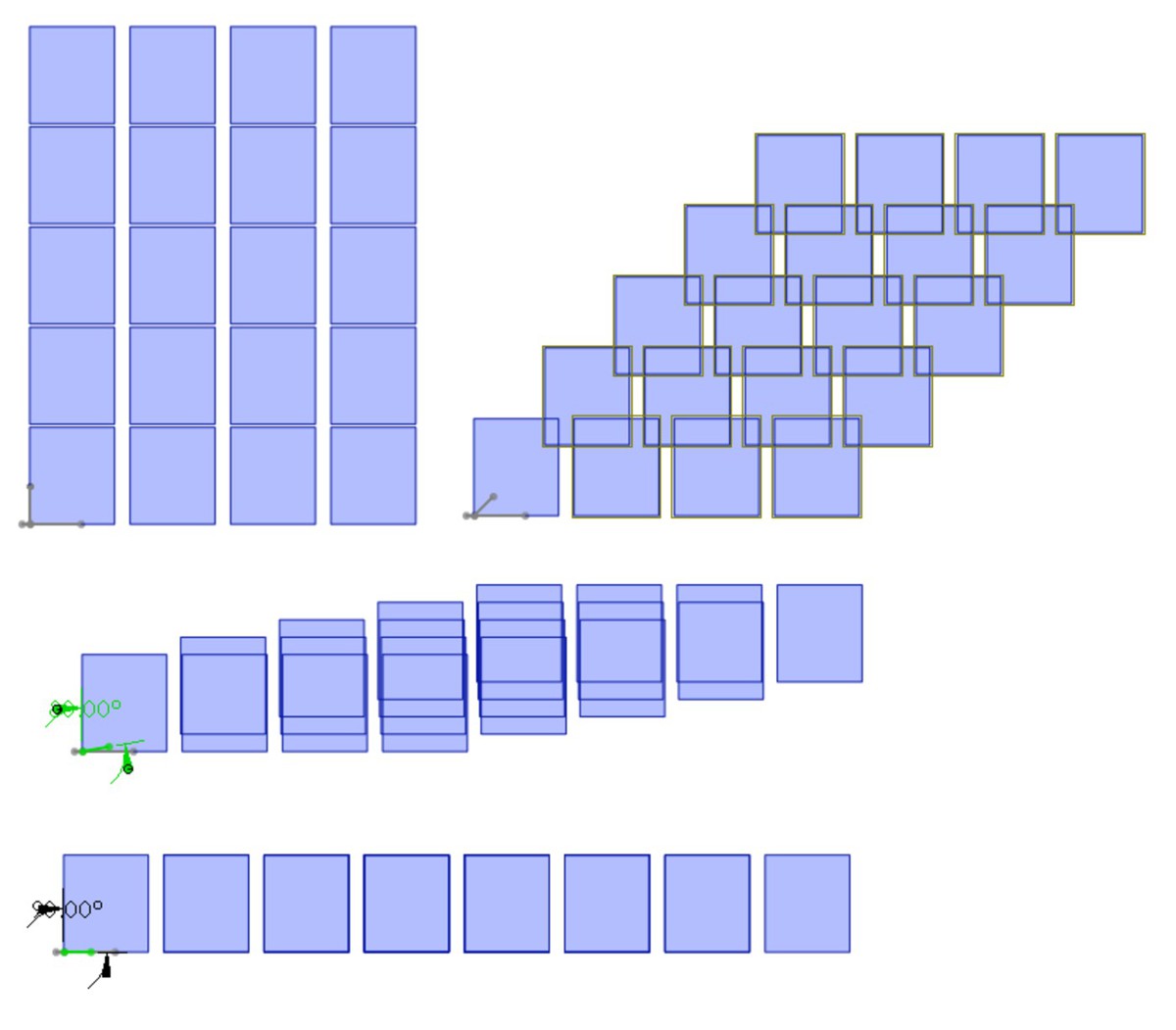

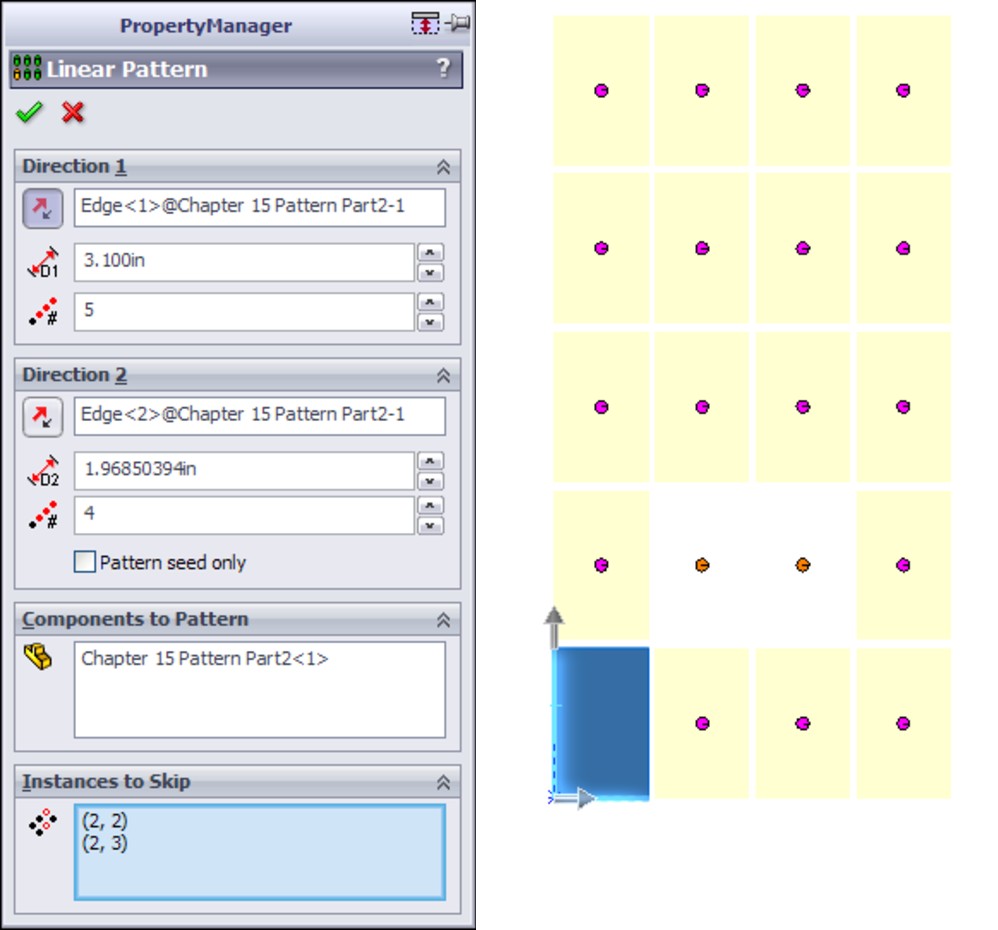

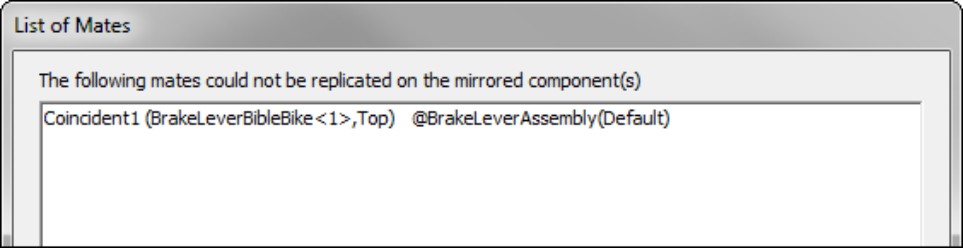

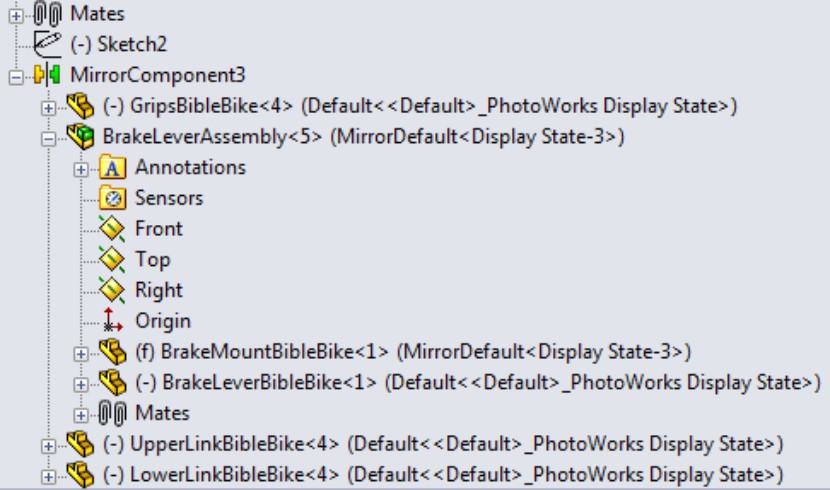

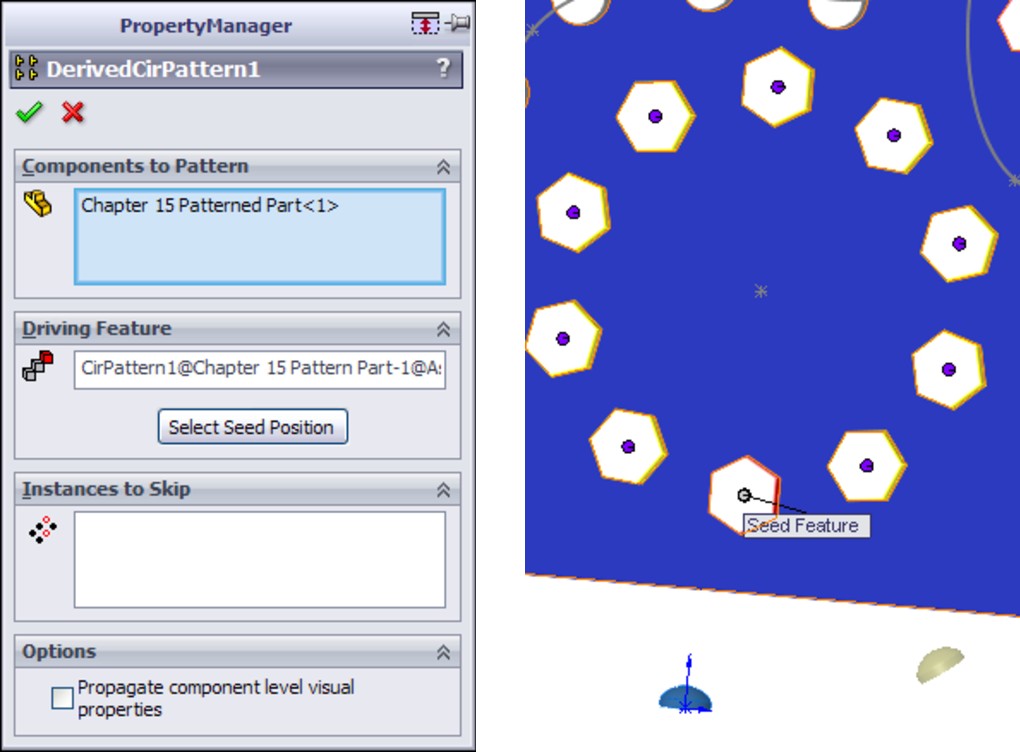

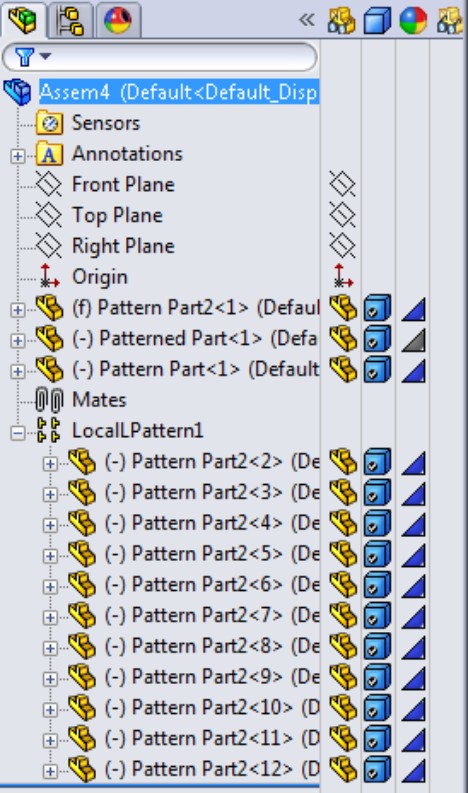

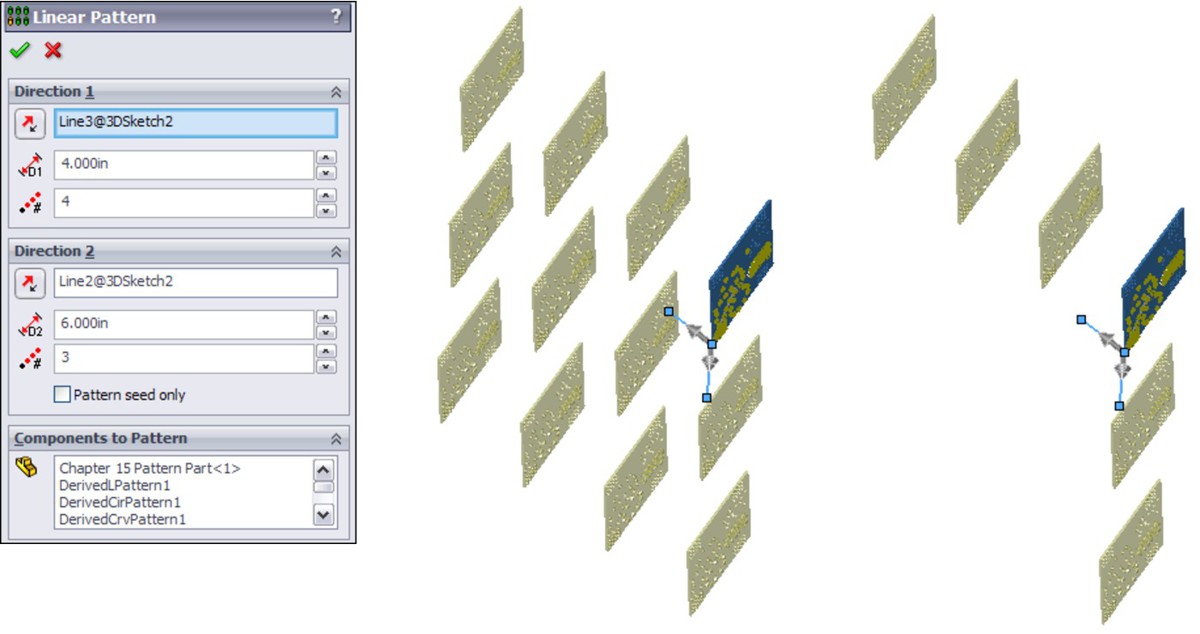

Chapter 9: Patterning and Mirroring Components

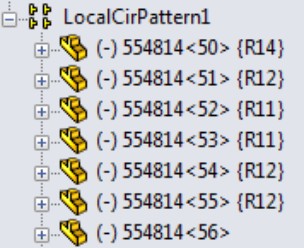

Using Local Component Patterns

Creating local pattern references

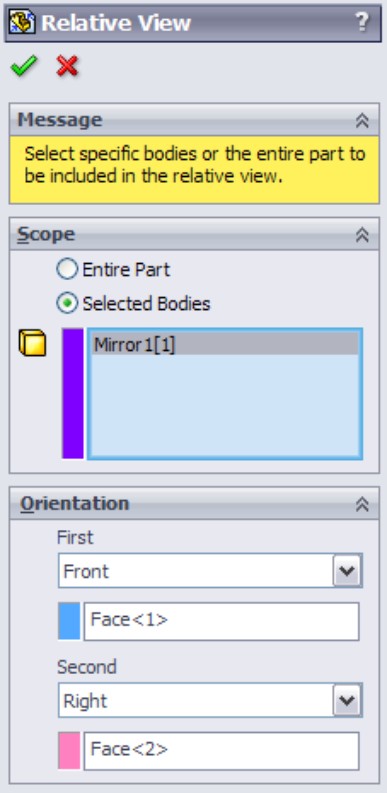

Using Mirror Components

Using Feature-Driven Component Patterns

Understanding Other Pattern Options

Tutorial: Creating Component Patterns

Summary

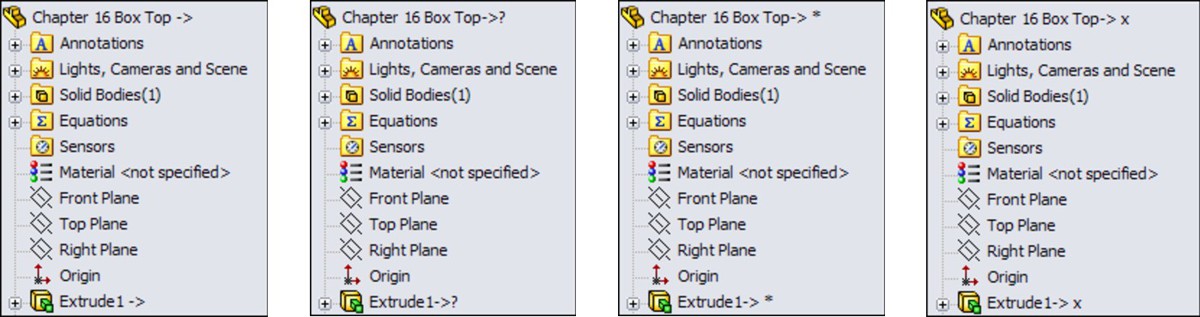

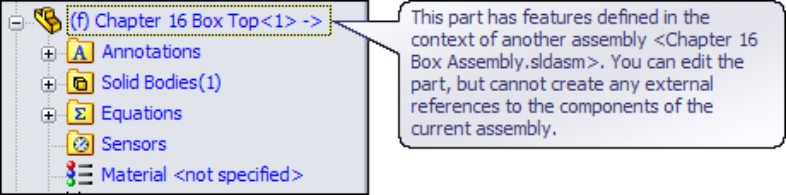

Chapter 10: Modeling in Context

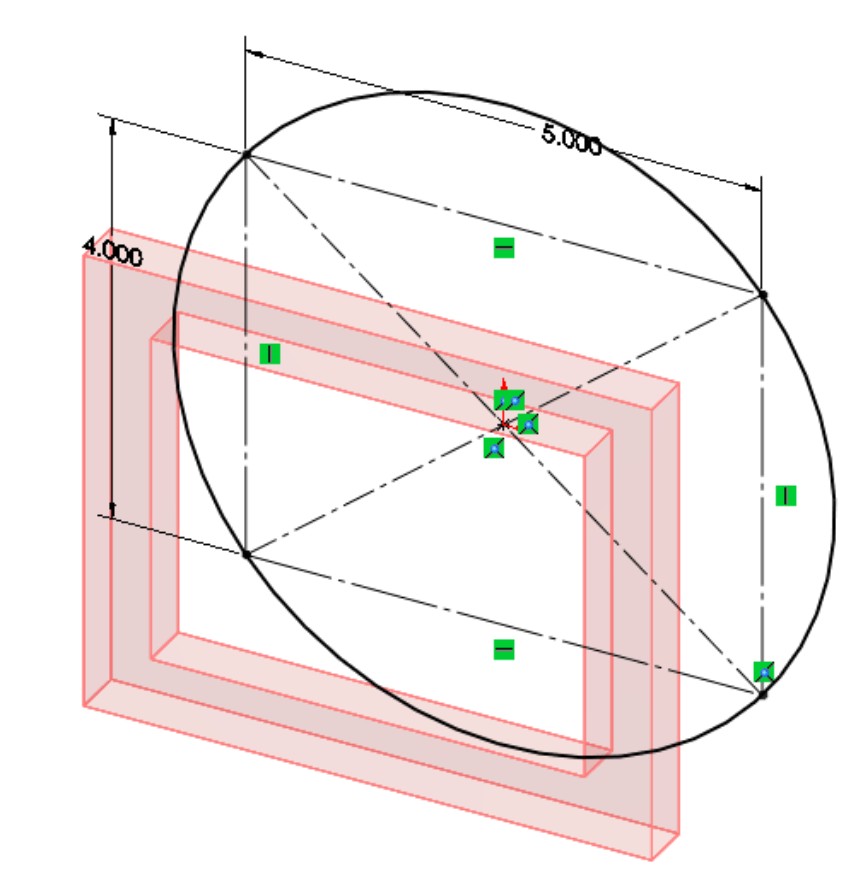

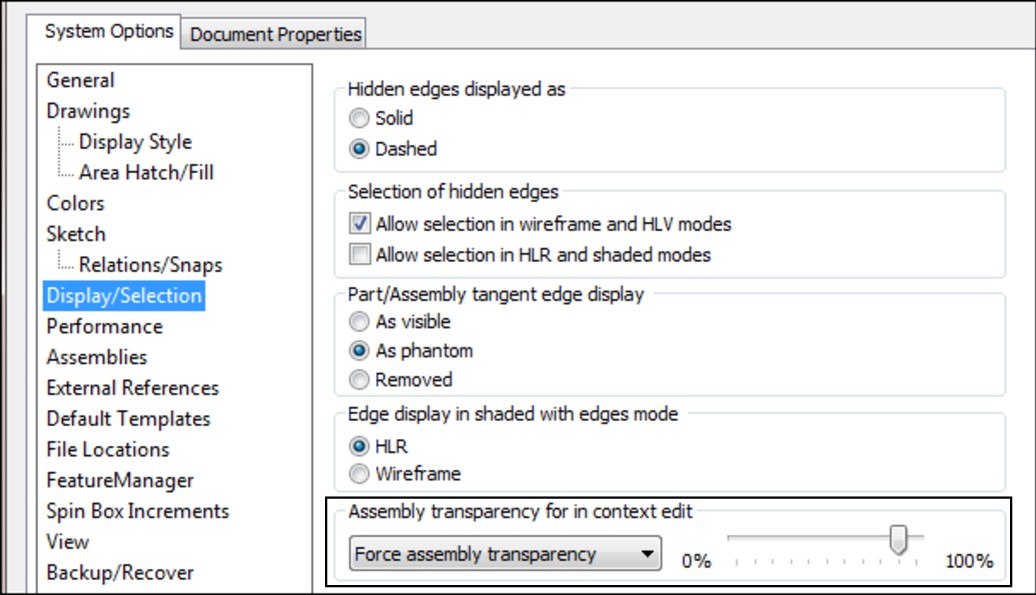

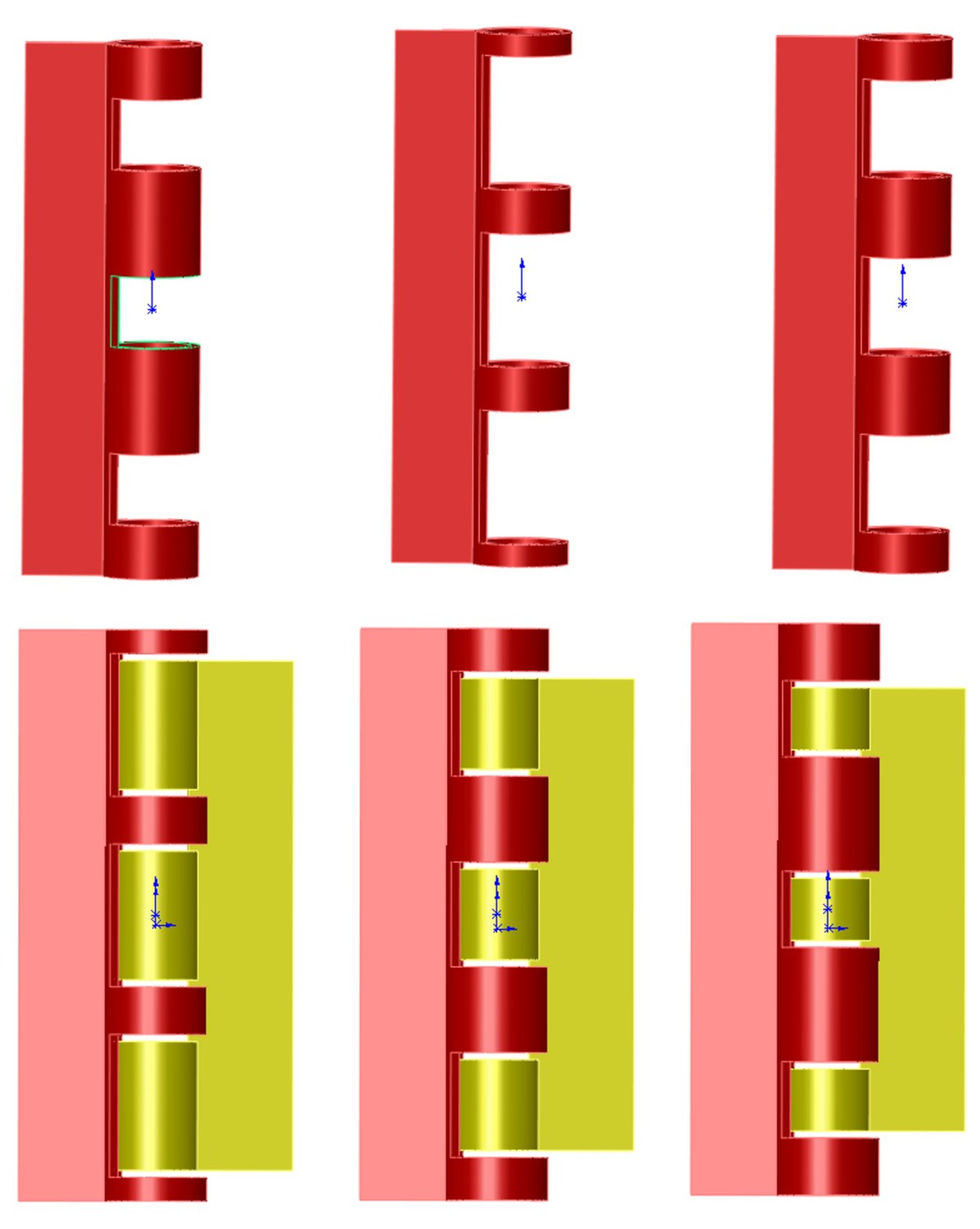

Understanding In-Context Modeling

Working through a simple in-context example

Weighing the advantages of in-context modeling

Anticipating problems with in-context modeling

Identifying alternatives to in-context modeling

Dealing with the Practical Details of In-Context Modeling

Understanding the in-context process

Looking at in-context best practices

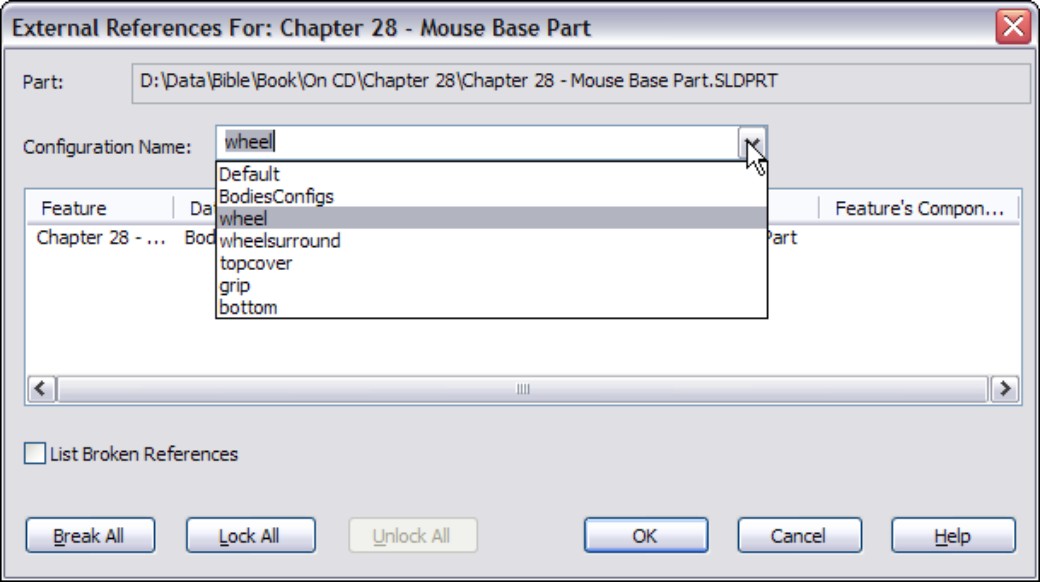

Using Other Types of External References

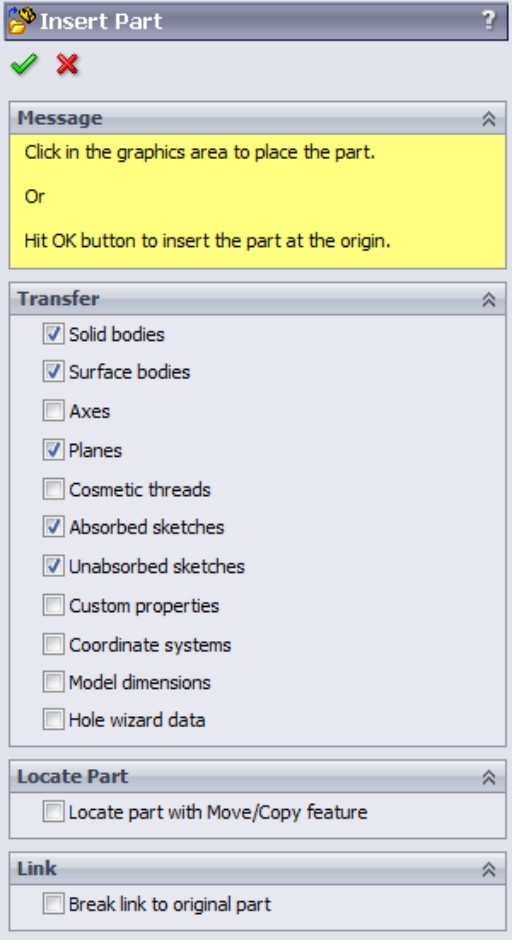

Using inserted parts

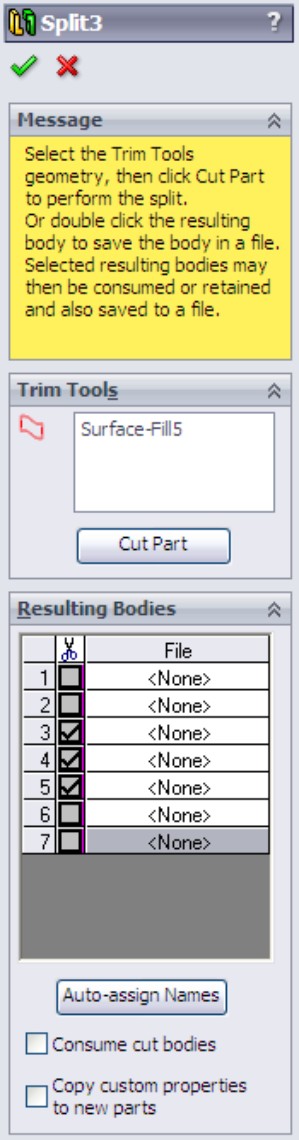

Working with split parts

Using mirror parts

Using the Layout Feature

Using the Layout workflow

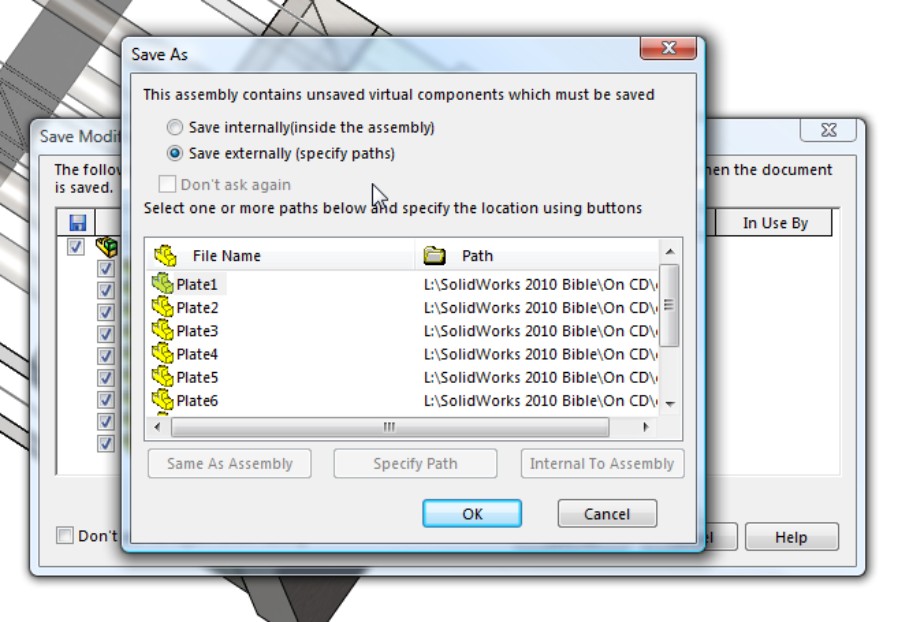

Understanding virtual components

Balancing advantages and limitations

Tutorial: Working In-Context

Summary

Chapter 11: Creating Assembly Features

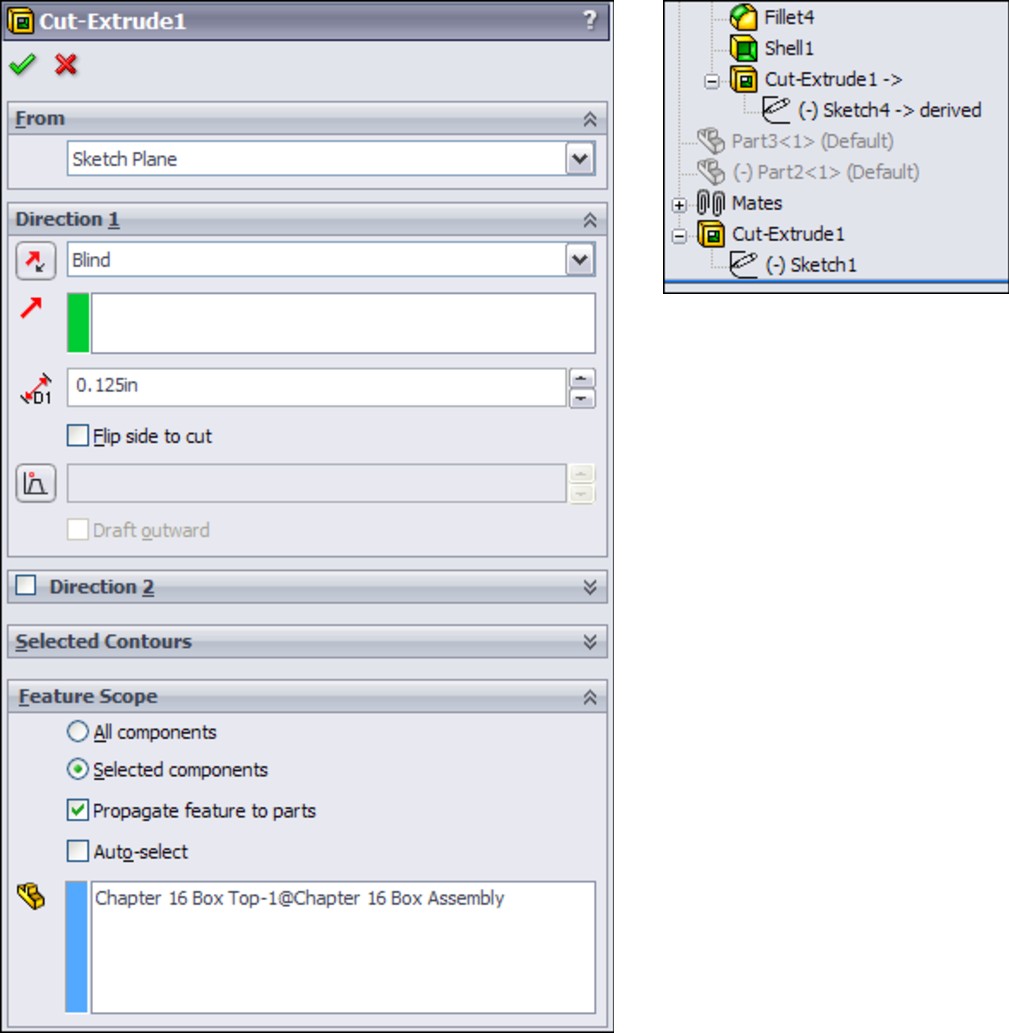

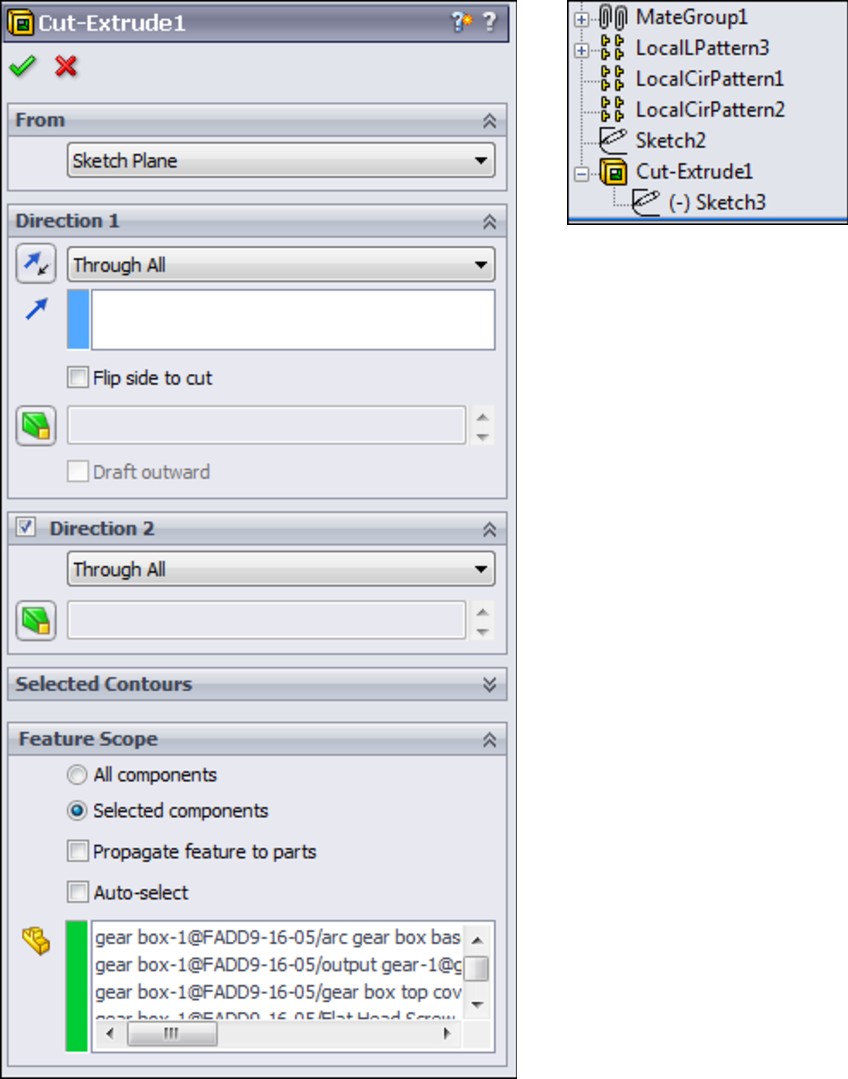

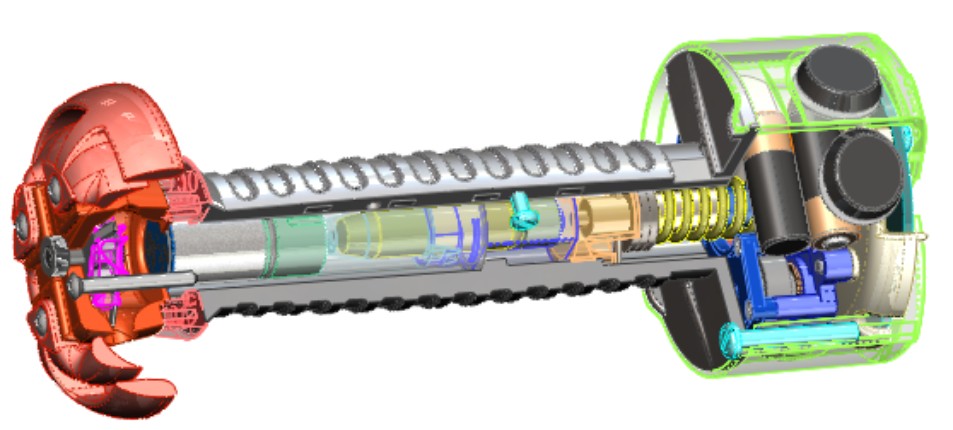

Creating Assembly Cuts

Using the Feature Scope

Propagating features to parts

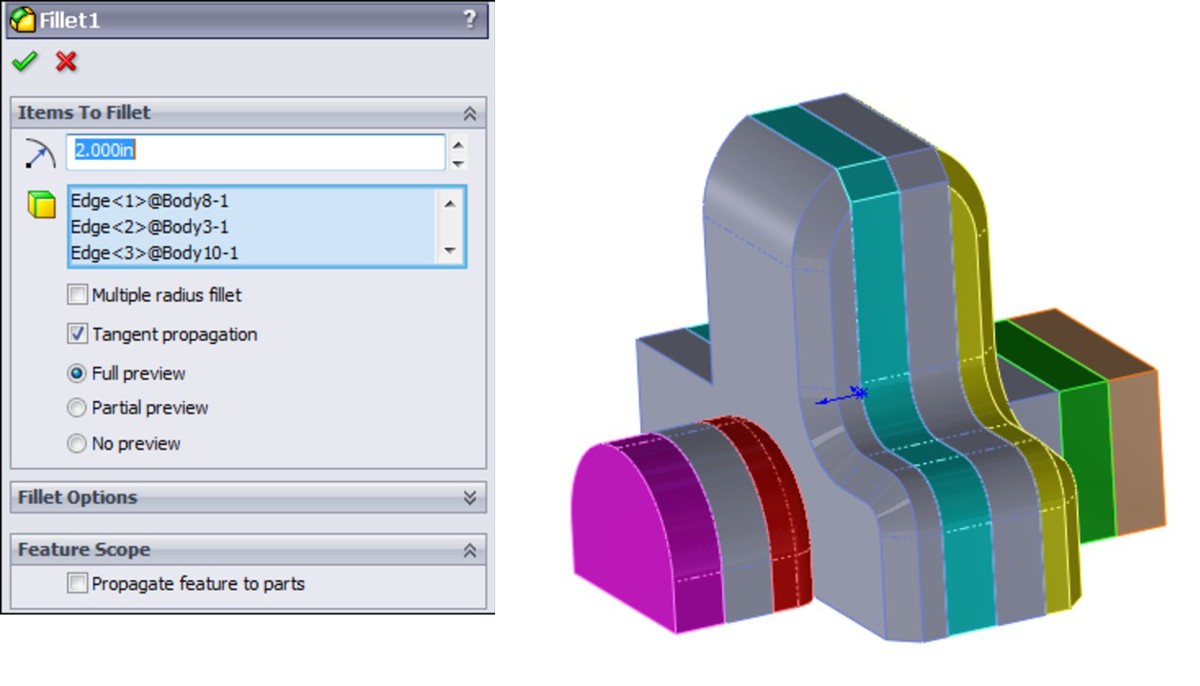

Making Fillets and Chamfers in Assemblies

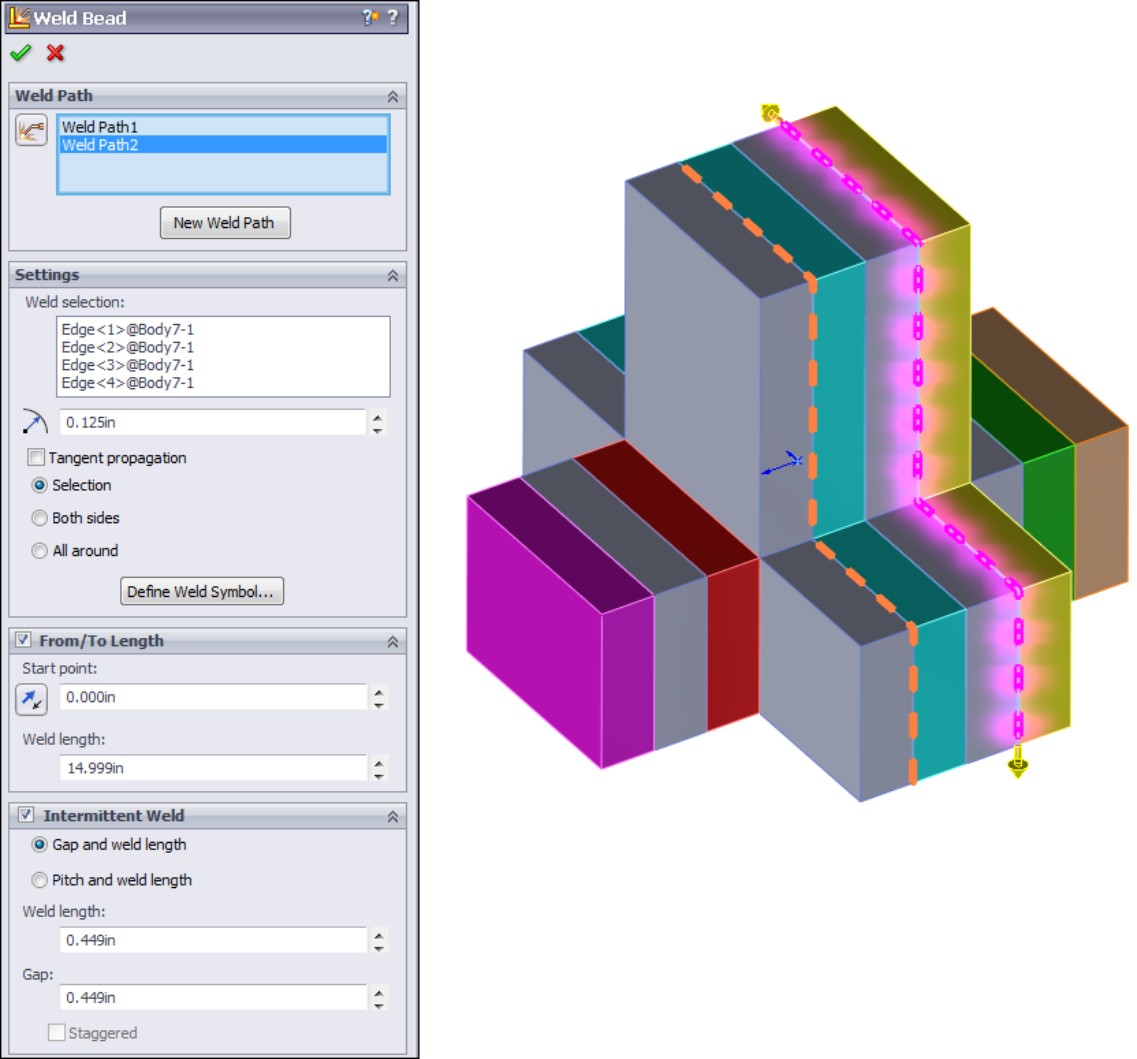

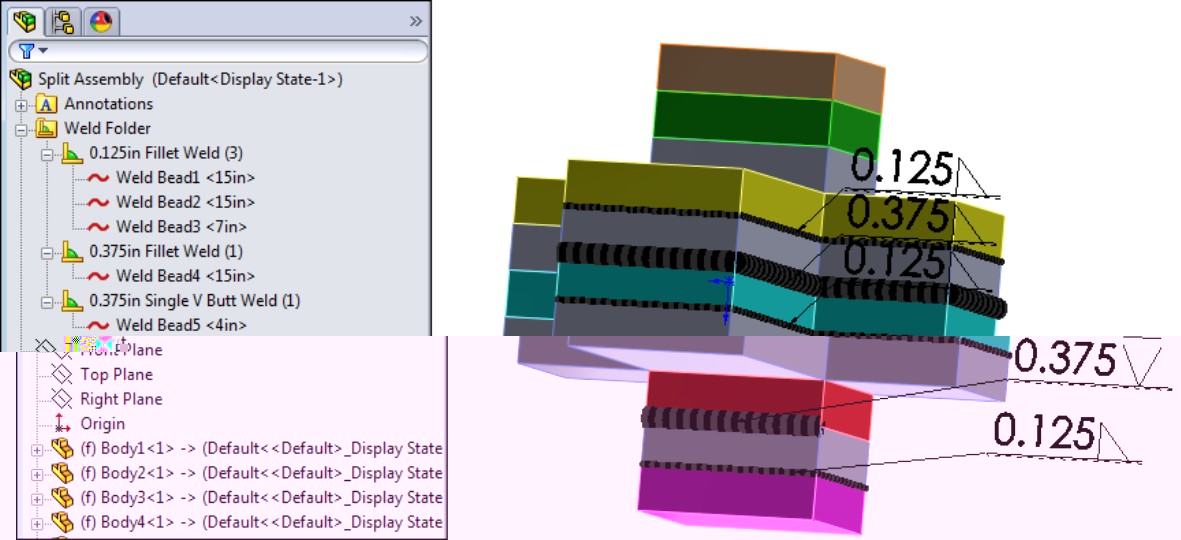

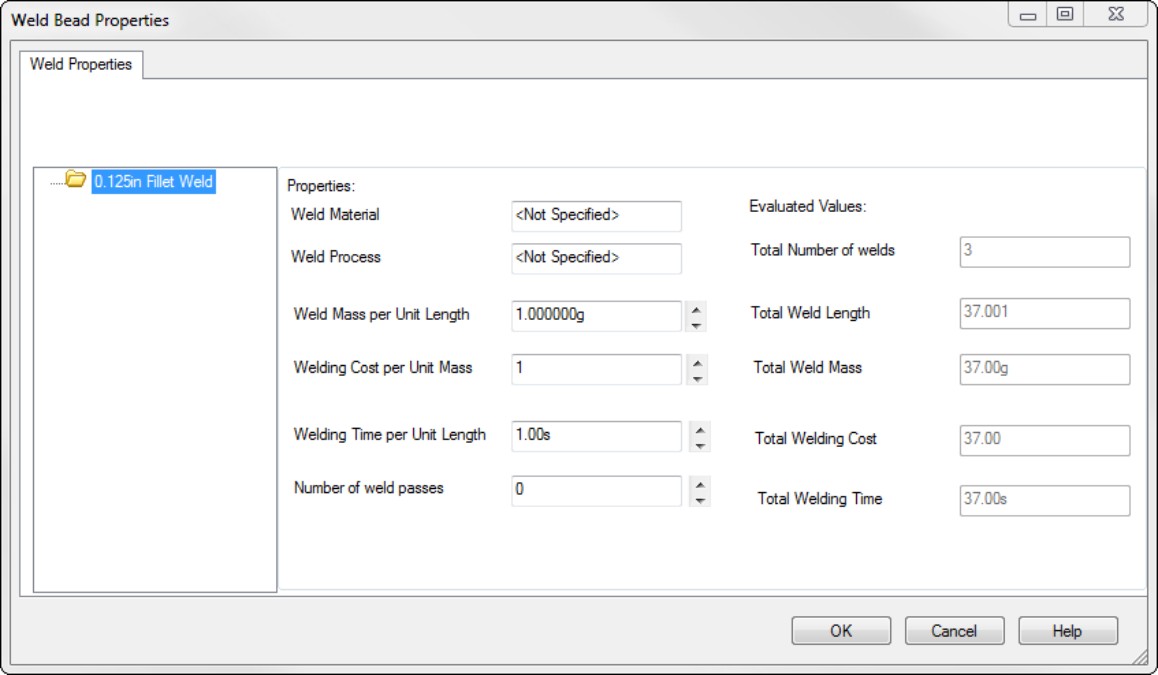

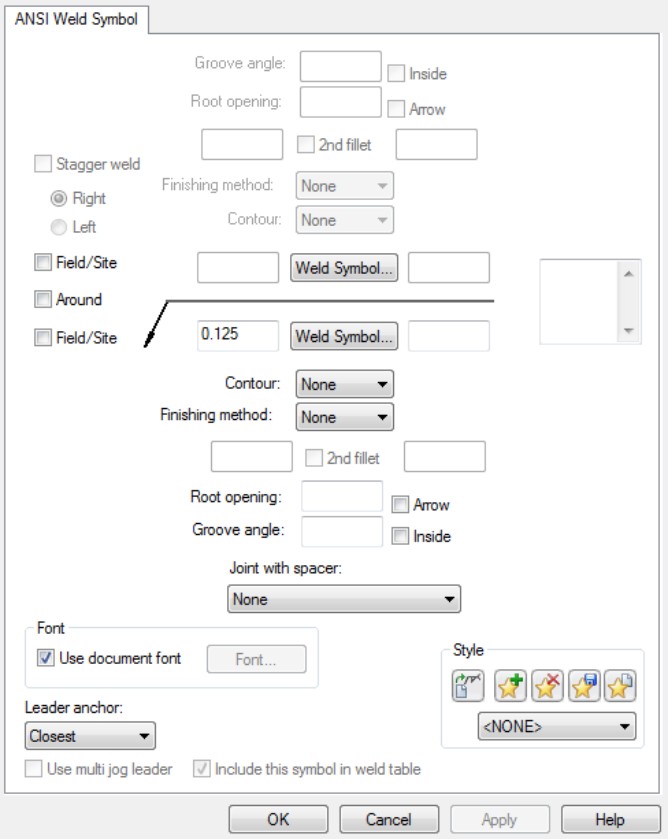

Creating Weld Beads

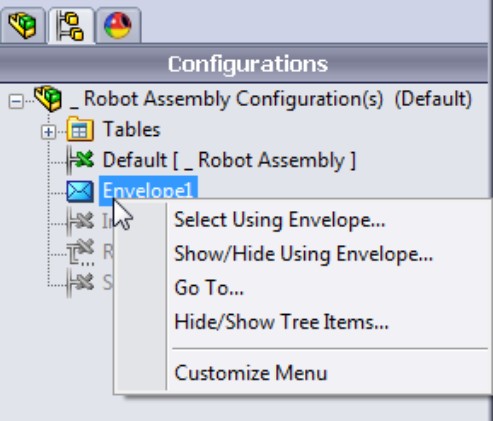

Working with Envelopes

Summary

Chapter 12: Using Parametric Links in Assemblies

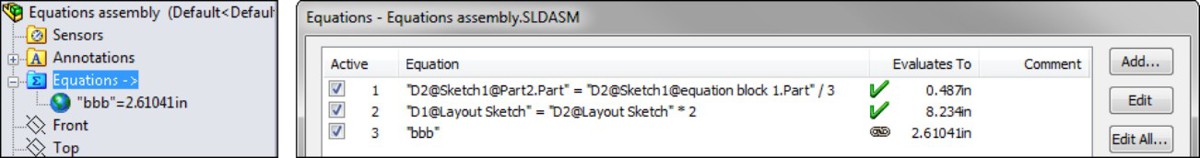

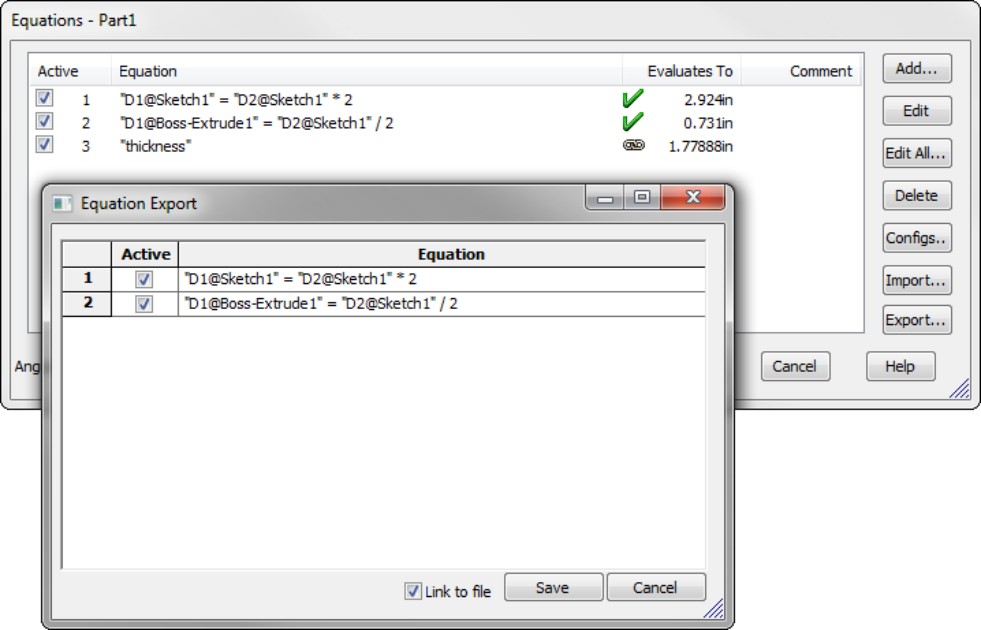

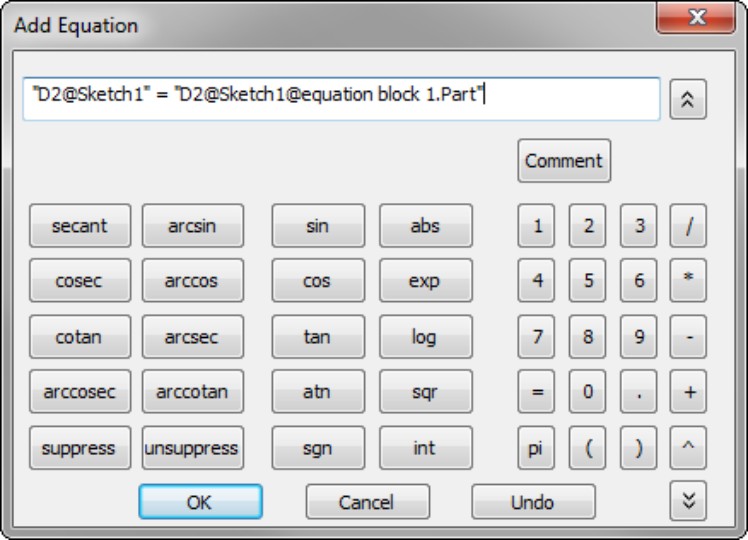

Using Equations in an Assembly

Tracking external references

Renaming documents referenced by equations

Sharing equations

Driving equations between parts

Following best practices

Using Link Values and Global Variables in Assemblies

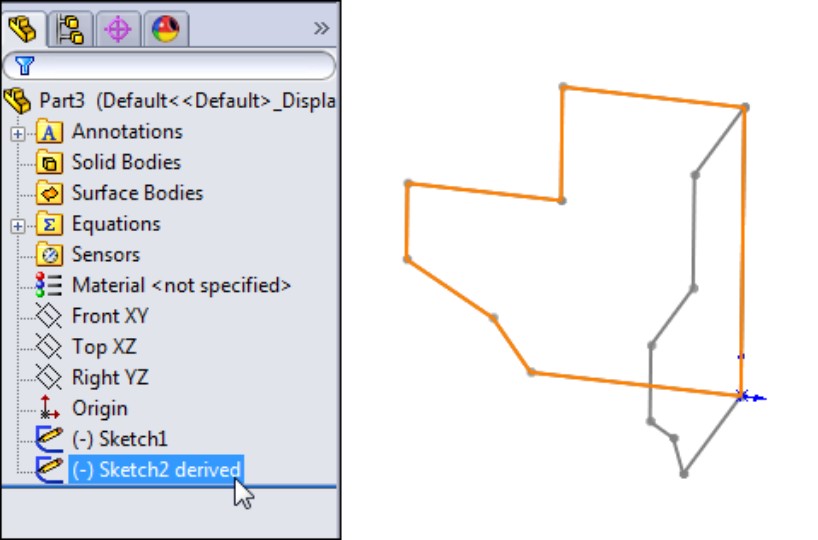

Working with Derived Sketches in Assemblies

Using Inserted Parts to Communicate Parametric Control

Summary

Chapter 13: Editing, Evaluating, and Troubleshooting Assemblies

Working with Mates

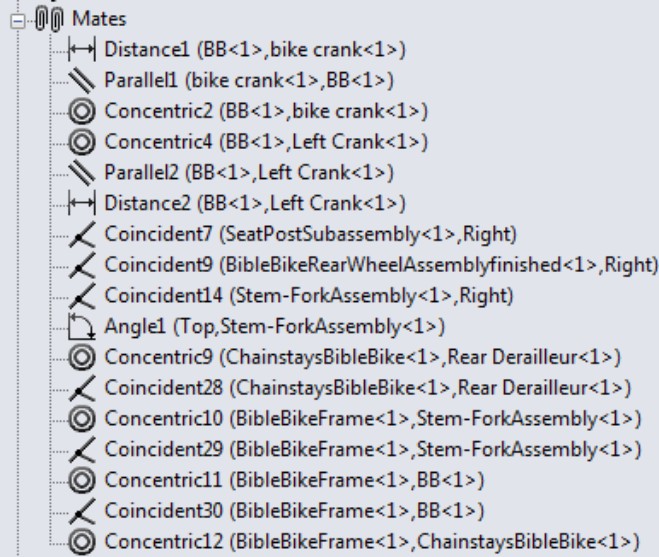

Listing mates in the Mates folder

Listing mates under the component

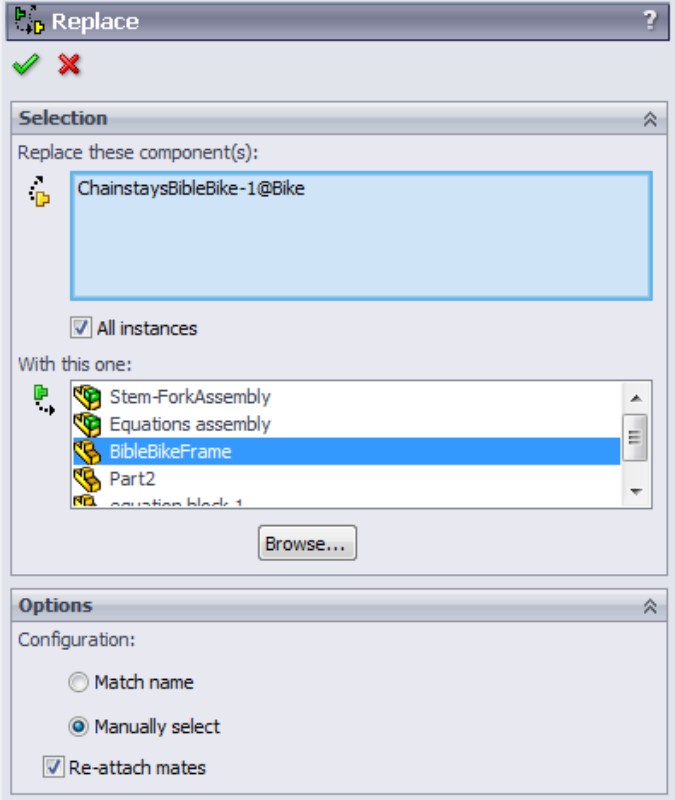

Replacing features with mates

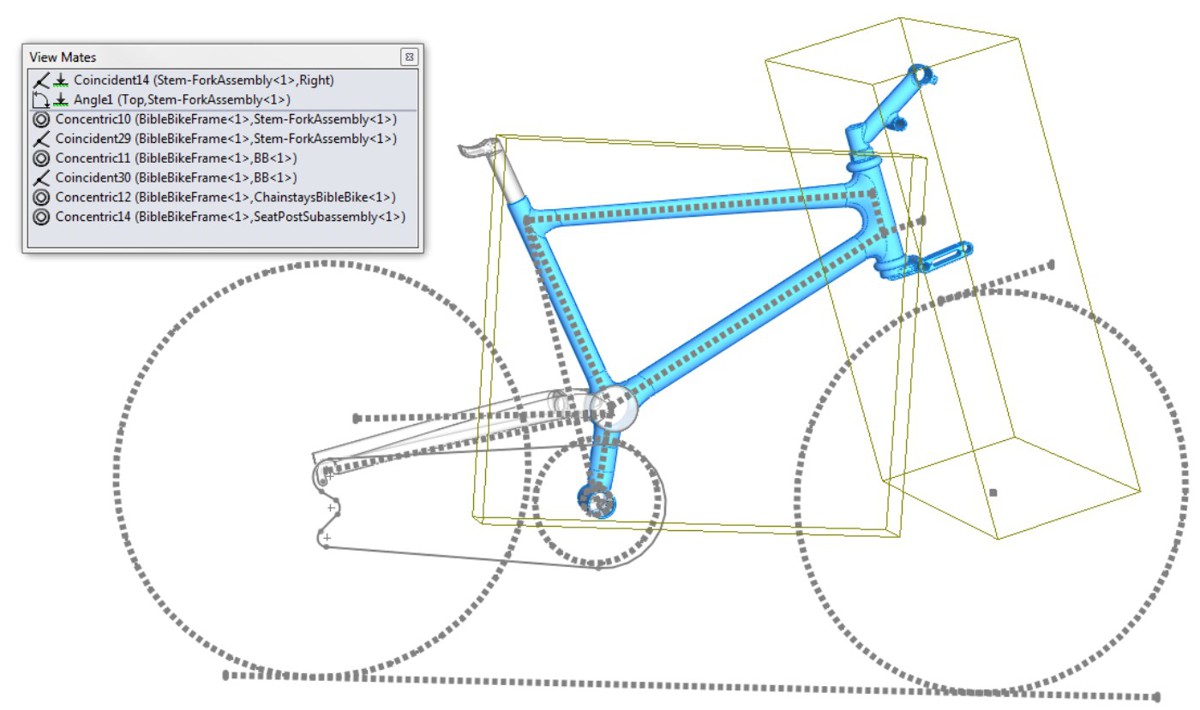

Working with the View Mates tool

Using the View Mate Errors window

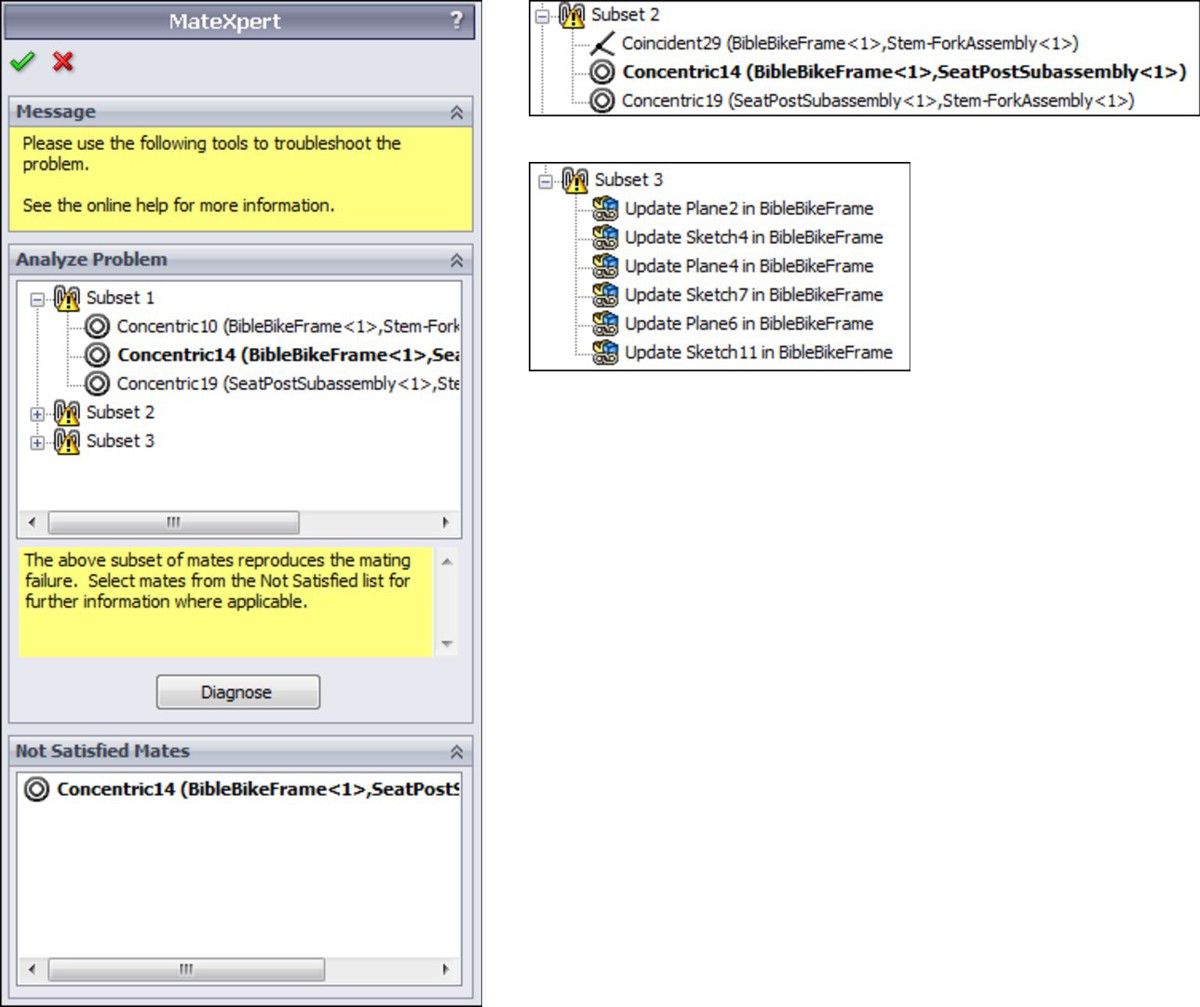

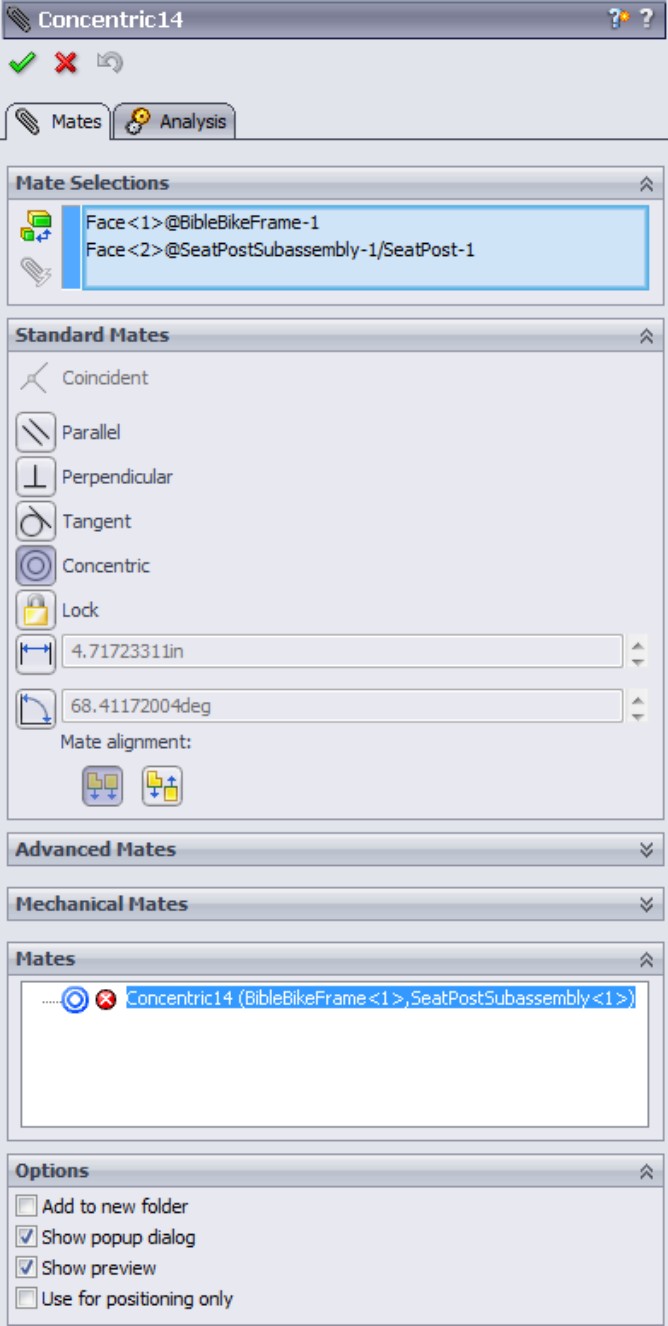

Using the MateXpert

Editing mates

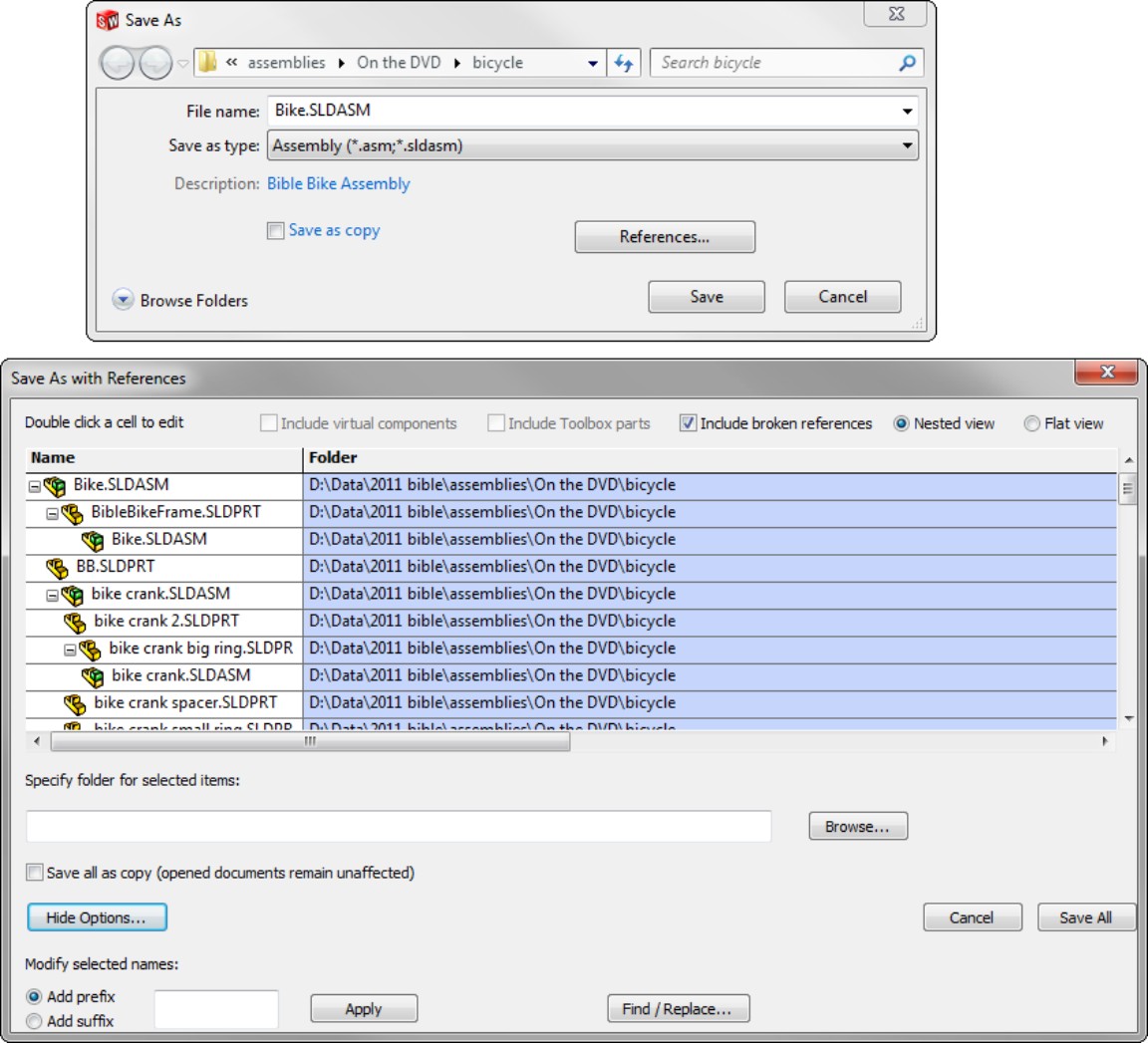

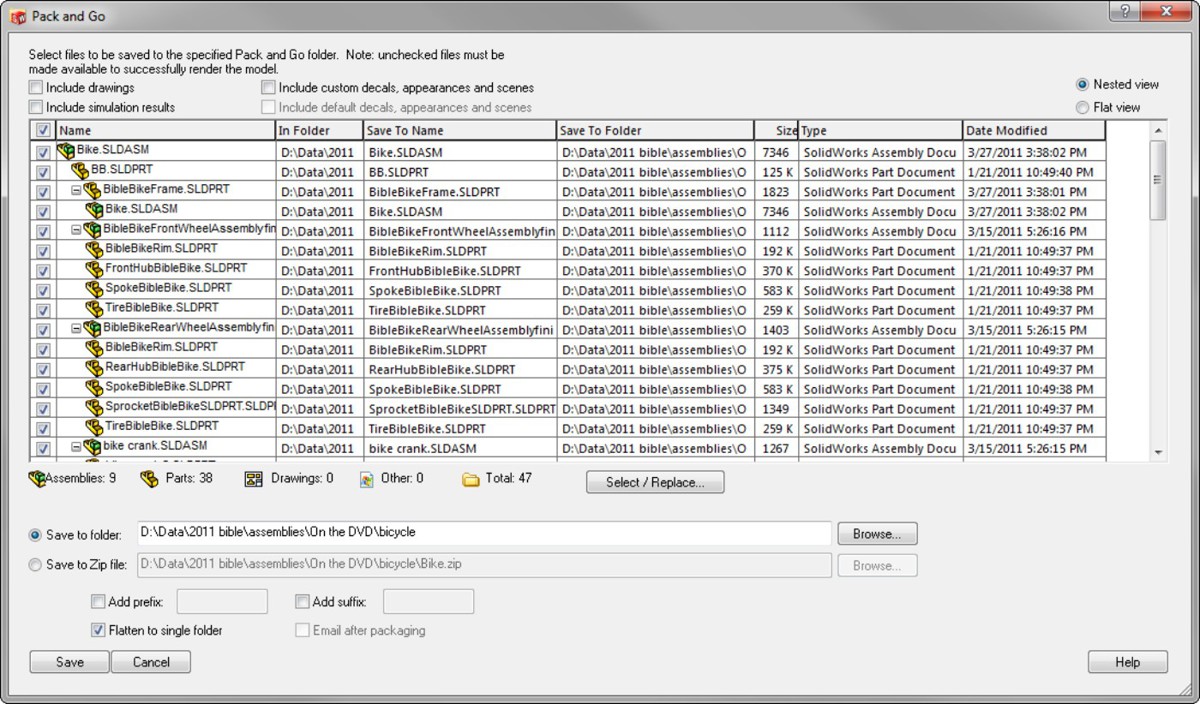

Editing File Management Issues

Using Save options and Pack and Go

Replacing components

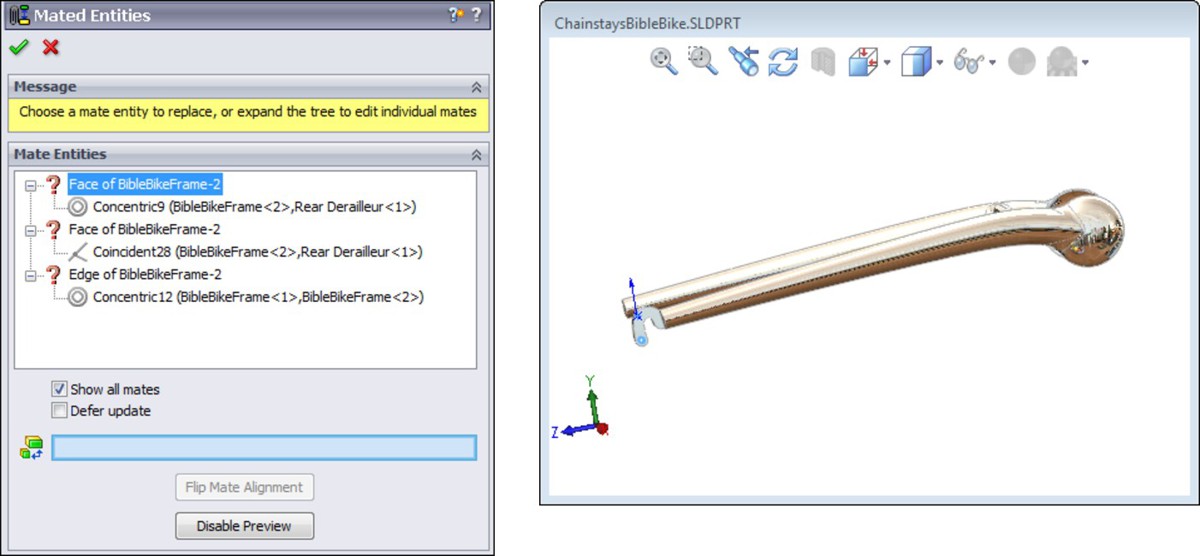

Forming and dissolving subassemblies

Evaluating Assemblies

Using the AssemblyXpert

Identifying FeatureManager symbols

Using the Isolate function

Using Reload

Summary

Part III: Creating and Using Libraries

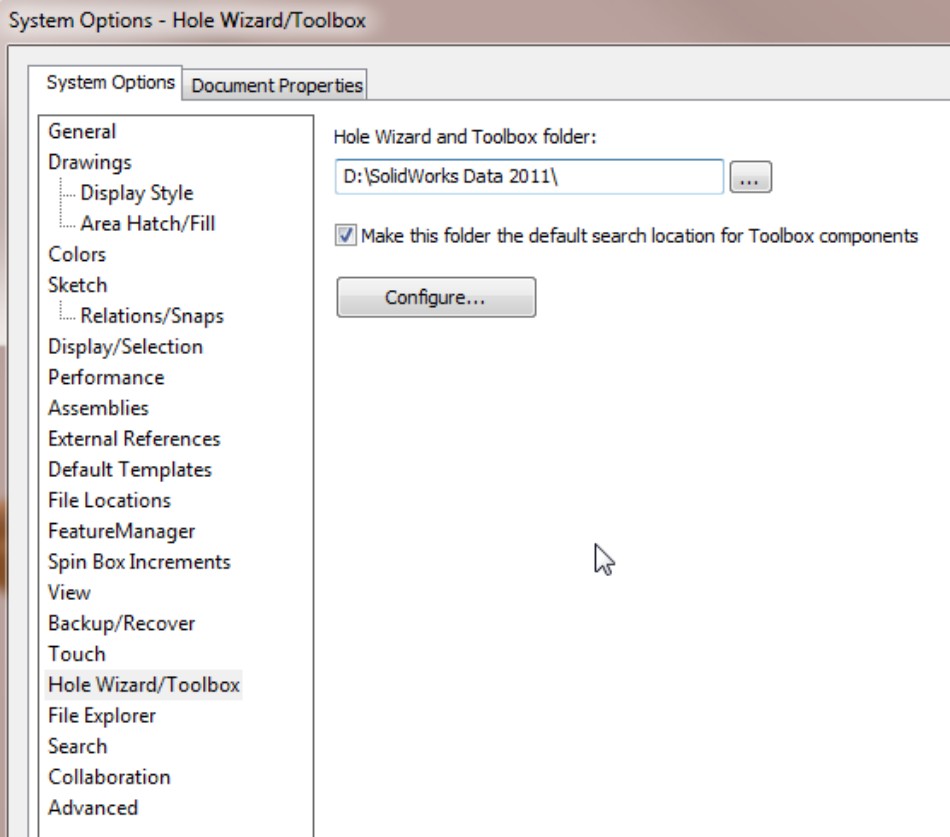

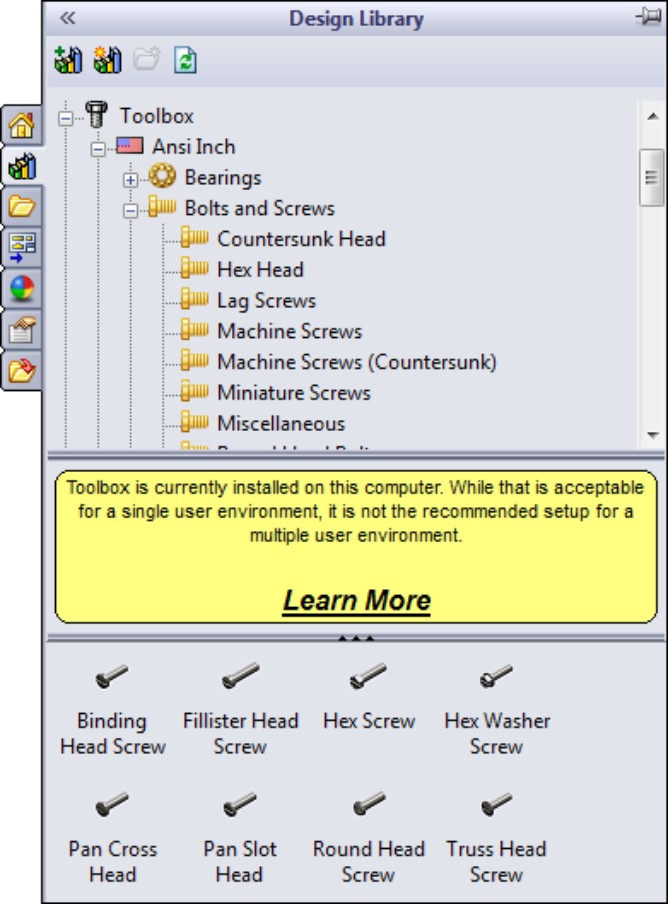

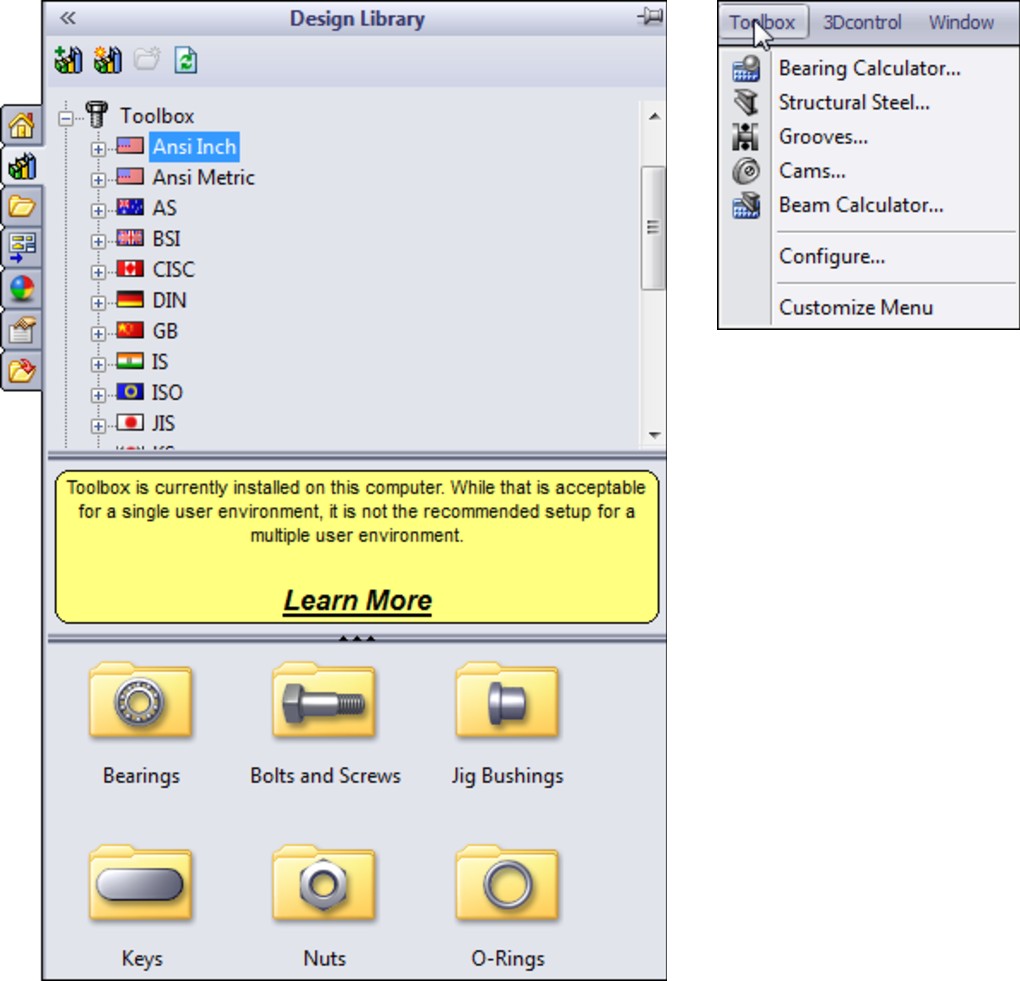

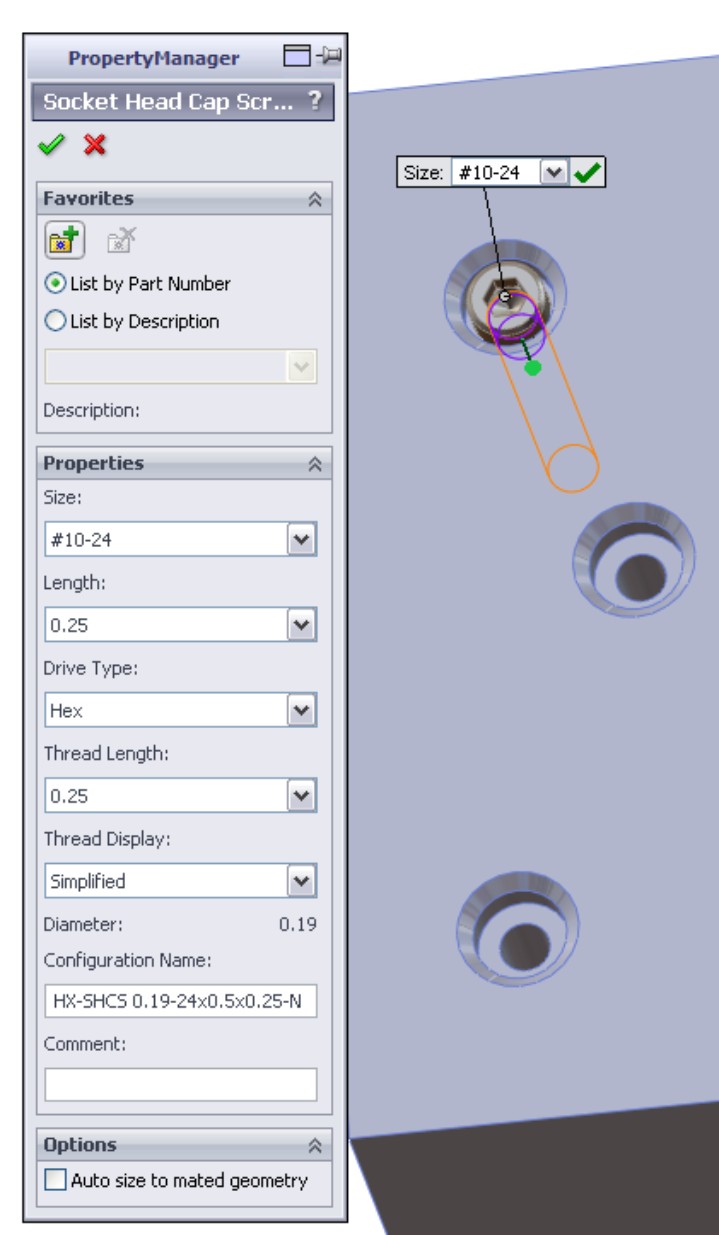

Chapter 14: Using Toolbox

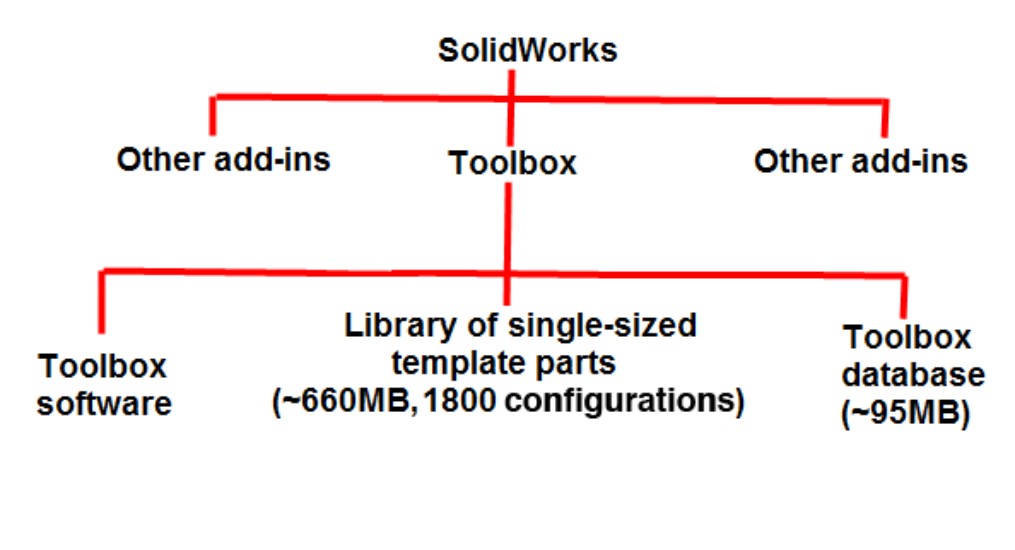

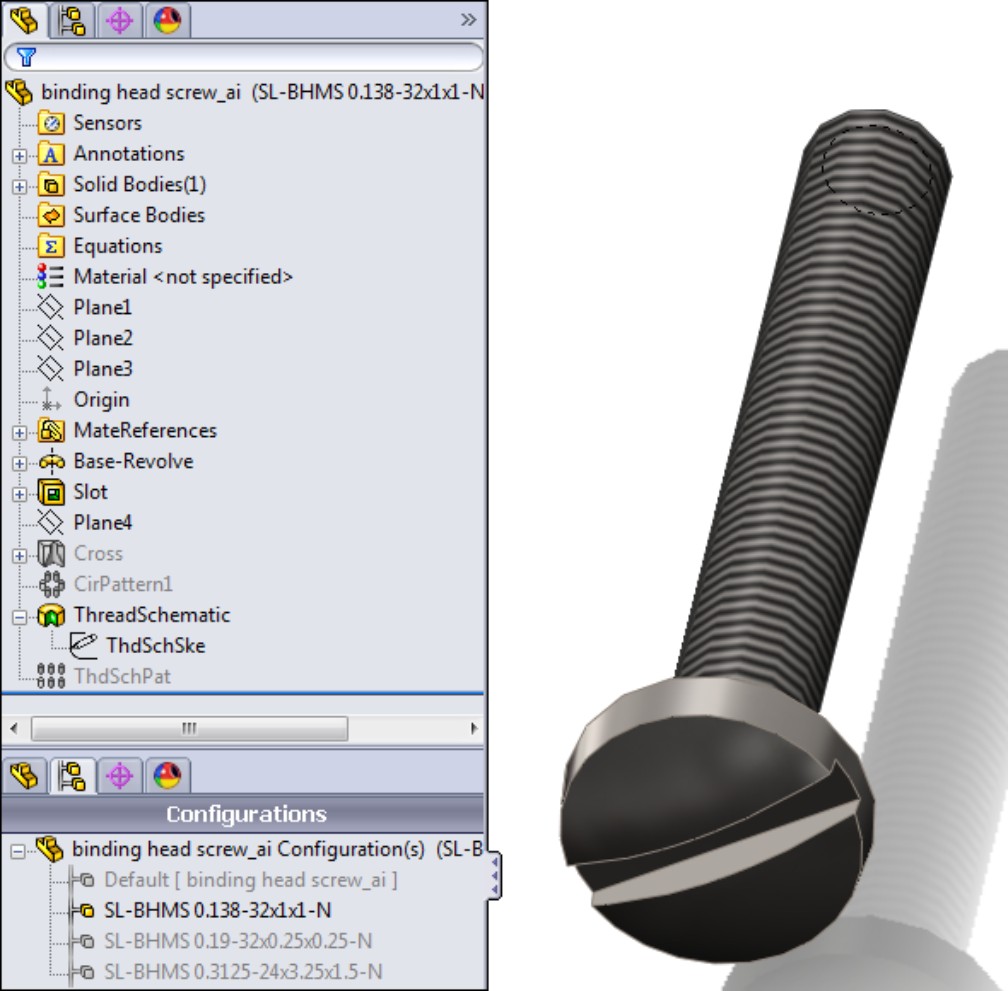

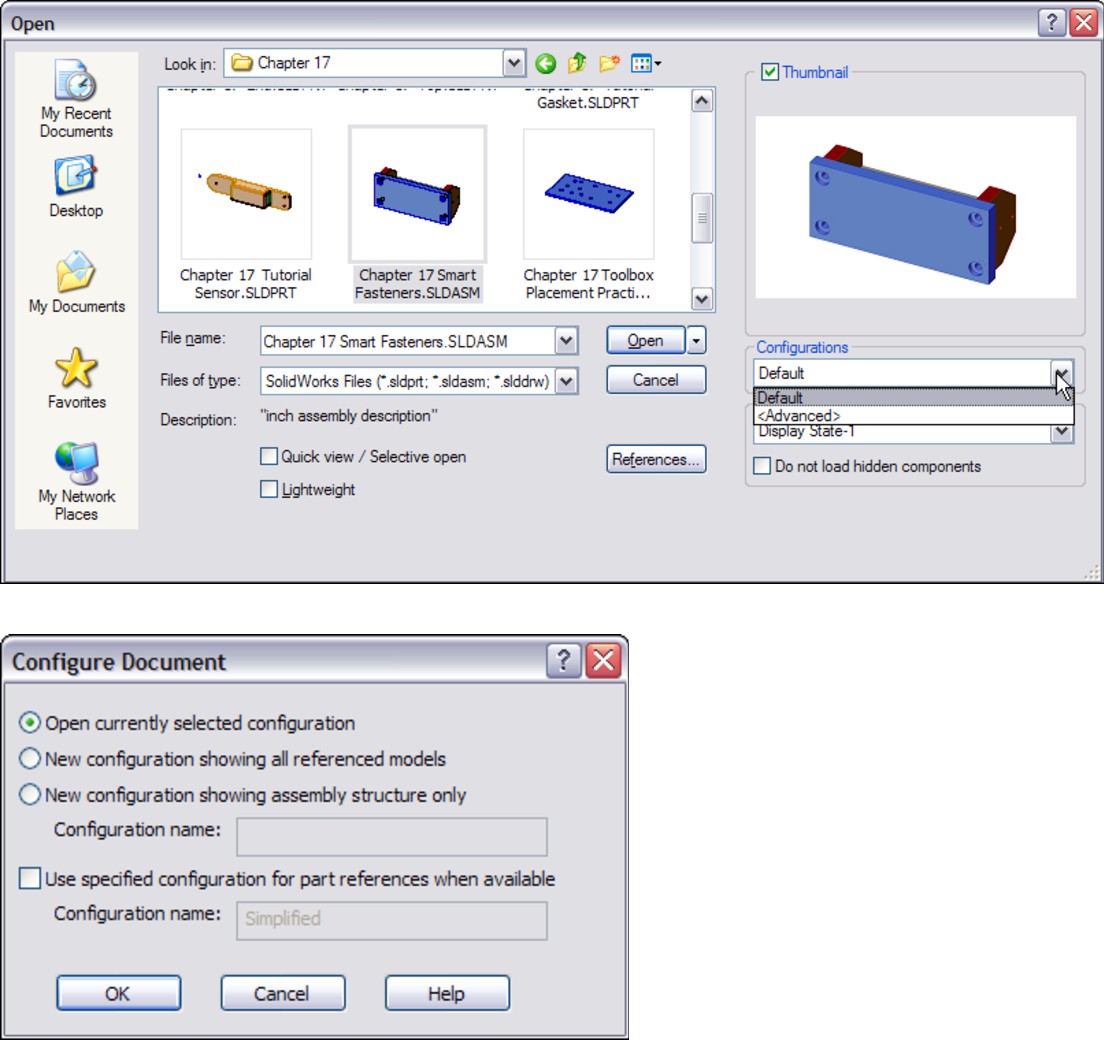

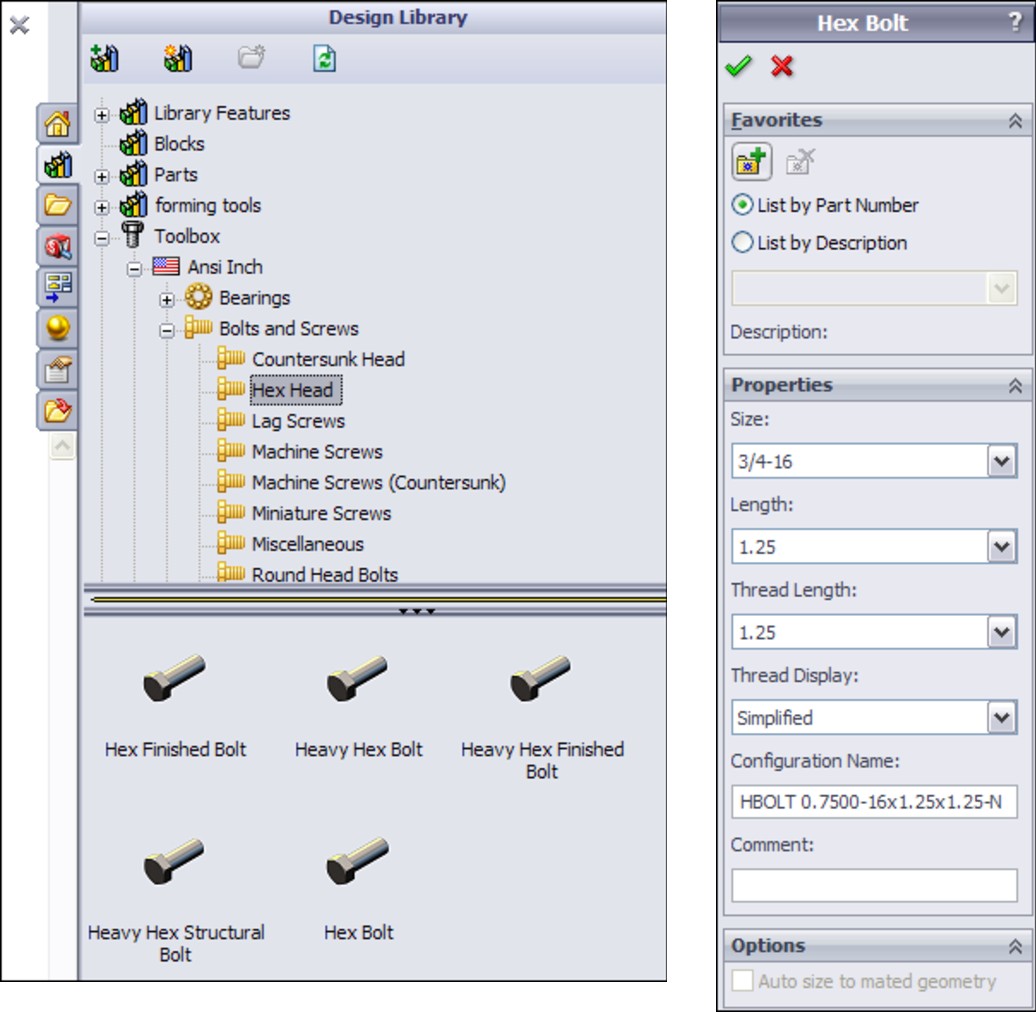

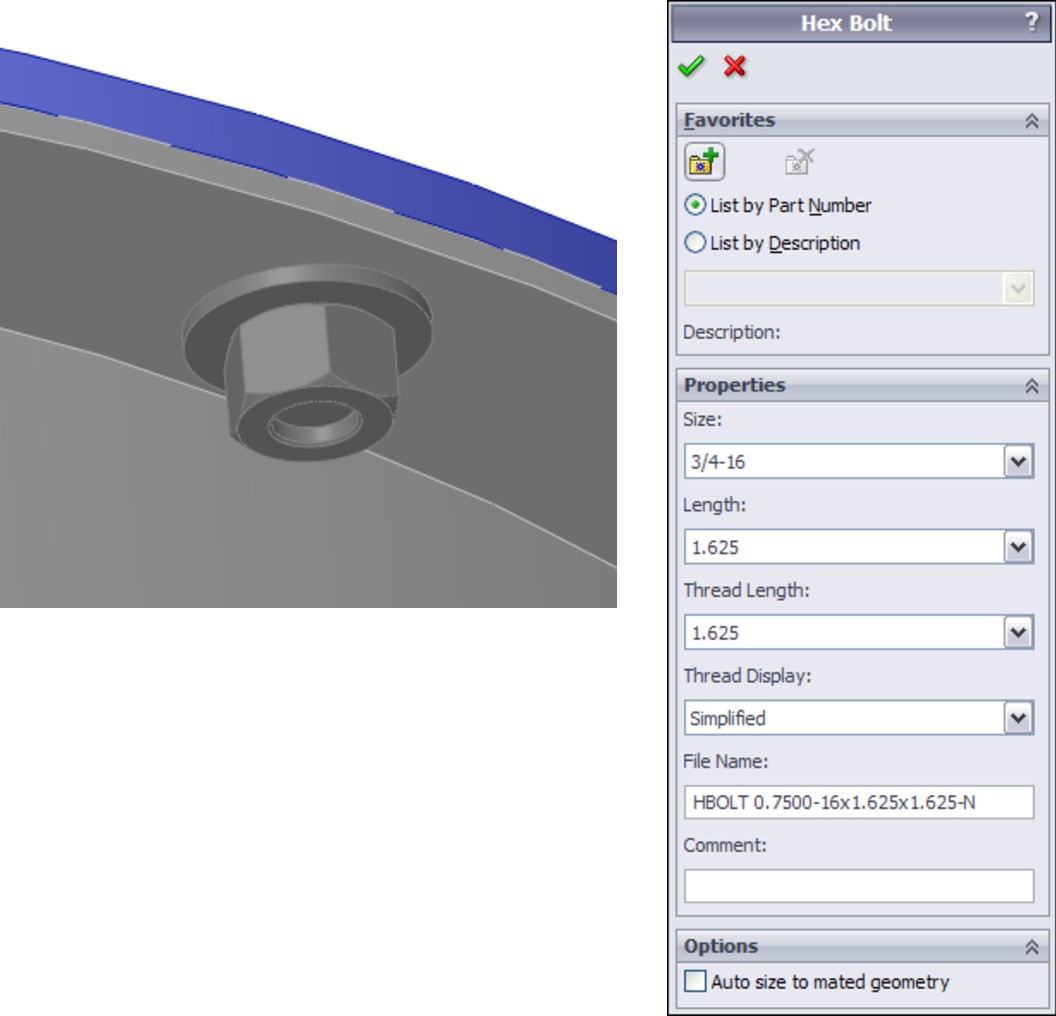

Understanding Toolbox

Comparing configurators and libraries

Taking a look at how Toolbox works

Using Toolbox

Organizing Toolbox parts in an assembly

Working recommendations

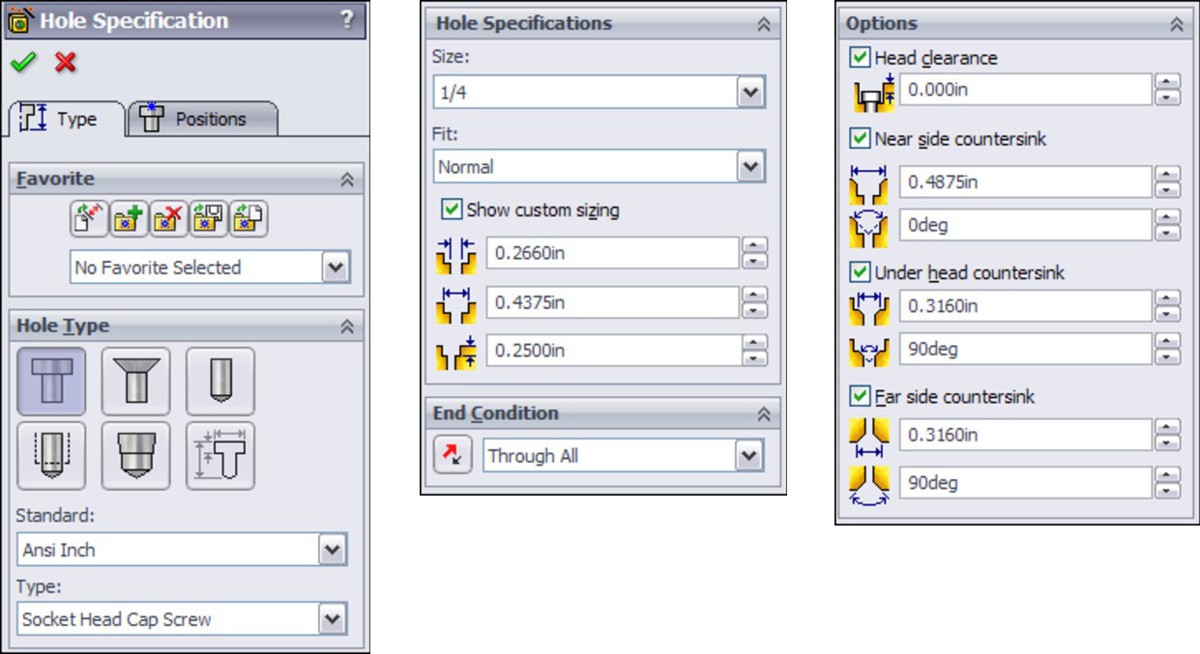

Using the Hole Wizard

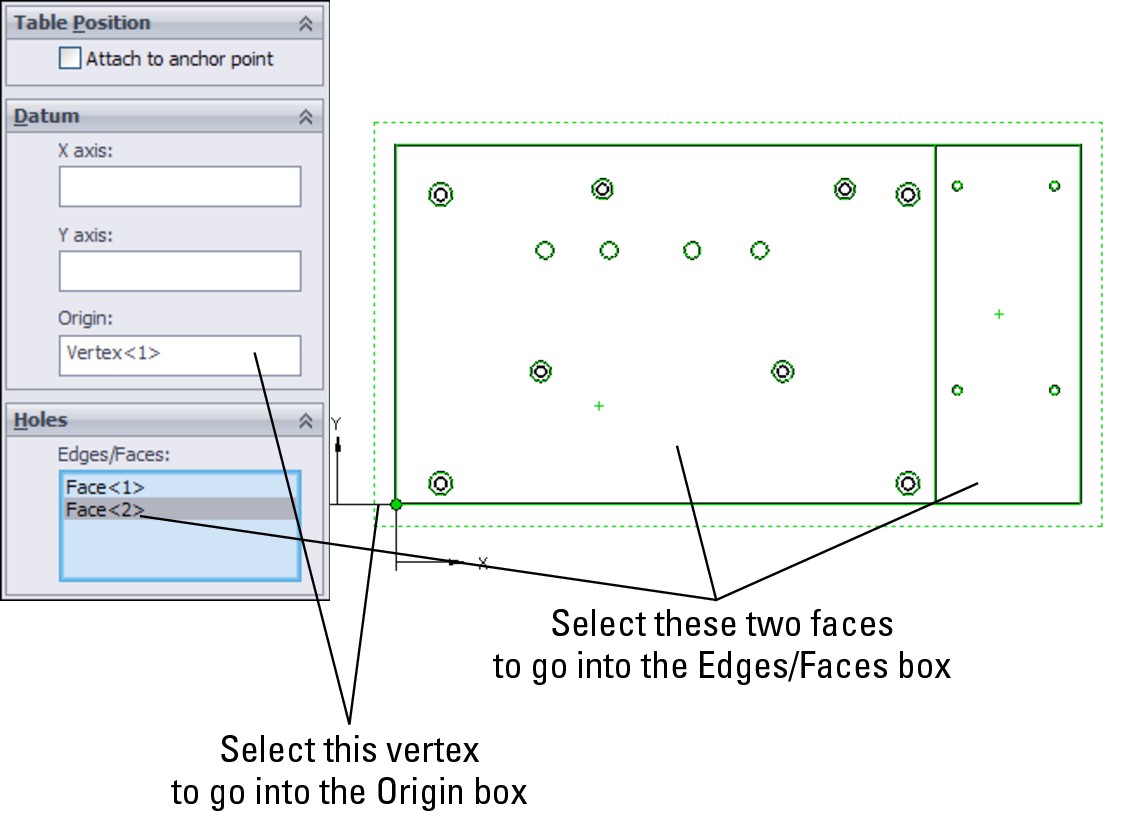

Exploring the Hole Series interface

Looking at Hole Series quirks

Tutorial: Gaining Experience with the Hole Wizard and Toolbox

Summary

Chapter 15: Working with Libraries

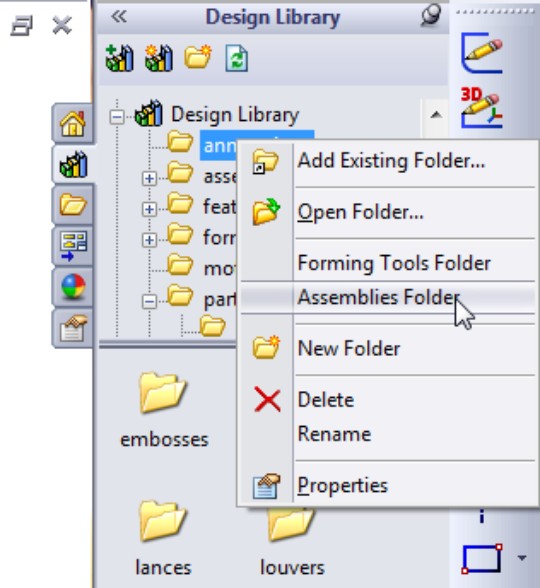

Setting Up a Library

Building the Design Library

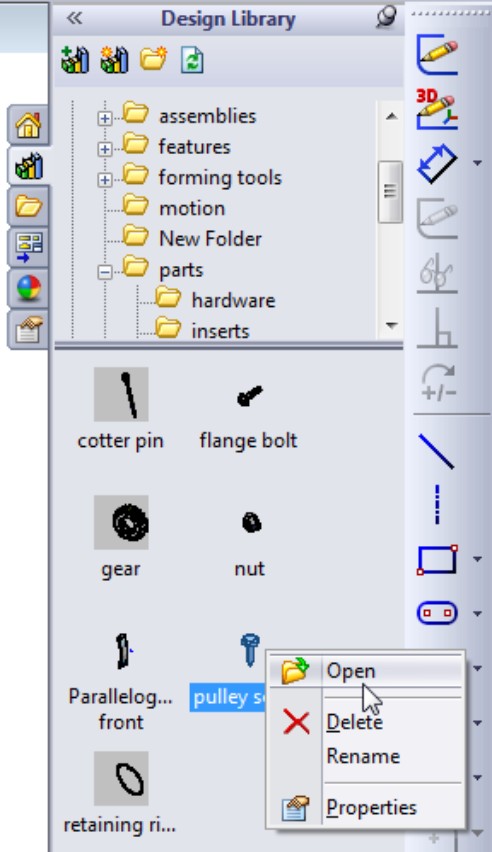

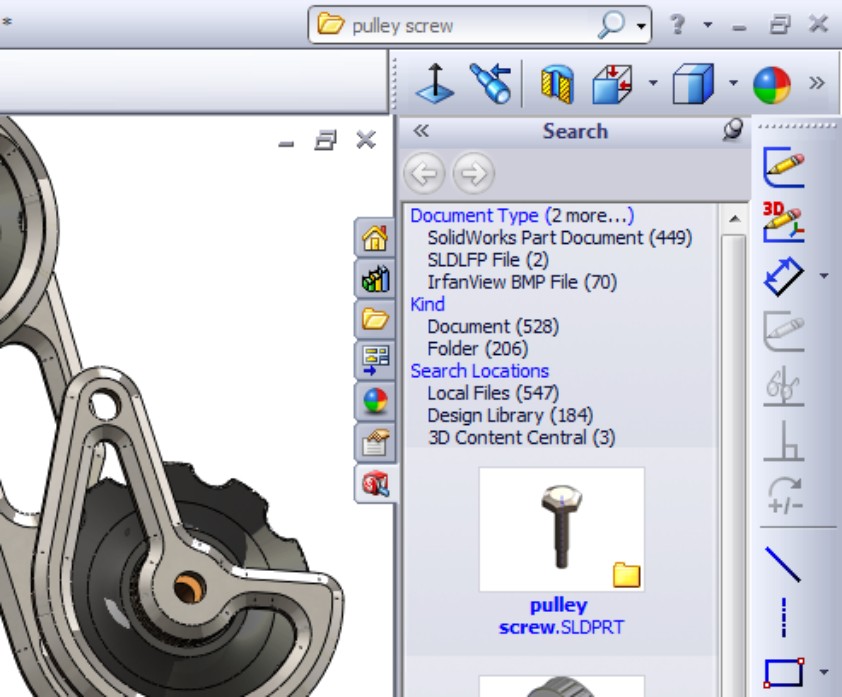

Using the Design Library

Exploring Other Design Library Functions

Using Annotations in the library

Using sheet metal–forming tools in the library

Using assemblies in the library

Routing

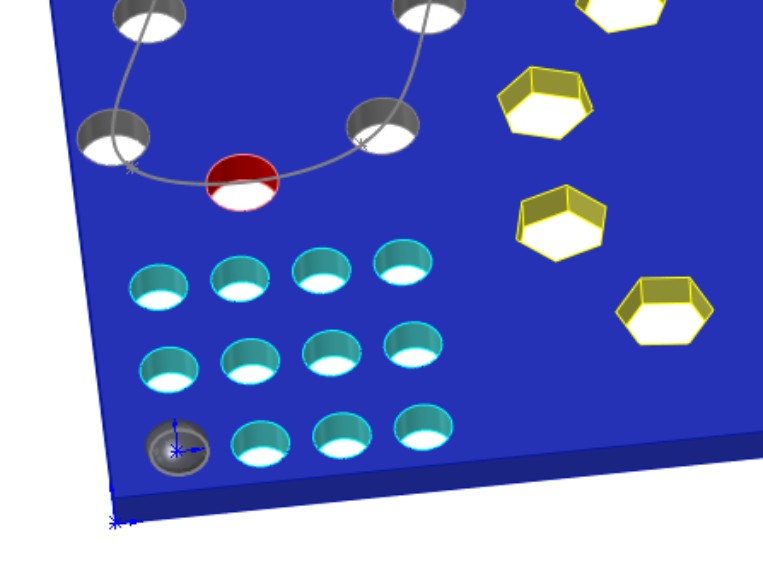

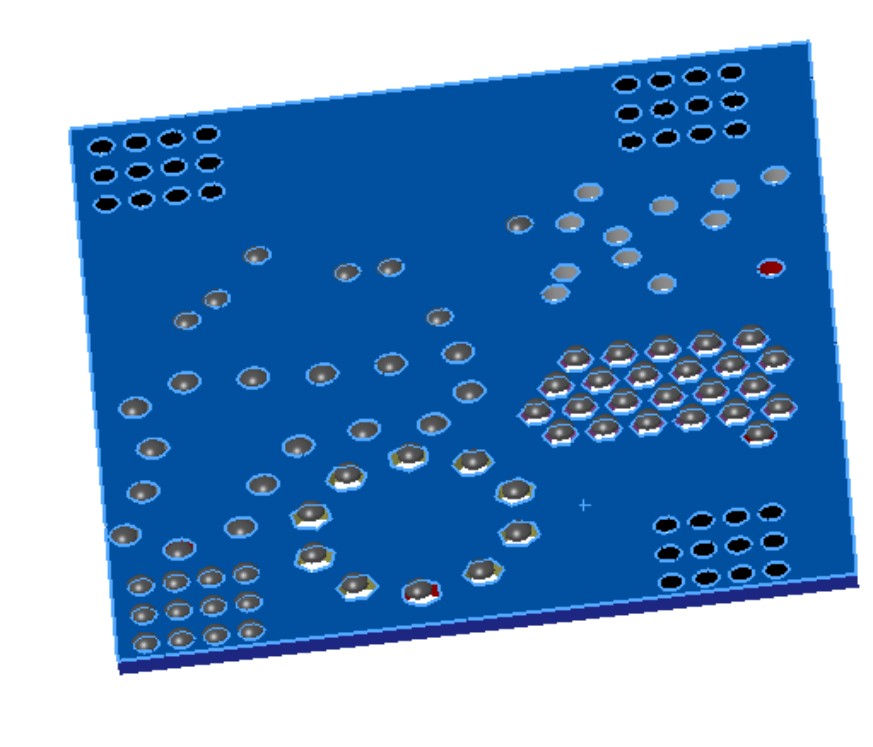

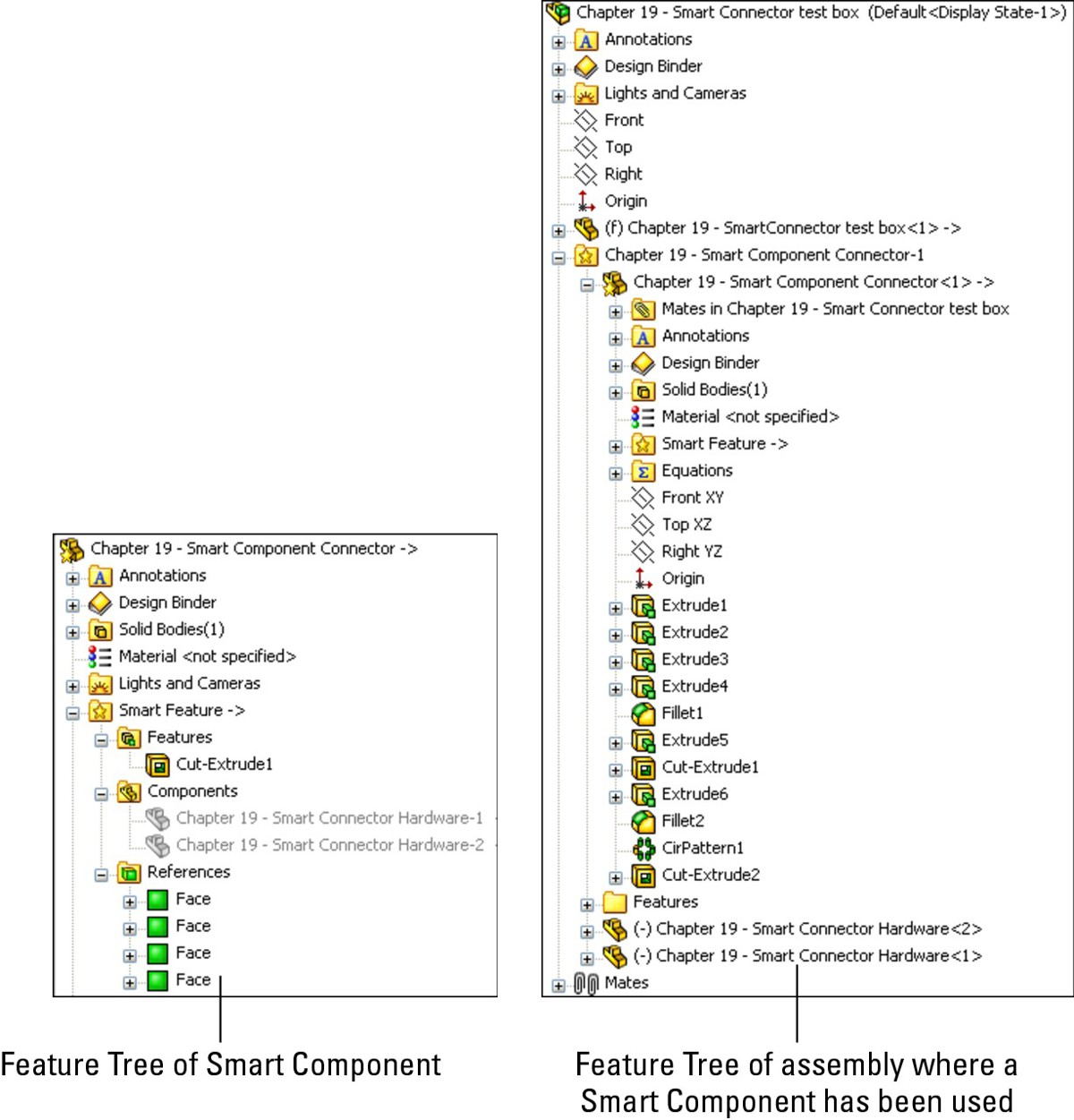

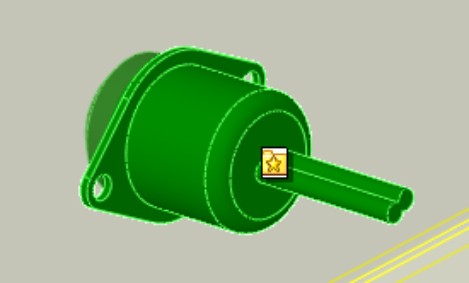

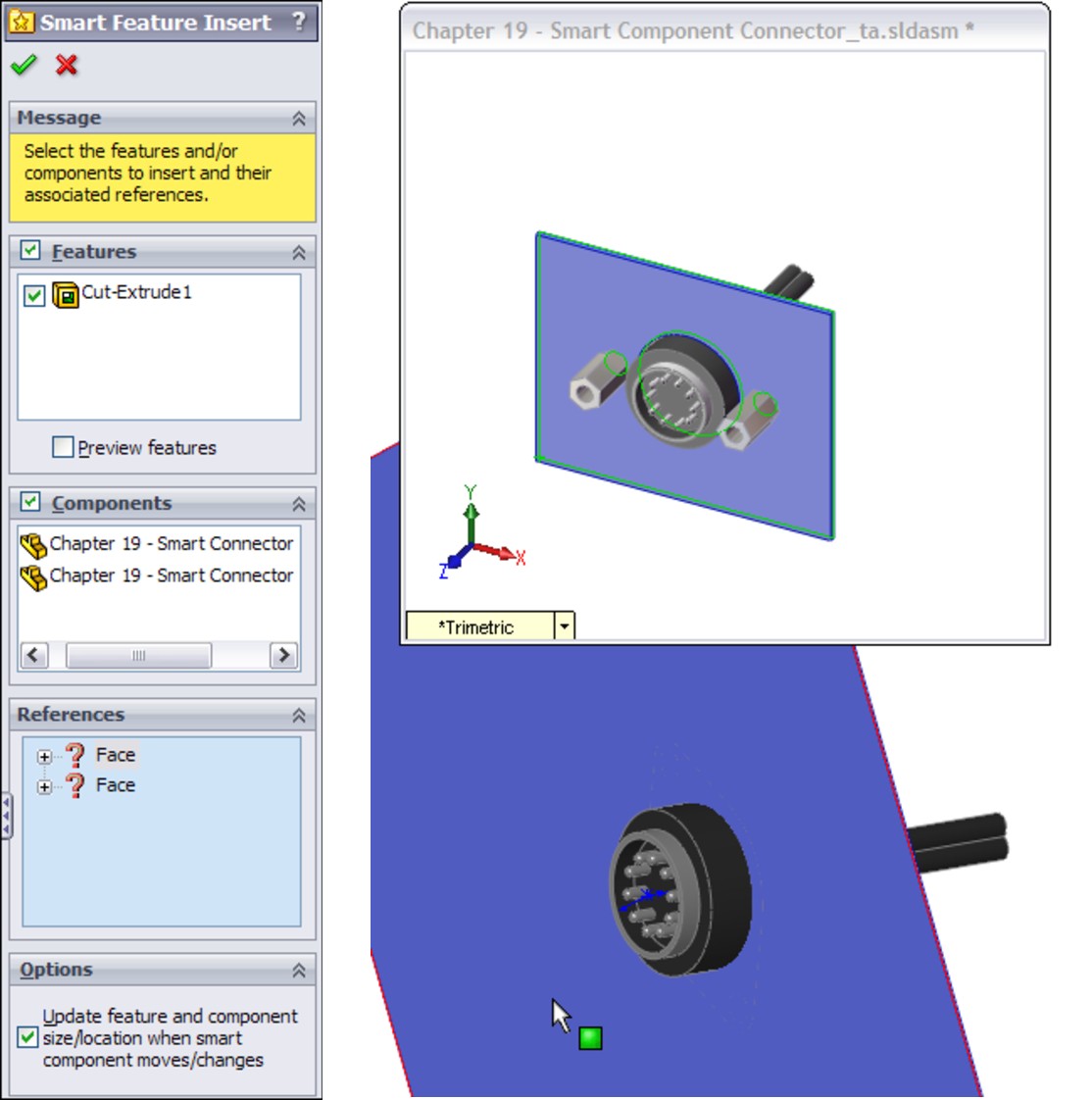

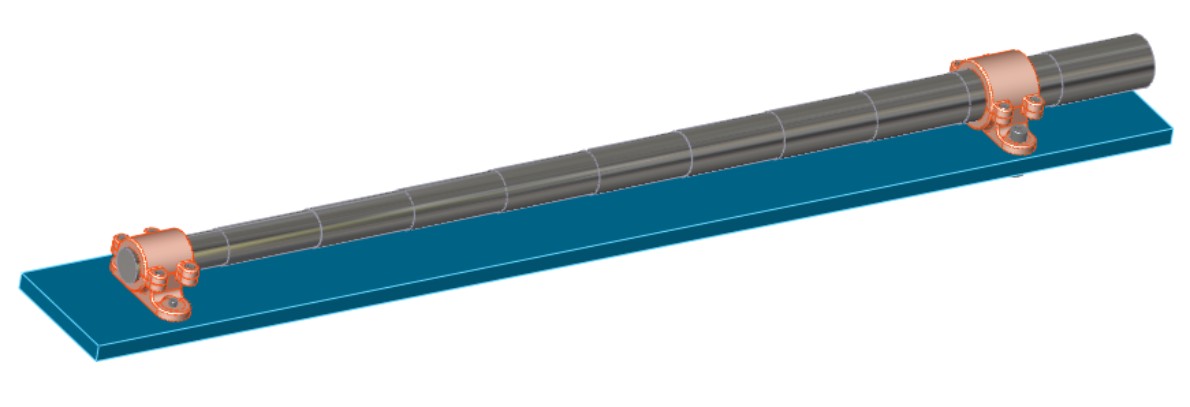

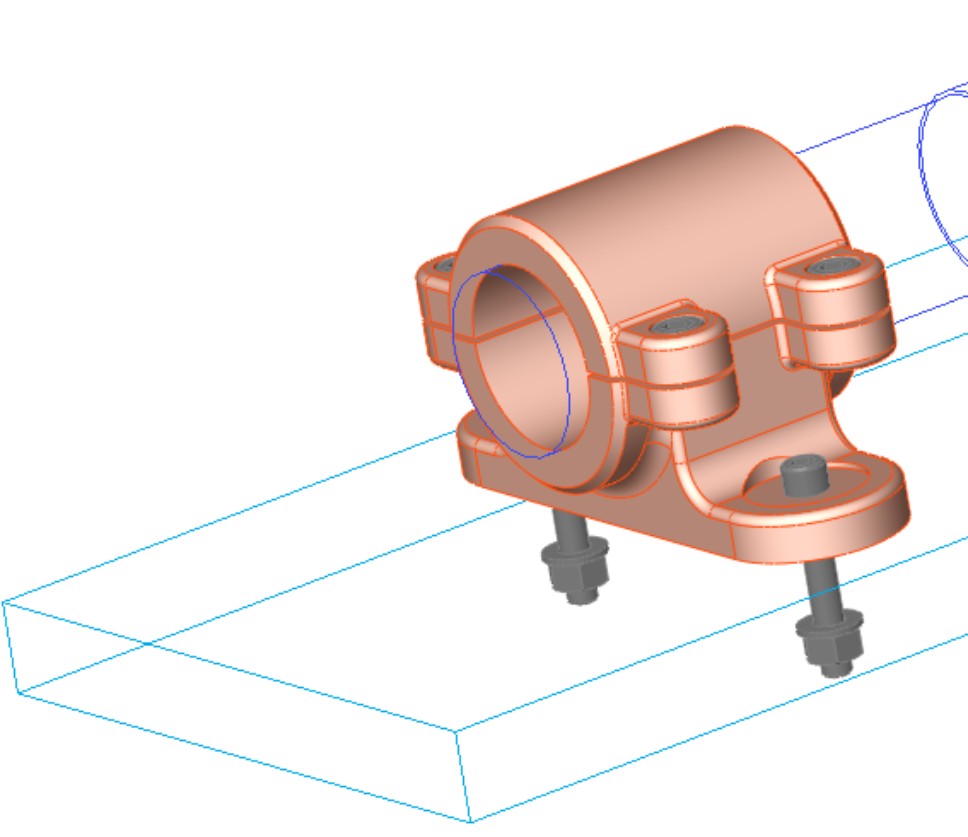

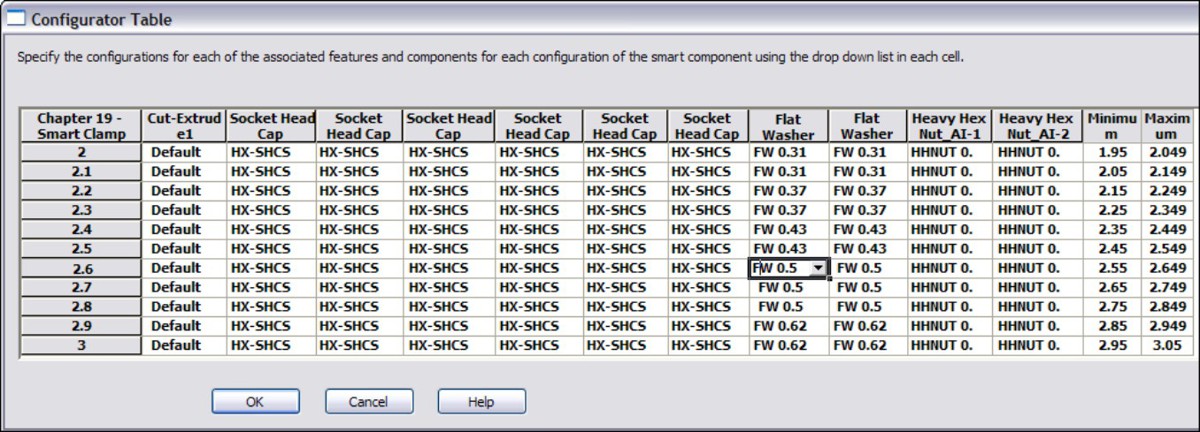

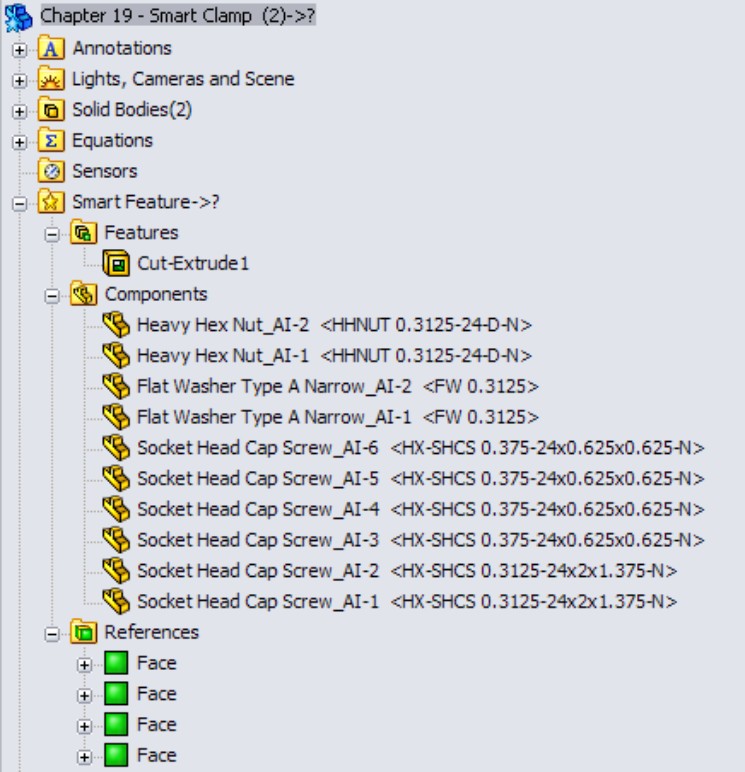

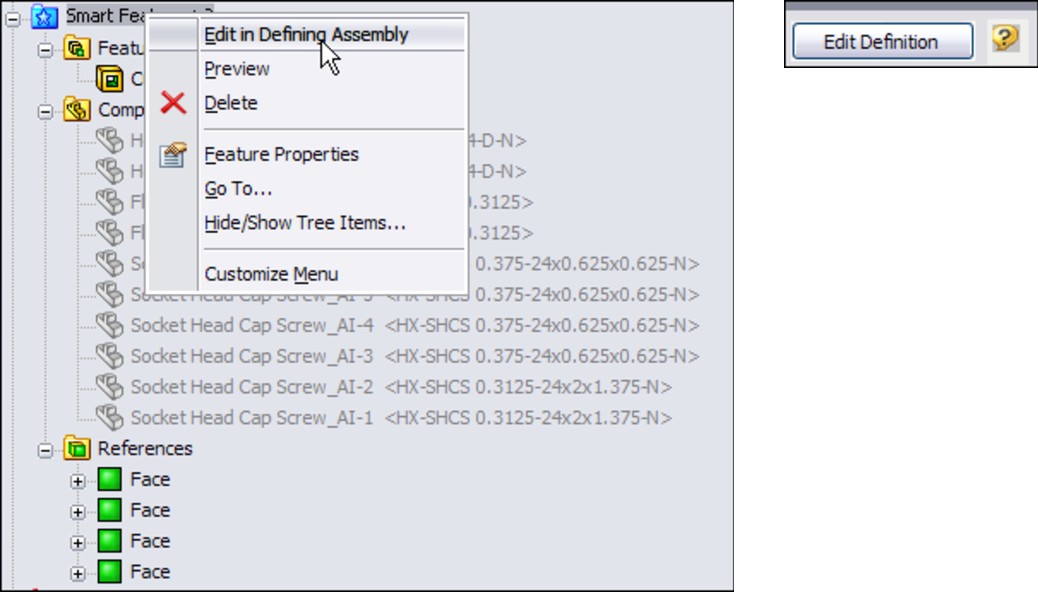

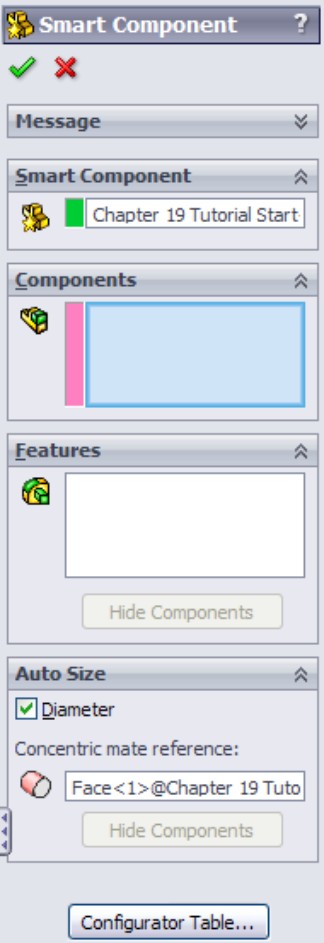

Understanding Smart Components

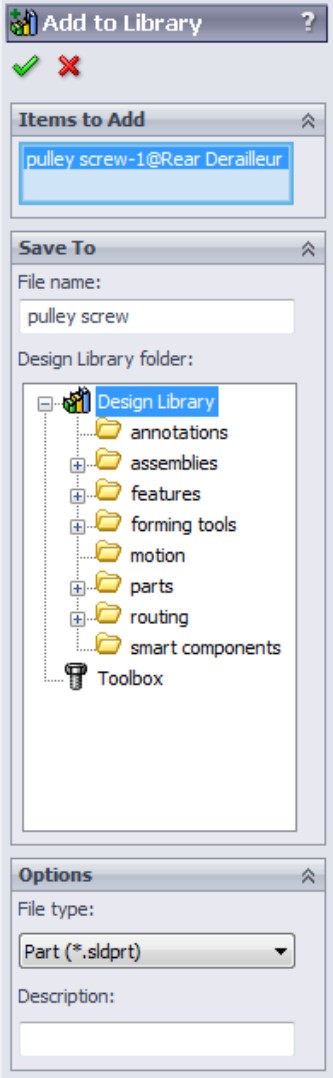

Using Smart Components

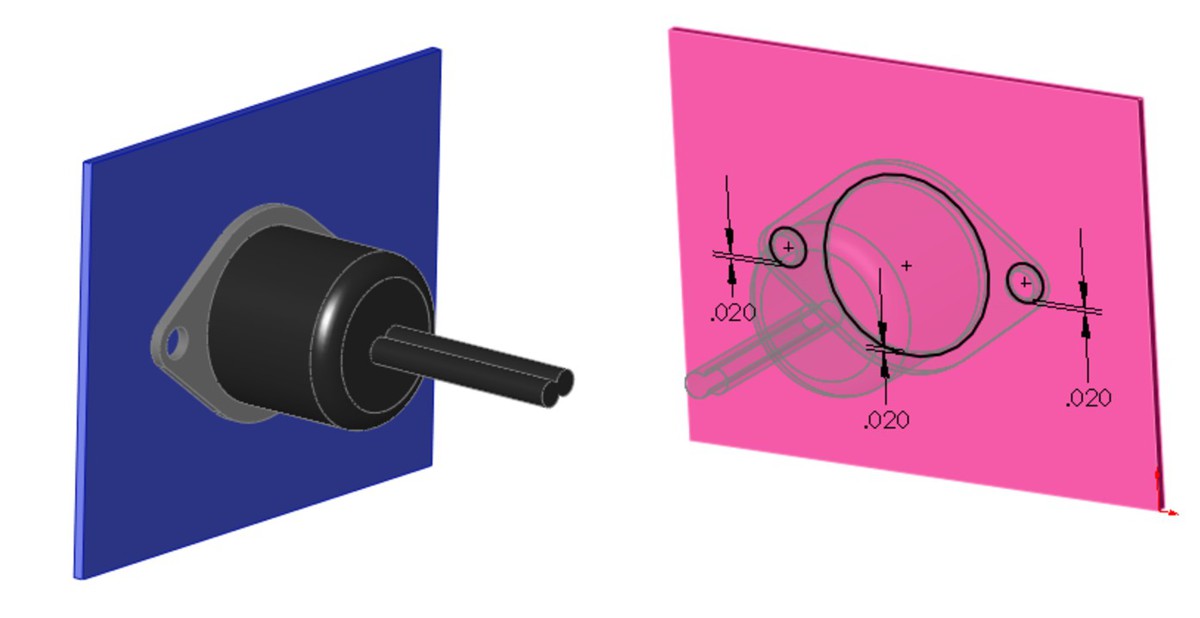

Getting started with a simple Smart Component

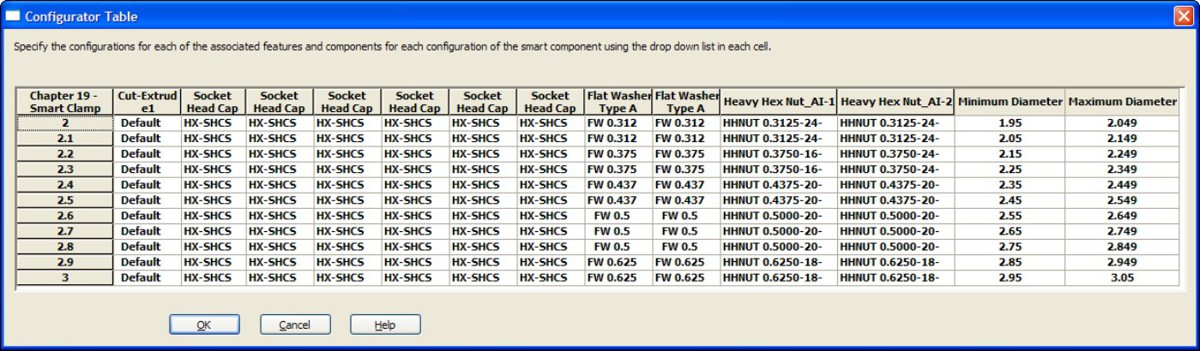

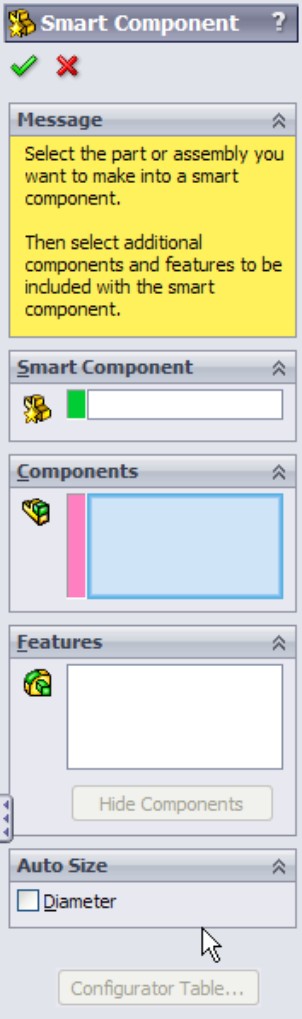

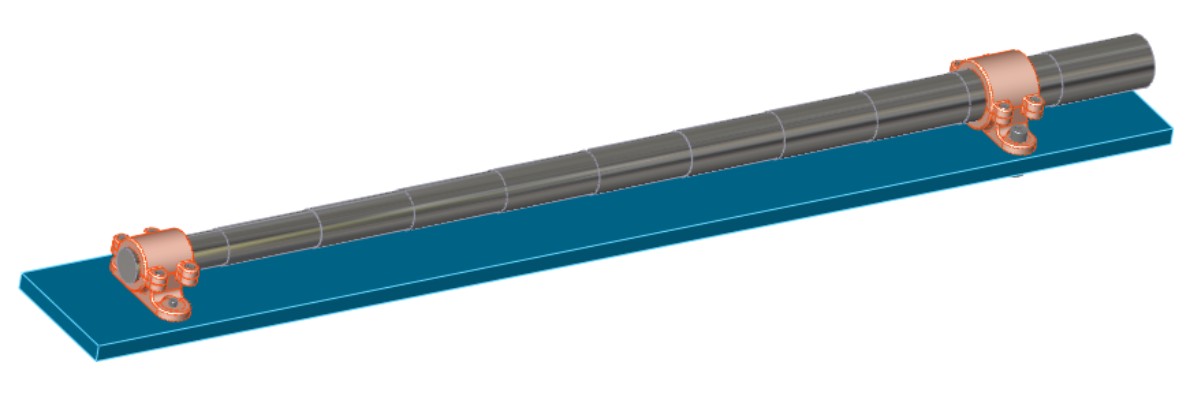

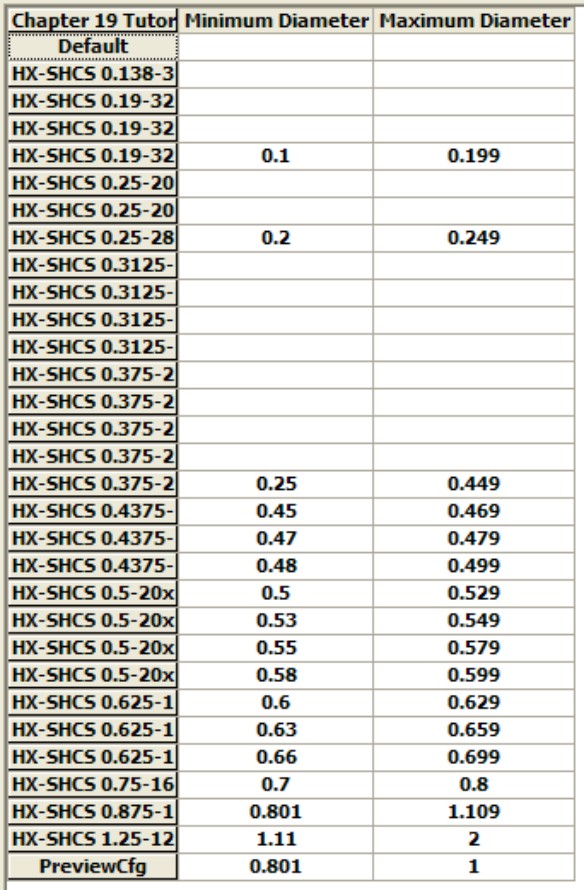

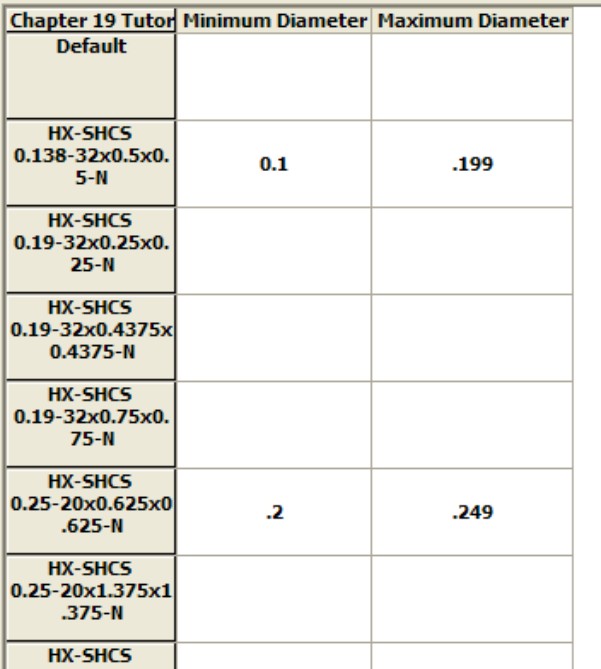

Auto-sizing Smart Components

Making Smart Components

Getting started with a simple Smart Component

Creating an auto-sizing Smart Component

Managing files with Smart Components

Editing Smart Components

Tutorial: Working with Smart Components

Summary

Part IV: Creating Assembly Drawings

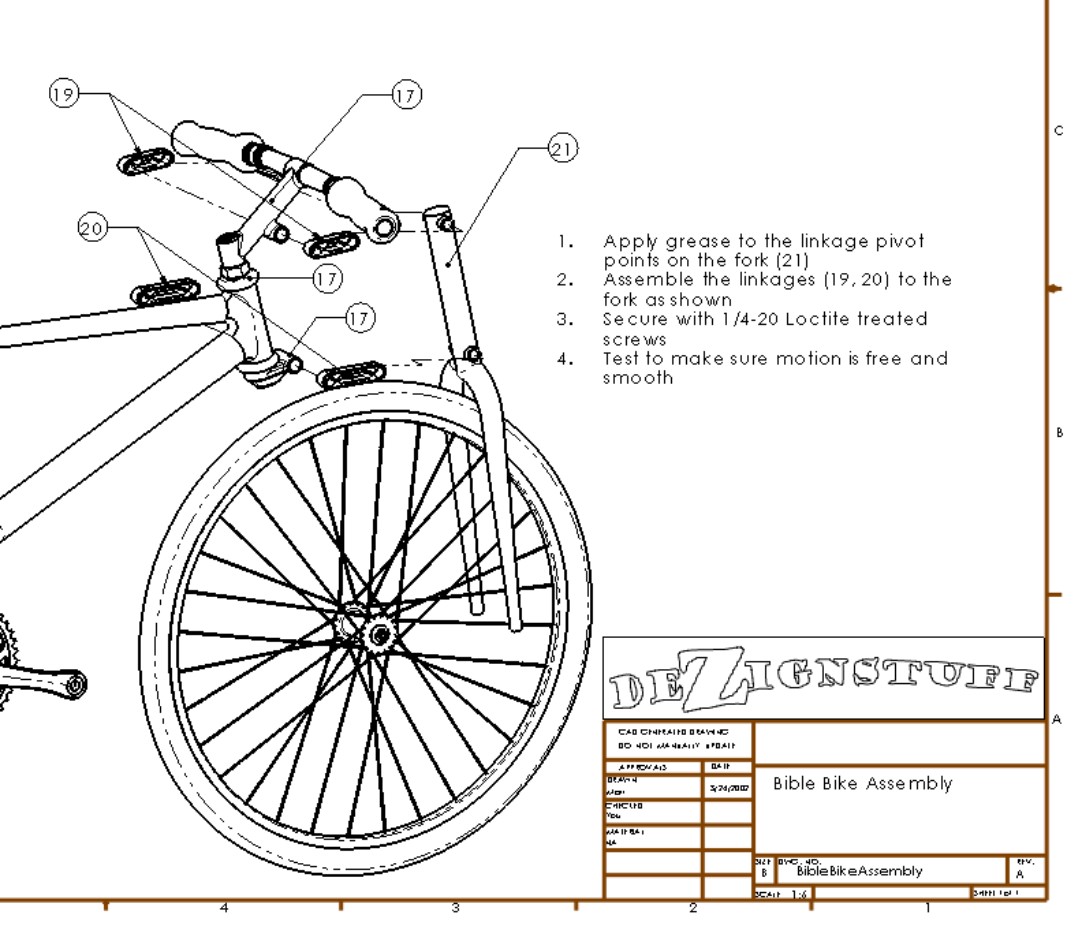

Chapter 16: Creating Assembly Drawings

Combining Parts and Assemblies on the Same Drawing

Dimensioning assembly features

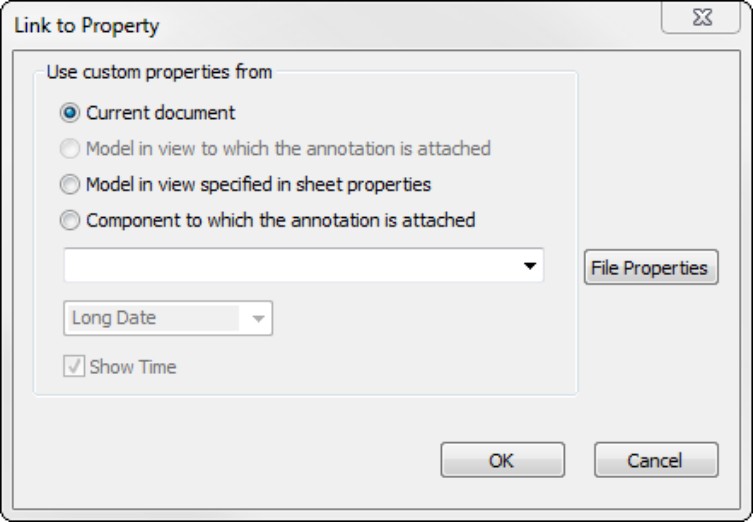

Assigning the document driving the custom properties

Using Multi-Page Templates

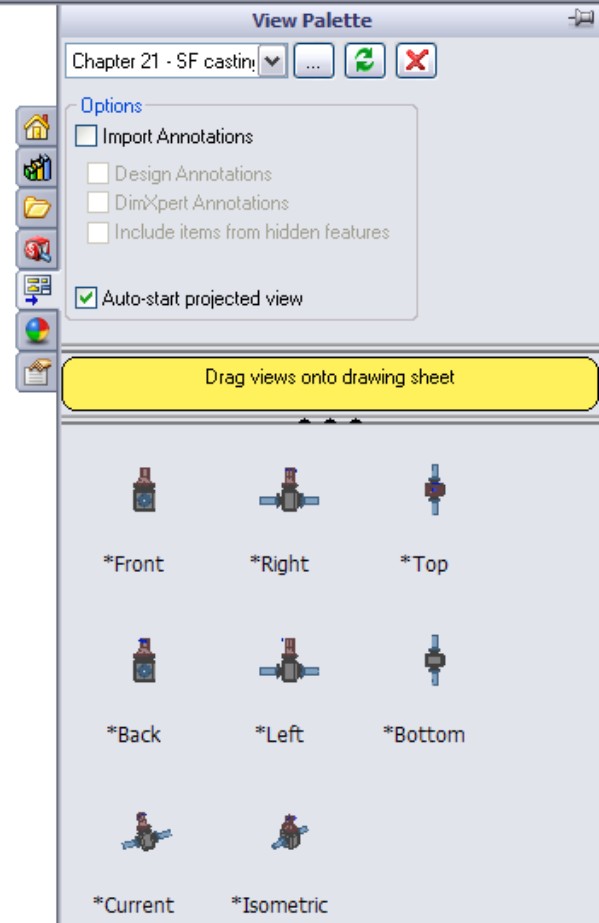

Using Views with Special Assembly Functions

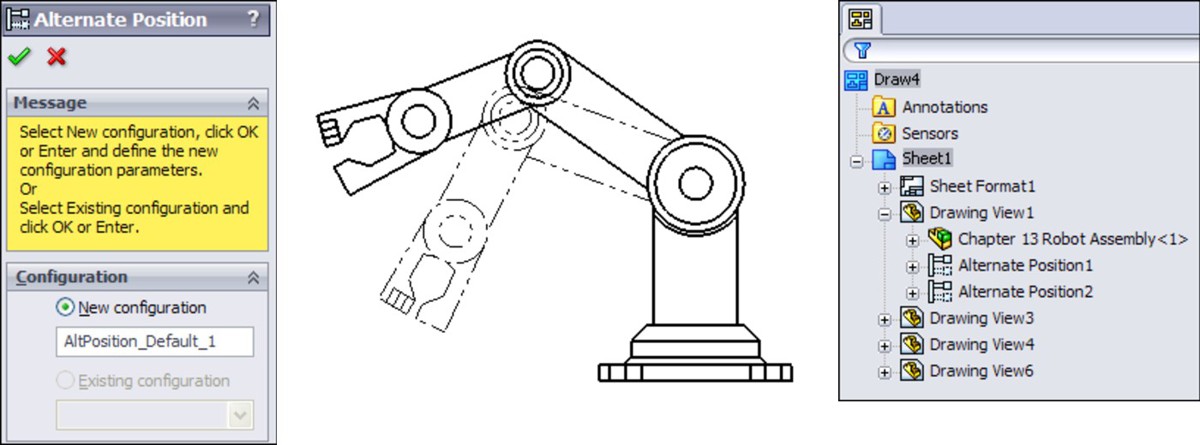

Using the Alternate Position View

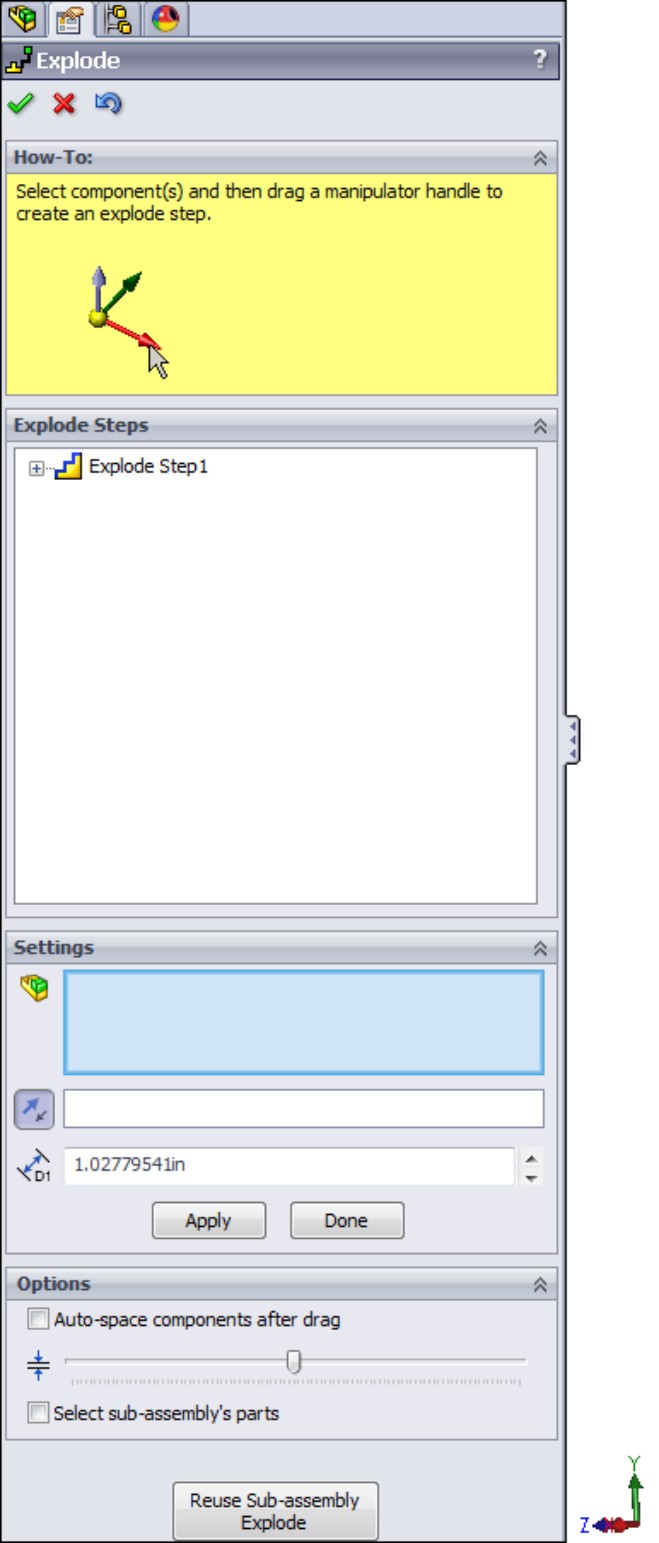

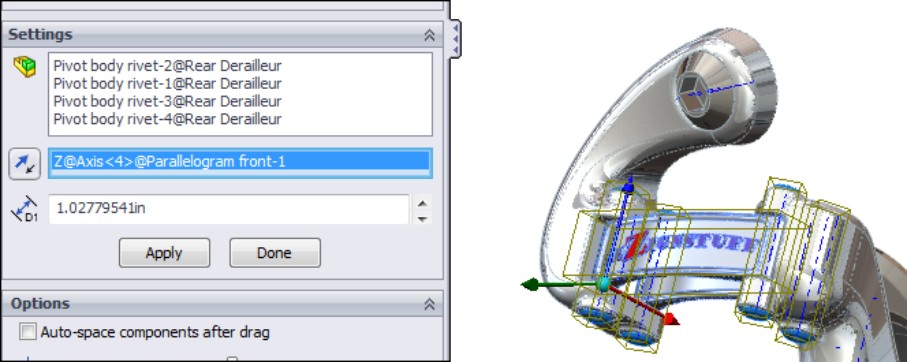

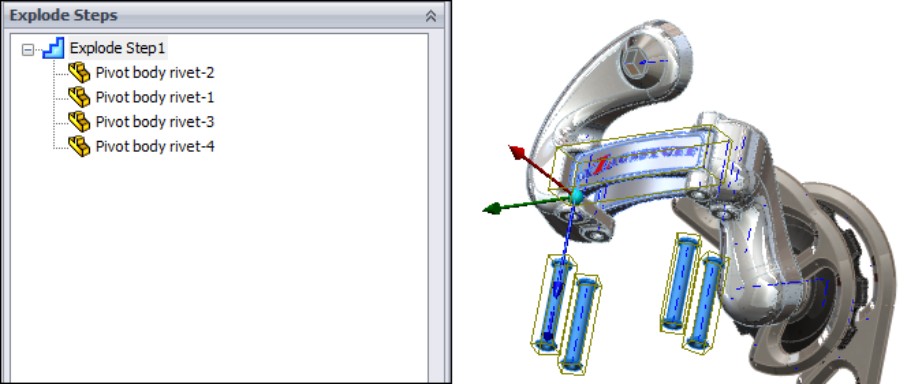

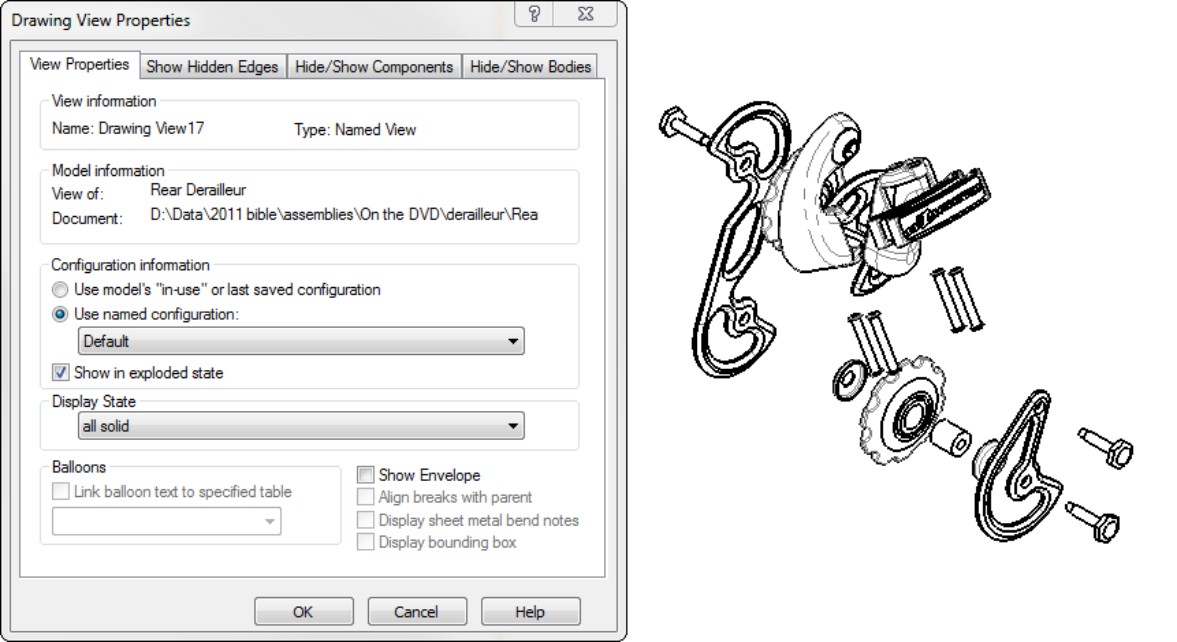

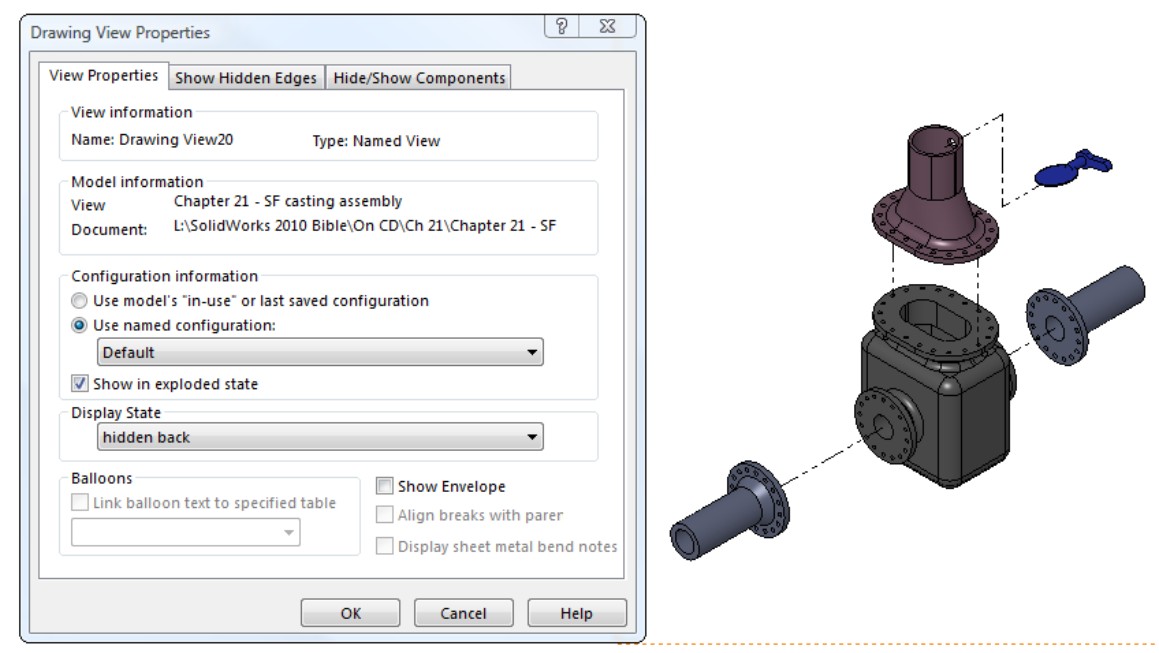

Creating views of an exploded assembly

Creating section views

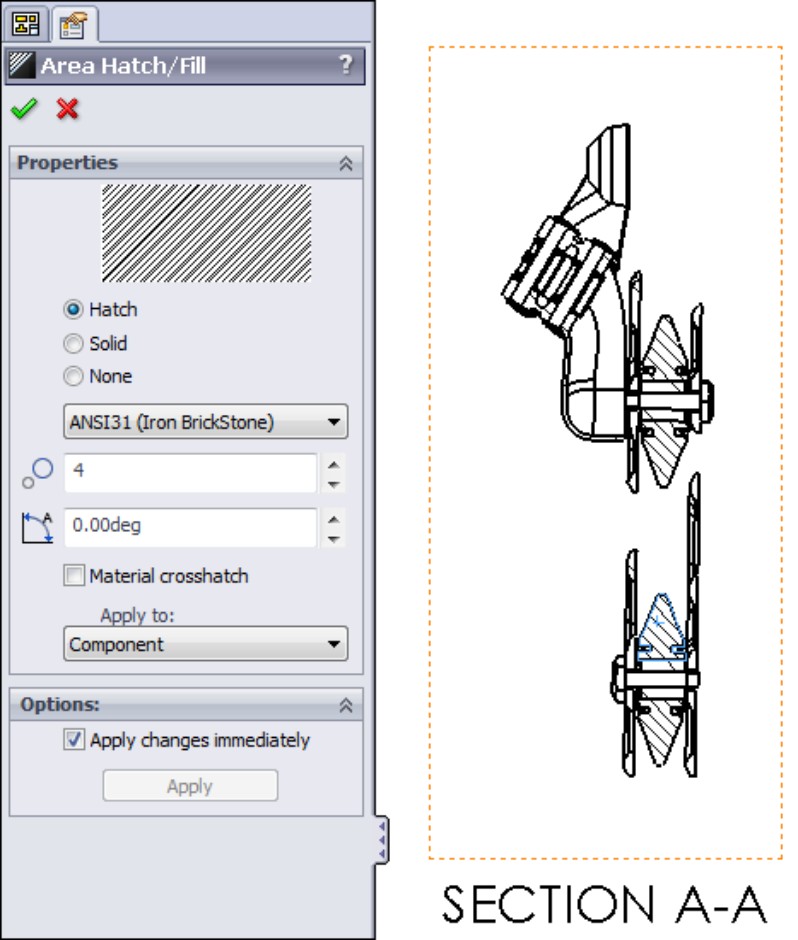

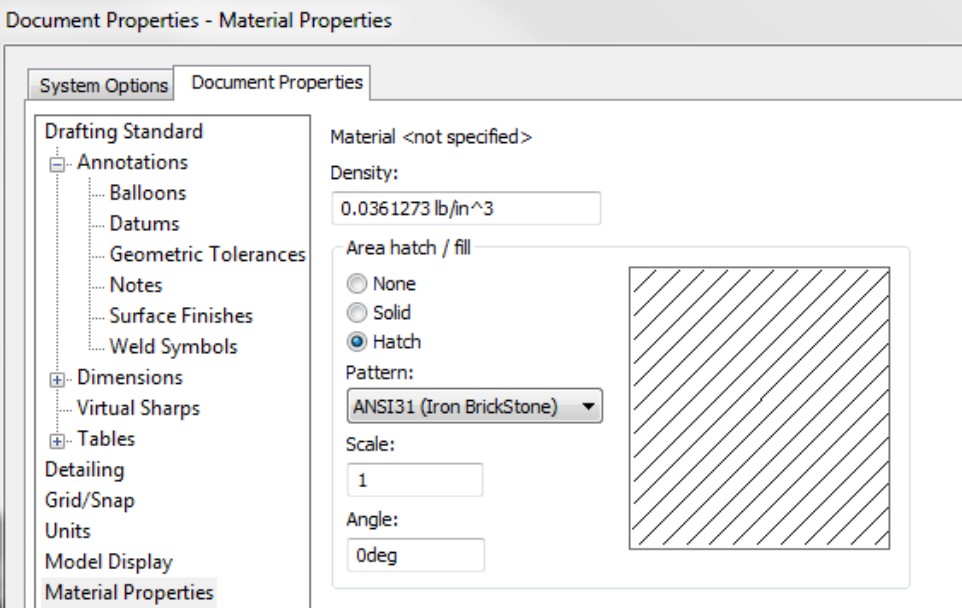

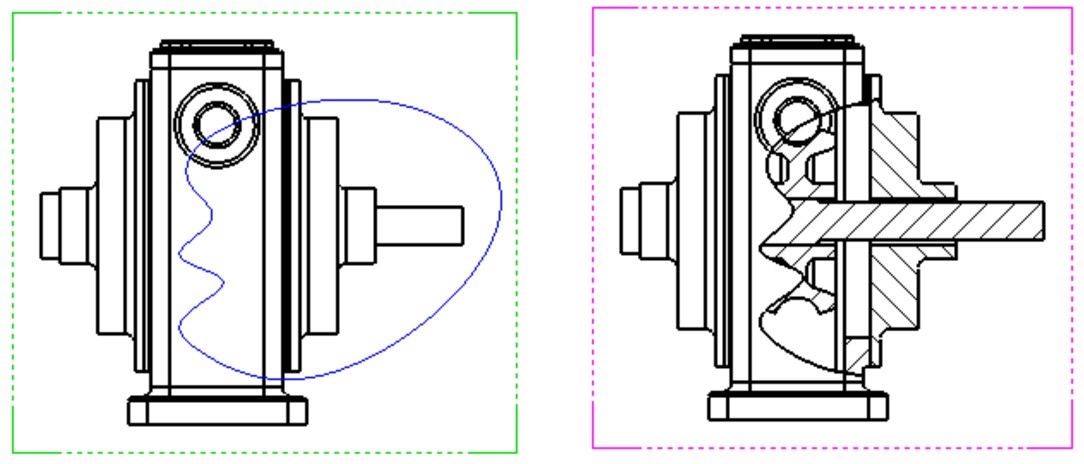

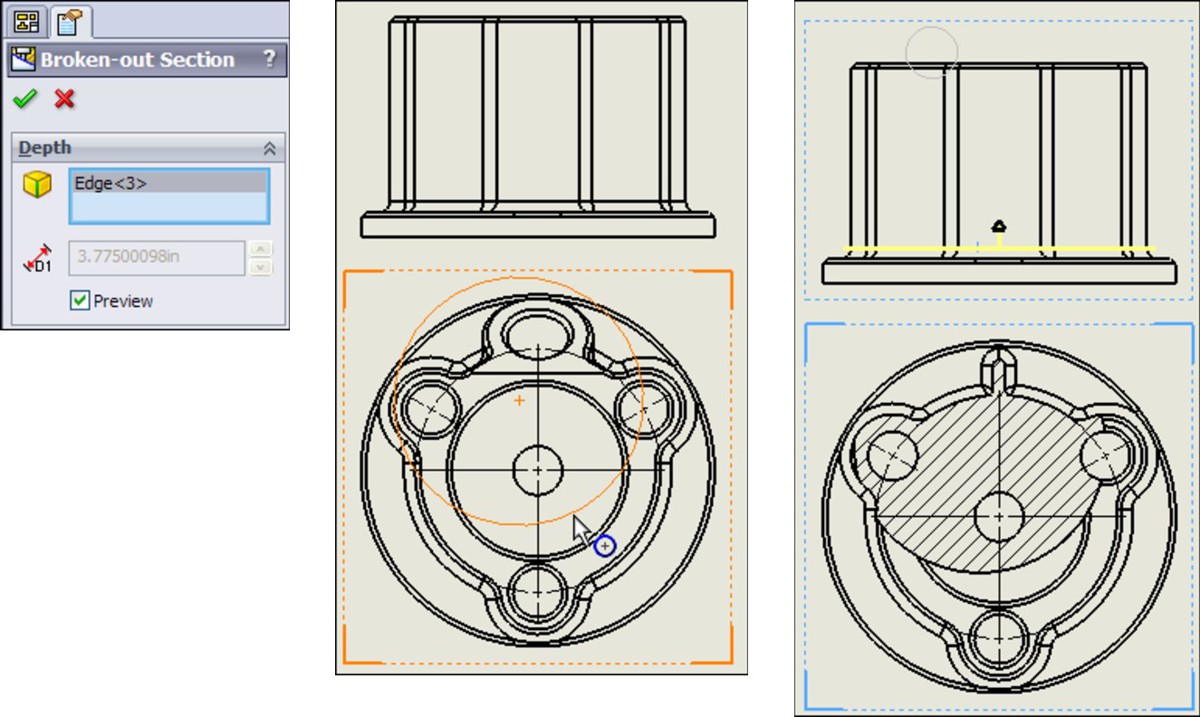

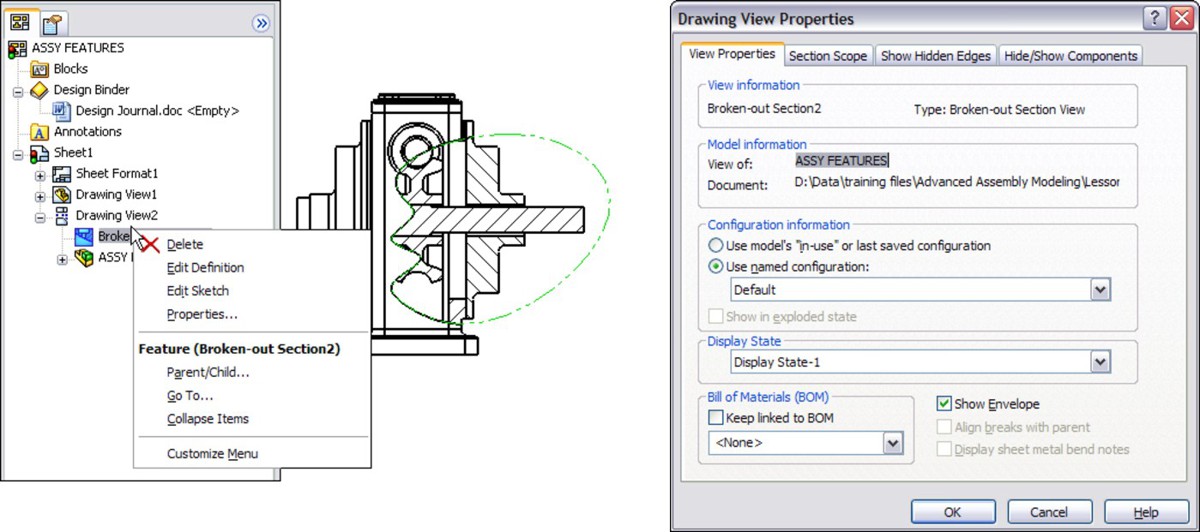

Broken-Out Section View

Using Color in Assembly Drawing Views

Setting Up Drawings of Large Assemblies

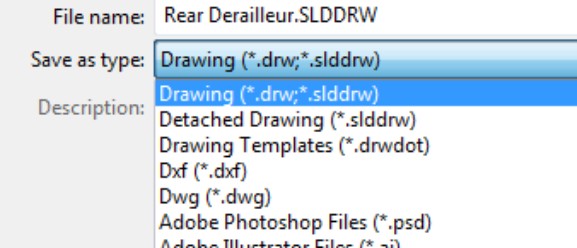

Using detached drawings

Working with lightweight drawings

Using SpeedPak with drawings

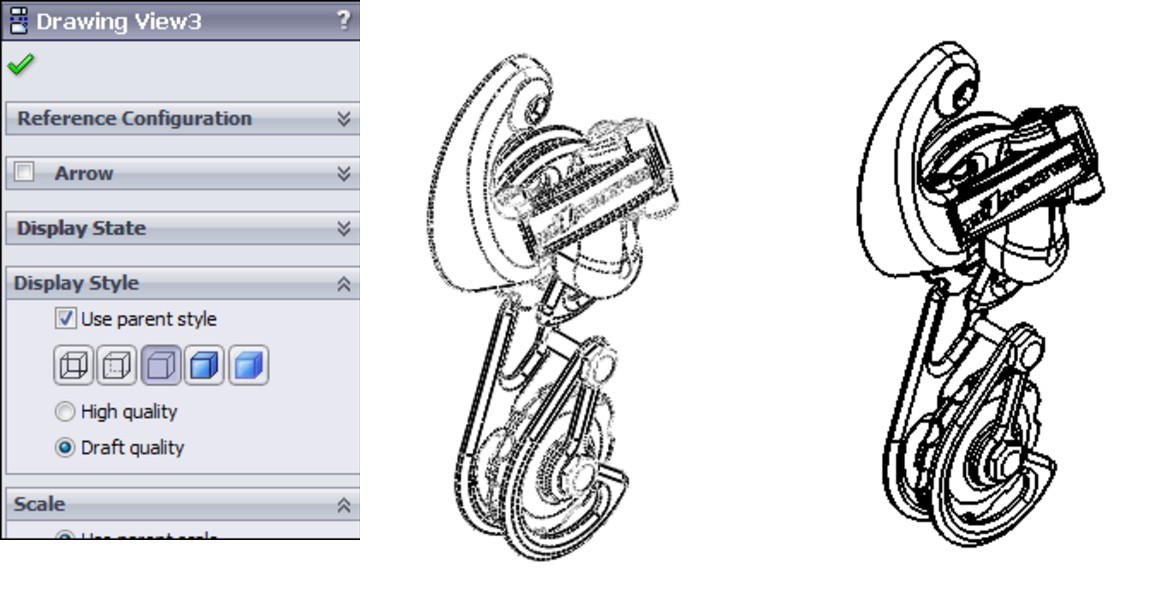

Using draft quality views

Tutorial: Creating a Simple Assembly Drawing

Summary

Chapter 17: Working with Tables and Drawings

Driving the Bill of Materials

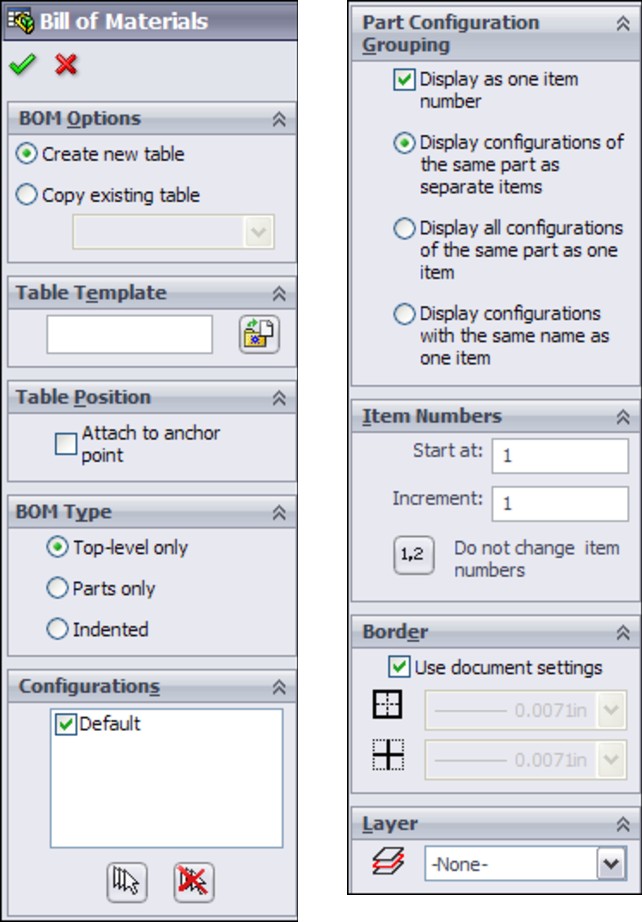

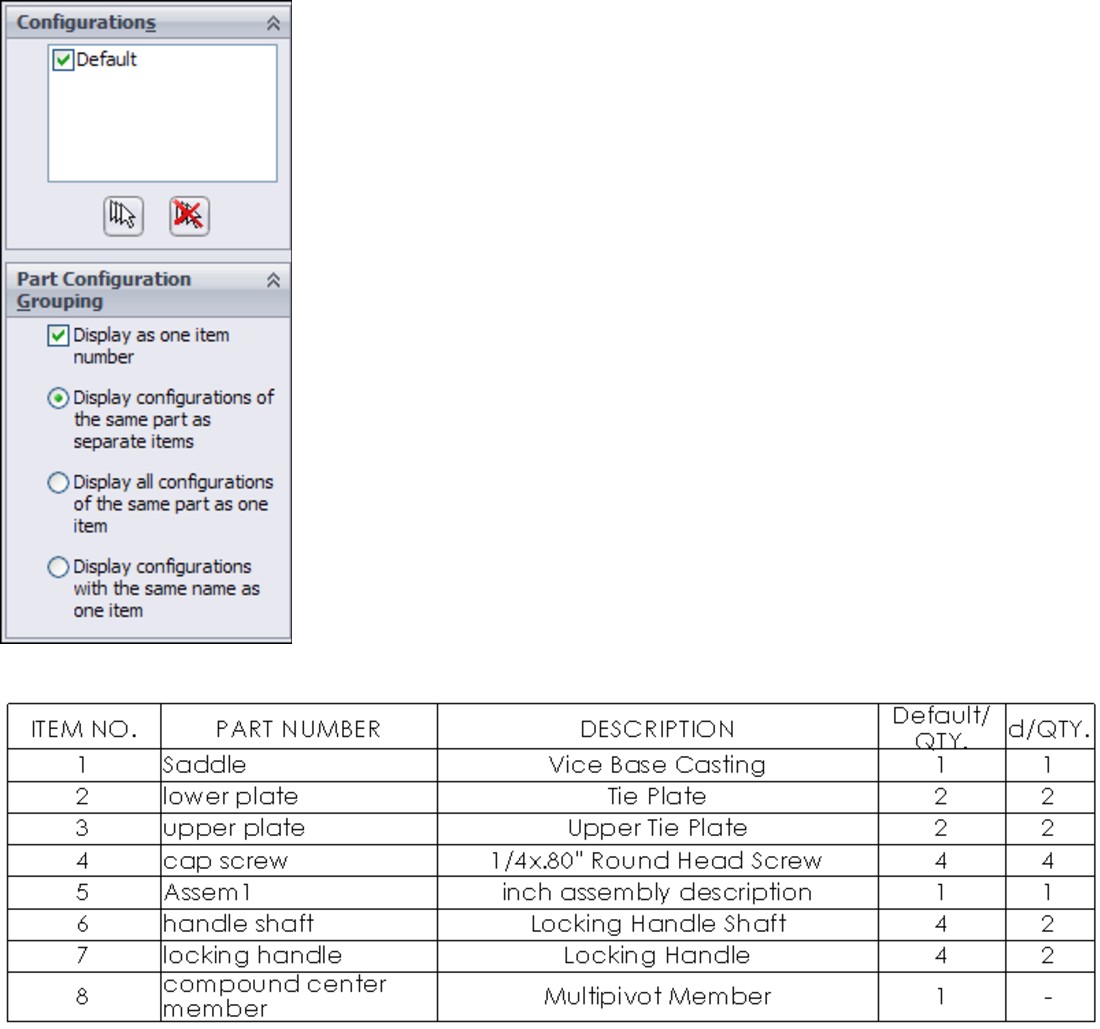

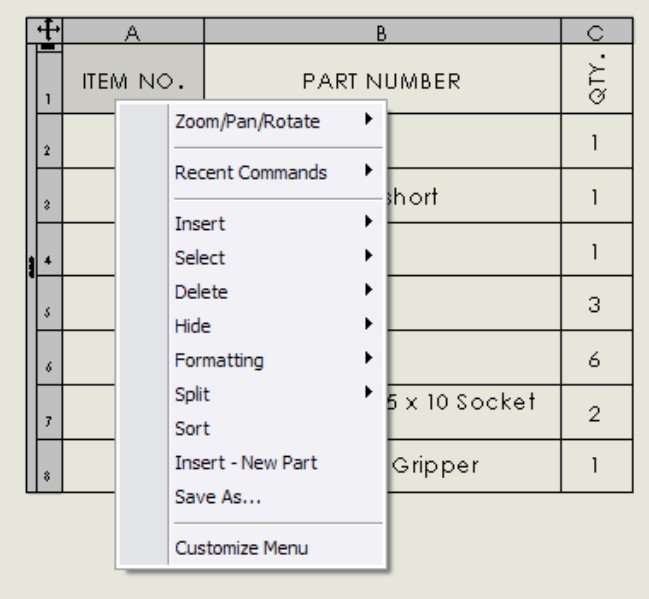

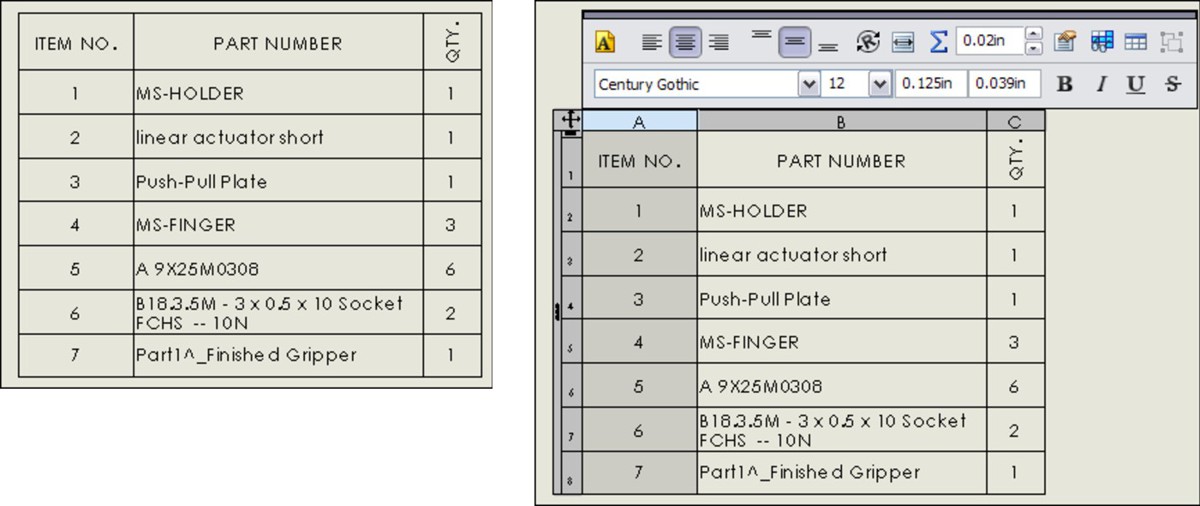

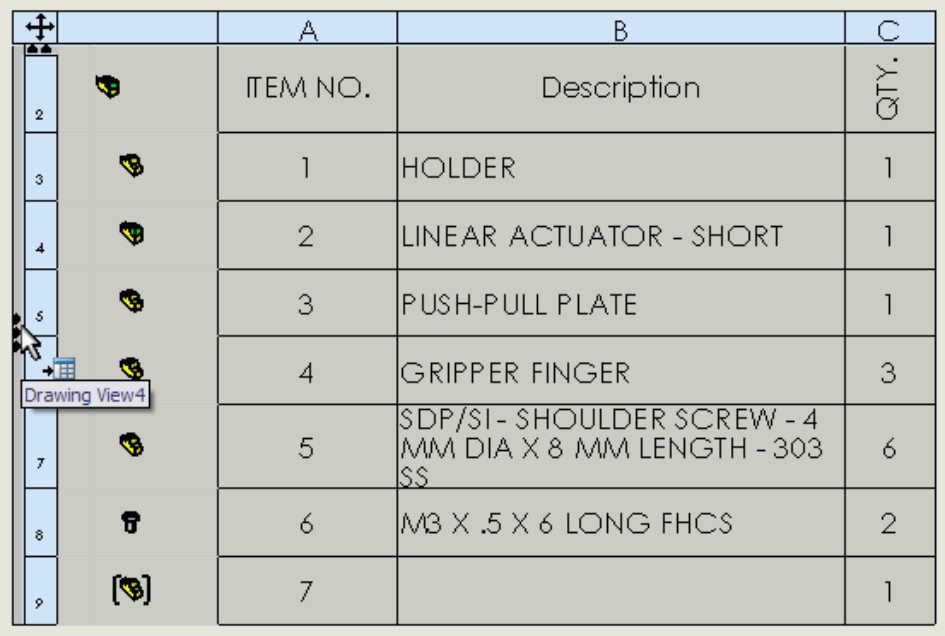

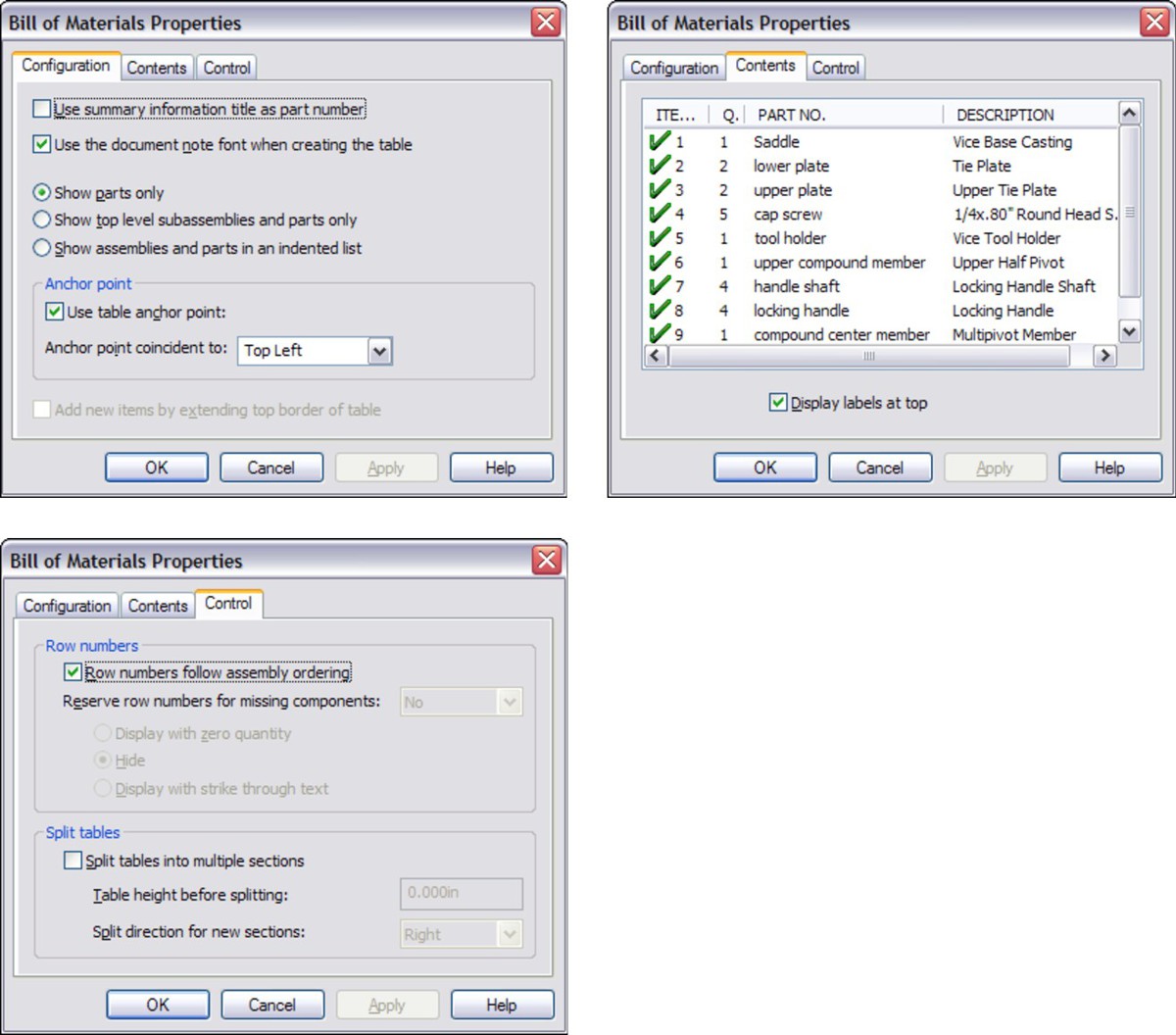

Examining the SolidWorks table-based BOM

Retiring the Excel-based BOM

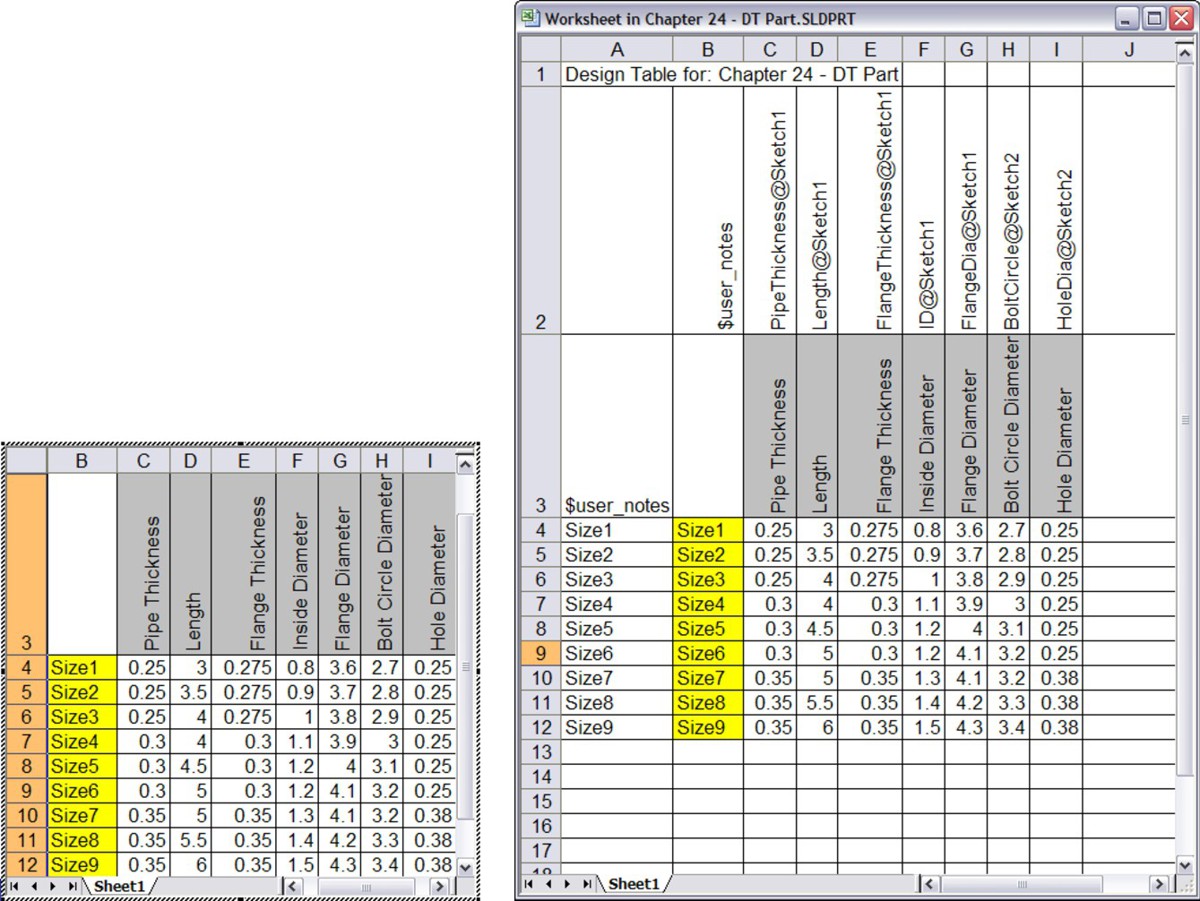

Using Design Tables

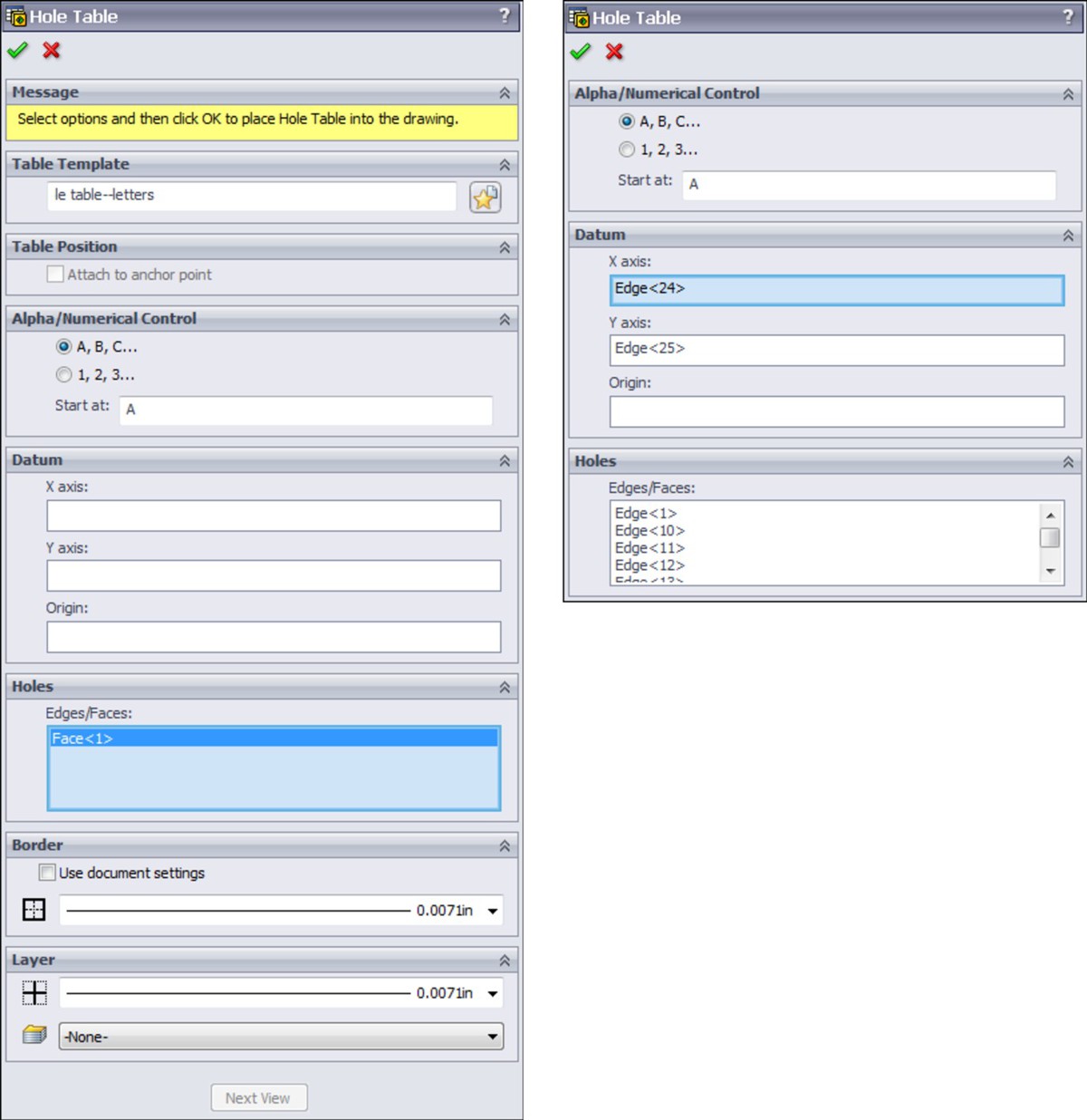

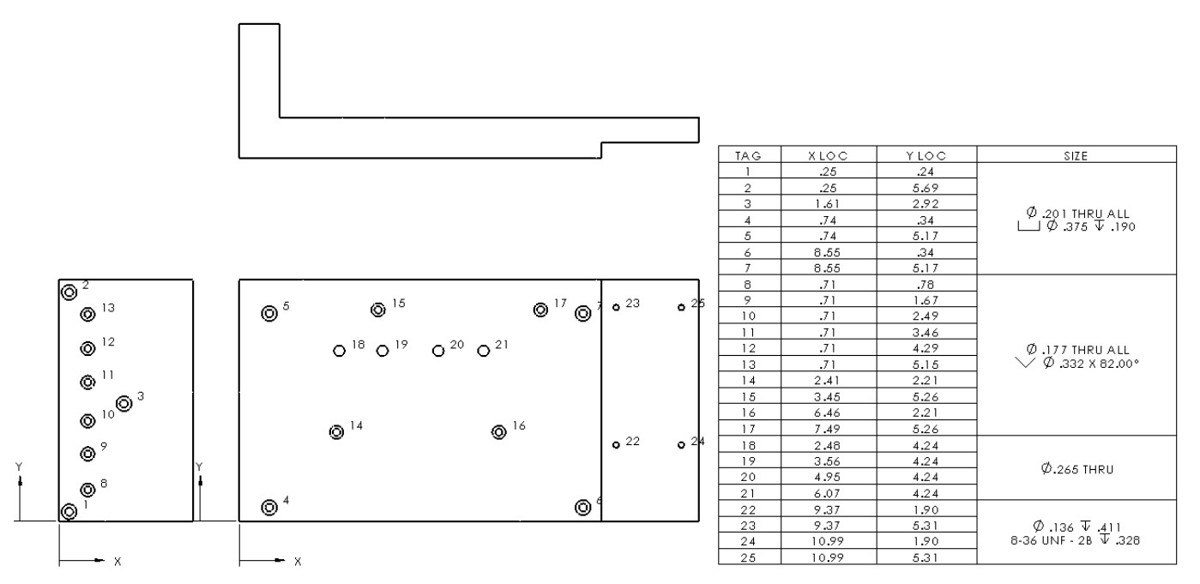

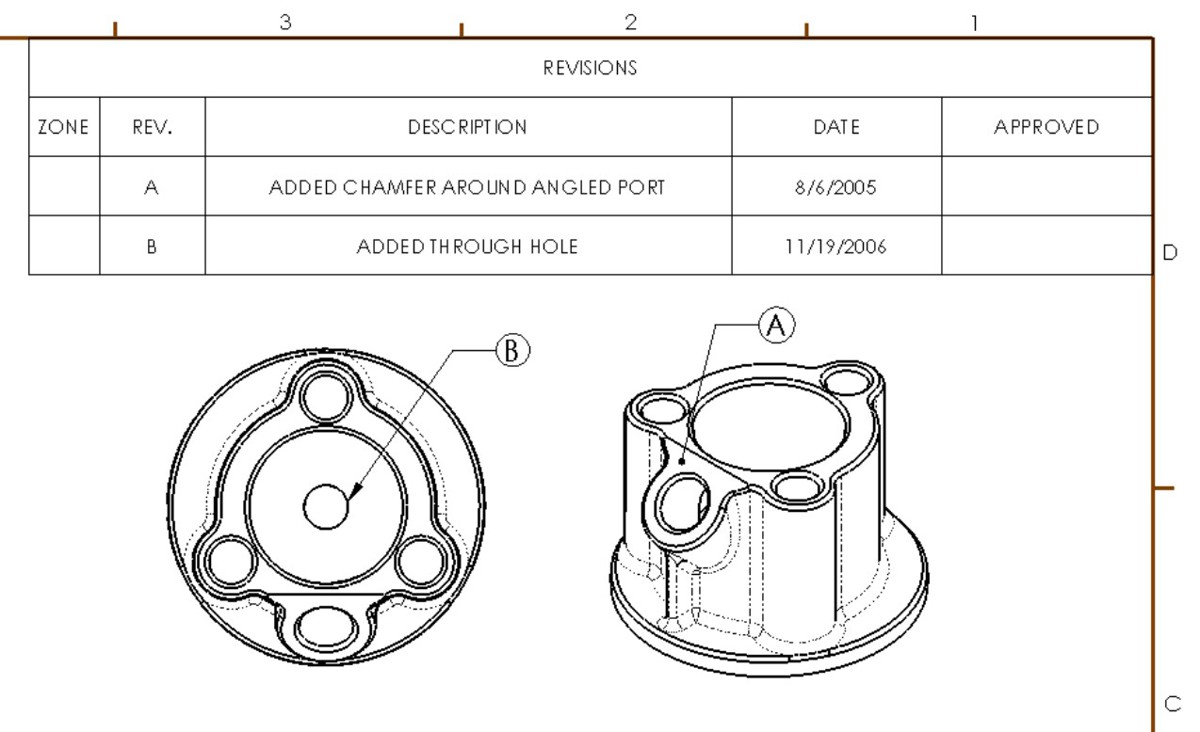

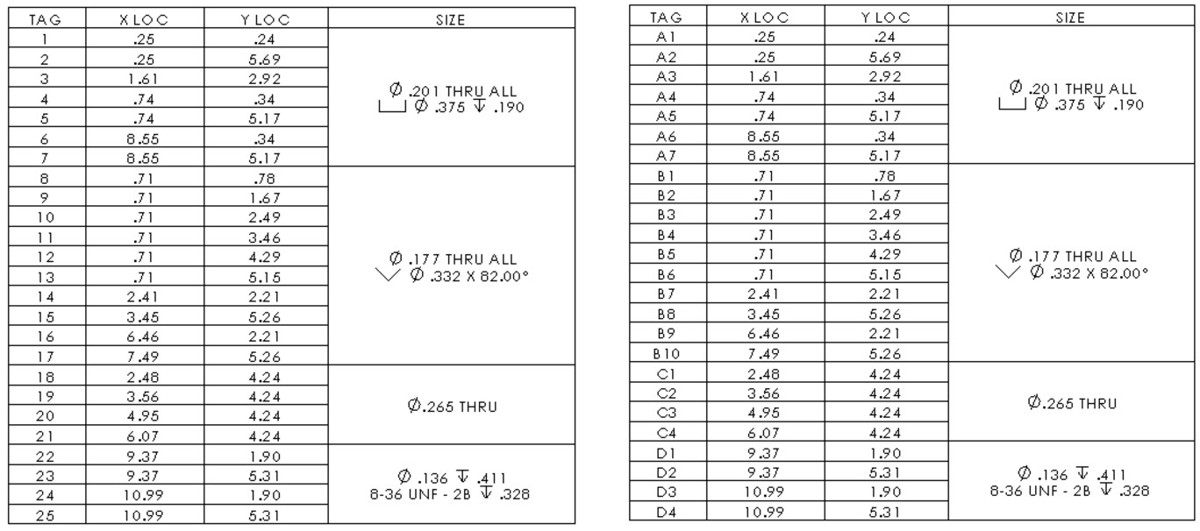

Placing Hole Tables on Drawings

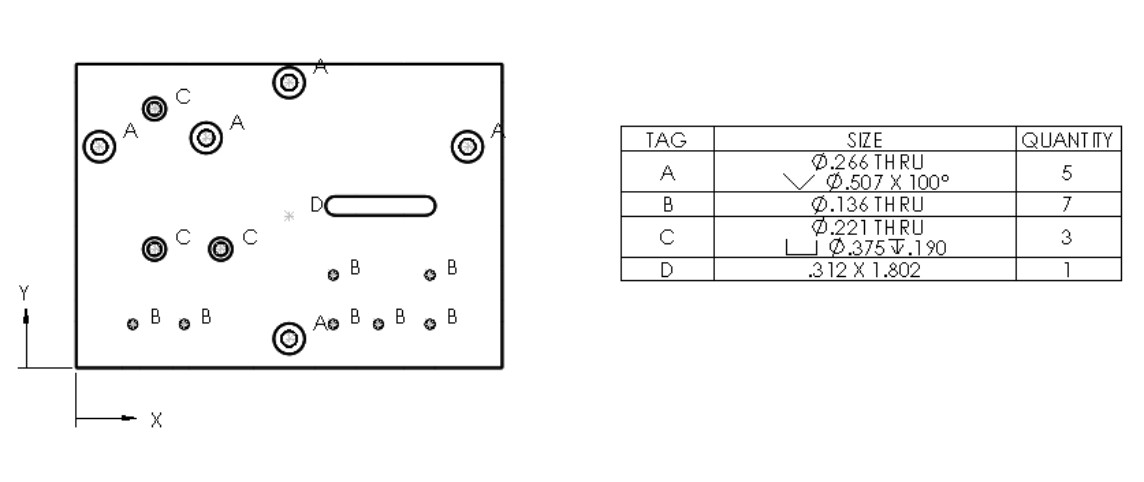

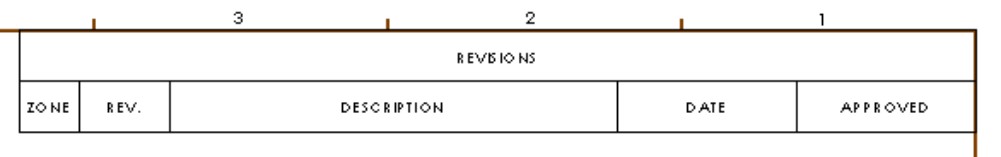

Using Revision Tables

Using General Tables

Working with Tables in Models

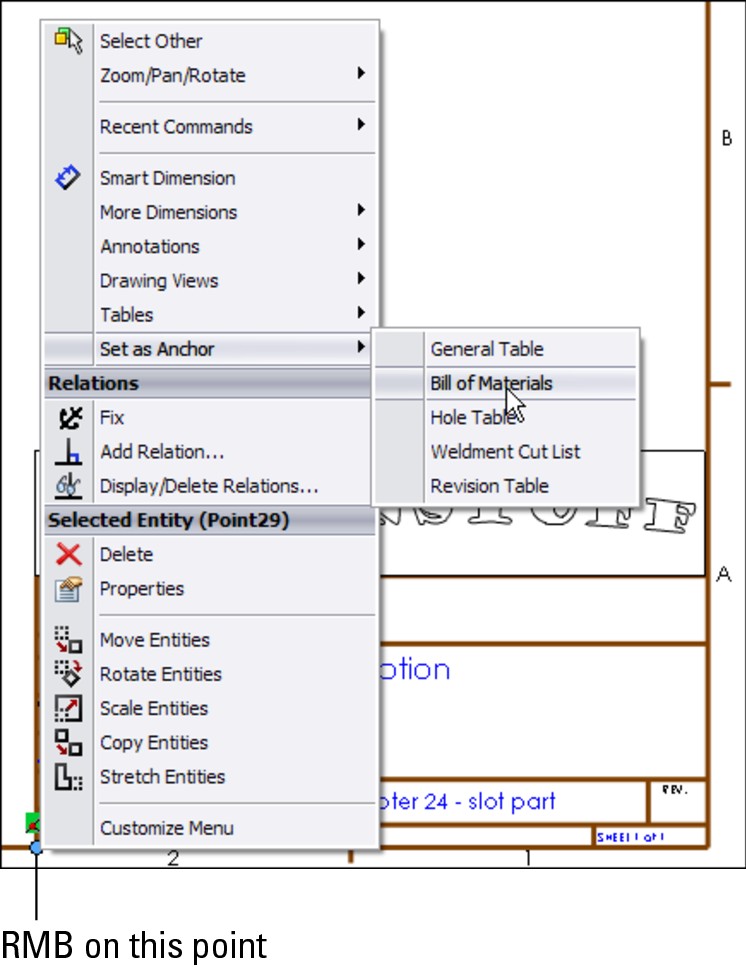

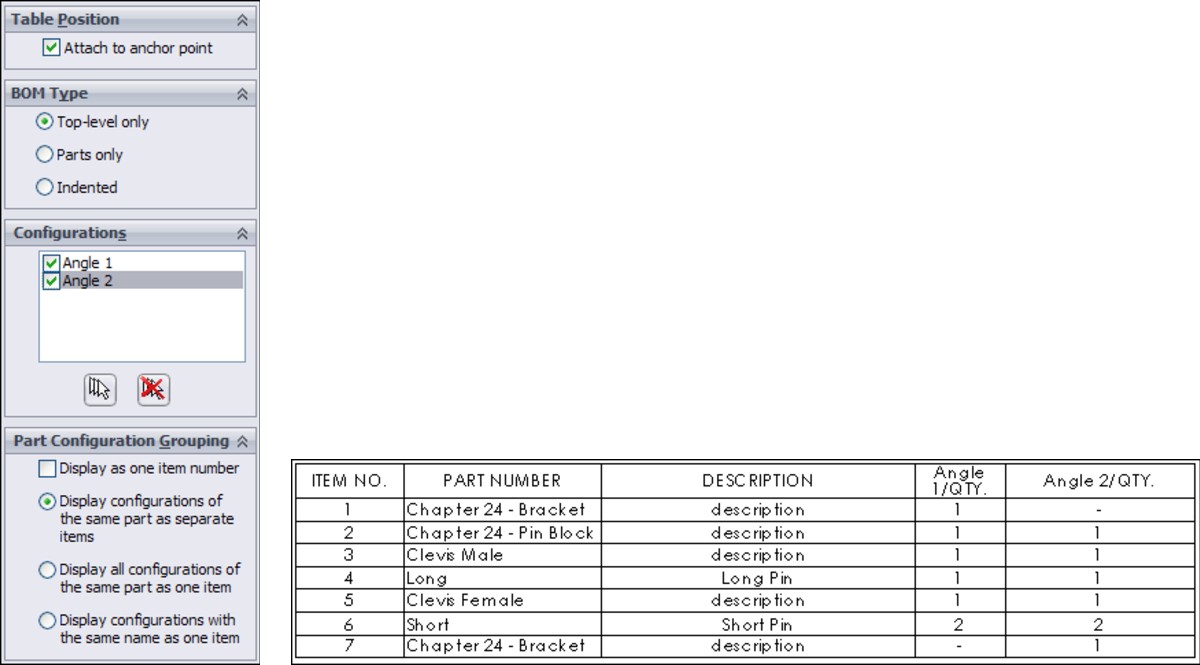

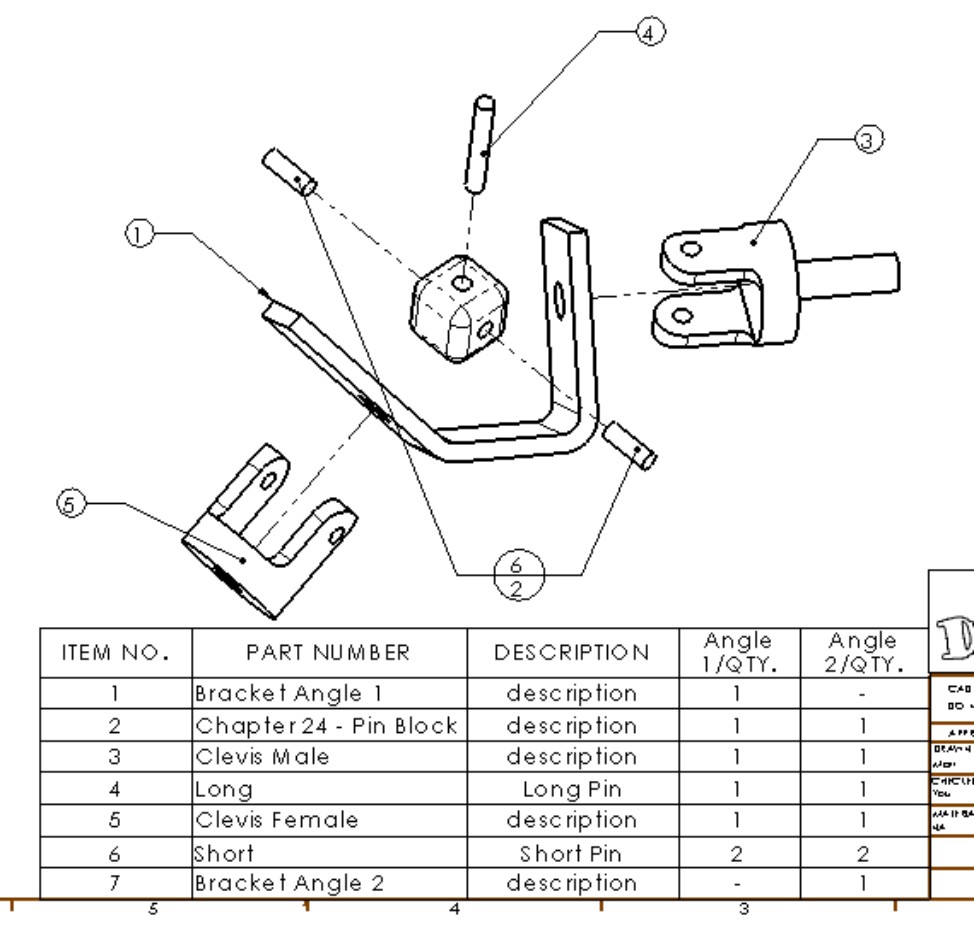

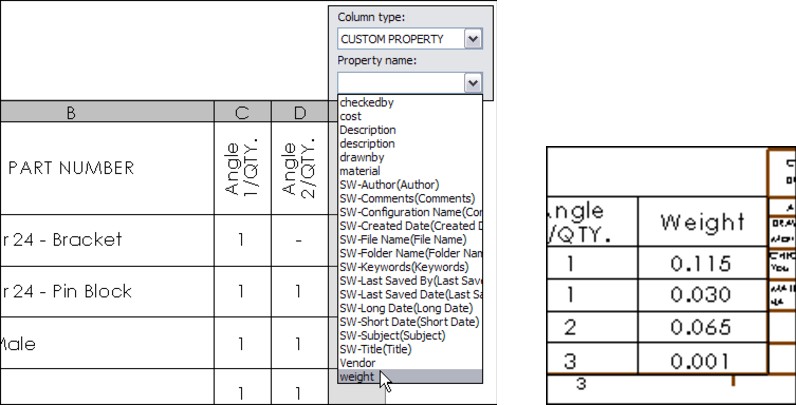

Tutorial: Using BOMs

Tutorial: Using Hole Tables

Tutorial: Using Revision Tables

Summary

Part V: Using Specialized or Advanced Techniques

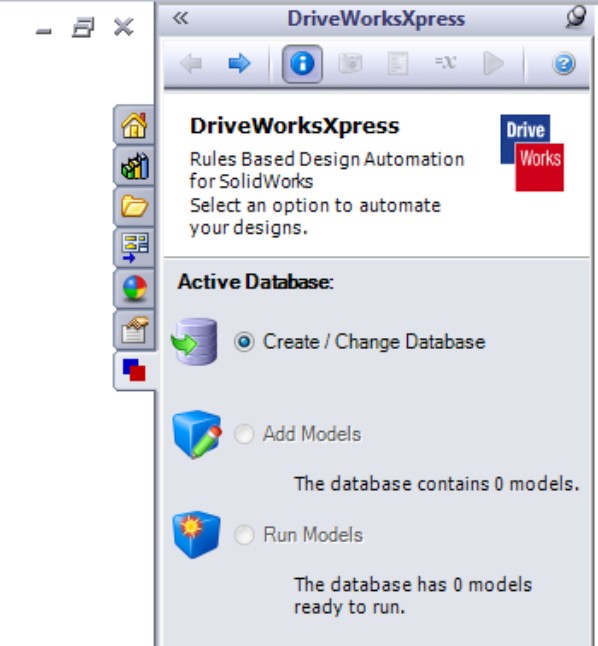

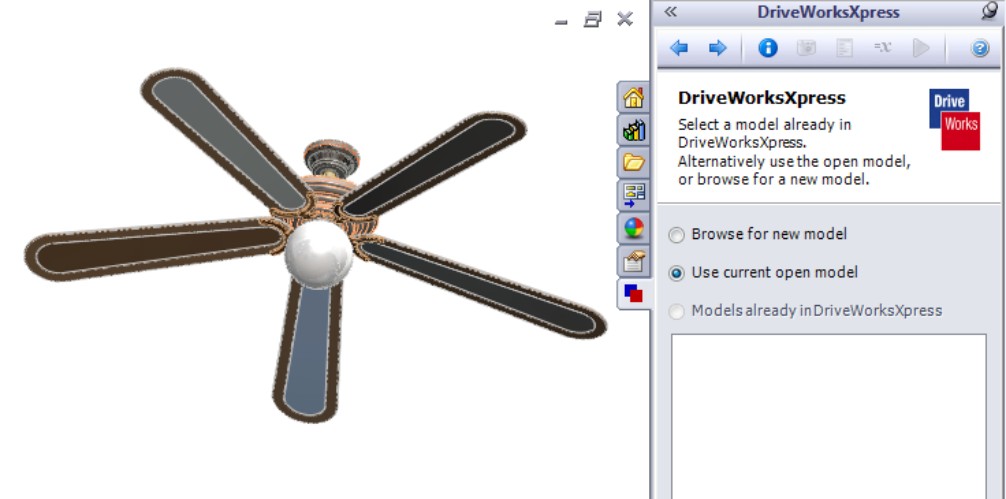

Chapter 18: Using DriveWorks Xpress

Introducing DriveWorks Xpress

Exploring DriveWorks Xpress for your products

Aligning expectations with some estimates

Building the Original Model

Automating an Example

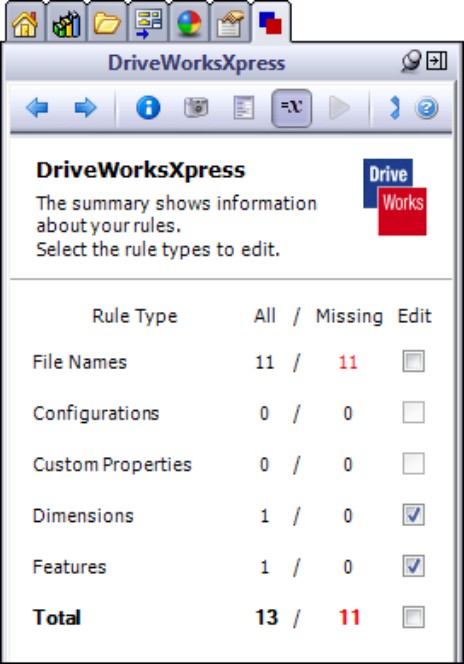

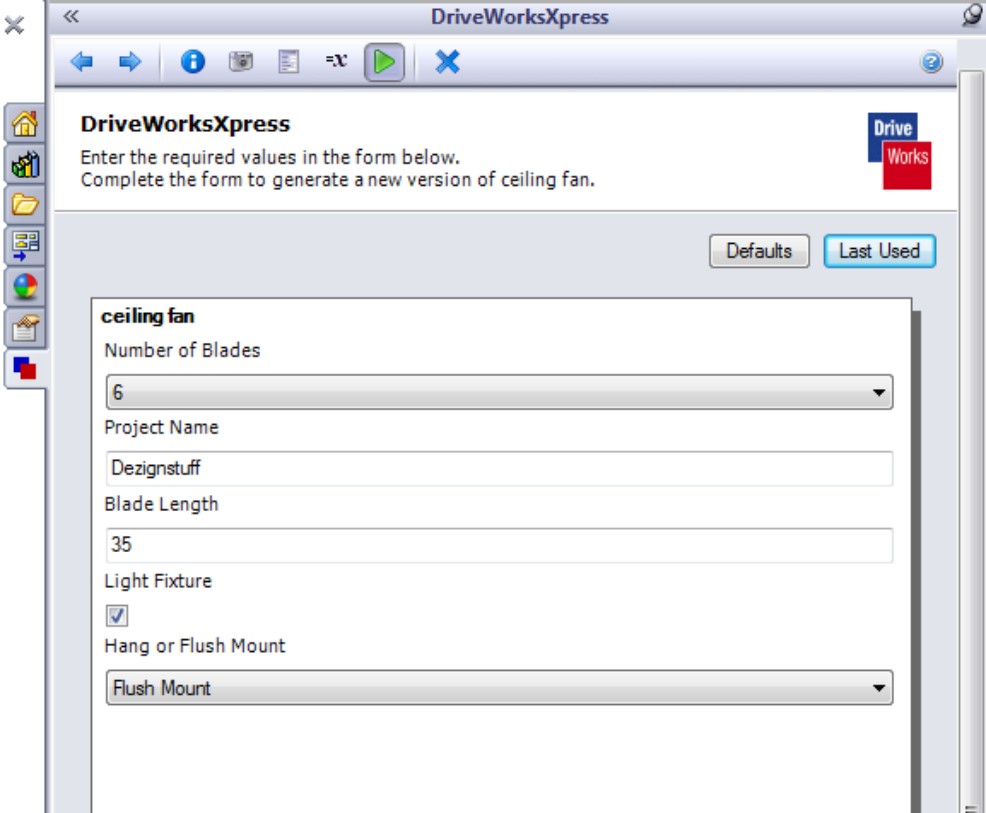

Getting Started: Automating a Design

Activating DriveWorks Xpress

Creating a database

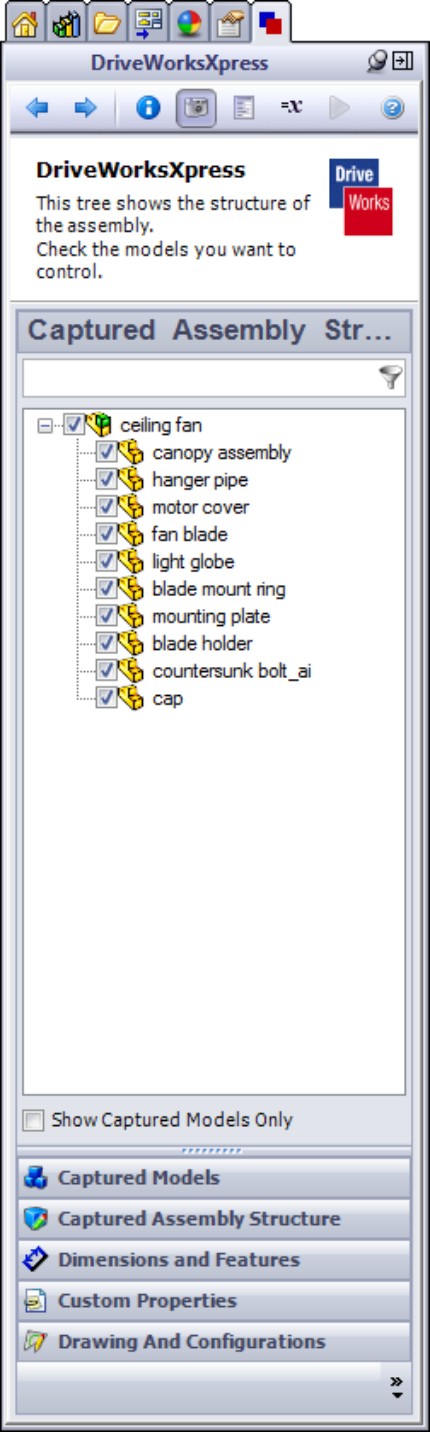

Capturing models

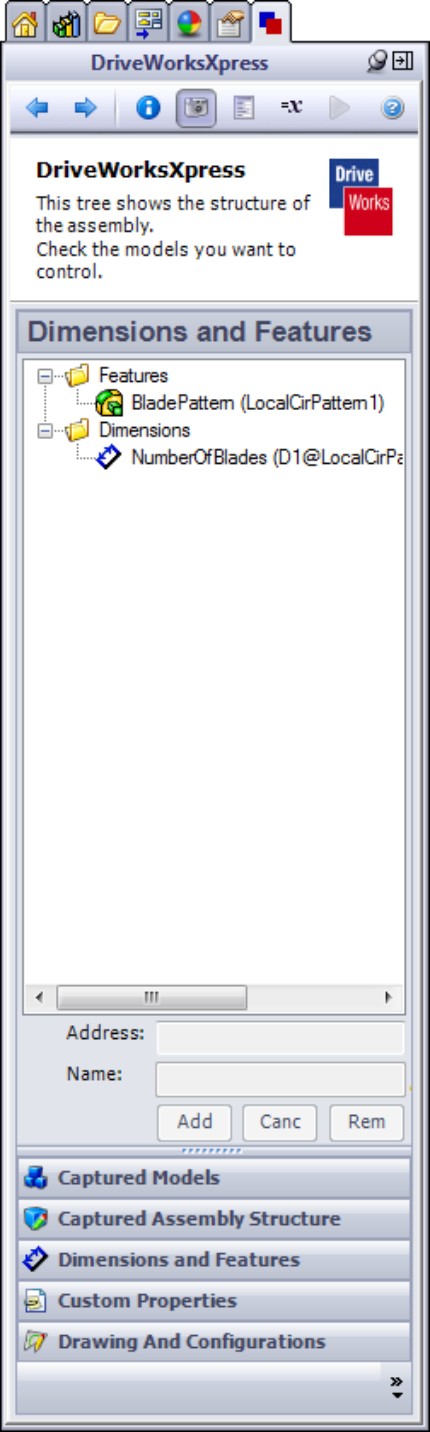

Adding features and dimensions

Creating fields for the form

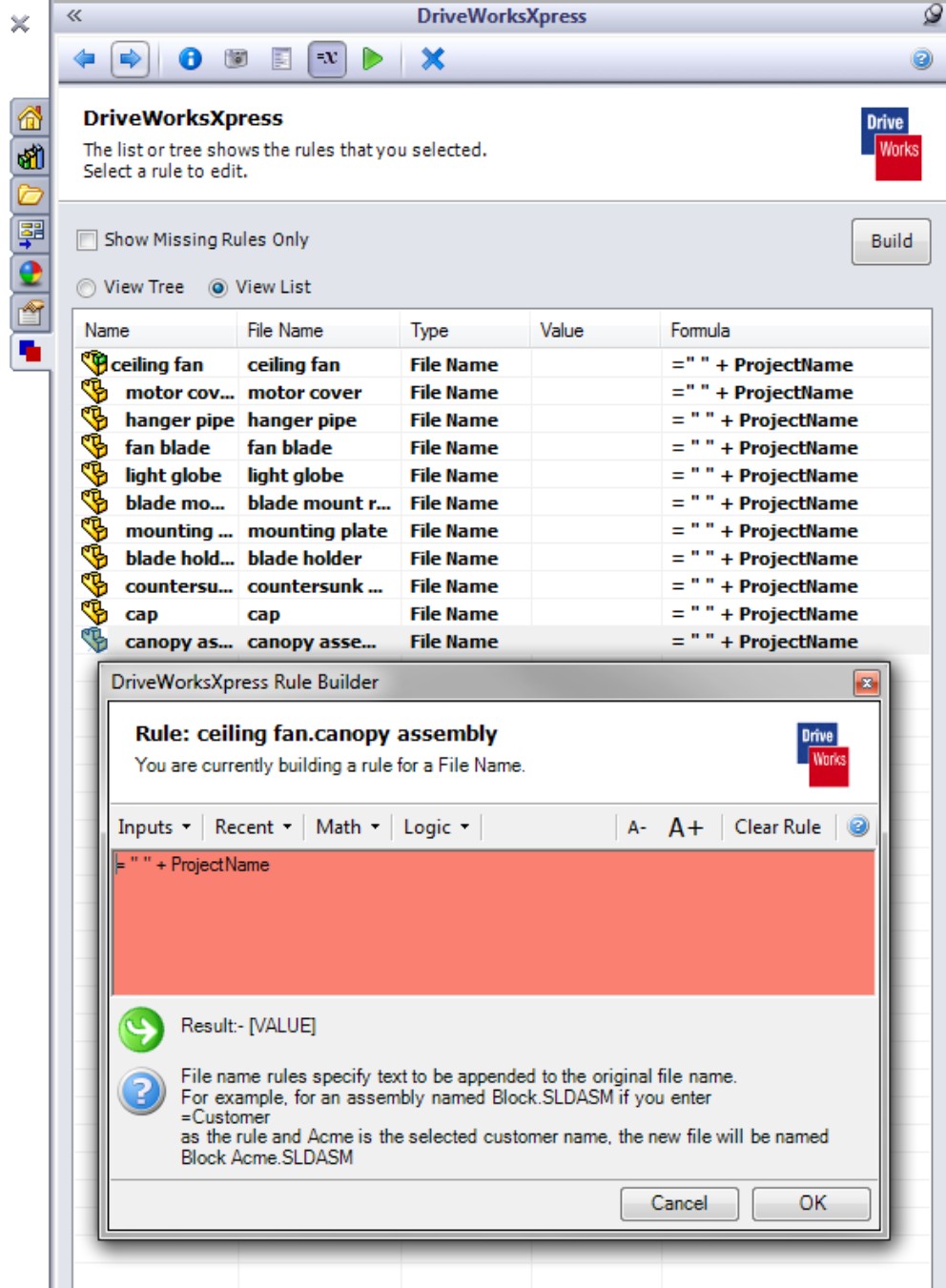

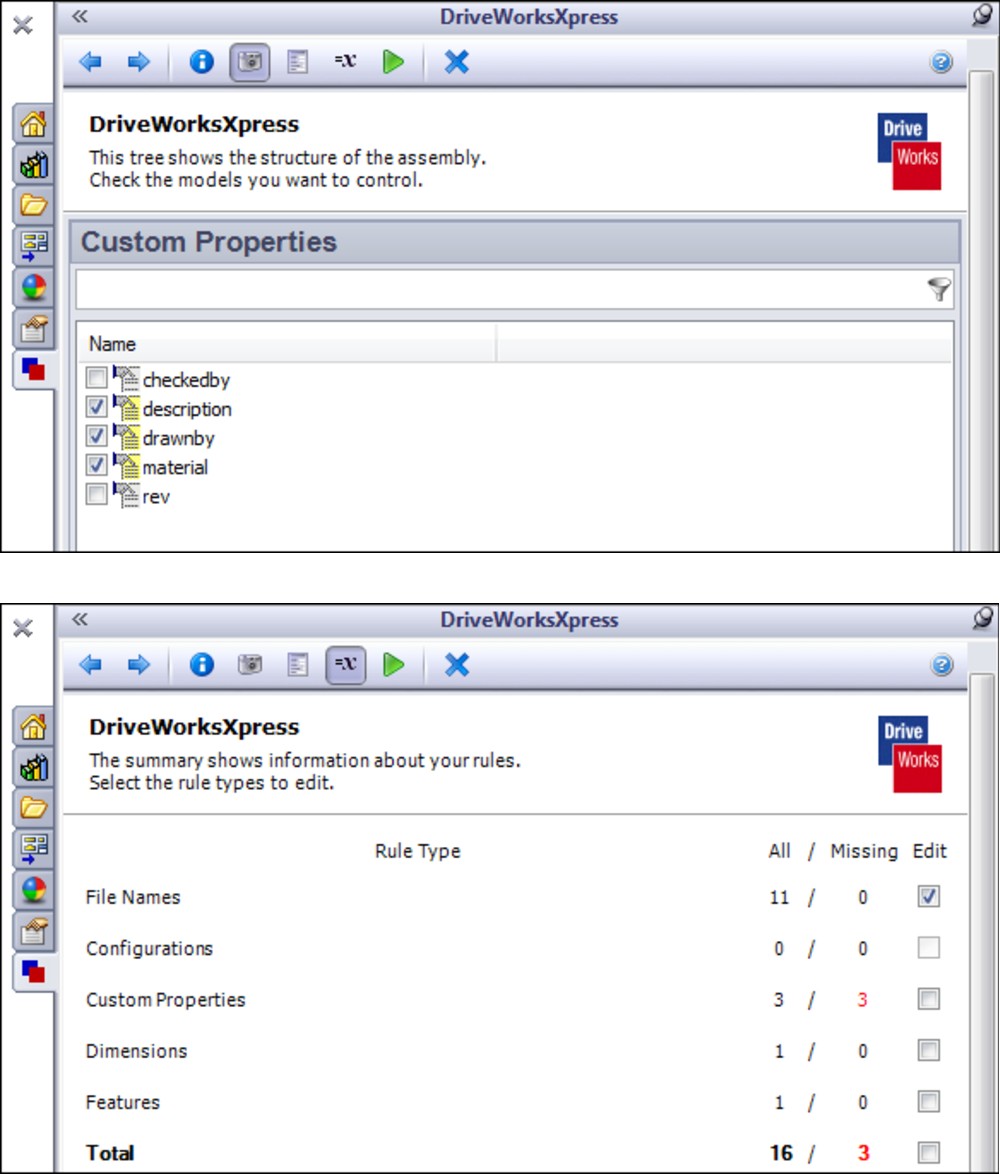

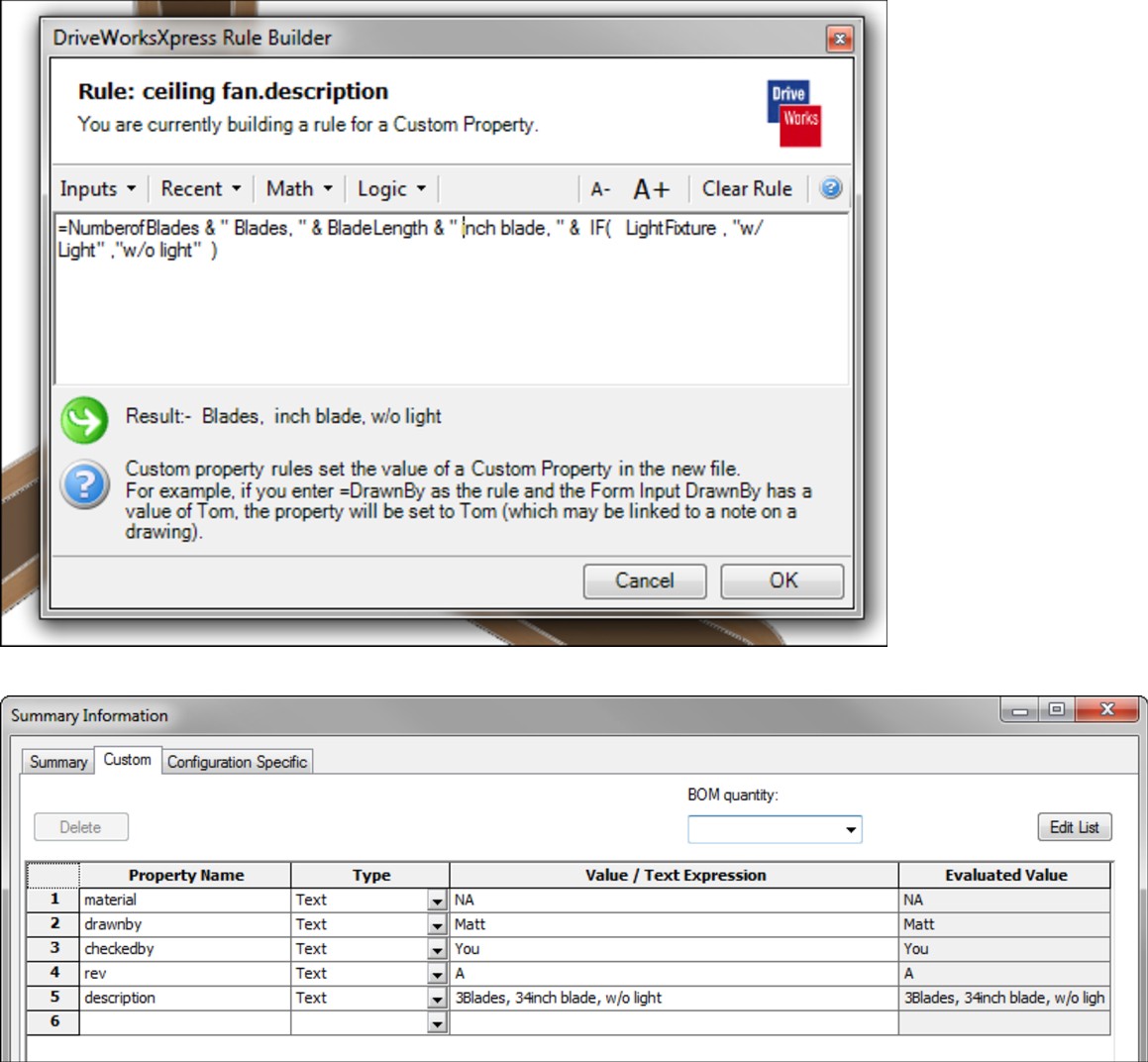

Building rules

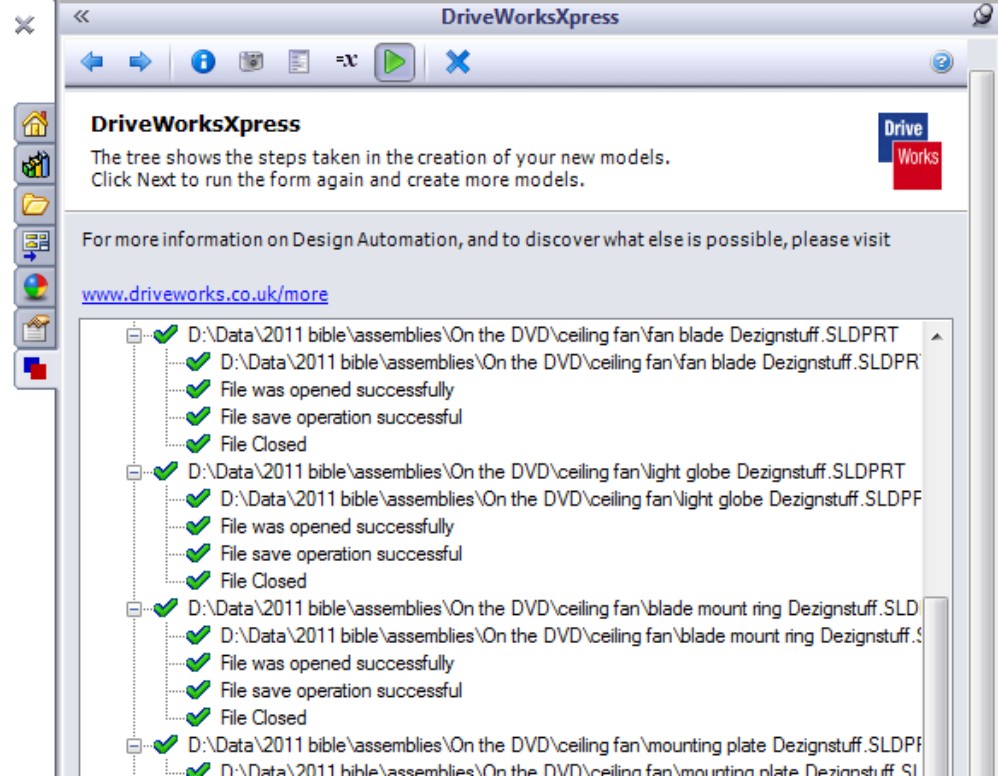

Running the example job

Working with drawings

Summary

Chapter 19: Employing Master Model Techniques

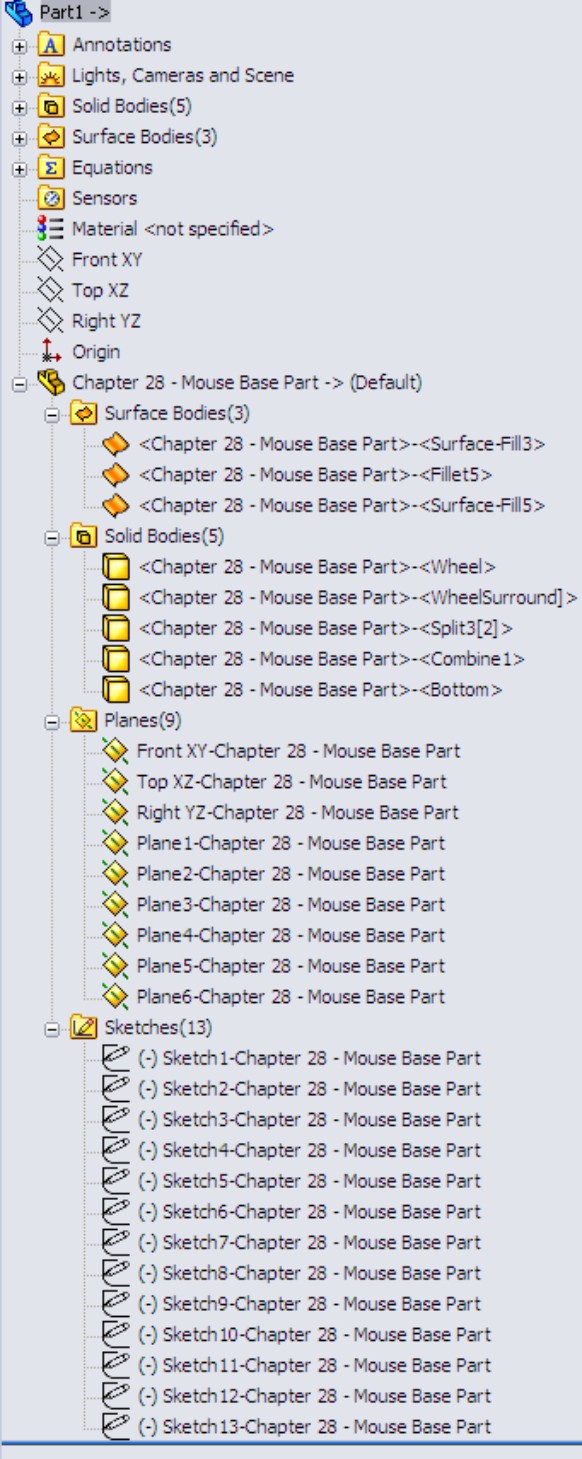

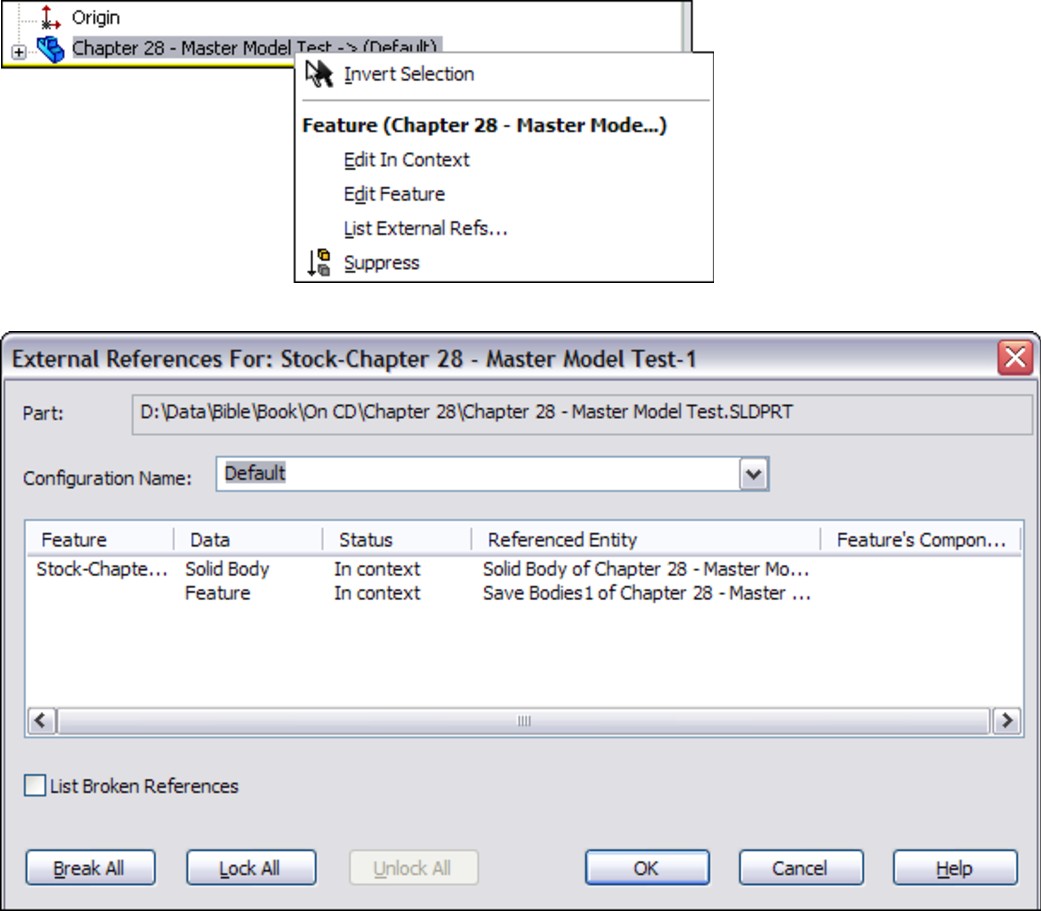

Using Pull Functions

Understanding the Insert Part feature

Understanding the Insert Into New Part feature

Using Push Functions

Working with the Split feature

Working with the Save Bodies feature

Tutorial: Working with Master Model Techniques

Summary

Chapter 20: Using Weldments

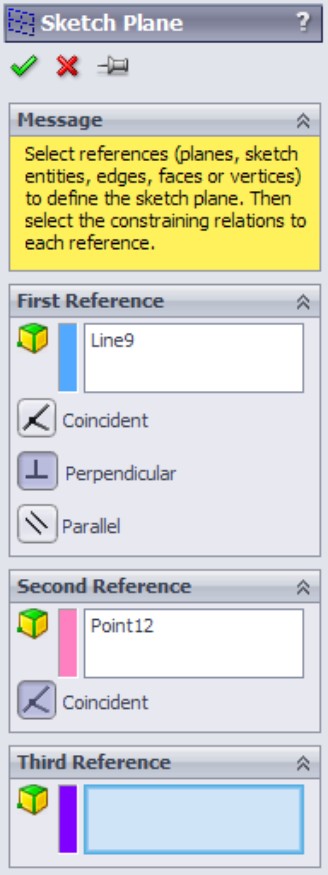

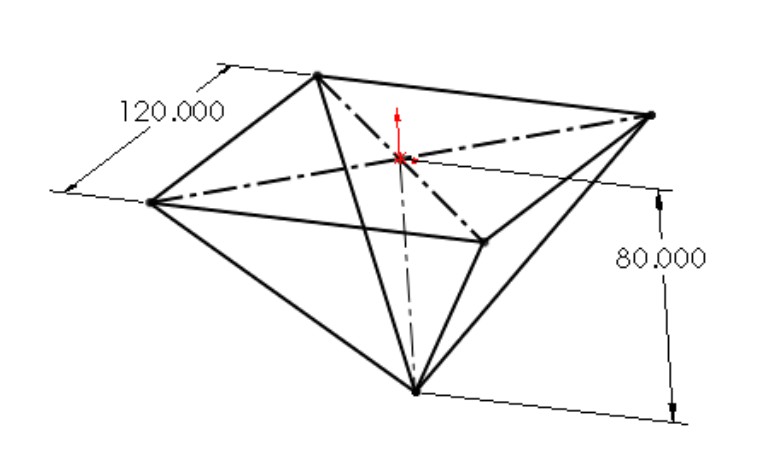

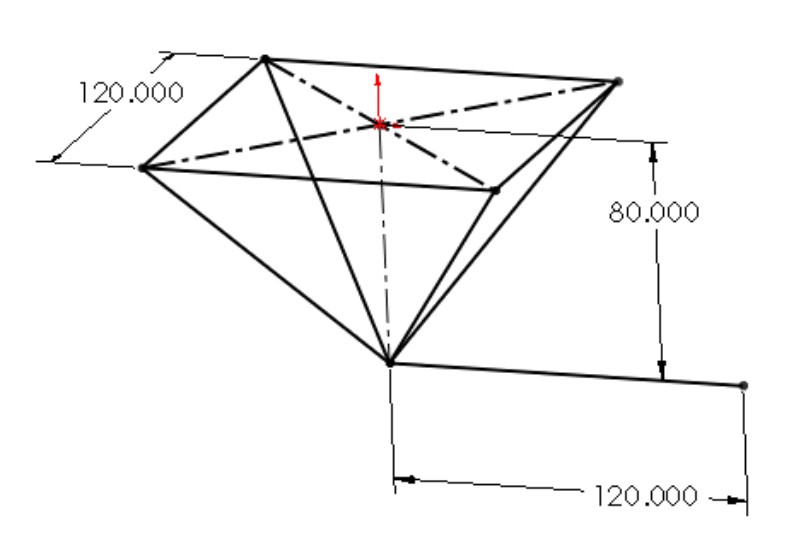

Sketching in 3D

Navigating in space

Understanding sketch relations in 3D sketches

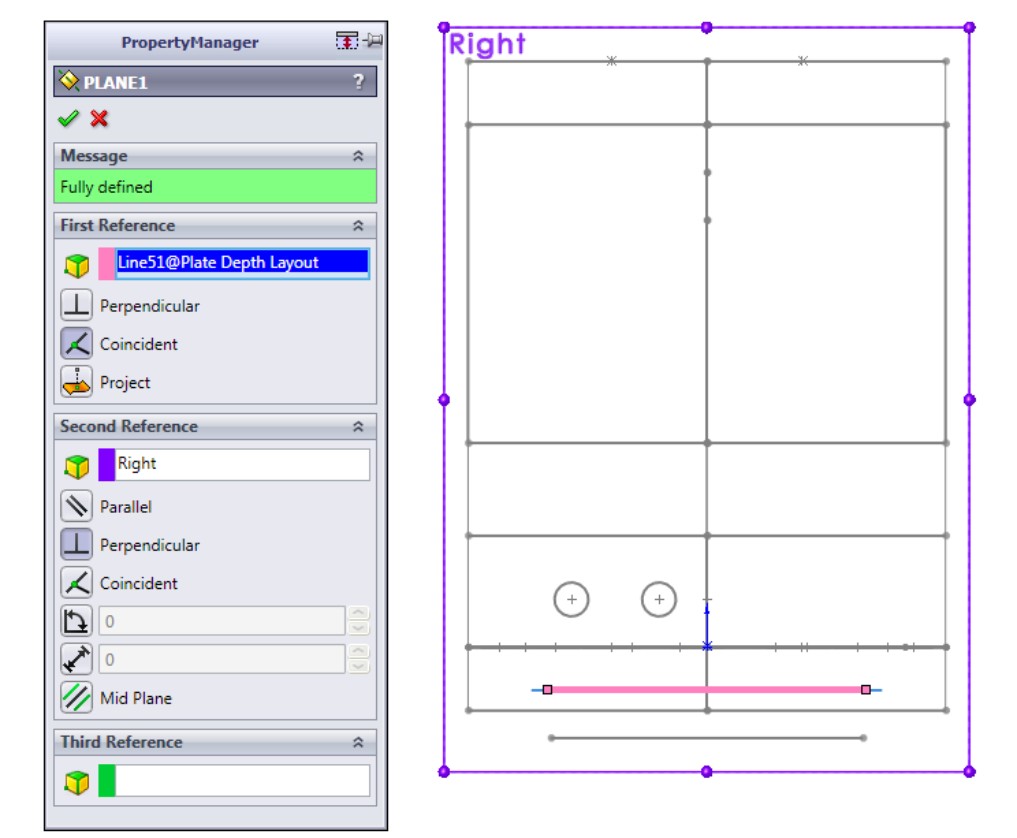

Creating planes in space

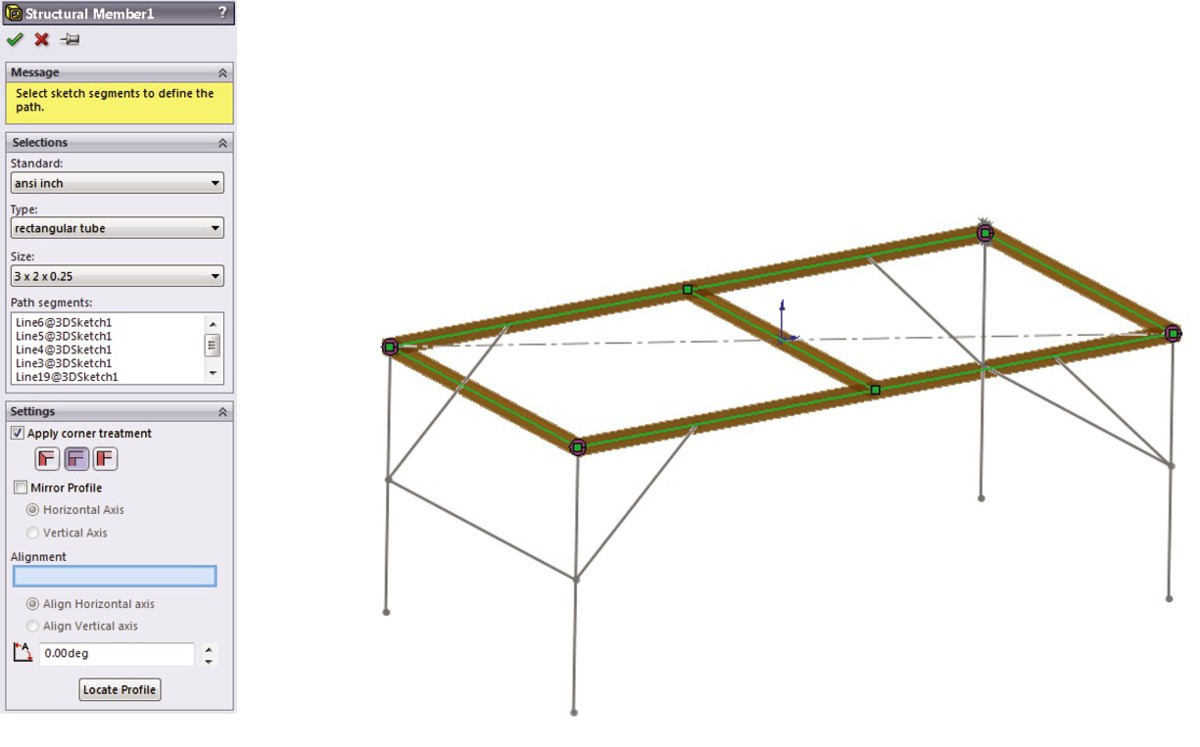

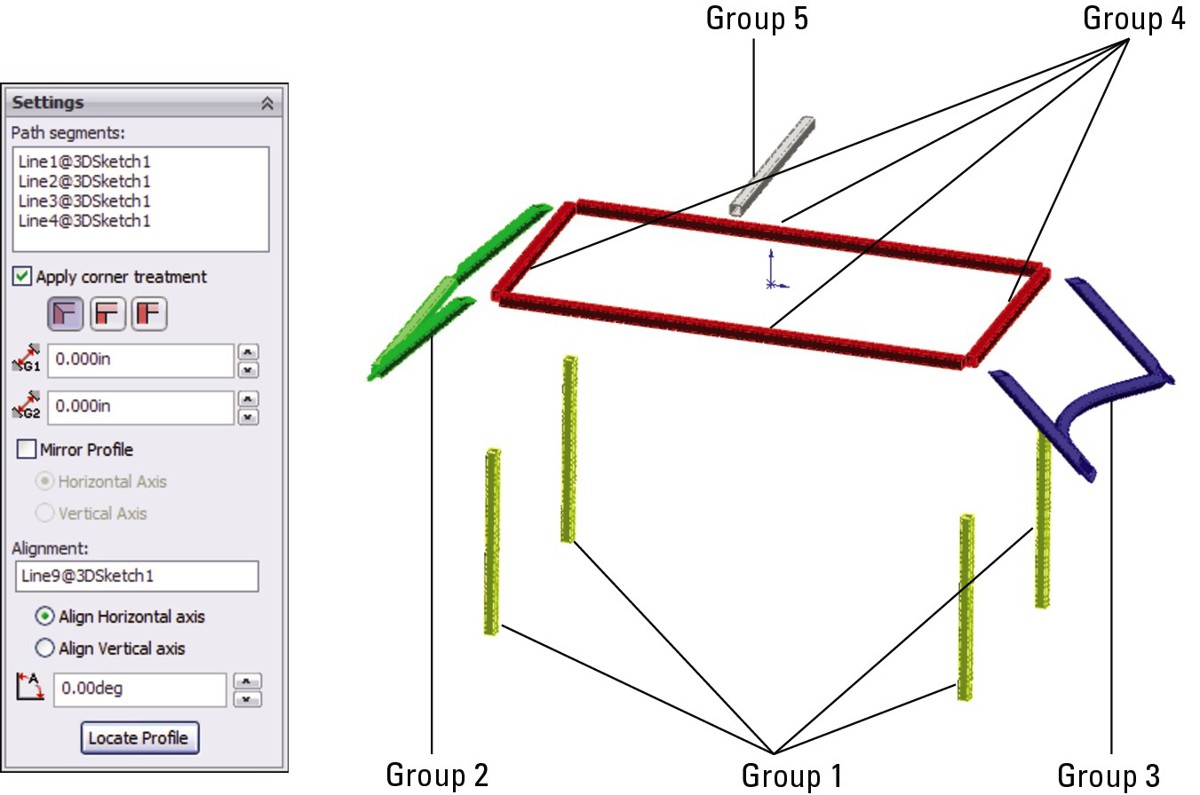

Limiting path segments

Using dimensions in 3D sketches

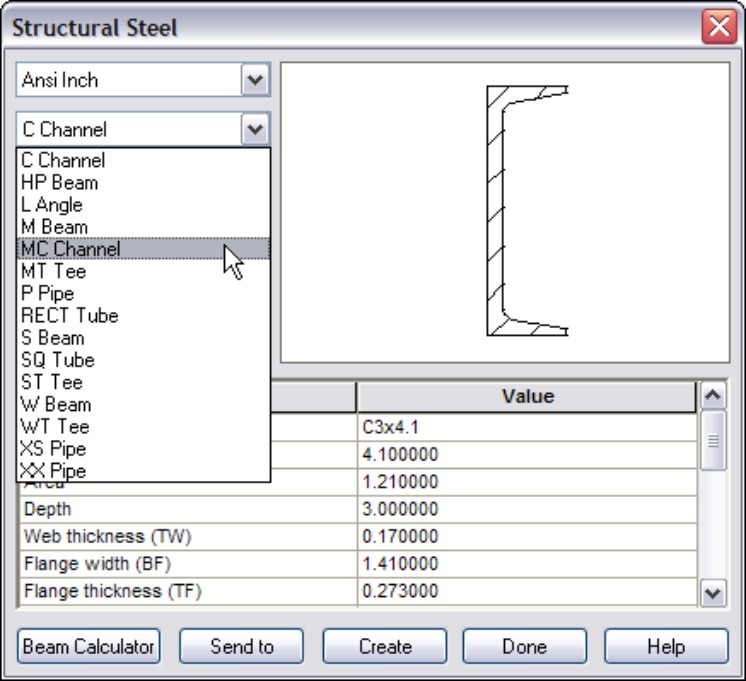

Using the Weldment Tools

Using the Weldment feature

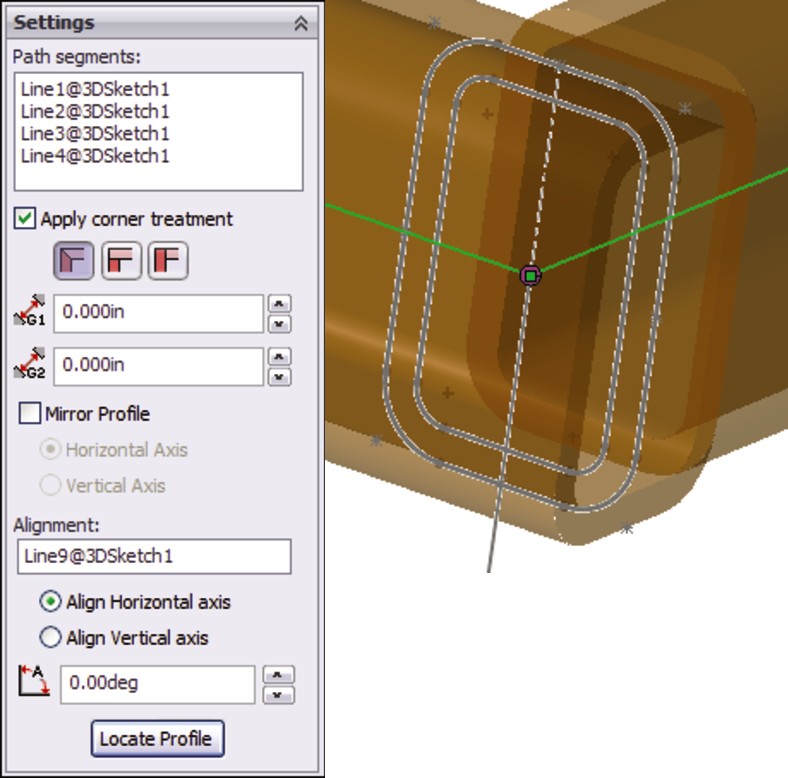

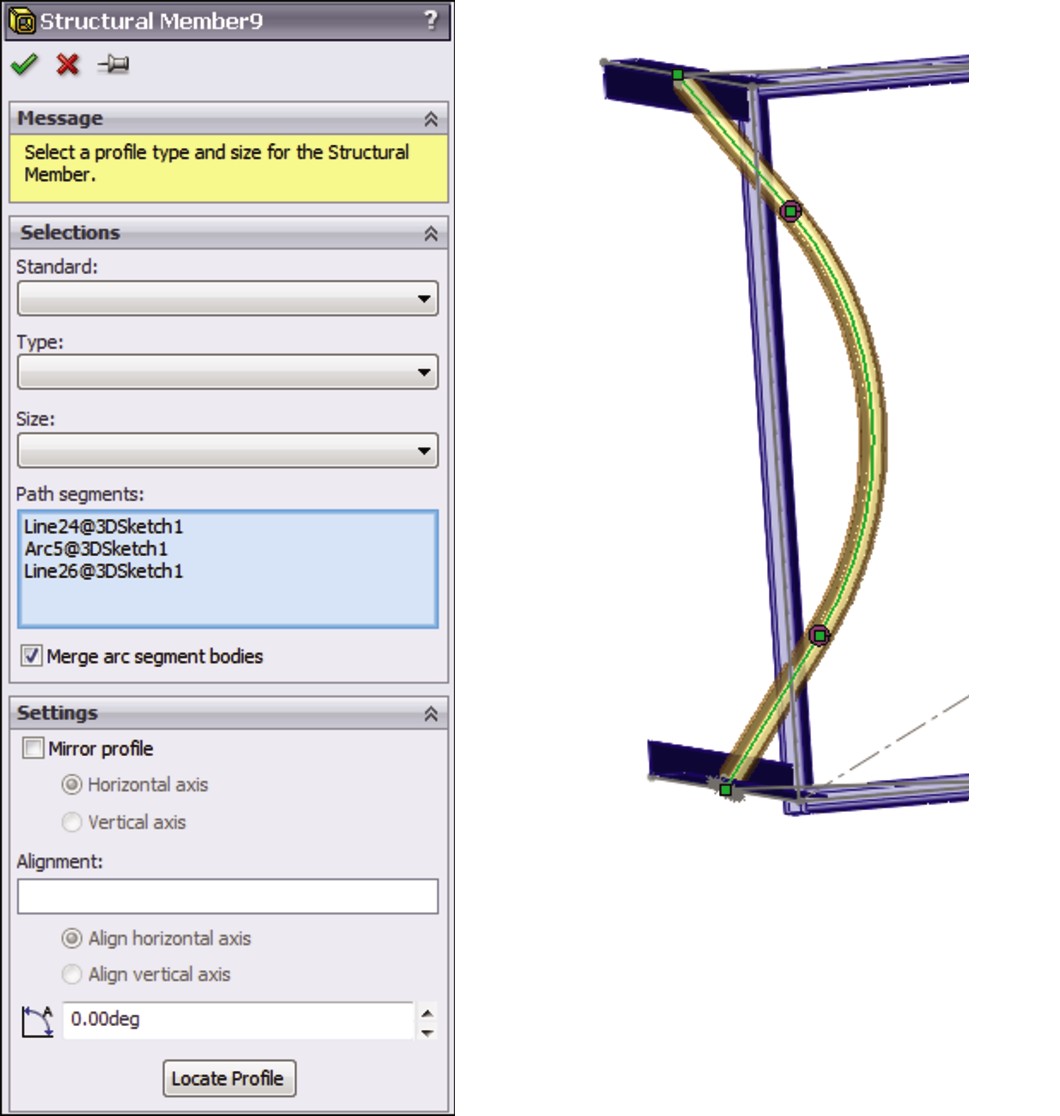

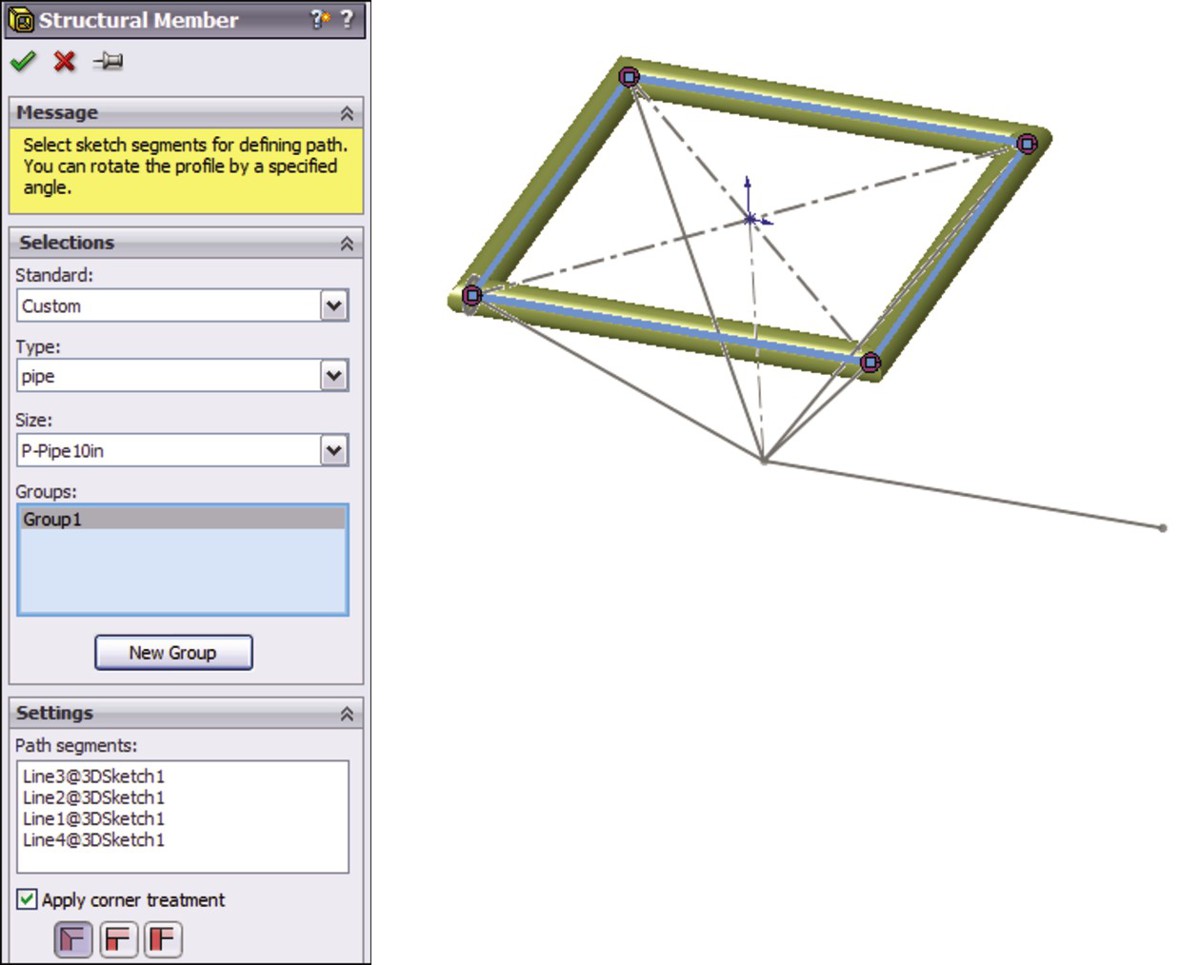

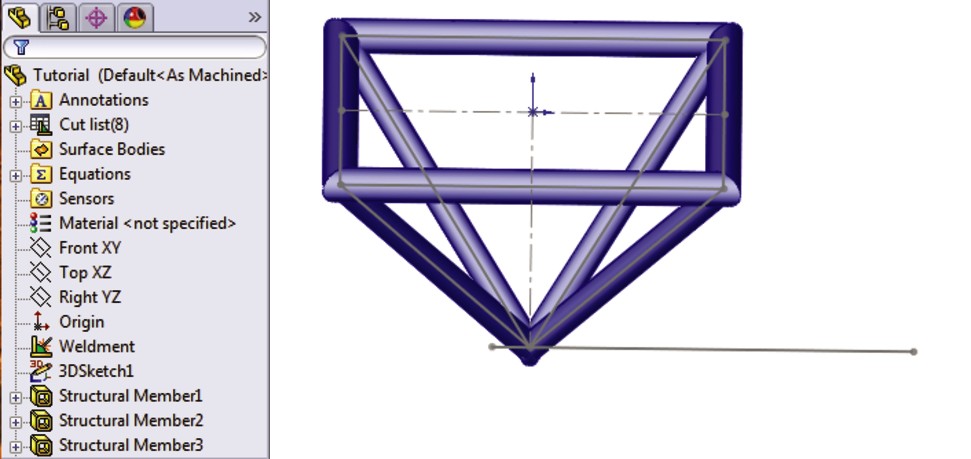

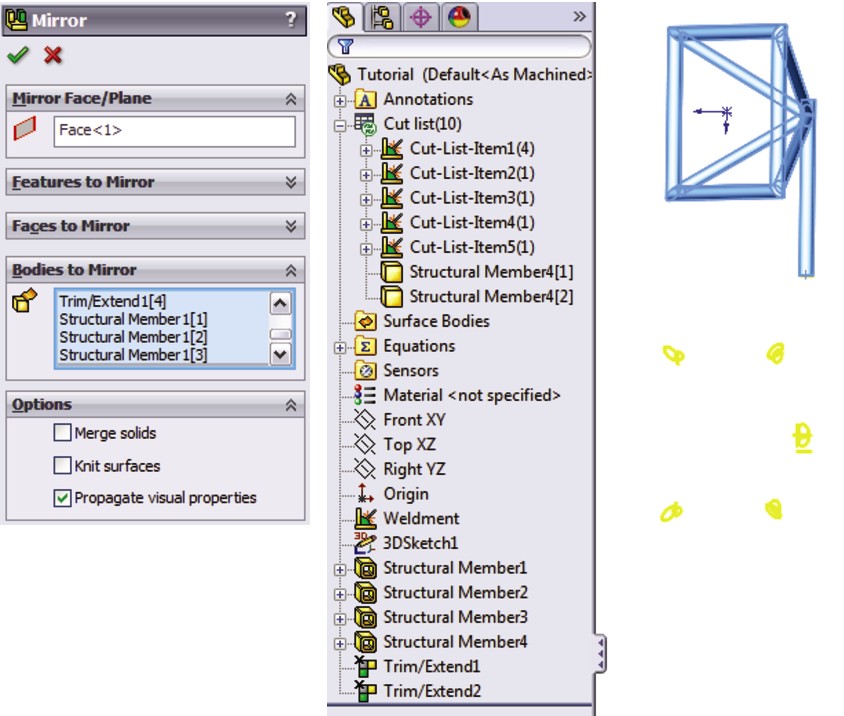

Introducing the Structural Member feature

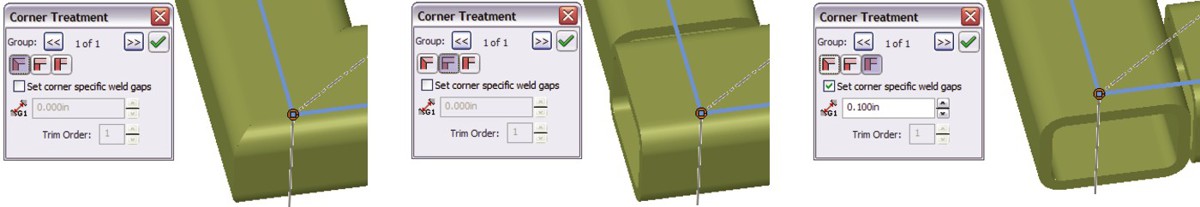

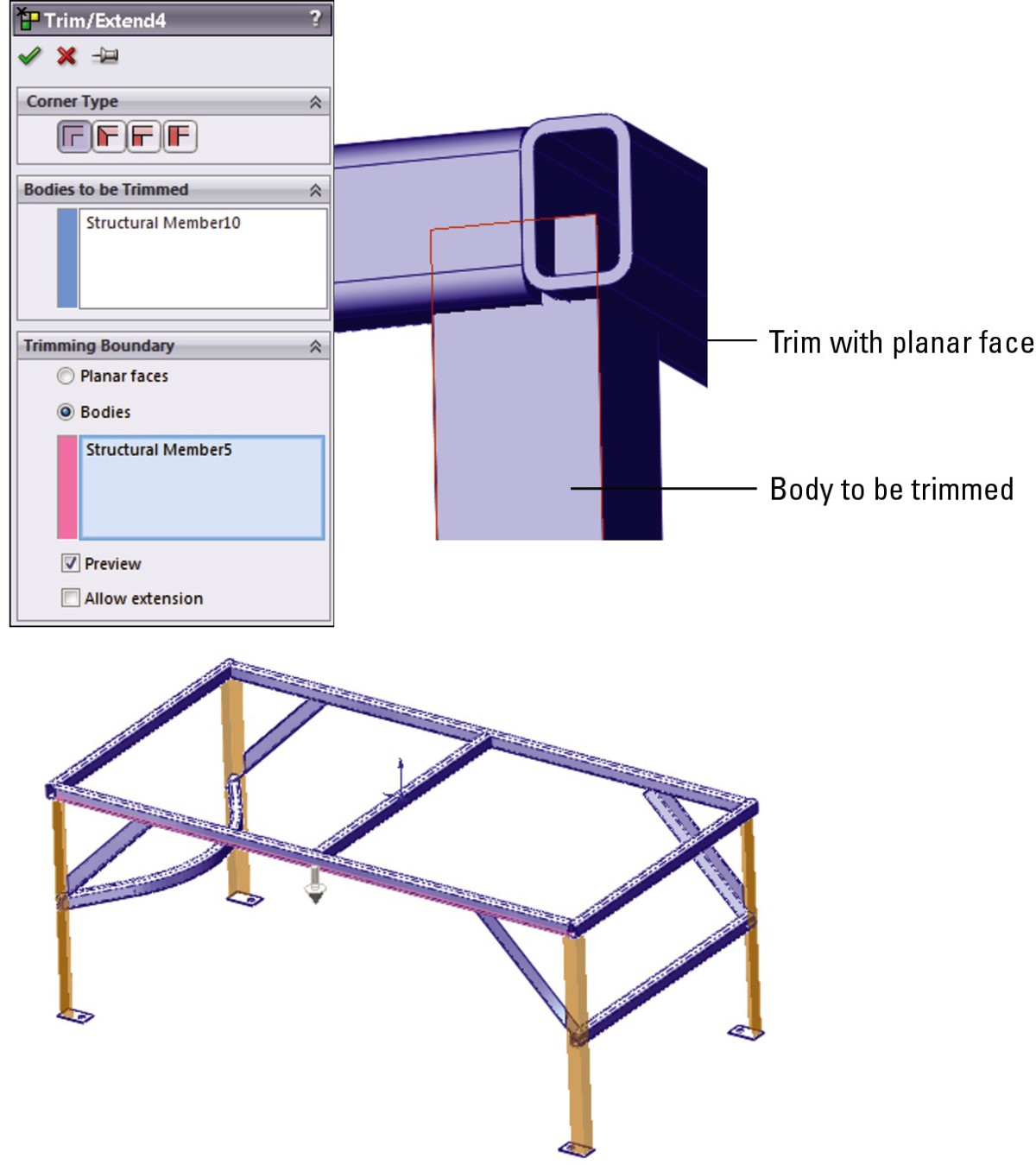

Using the Trim/Extend feature

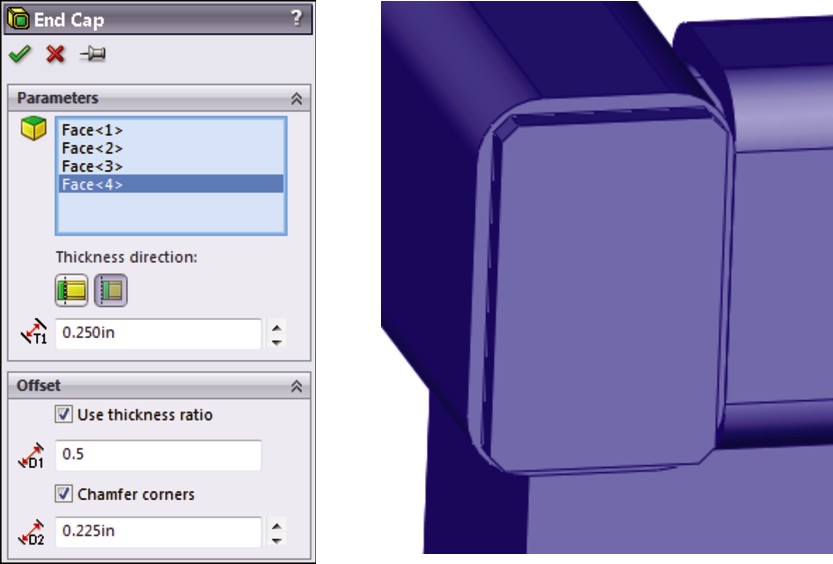

Using the End Cap feature

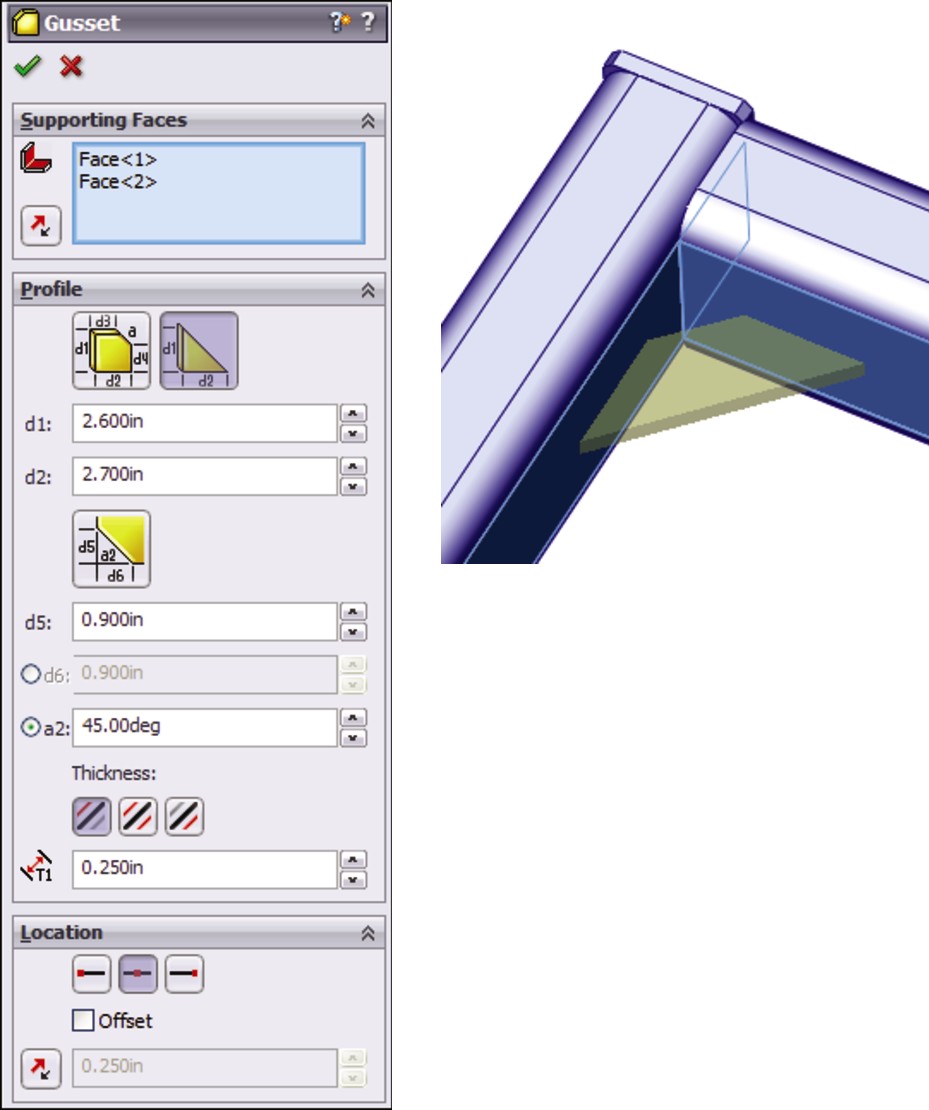

Working with the Gusset feature

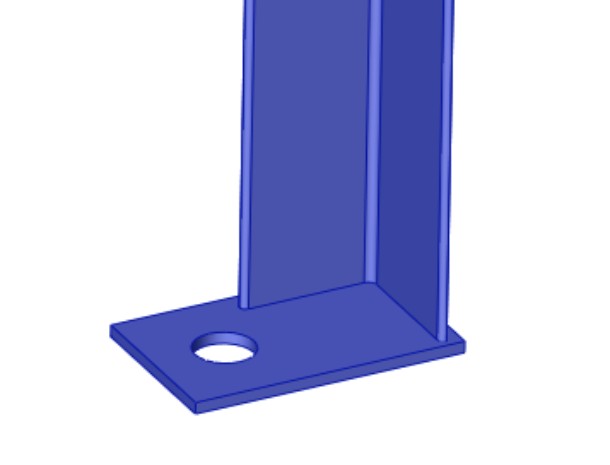

Using Non-Structural Components

Using Sub-Weldments

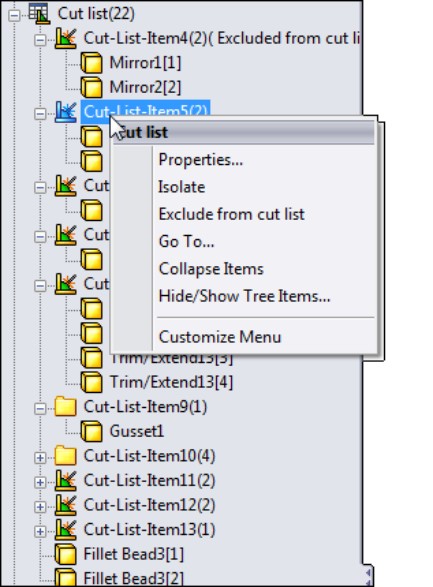

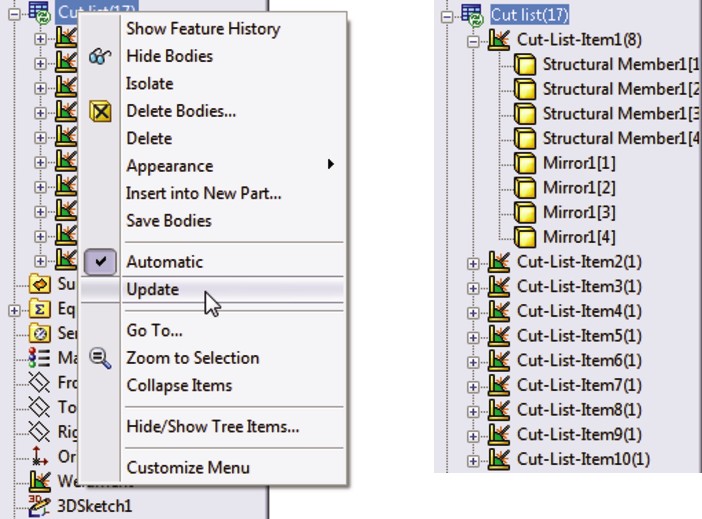

Working with Cut Lists

Using Cut-List Properties

Excluding and reordering cut list items

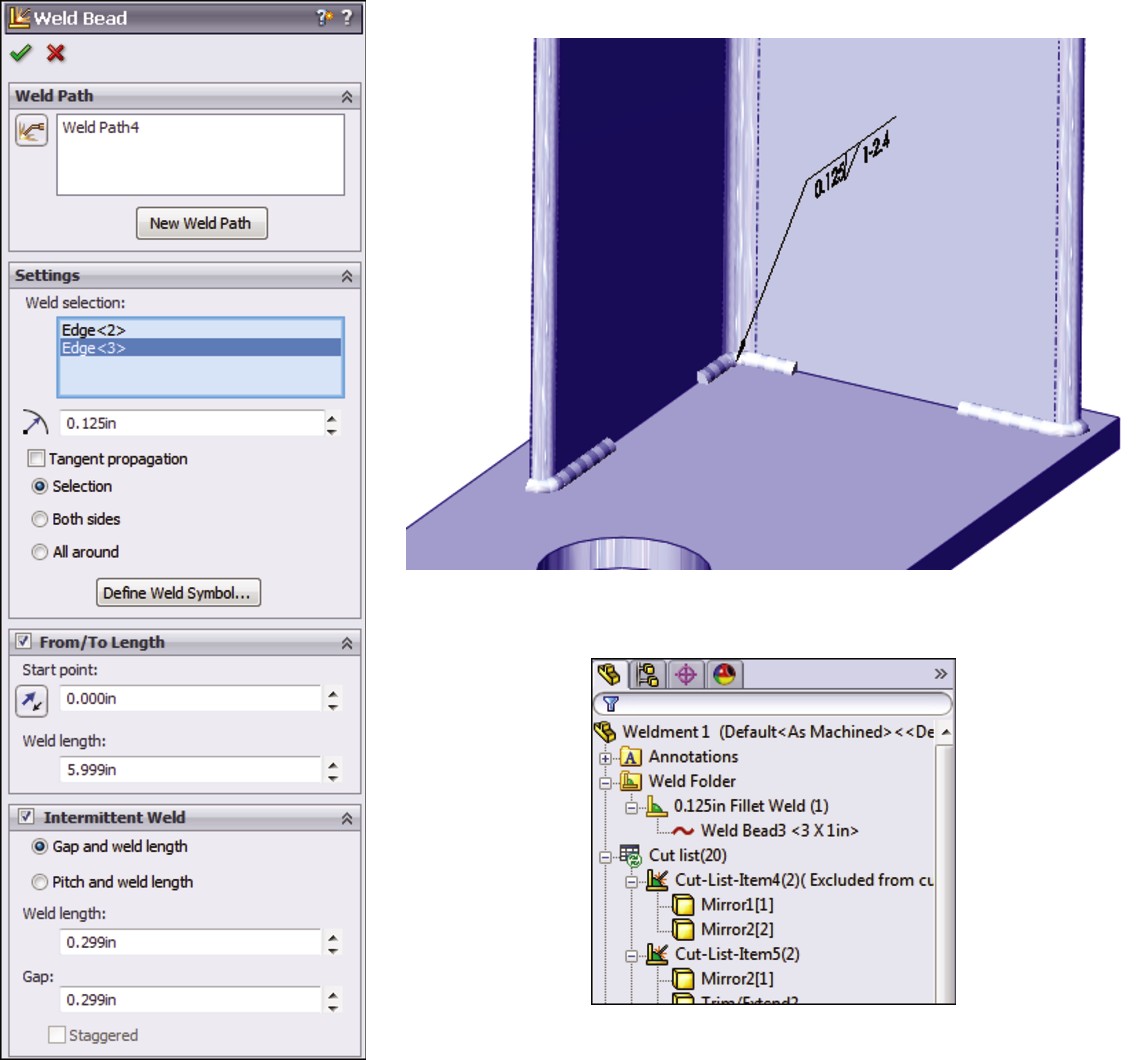

Using weld beads and fillet beads in weldments and assemblies

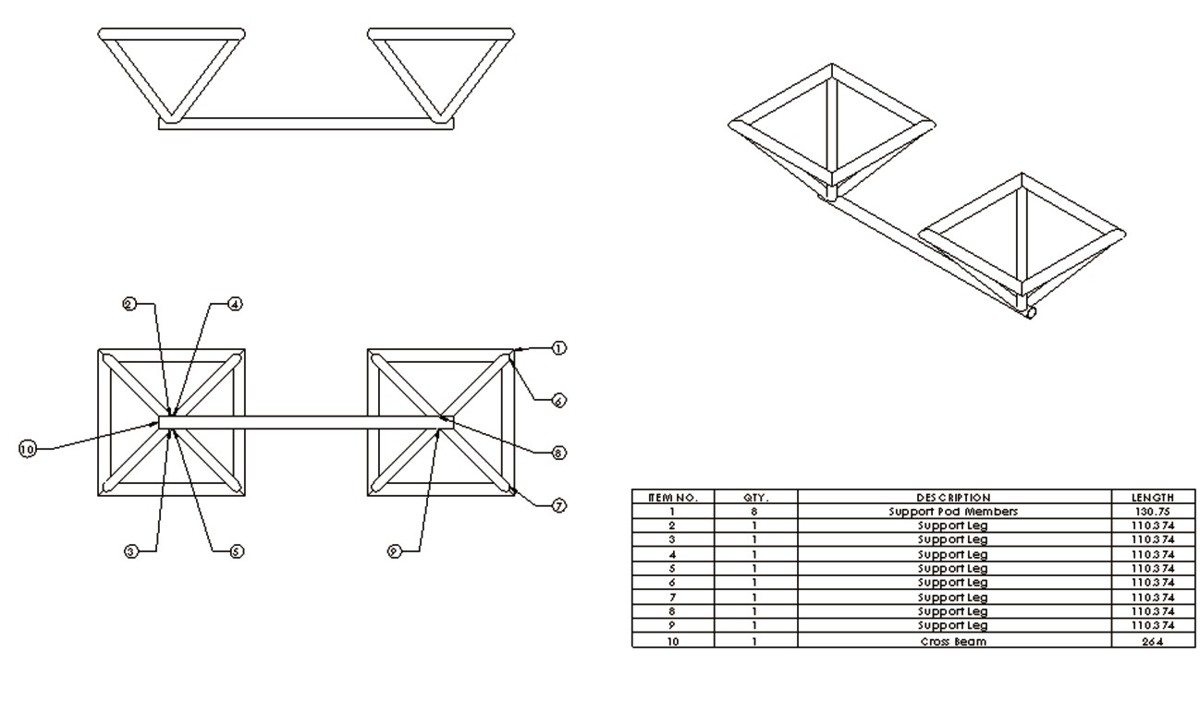

Creating Weldment Drawings

Tutorial: Working with Weldments

Summary

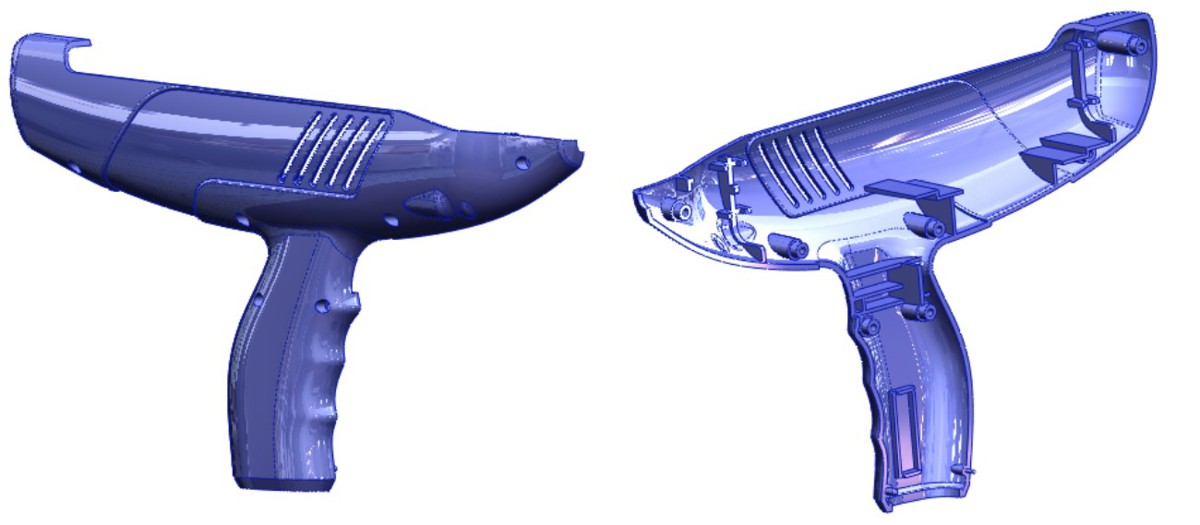

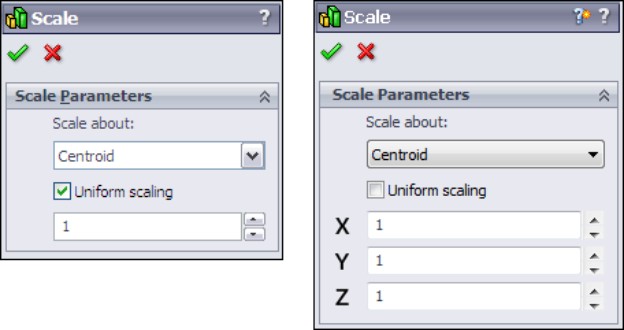

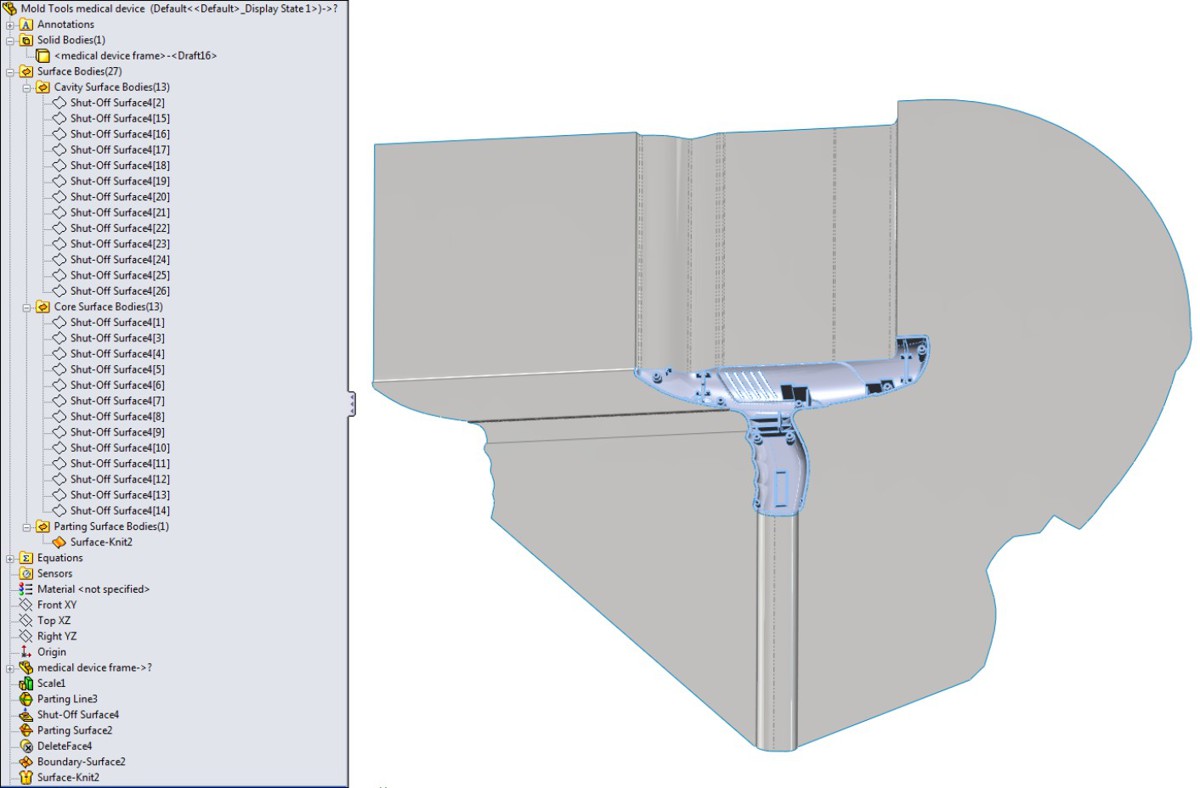

Chapter 21: Using Mold Tools

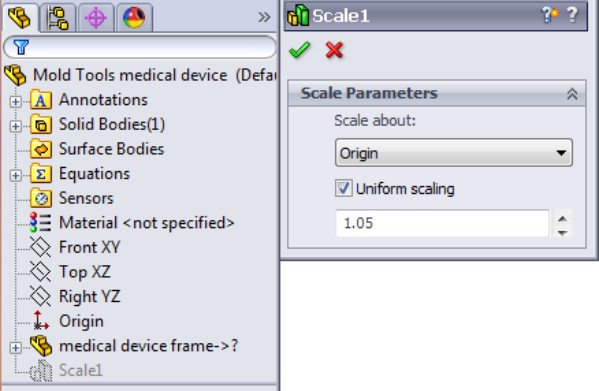

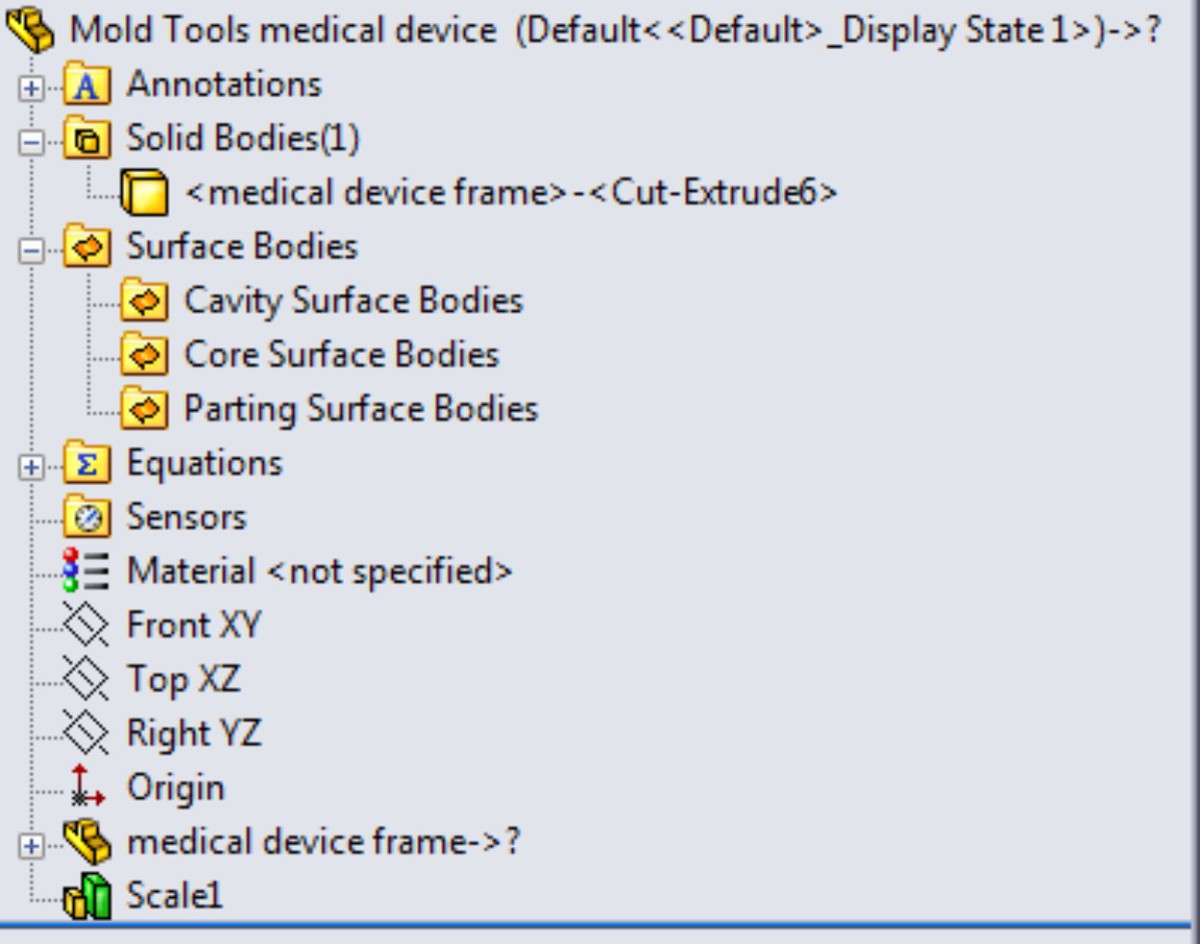

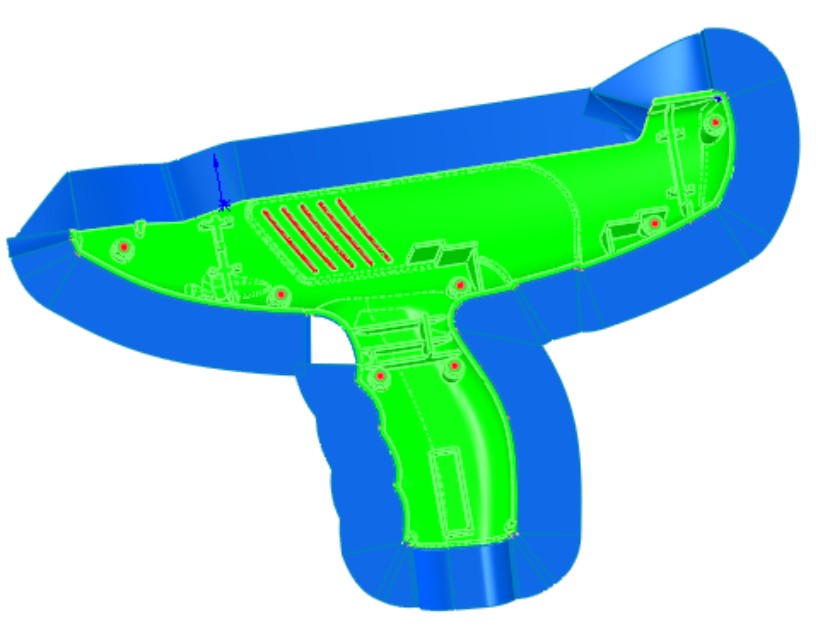

Working with the Mold Tools Process

Preparing the plastic part for Mold Tools

Inserting Mold folders

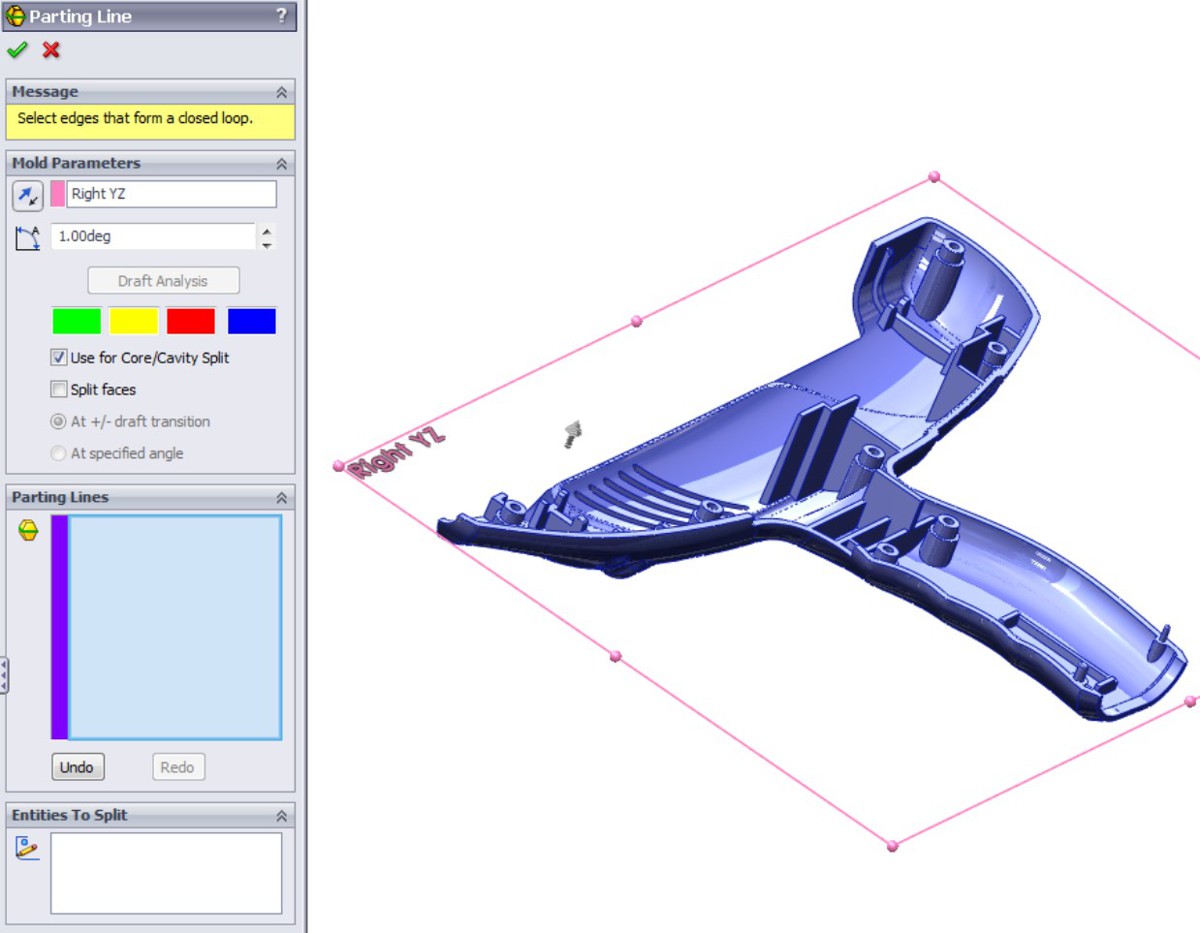

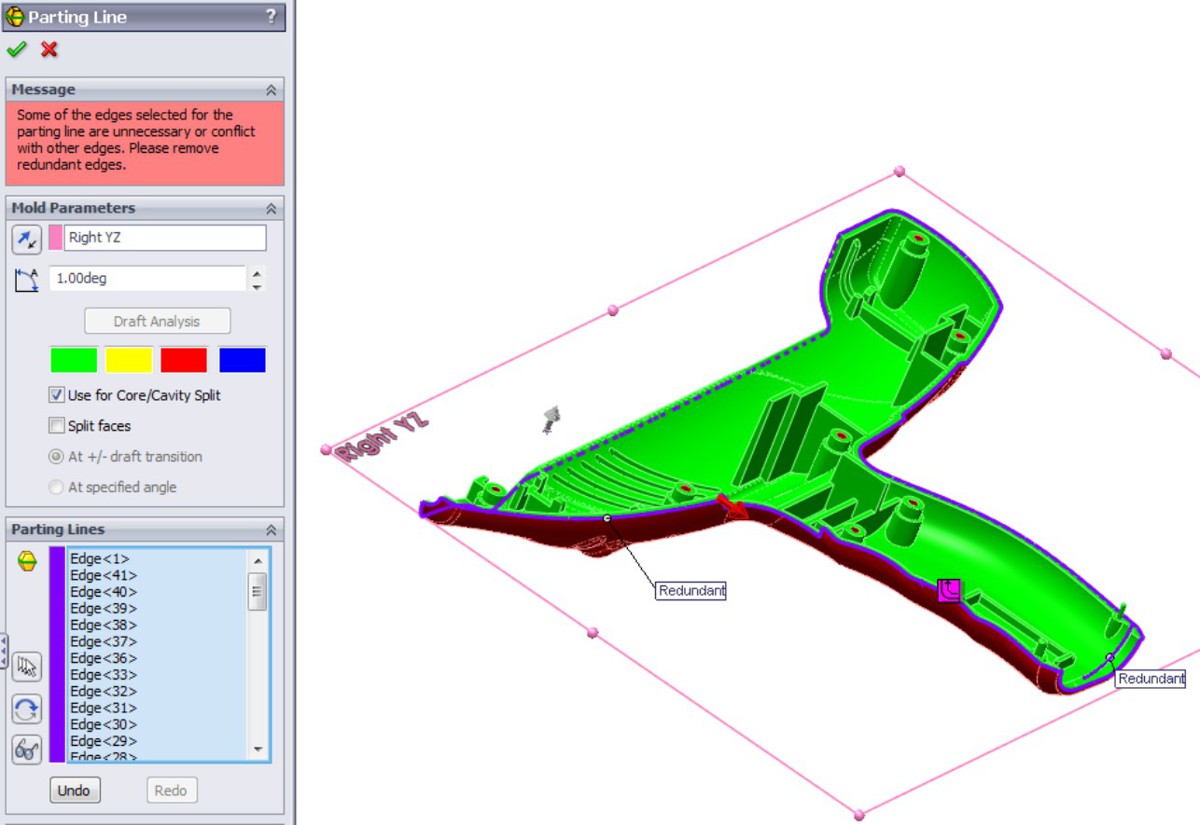

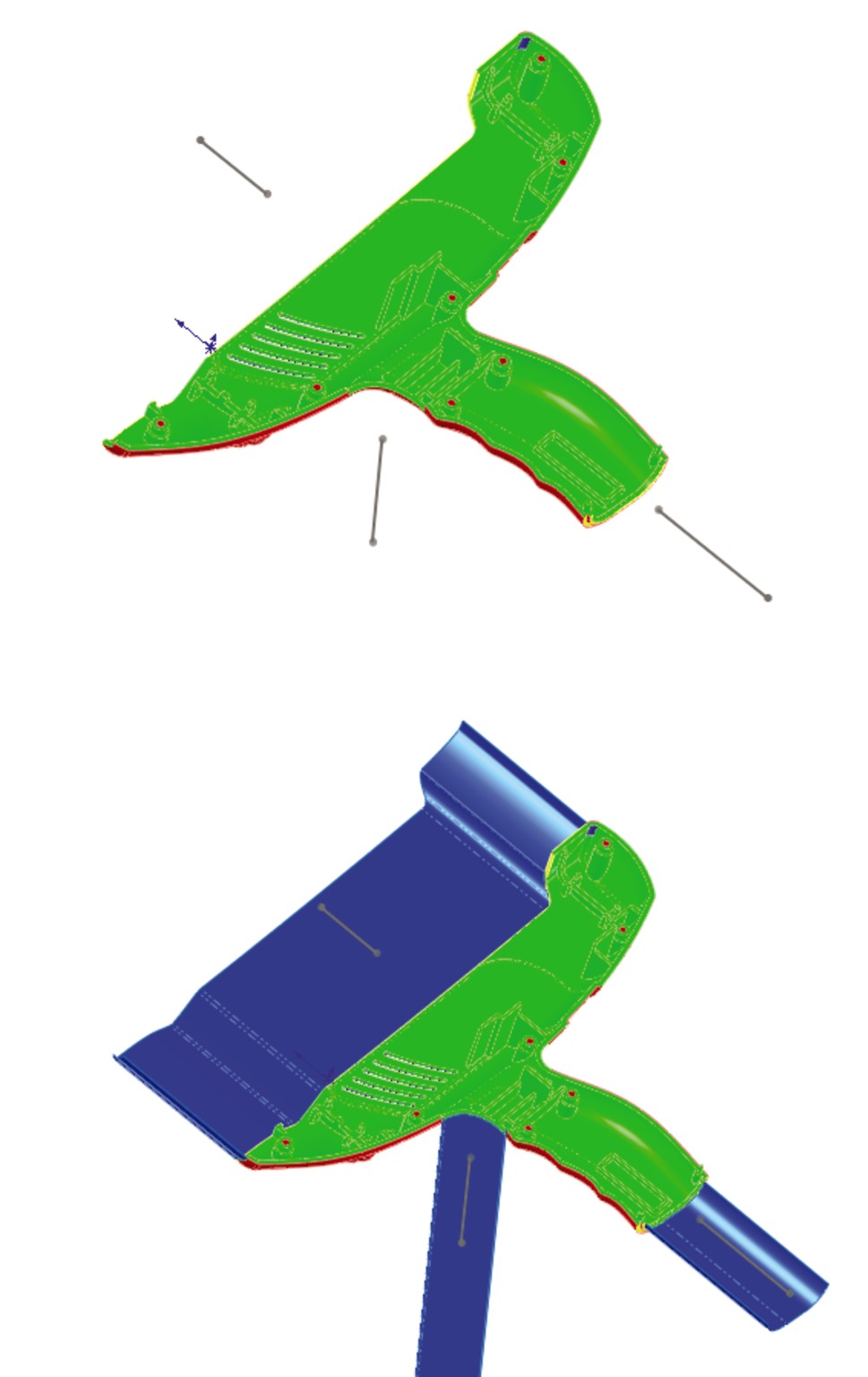

Parting lines

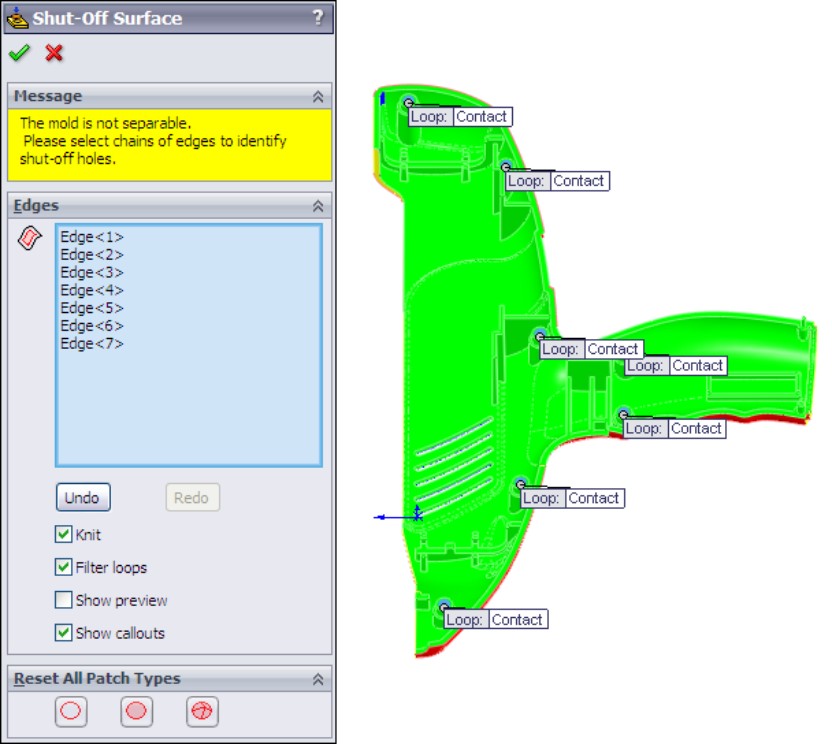

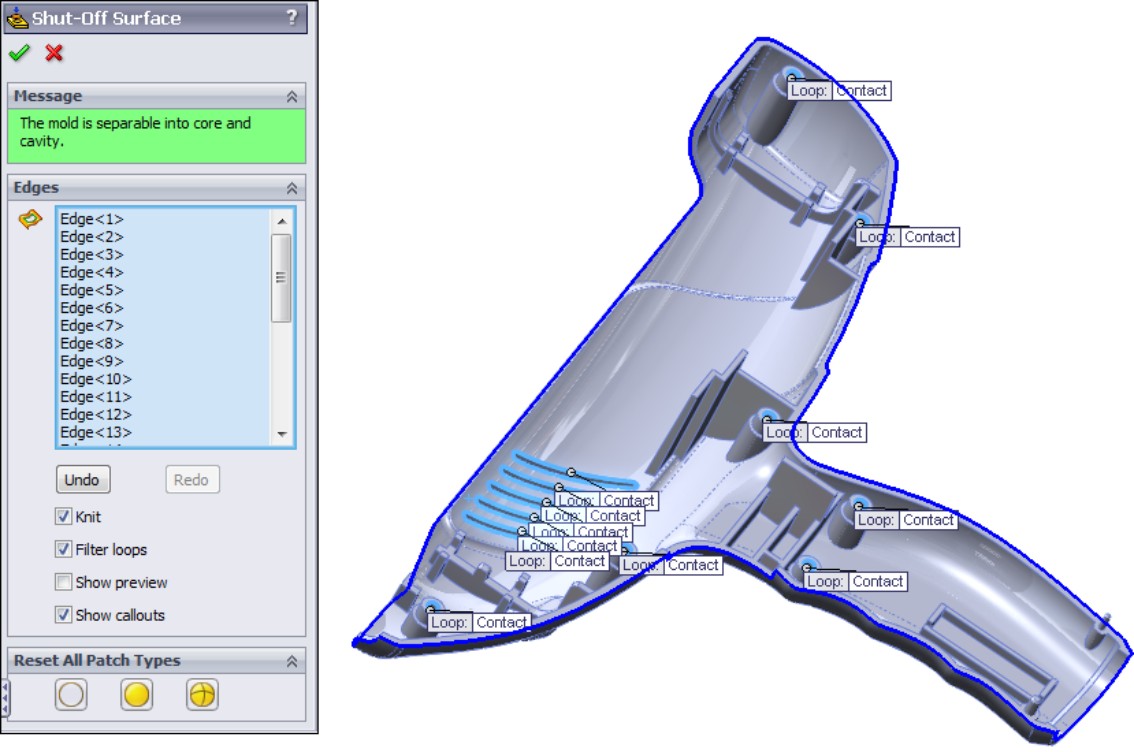

Initiating the shut-off surfaces

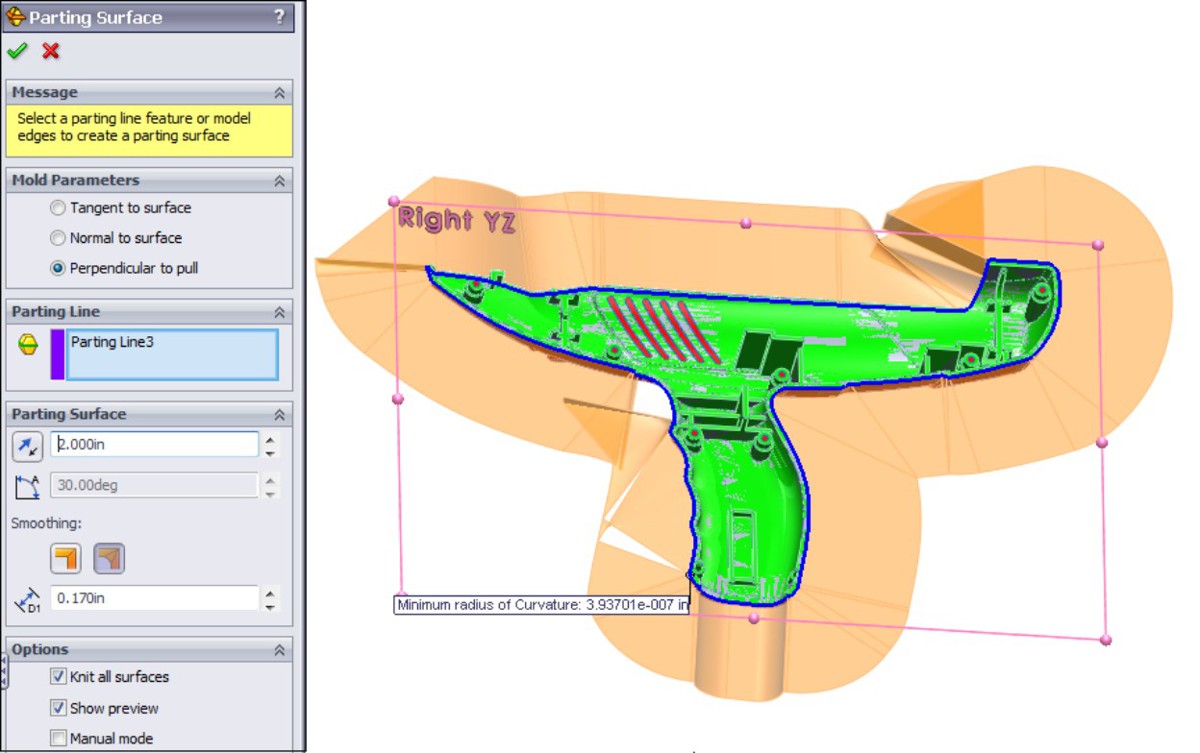

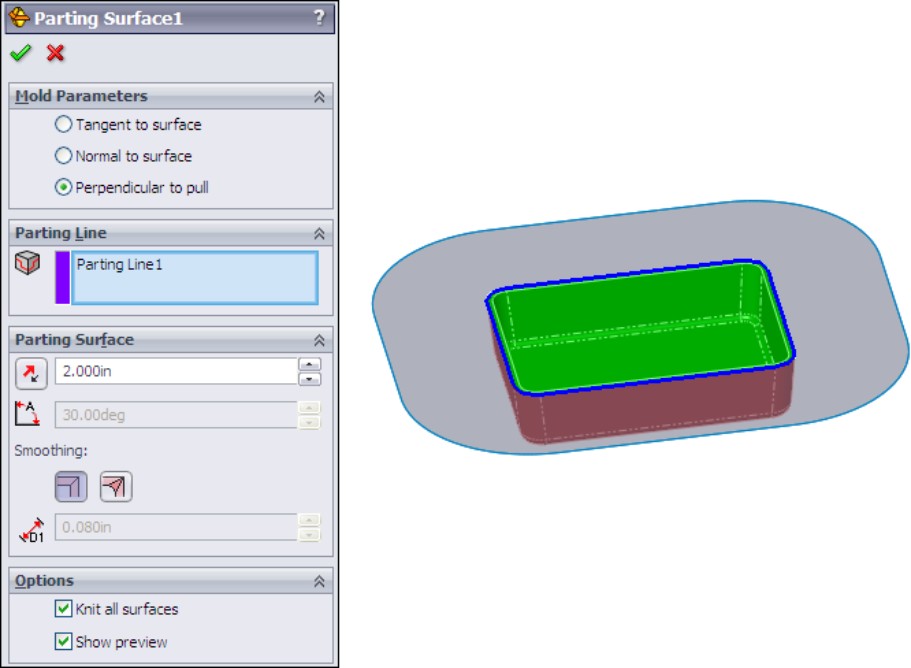

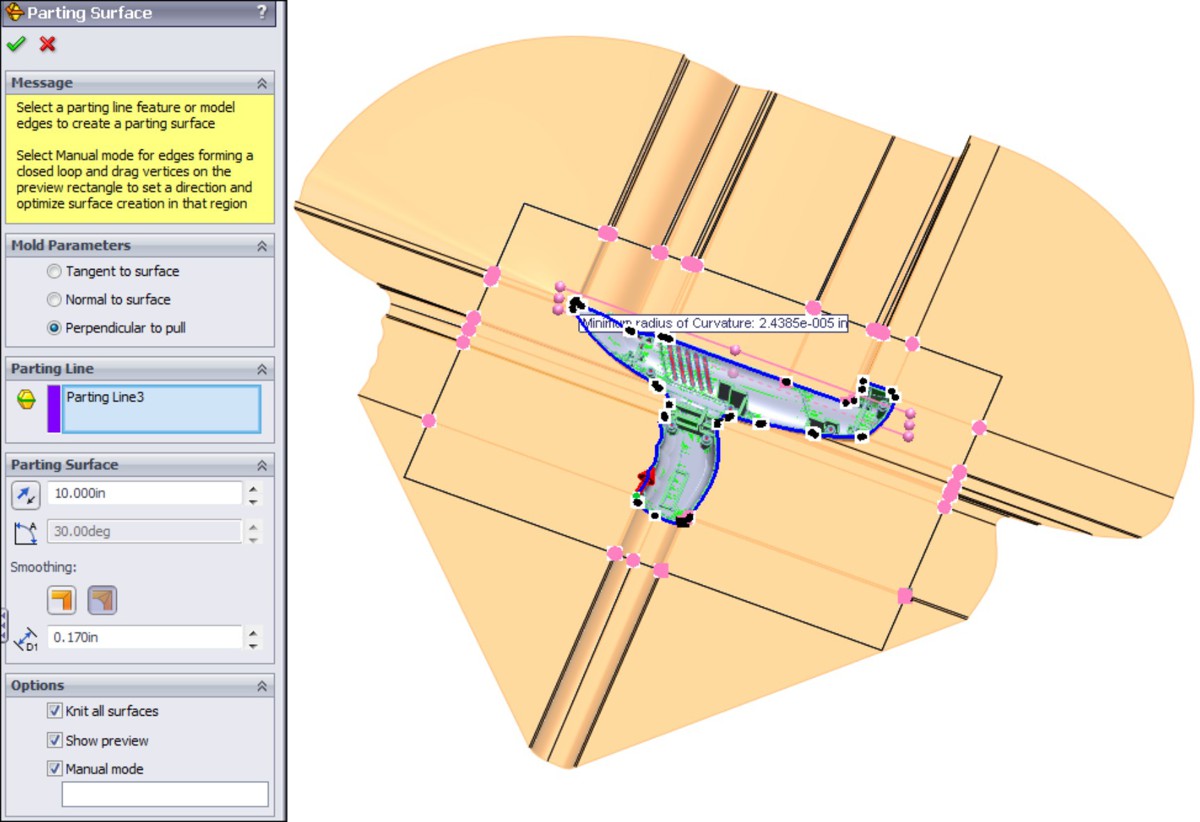

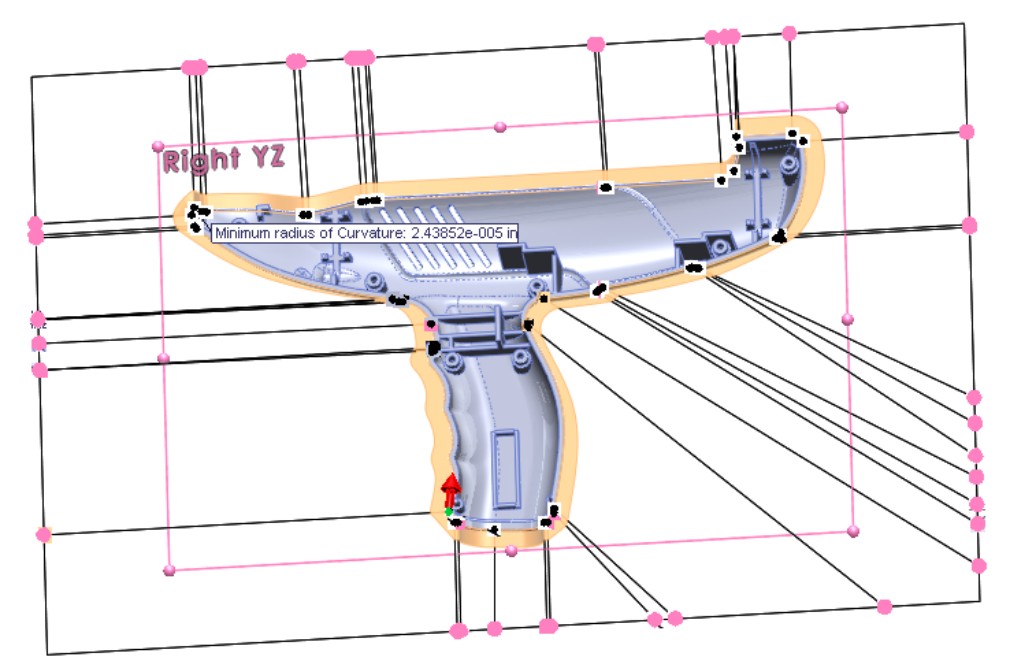

Parting surface

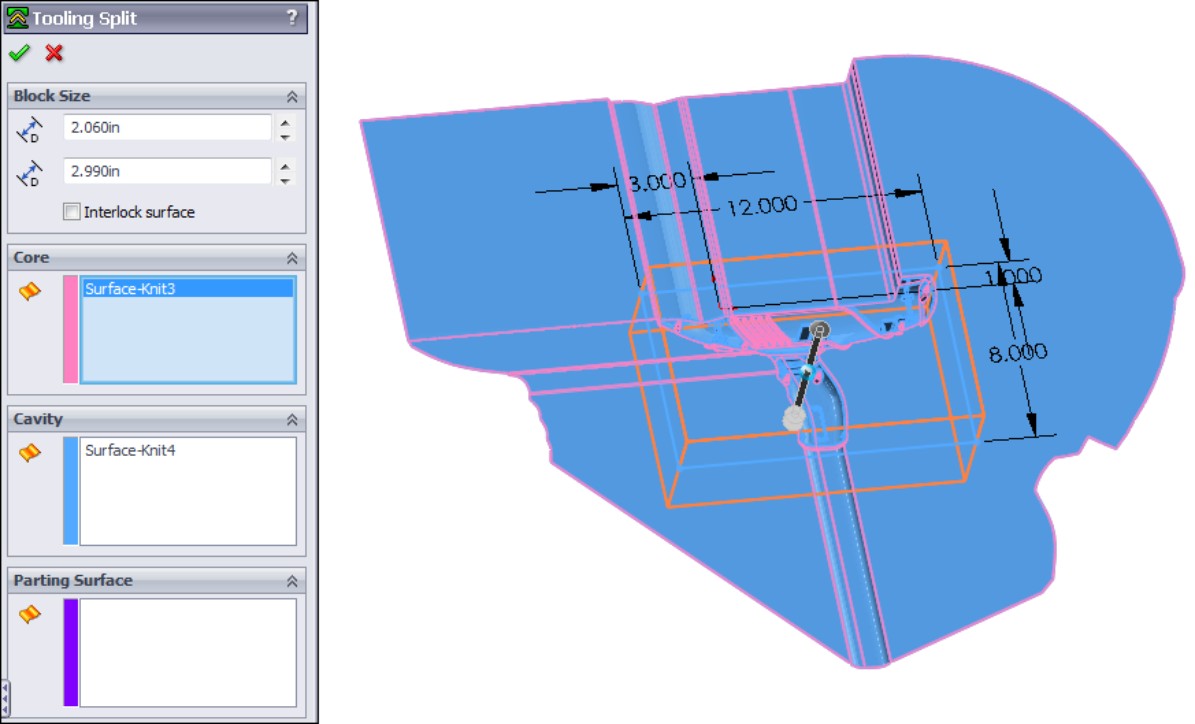

Tooling split

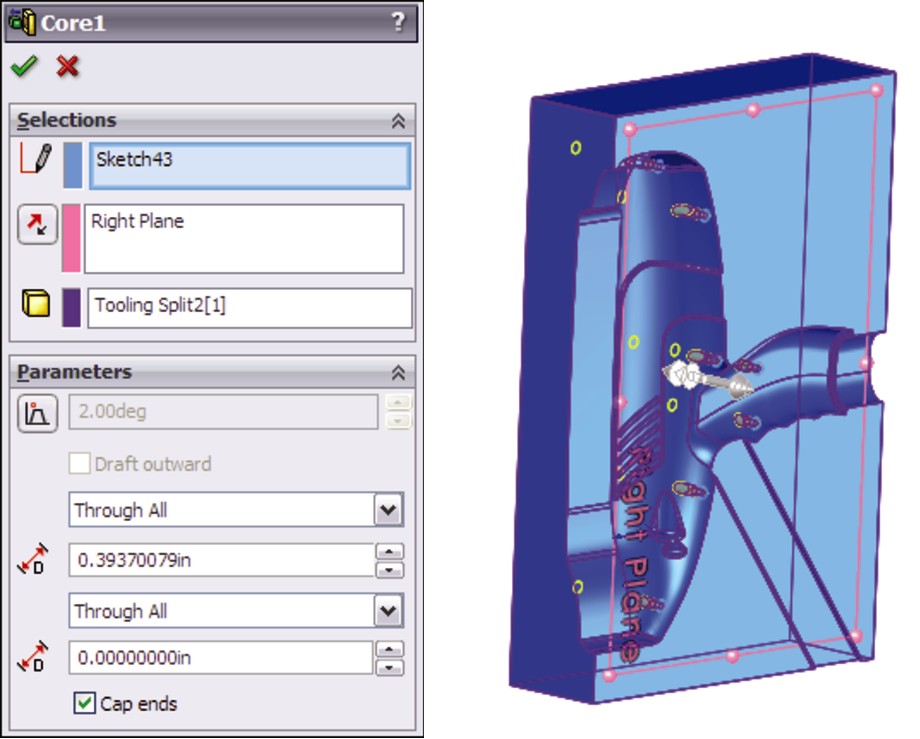

Using the Core feature

Intervening Manually with Mold Tools

Passing shut-offs

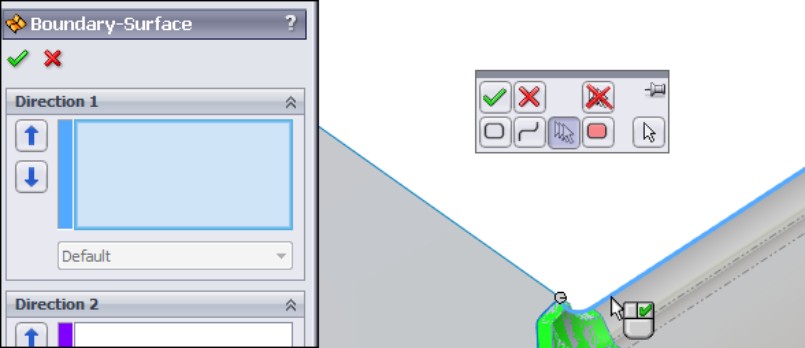

Creating non-planar parting surfaces

Summary

Chapter 22: Working with Large Scale Design

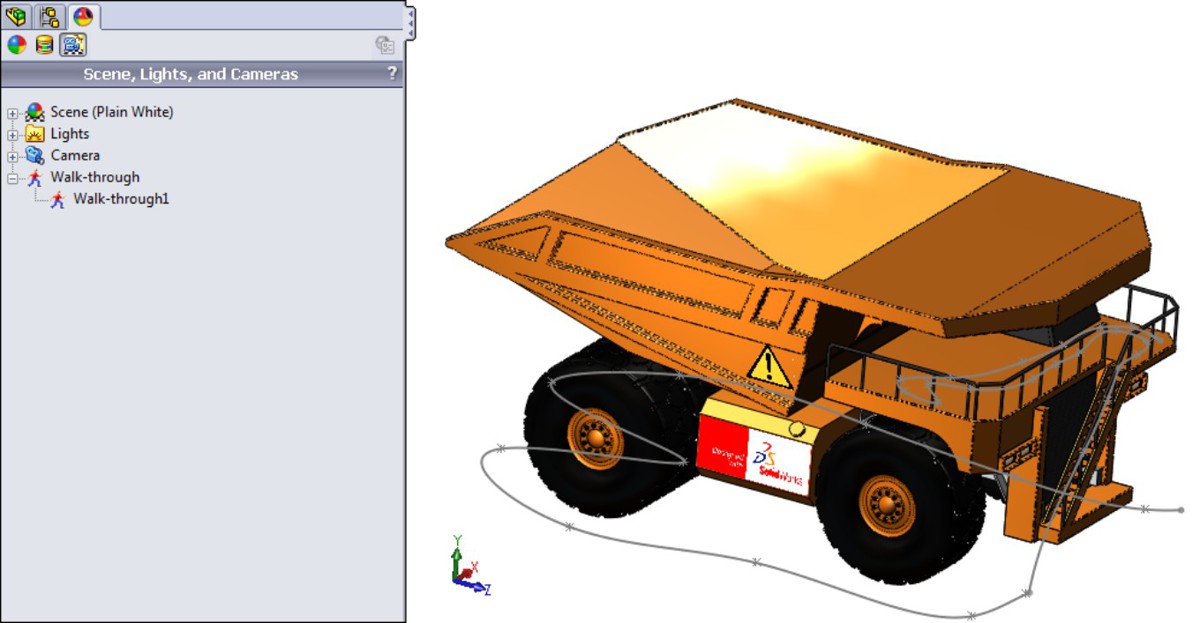

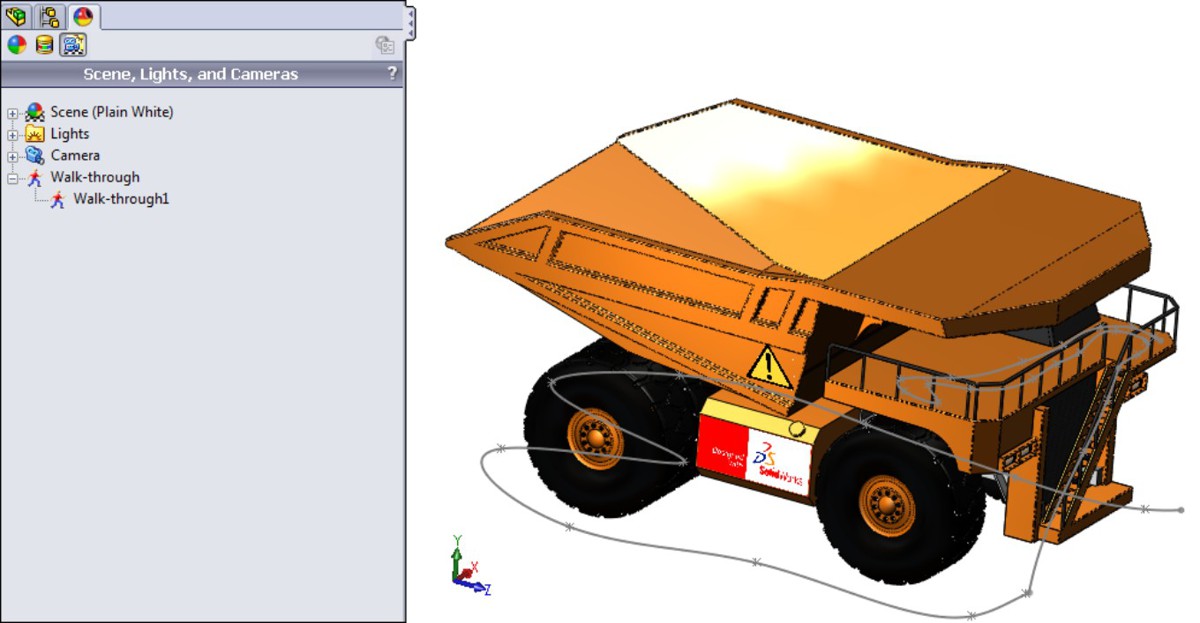

Creating a Walk-Through

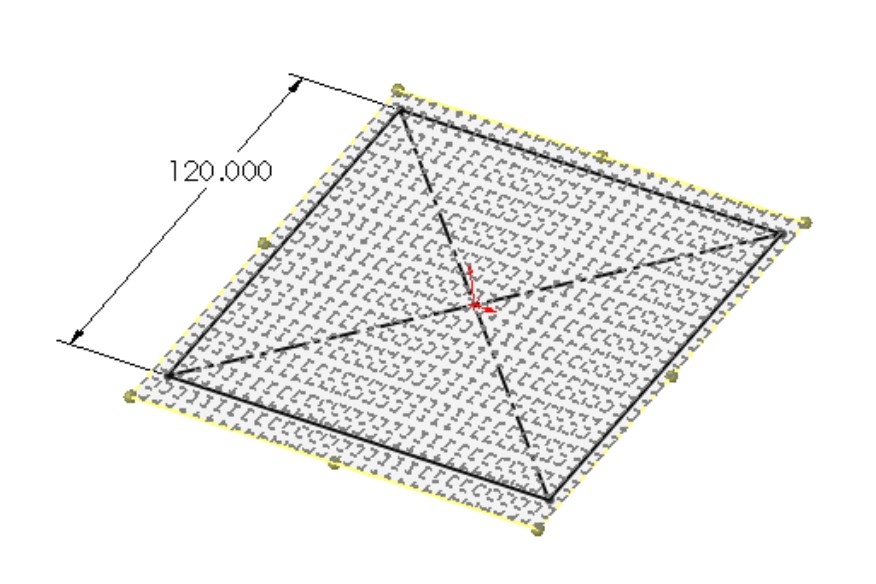

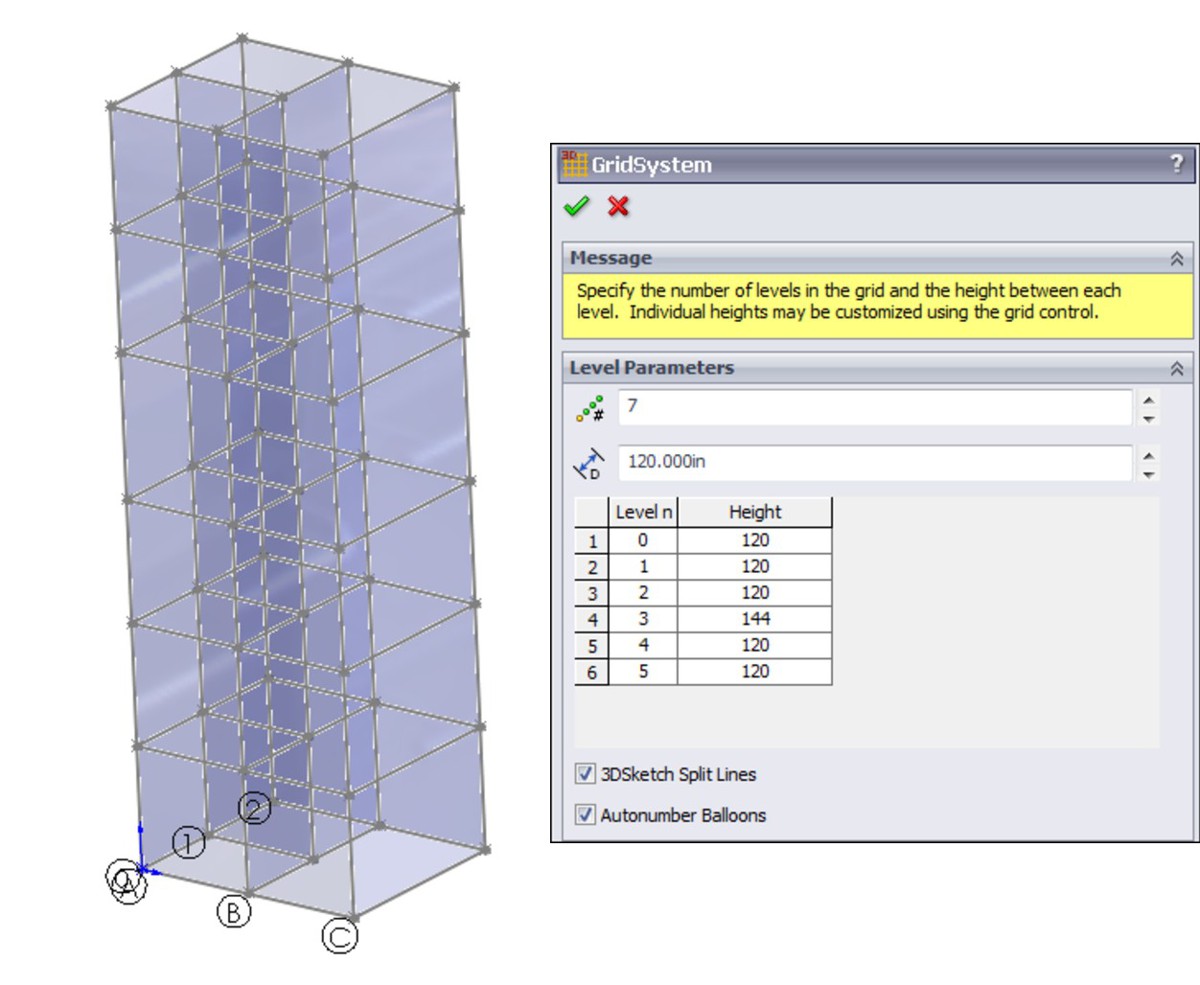

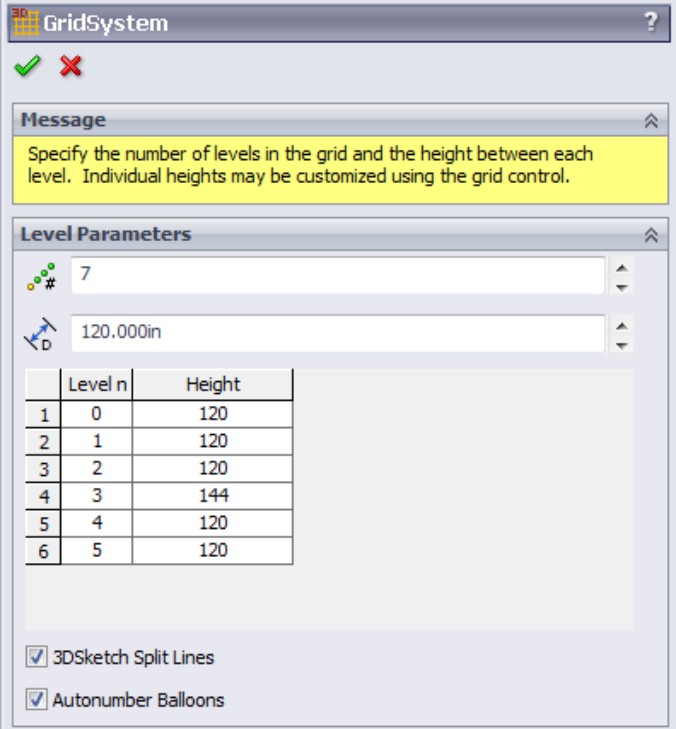

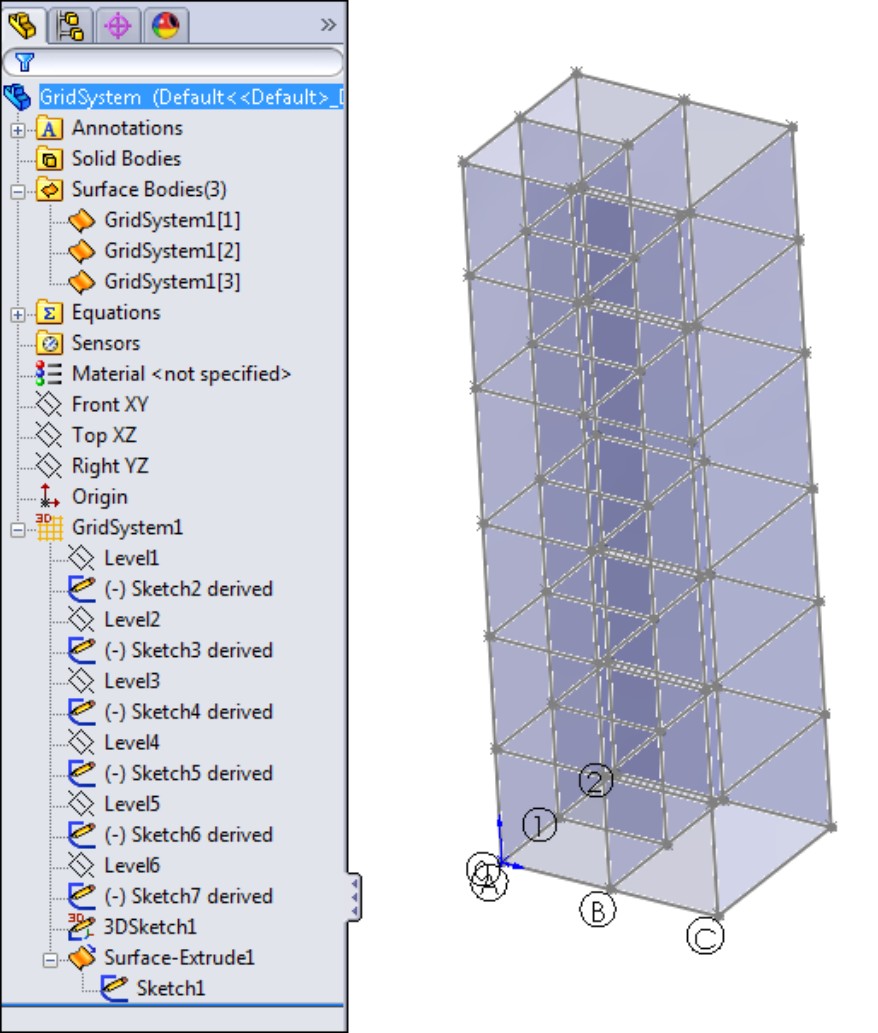

Creating a GridSystem

Starting the GridSystem feature

Creating the sketch

Using the GridSystem PropertyManager

Understanding the GridSystem output

Viewing the Grid Components

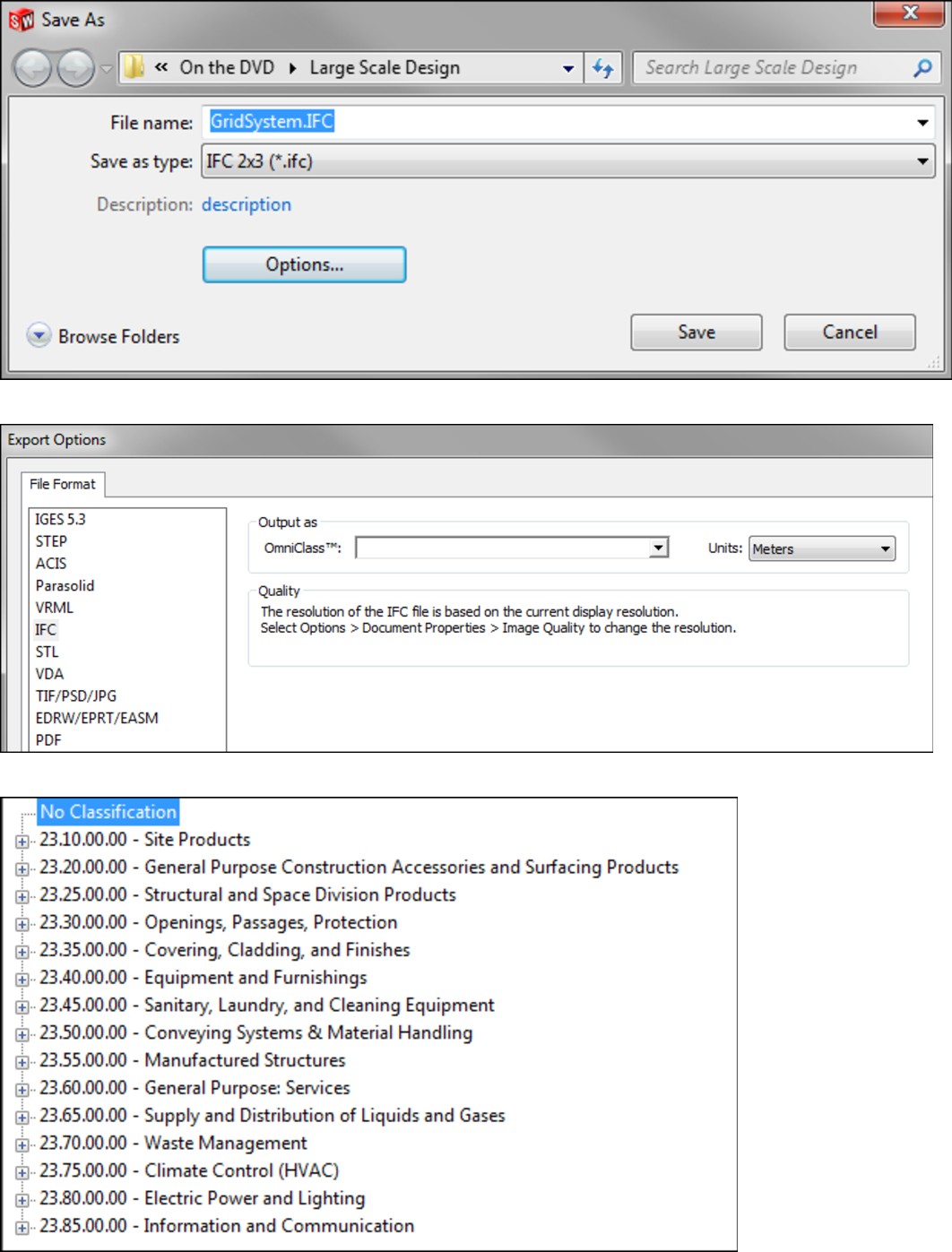

Transferring Data with the IFC File Type

Summary

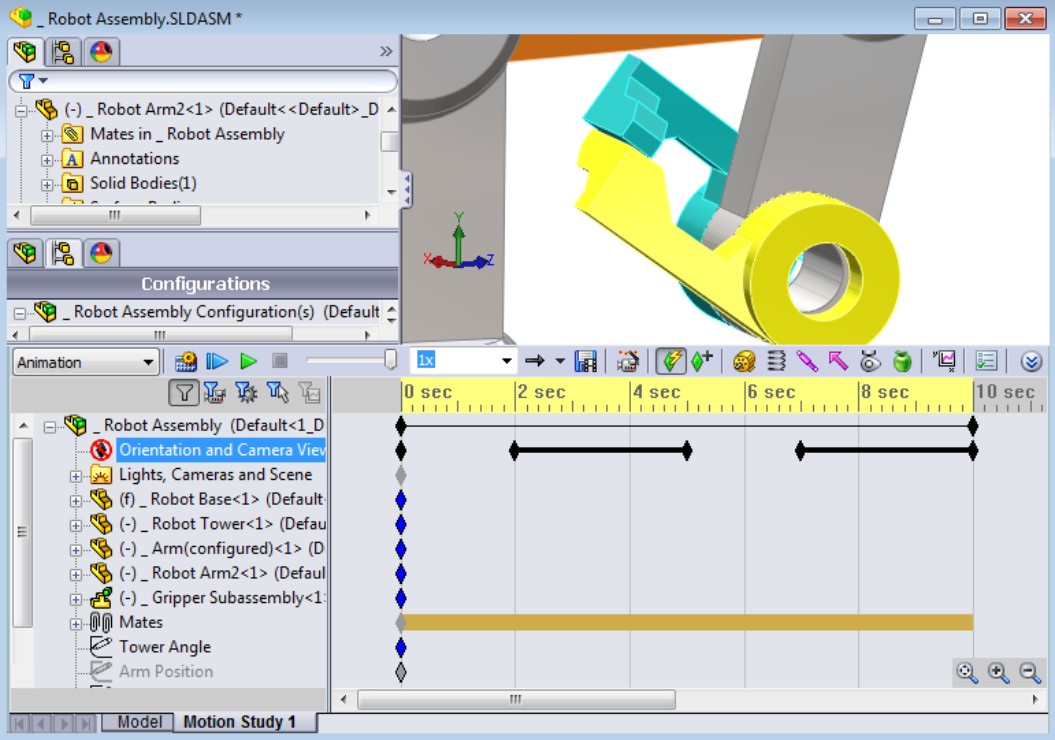

Chapter 23: Animating with the MotionManager

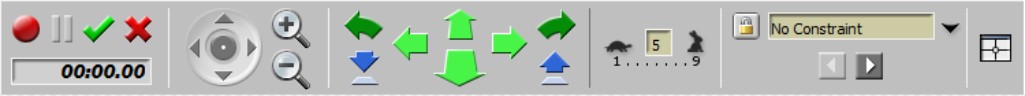

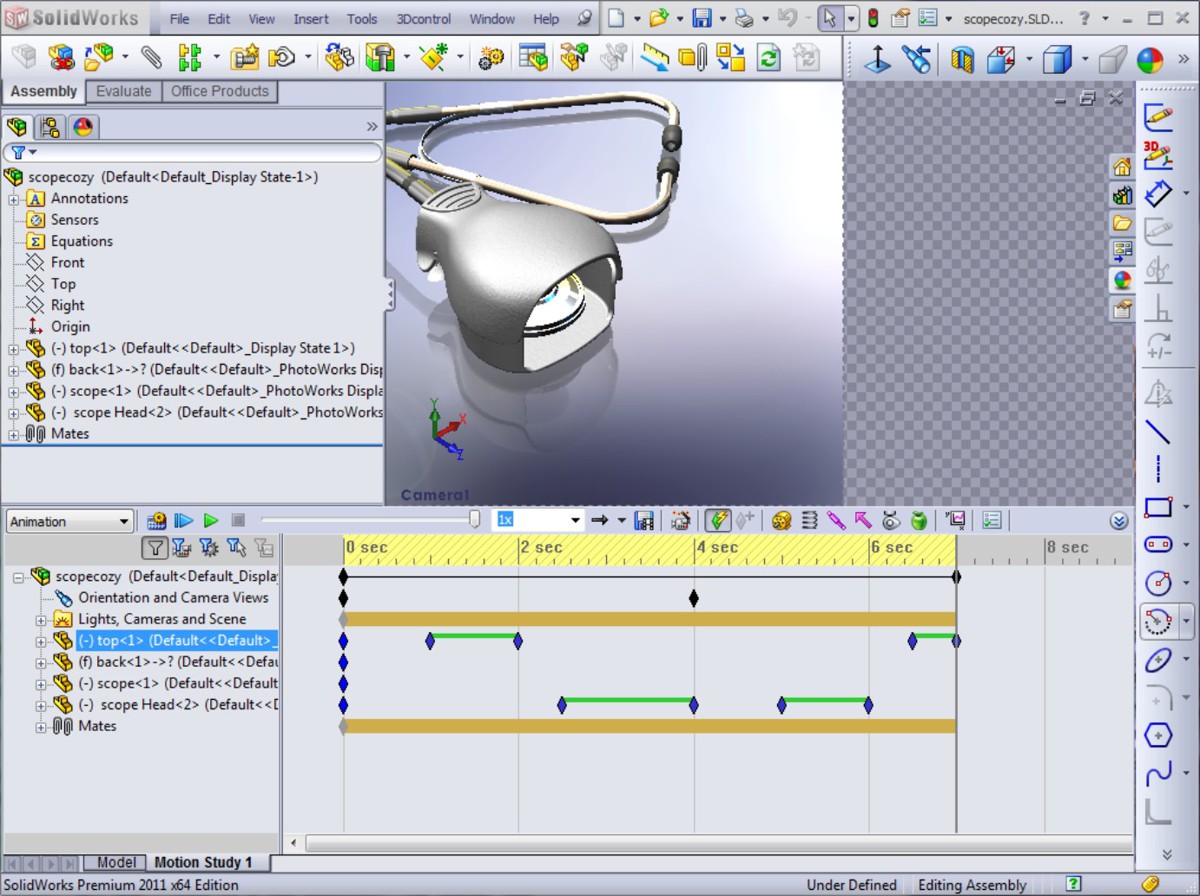

Familiarizing Yourself with the MotionManager

Understanding the terminology

Driving an animation

Planning an animation

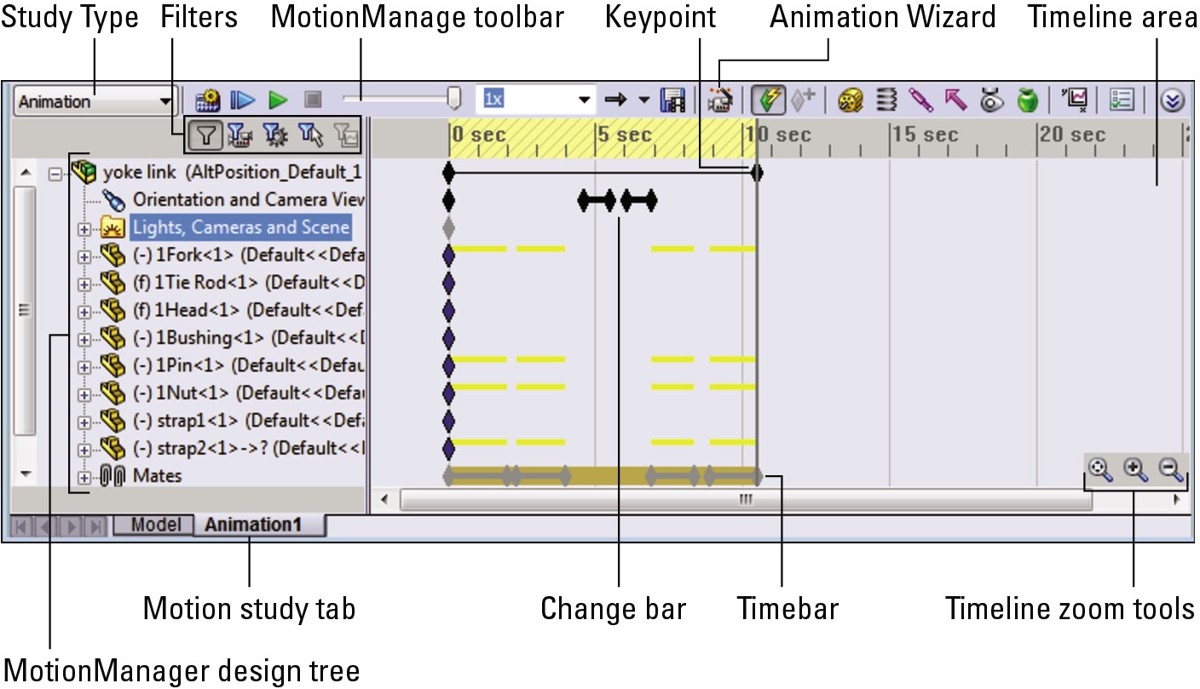

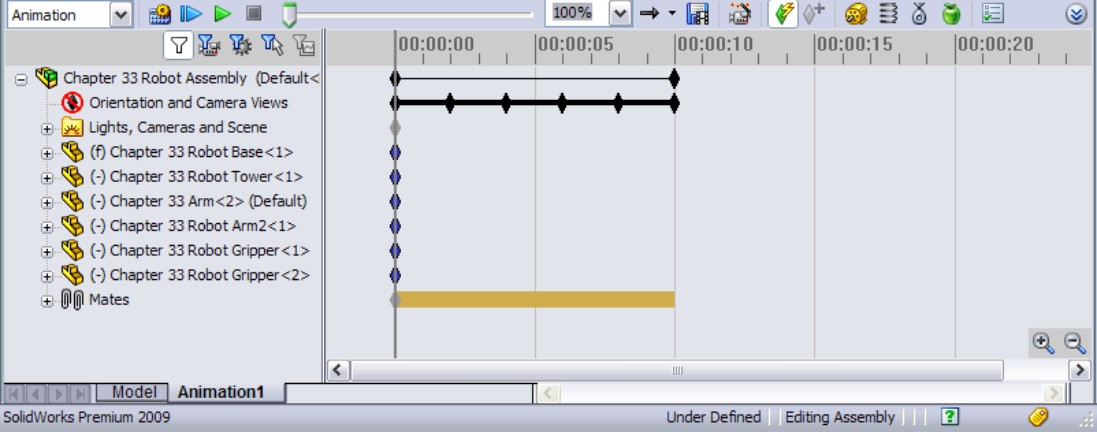

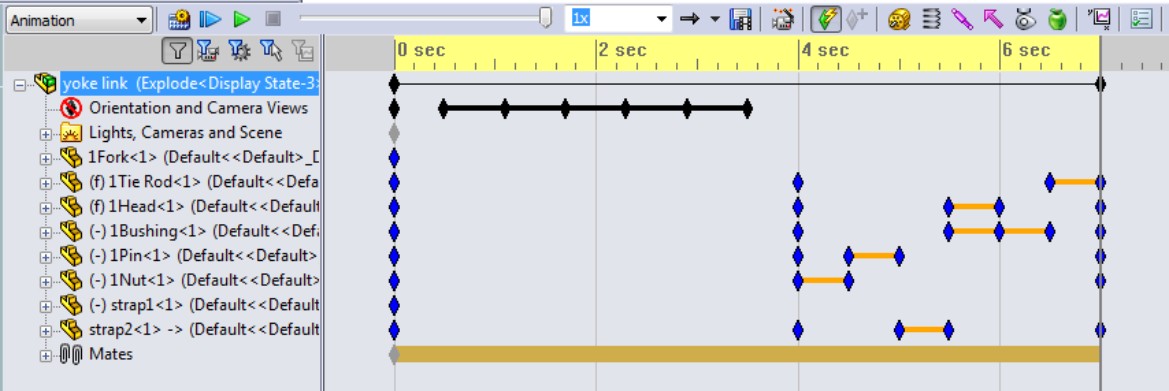

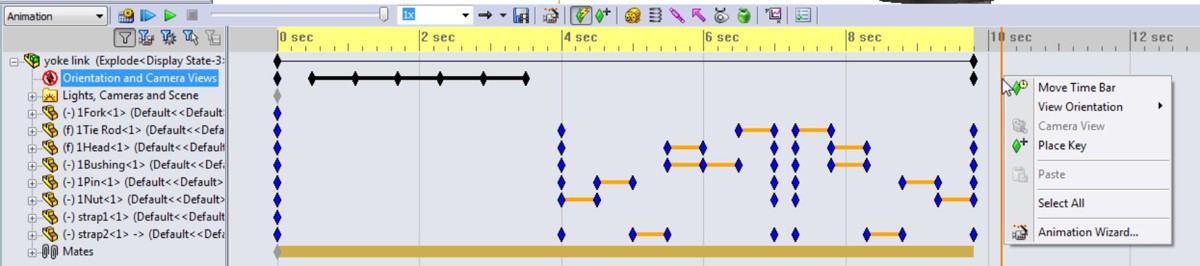

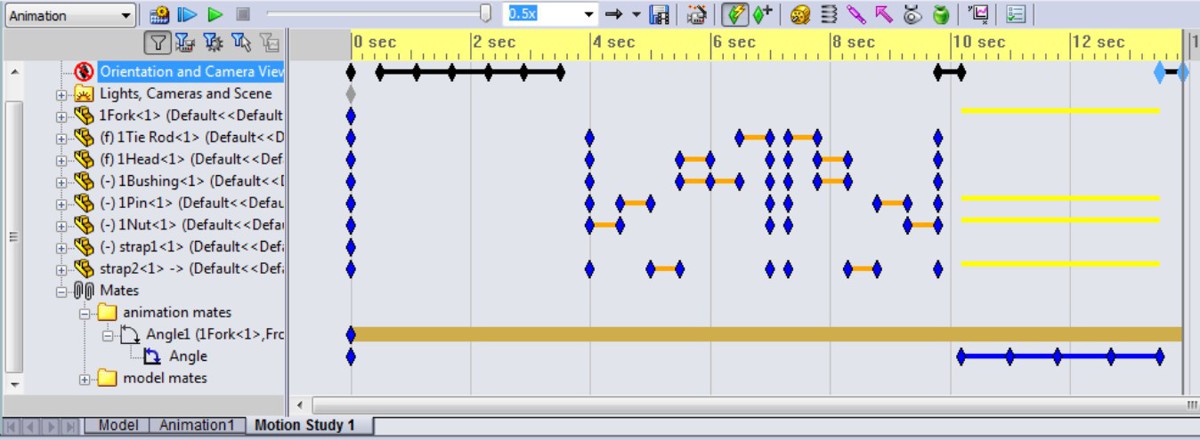

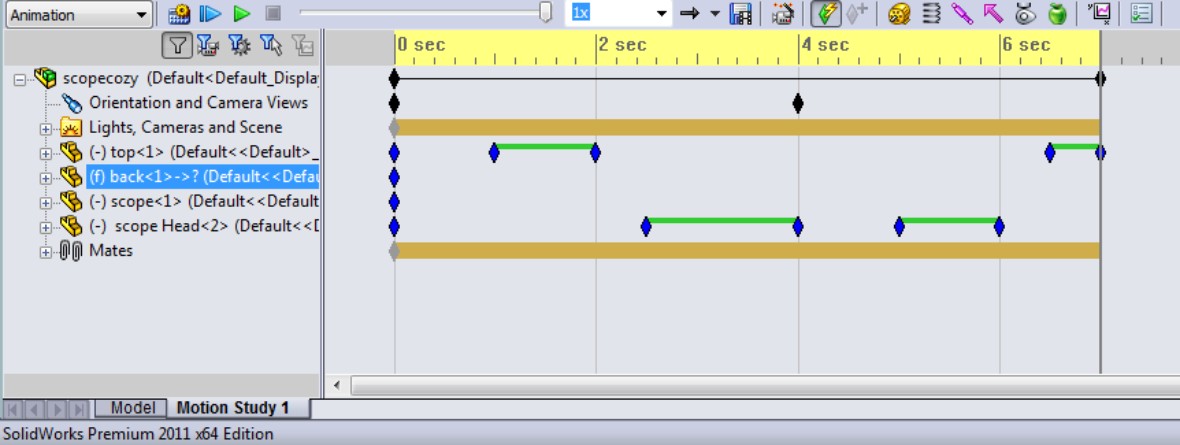

Identifying elements of the MotionManager

Using display options

Using the MotionManager interface

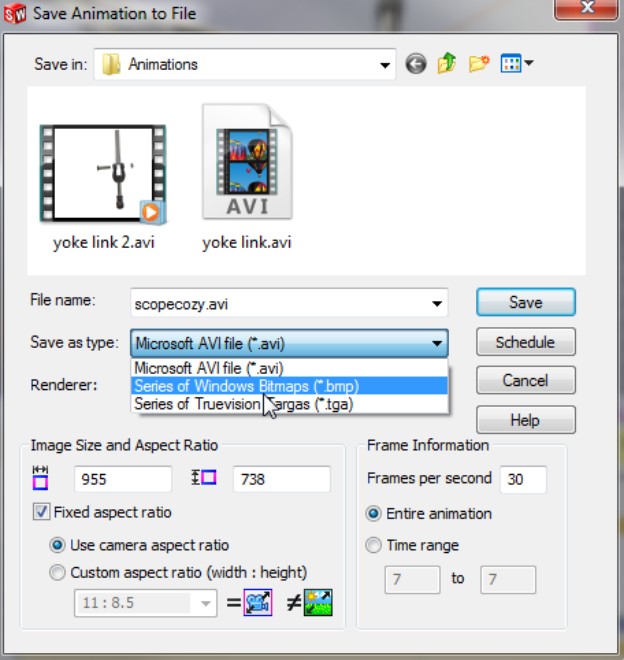

Formatting output

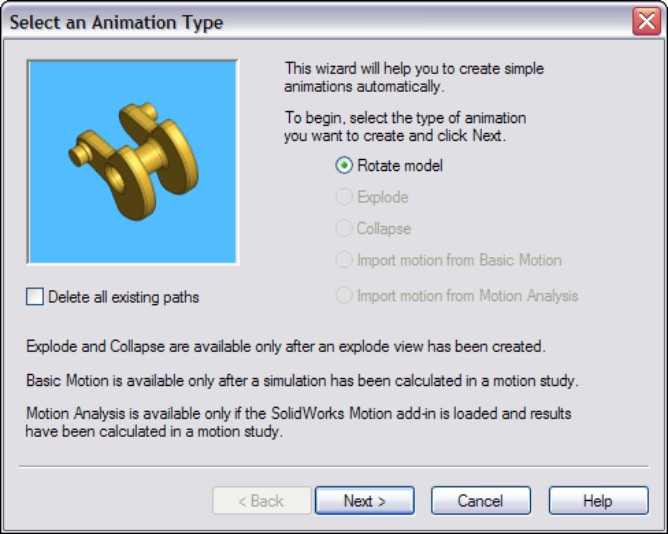

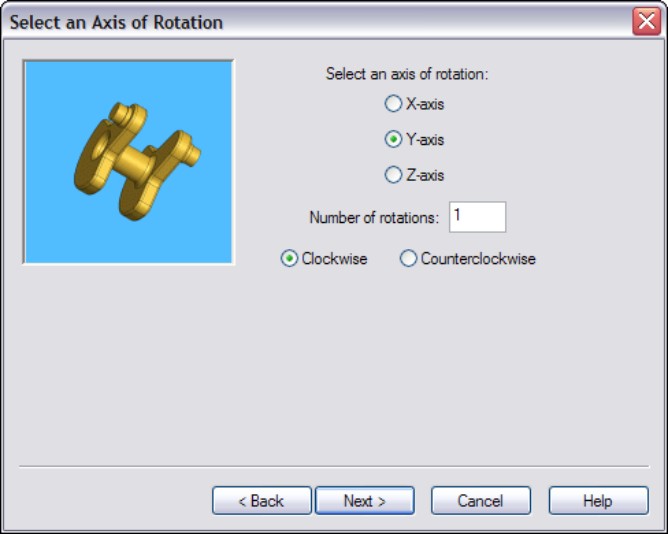

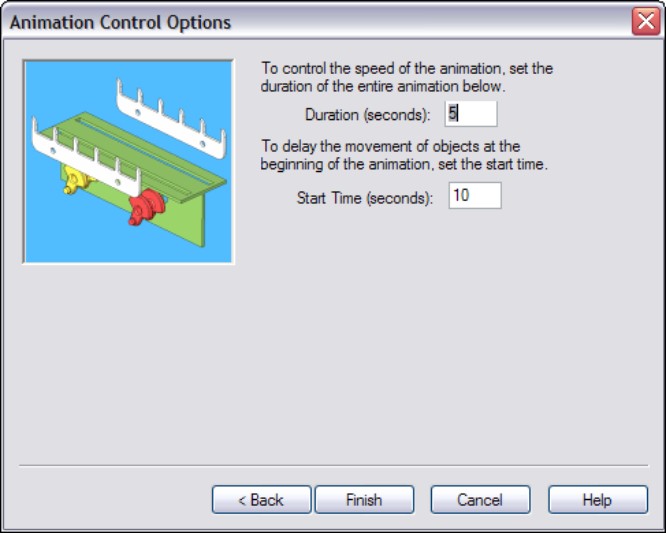

Using the Animation Wizard

Creating a rotating animation

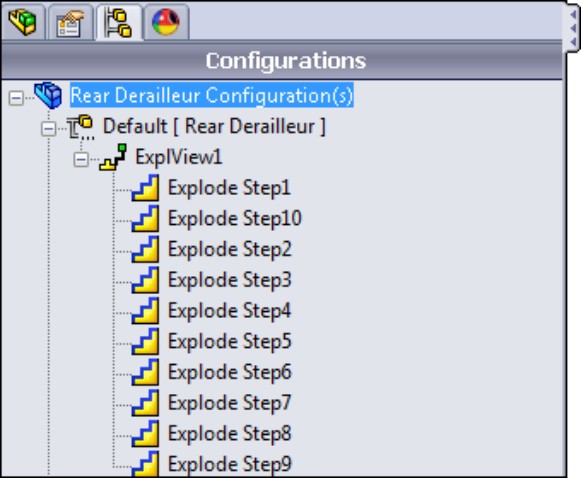

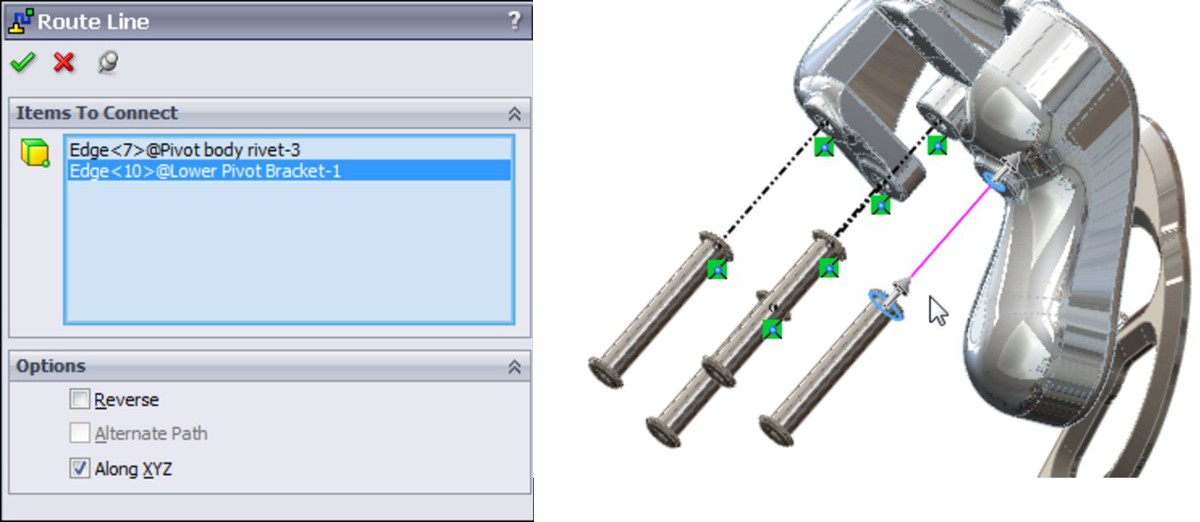

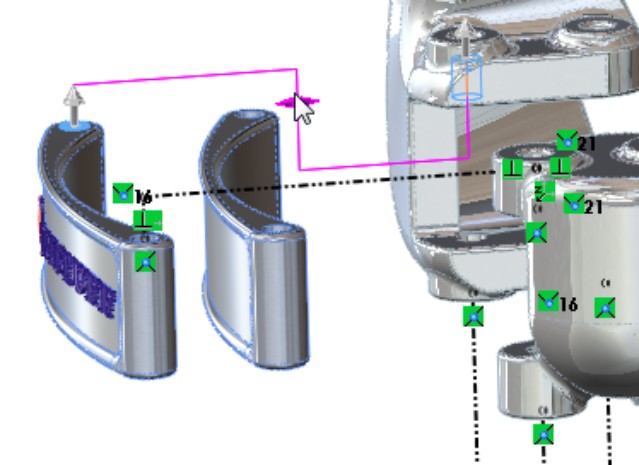

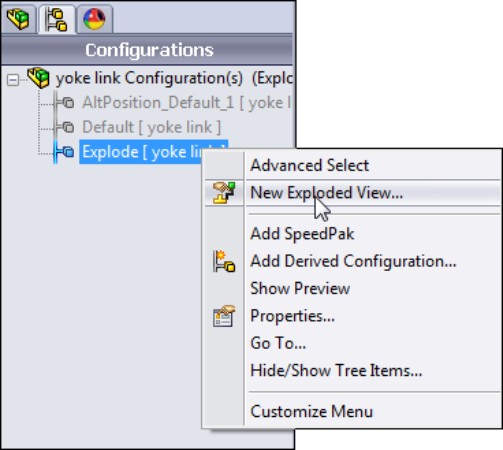

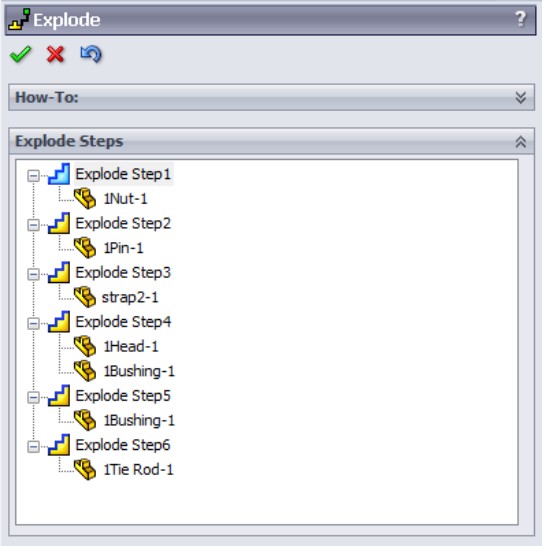

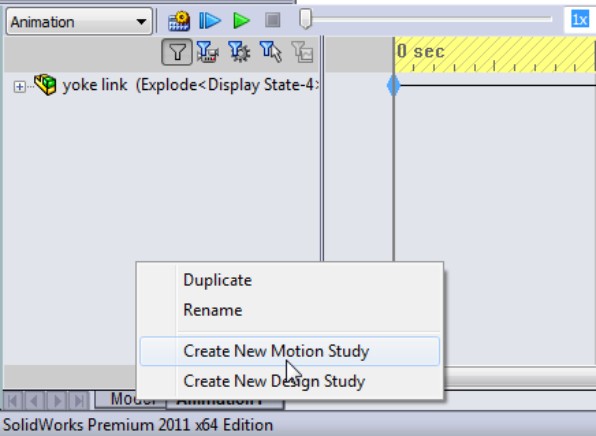

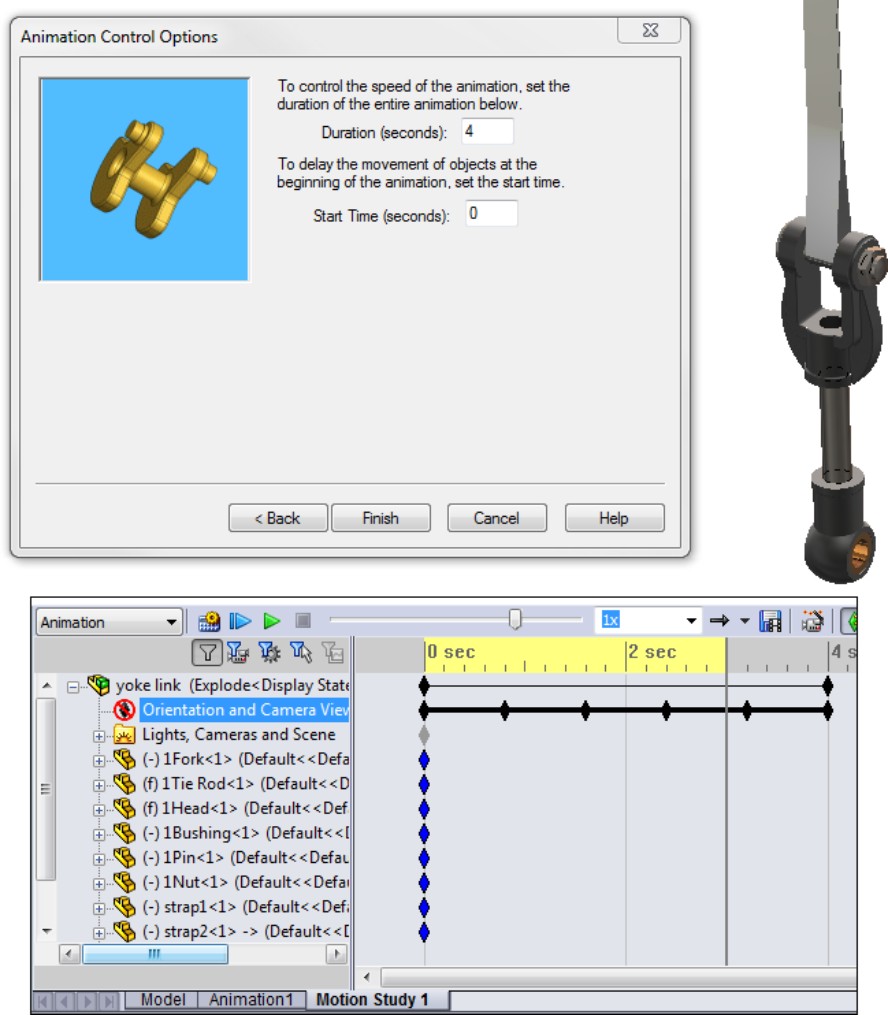

Creating an exploded view animation

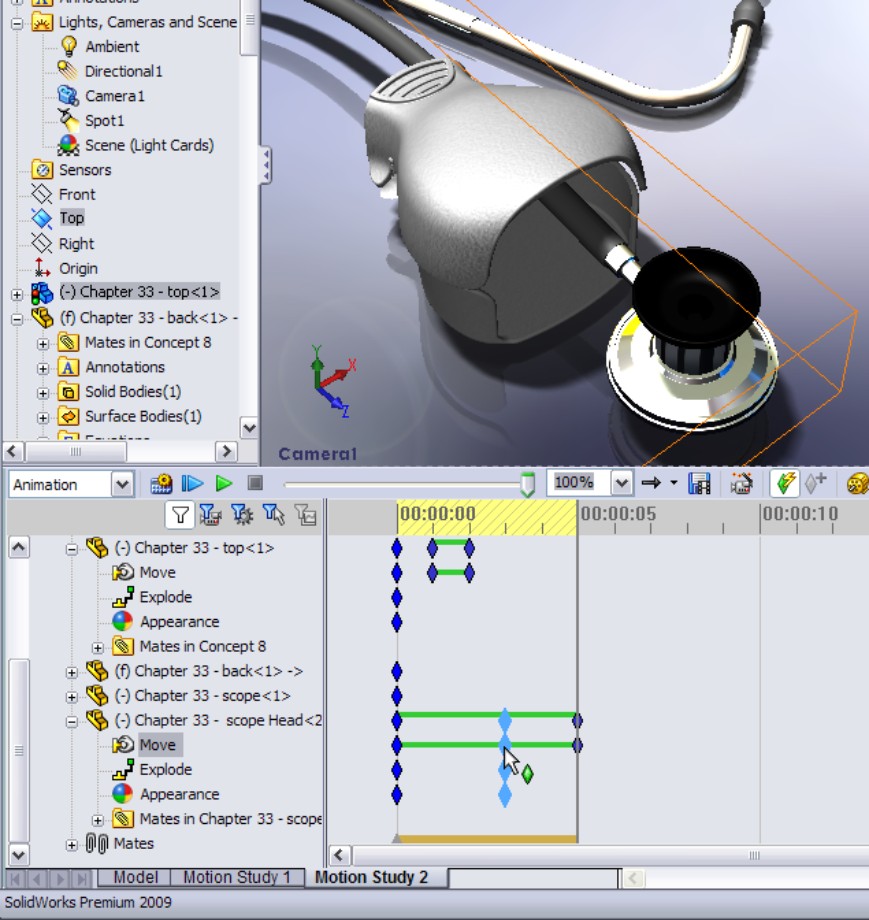

Animating an assembly

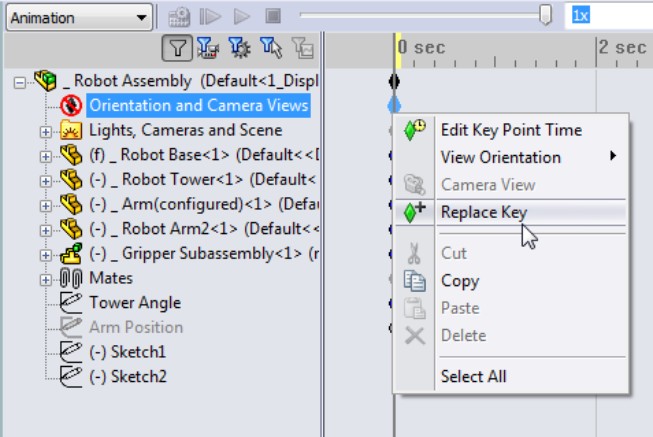

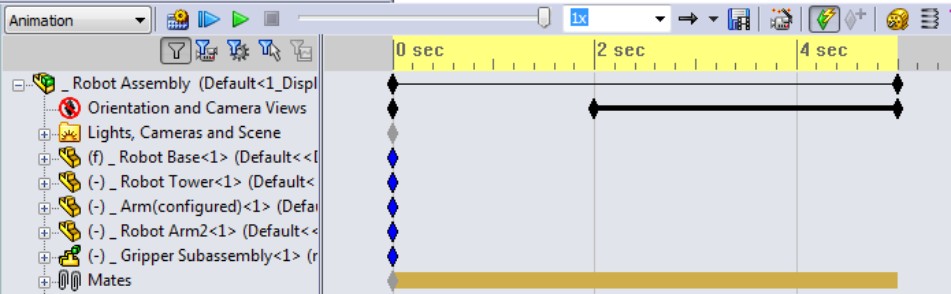

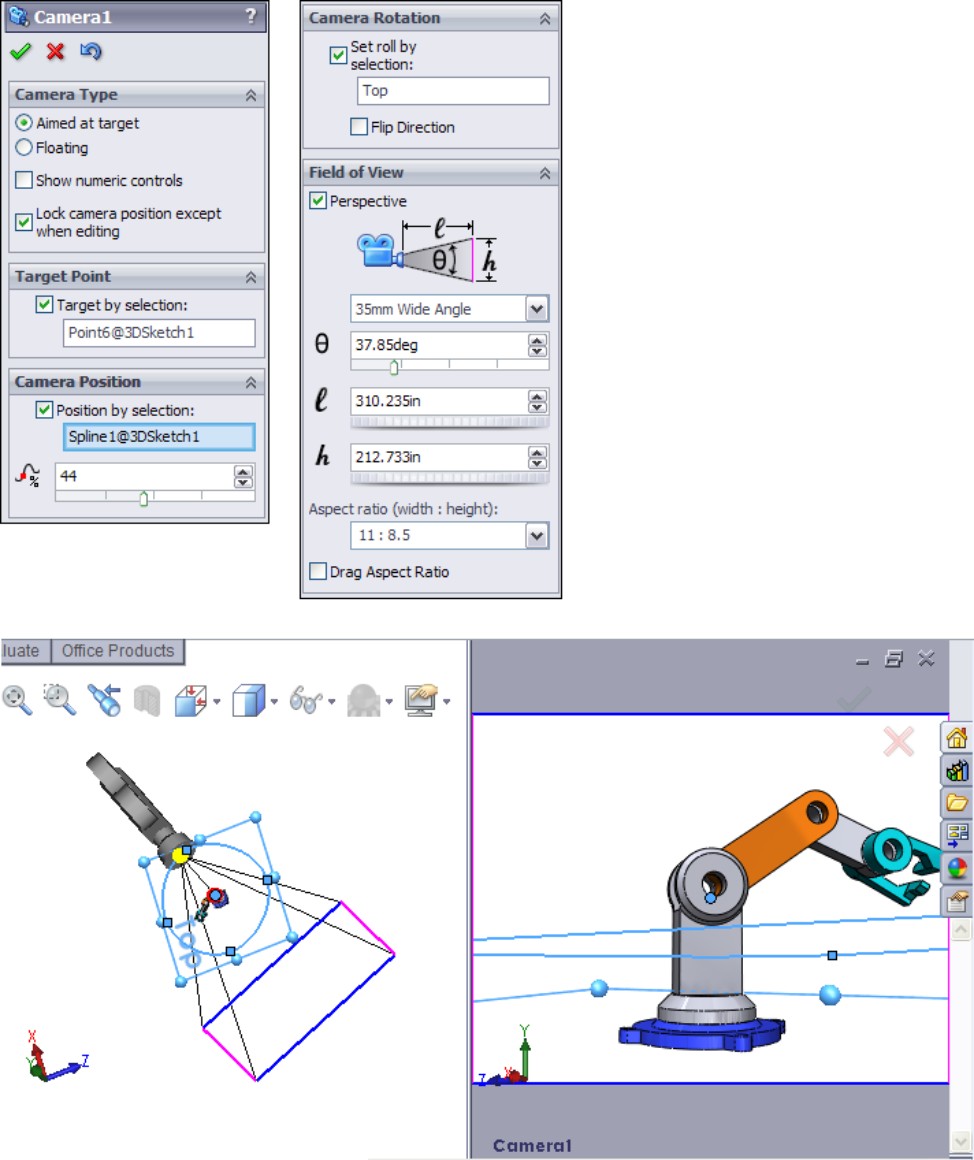

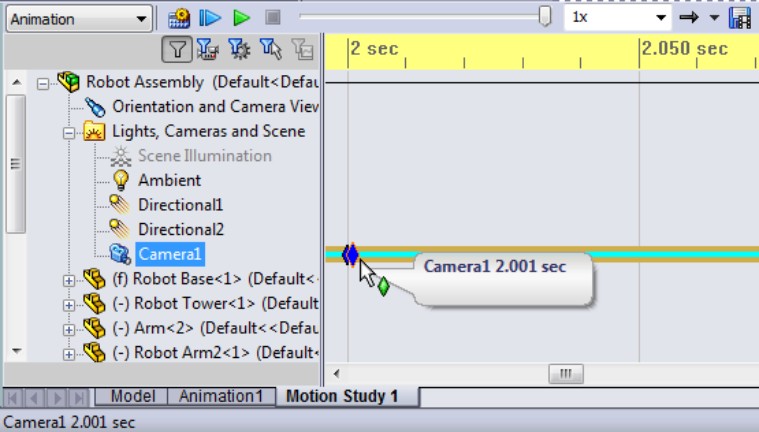

Animating the View

Driving the view with key points

Using paths to control cameras

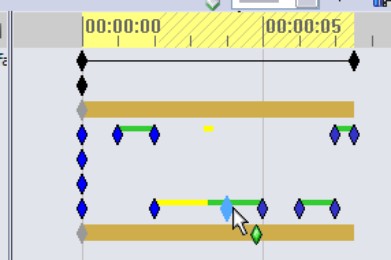

Animating with Key Points

Getting started

Using the timebar with key points

Copying and mirroring motion

Adjusting the speed of actions

Outputting the animation

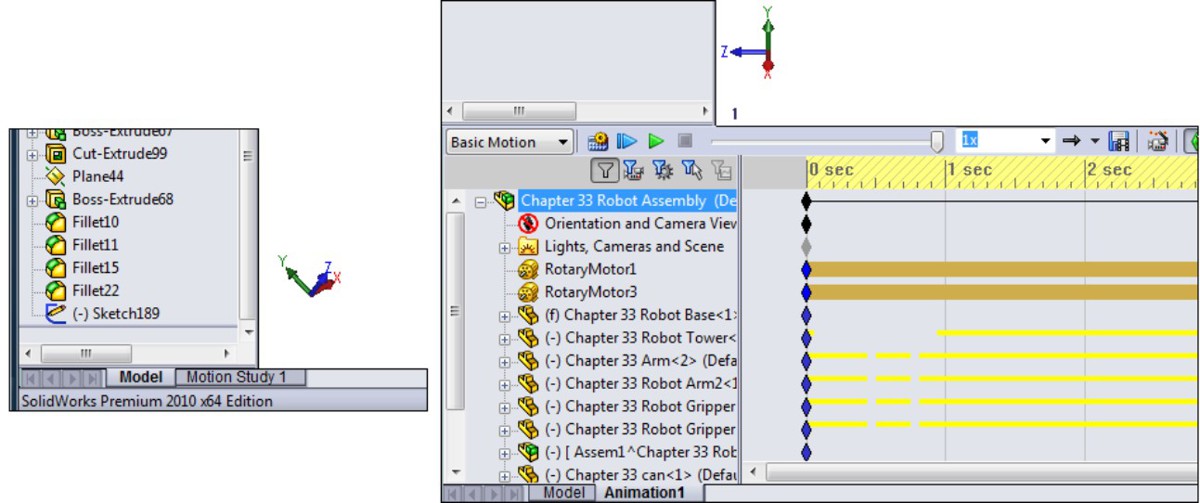

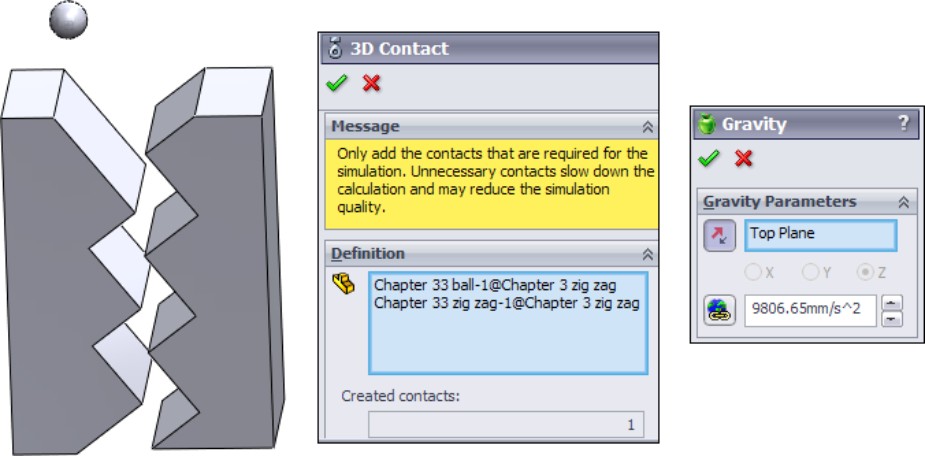

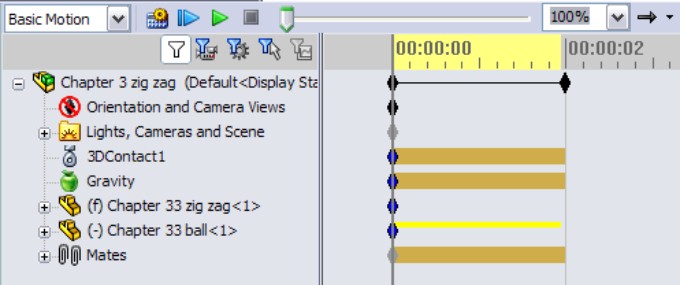

Animating with Basic Motion

Using gravity and contact

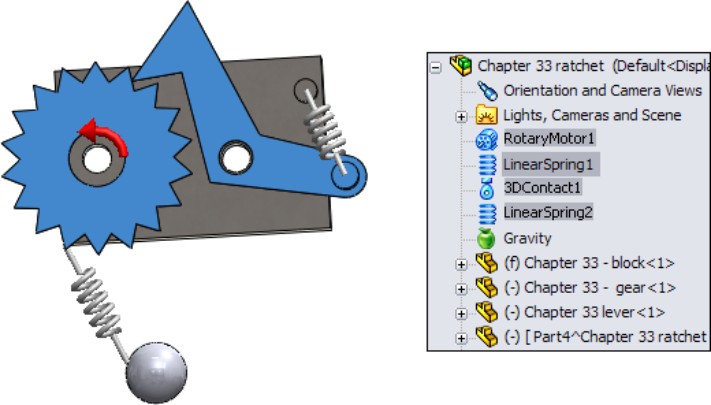

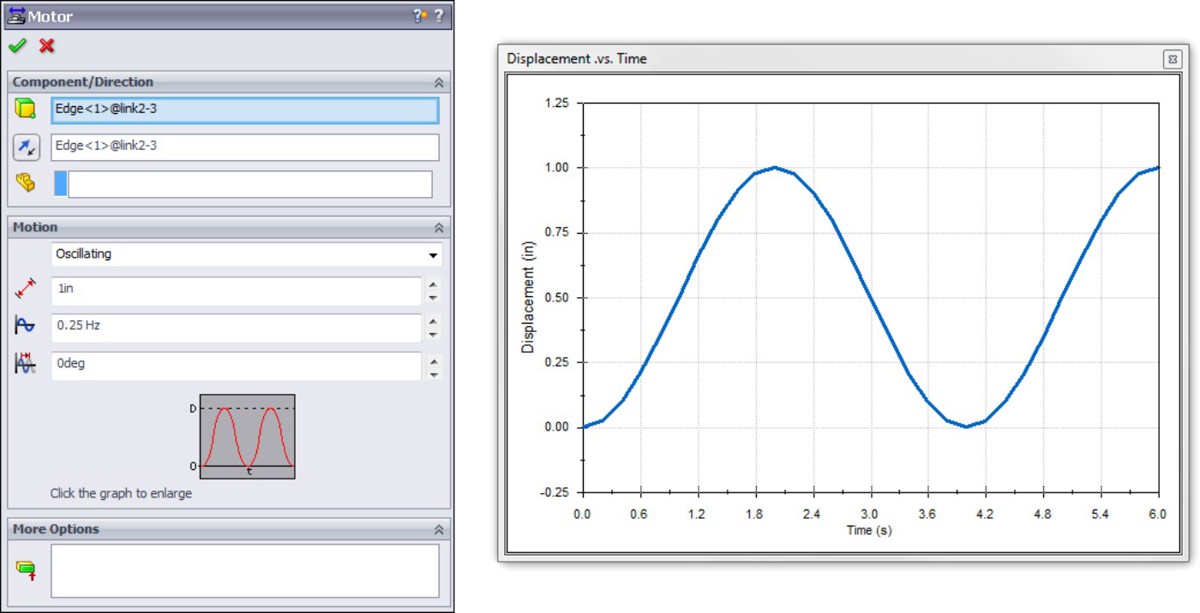

Using motors and springs

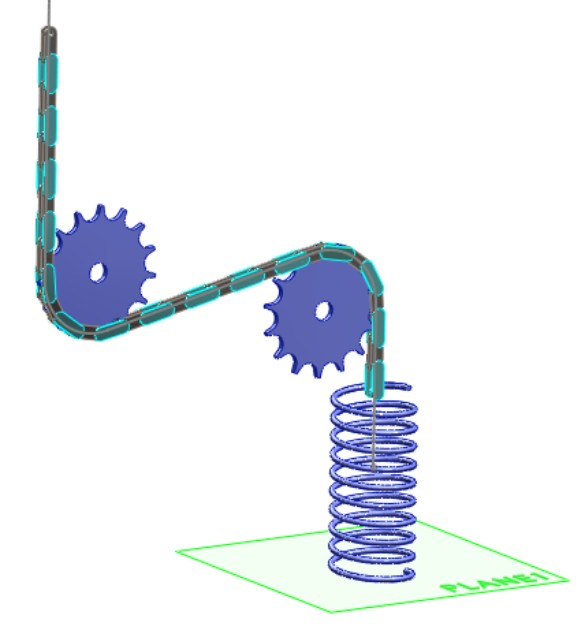

Animating a chain and a spring using motors

Summary

Part VI: Appendixes

Appendix A: Finding Help

SolidWorks Web Help

Contents

Index

Search

SolidWorks Forums

Knowledge Base

Software downloads

Release Notes

What's New

Installation and administration guides

PDMWorks Workgroup Vault Debug Guide

FLEXlm End Users Guide

Blogs

Forums

Appendix B: What's on the DVD

Windows versions

SolidWorks versions

Using the author files folder

Using the video tutorials folder

Using the TechSmith Screen Capture Codec

Accessing additional author videos

SolidWorks® 2011 Assemblies Bible

Matt Lombard

SolidWorks® 2011 Assemblies Bible

Published by

Wiley Publishing, Inc.

10475 Crosspoint Boulevard

Indianapolis, IN 46256

www.wiley.com

Copyright © 2011 by Wiley Publishing, Inc., Indianapolis, Indiana

Published by Wiley Publishing, Inc., Indianapolis, Indiana

Published simultaneously in Canada

ISBN: 978-1-118-00276-6

Manufactured in the United States of America

10 9 8 7 6 5 4 3 2 1

No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning or otherwise, except as permitted under Sections 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 646-8600. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, 201-748-6011, fax 201-748-6008, or online at http://www.wiley.com/go/permissions.

Limit of Liability/Disclaimer of Warranty: The publisher and the author make no representations or warranties with respect to the accuracy or completeness of the contents of this work and specifically disclaim all warranties, including without limitation warranties of fitness for a particular purpose. No warranty may be created or extended by sales or promotional materials. The advice and strategies contained herein may not be suitable for every situation. This work is sold with the understanding that the publisher is not engaged in rendering legal, accounting, or other professional services. If professional assistance is required, the services of a competent professional person should be sought. Neither the publisher nor the author shall be liable for damages arising herefrom. The fact that an organization or Website is referred to in this work as a citation and/or a potential source of further information does not mean that the author or the publisher endorses the information the organization or Website may provide or recommendations it may make. Further, readers should be aware that Internet Websites listed in this work may have changed or disappeared between when this work was written and when it is read.

For general information on our other products and services or to obtain technical support, please contact our Customer Care Department within the U.S. at (877) 762-2974, outside the U.S. at (317) 572-3993 or fax (317) 572-4002.

Library of Congress Control Number: 2011932103

Trademarks: Wiley and related trade dress are registered trademarks of Wiley Publishing, Inc., in the United States and other countries, and may not be used without written permission. SolidWorks is a registered trademark of Dassault Systèmes SolidWorks Corporation. All other trademarks are the property of their respective owners. Wiley Publishing, Inc., is not associated with any product or vendor mentioned in this book.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic books.

About the Author

Matt Lombard is an independent engineering consultant specializing in plastic parts and complex shapes. He also writes a blog on SolidWorks, which you can find at www.dezignstuff.com/blog. Matt lives in the picturesque Shenandoah Valley of Virginia, where he enjoys reading the classics and fishing.

Credits

Senior Acquisitions Editor

Stephanie McComb

Project Editor

Jade L. Williams

Technical Editor

Charles Culp

Copy Editor

Marylouise Wiack

Editorial Director

Robyn Siesky

Business Manager

Amy Knies

Senior Marketing Manager

Sandy Smith

Vice President and Executive Group Publisher

Richard Swadley

Vice President and Executive Publisher

Barry Pruett

Senior Project Coordinator

Kristie Rees

Graphics and Production Specialists

Ana Carillo

Jill A. Proll

Quality Control Technician

Laura Albert

Proofreading

Christine Sabooni

Indexing

BIM Indexing & Proofreading Services

Media Development Project Manager

Laura Moss

Media Development Assistant Project Manager

Jenny Swisher

Media Development Associate Producer

Marilyn Hummel

Acknowledgments

I would like to acknowledge the efforts of the staff at Wiley for their dedication in editing the text of these books. It can be a difficult job making sure that a technical subject is treated properly. I'd also like to thank Charles Culp, the technical editor, for taking the time out of his schedule to make sure the material is accurate. Thanks also to Kim and Zoey, who help with the details in life allowing me to do this kind of work.

Introduction

SolidWorks is a huge, sprawling topic. There is a lot for you, the reader, to know, and for me to write about. As a result, with the 2011 edition, I have taken this book from a single volume of an immense scope to two individual volumes, each still fairly large, one covering parts and part drawings, and the other covering assemblies and assembly drawings. There is some overlap between these topics, but I have tried to divide the material evenly and in a way, that makes the most sense for the reader. Depending on your needs, you will probably find both volumes to be very useful references.

This book is primarily meant as an encyclopedic desk reference for SolidWorks Standard users who want a more thorough understanding of the software and process than can be found in other available documentation. As such, it is not necessarily intended to be a guide for beginners, although it has elements that beginners would find useful. Nor is it necessarily intended as a classroom guide, but I have seen people use it for that as well.

Beginners will find the step-by-step tutorials useful. However, because you are only a beginner for a short period of time, the book is intended to be most useful when you reach an intermediate level, as it takes a more conceptual approach to explaining functionality. I try to help you make the decisions about how to apply the tools to your tasks rather than demonstrating simple tasks that you will never need to do again. You will not learn to model a teapot in this book, because in your work, knowing how to model a teapot will probably not help you. However, you will learn how to make decisions that should enable you to model just about anything you want, including teapots.

To keep the size of the book manageable, I have tried to avoid topics found only in SolidWorks Professional or Premium, although I do talk about these topics when they are relevant.

While the book does point out limitations, bugs, and conceptual errors in the software, and from time to time ventures into the realm of opinion, in every case this is meant to give you a more thorough understanding of the software, and how it is applied in the context of everyday design or engineering practice.

The overall goal of this book is not to fill your head with facts, but to help you think like the software, so that you can use the tool as an intuitive extension of your own process. As your modeling projects become more complex, you will need to have more troubleshooting and work-around skills available to you. Along with best practice recommendations, these are the most compelling reasons to use this book.

Thank you for your interest.

About This Book

You will find enough information here that this book will grow with your SolidWorks needs. I have written tutorials for most of the chapters with newer users in mind, because for them, it is most helpful to see how things are done in SolidWorks step by step. The longer narrative examples give more in-depth information about features and functions, as well as the results of various settings and options.

This book includes many details that come from practical usage and is focused on the needs of professional users, not on student learners. My approach is to teach concepts rather than how to push buttons.

How This Book Is Organized

This book is divided into six parts.

Part I: Introducing Assembly Basics

This part explores basic concepts and terminology used in SolidWorks. You need to read this section if you are a new SolidWorks user, especially if you are new to 3D modeling or parametric history-based design.

Part II: Working with Assemblies

This part takes a deeper look at creating parametric relations to automate changes.

Part III: Creating and Using Libraries

This part examines the functionality within the 2D drawing side of the software. Whether you are creating views, making tables, or customizing annotations, you will find these chapters useful.

Part IV: Creating Assembly Drawings

This part examines several types of advanced techniques, such as surface modeling and multi-body modeling. This is information you won't find in other SolidWorks books, and is explained here by someone who uses the functionality daily.

Part V: Using Specialized or Advanced Techniques

Specialized functionality, such as sheet metal and plastics, requires detailed information. This part includes the topics that are key to unlocking all the power available in SolidWorks.

Part VI: Appendixes

The Appendixes in this book contain additional information, such as the contents of the DVD and other sources of help.

Icons Used in This Book

This book uses a set of icons to point out certain details in the text. While they are relatively self-explanatory, here is what each of these icons indicates:

Caution

The Caution icon warns you of potential problems before you make a mistake.

Cross-Reference

The Cross-Reference icon points out where you can find additional information about a topic elsewhere in the book.

New Feature

The New Feature icon highlights features and functions that are new to SolidWorks 2011.

Note

The Note icon highlights useful information that you should take into consideration, or an important point that requires special attention.

On the DVD

This icon points you toward related material on the book's DVD.

Tip

Each Tip provides you with additional advice that makes the software quicker or easier to use.

The SolidWorks 2011 Assemblies Bible is unique in its use of the following two icons:

Best Practice

The Best Practice icon points out recommended settings or techniques that are safe in most situations.

Performance

Each Performance icon elaborates on how certain settings, features, or techniques affect rebuild speed or file size.

These icons point out and describe techniques and settings that are either recommended or not recommended for specific reasons. Best practice is usually considered very conservative usage, where the stability of the parametrics and performance (another way of saying rebuild speed) are the ultimate goals. These two aspects of SolidWorks models are usually weighed against modeling speed (how long it takes you to create the model).

You should take Best Practice and Performance recommendations seriously, but as guidelines rather than as rules. When it comes right down to it, the only hard and fast rule about SolidWorks is that there are no hard and fast rules. In fact, I believe that the only reason to have rules in the first place is so that you know when you can break them. Parametric stability and modeling speed are not always the ultimate goals and are often overridden when work-around techniques are used simply to accomplish a geometric goal.

Because not everyone models with the same goals in mind, a single set of rules can never apply for everyone. You must take the best practice suggestions and apply them to your situation using your own judgment.

Because I actually use the software in my work, I viewed it from a practical standpoint while writing this book. I approached the software objectively as a tool, recognizing that complex tools are good at some things and not so good at others. Knowing the strengths and limitations of the software is helpful to you. Pointing out negatives in this context should not be construed as criticizing the SolidWorks software, but rather as preparing you for real-world use of the software. Any tool this complex is going to have imperfections. I hope that some of my enthusiasm for the software also shows through and is to some extent contagious.

Terminology

An important concept referred to frequently in SolidWorks is design intent. As a practical matter, I use the phrase design for change to further distinguish design intent from other design goals.

You will need to be familiar with some special terminology before continuing. In many cases, I use a SolidWorks vernacular or slang when the official terminology is either not descriptive enough or has multiple meanings. For example, the word shortcut can mean several things in the SolidWorks interface; it is used to describe right mouse button (RMB) menus as well as hotkeys. As a result, I have chosen not to use the word shortcut and instead substitute the words RMB and hotkey.

I frequently use RMB to refer to right mouse button menus, or other data that you access by clicking the right mouse button on an item. The word tree refers to the list of features in the FeatureManager.

Differences are frequently found between the names of features on toolbars and the names in the tool tips, menus, or PropertyManager titles. In these cases, the differences are usually minor, and either name may be used.

Most functions in SolidWorks can work with either the object-action or the action-object scenarios. These are also called pre-select and select, respectively. The Fillet feature shows no difference between using pre-selection and selection, although for some fillet options such as face fillet, pre-select is not enabled. Most features allow pre-selection, and some functions, such as inserting a design table, require pre-selection. Although you cannot identify a single rule that covers all situations, most functions accept both.

Frequently in this book, I have suggested enhancement requests that the reader may want to make. This is because SolidWorks development is driven to a large extent by customer requests, and if a large number of users converge on a few issues, then those issues are more likely to be fixed or changed. Again, the enhancement request suggestions are not made to criticize the software, but to make it better. I hope that you will join me in submitting enhancement requests.

SolidWorks is an extremely powerful modeling tool, very likely with the best combination of power and accessibility on the MCAD market today. This book is meant to help you take advantage of its power in your work and even hobbyist applications. If I could impart only a single thought to you, it would be that with a little curiosity and some imagination, you could begin to access the power of SolidWorks for geometry creation and virtual product prototyping. You should start with the assumption that there is a way to do what you are imagining, and that you should be open to using different techniques.

Because I wrote this book to help you look beyond simply asking what different buttons do, I hope that it will help you develop an intuition for thinking like the software. Jeff Ray, CEO of the SolidWorks Corporation, has said that the goal is to make the software as “intuitive as a light switch.” While most people will agree that they have some work left to achieve that particular goal, I believe that approaching the interface intuitively, rather than attempting to remember it all by rote, is the best method. Good luck to you.

Contacting the Author

If you want to contact me, to ask a question about the book's content or to make a suggestion for improving future editions, the best ways to do this are through e-mail ([email protected]) or my blog (http://dezignstuff.com/blog). On the blog, you can leave comments and read other things I have written about the SolidWorks software, CAD, and engineering or computer topics in general. If you want to contact me for commercial help with a modeling project, my e-mail address is the best place to start that type of conversation. I always look forward to hearing what real users think about the material.

Thank you very much for buying and reading this book. I hope the ideas and information within its pages help you accomplish your professional goals.

Part I: Introducing Assembly Basics

In This Part

Chapter 1

Understanding Assemblies

Chapter 2

Navigating the Assembly Interface

Chapter 3

Visualizing Assemblies

Chapter 1: Understanding Assemblies

In This Chapter

Why use assemblies

Creating assemblies

Positioning parts into assemblies

Working with external references

This chapter serves as an overview of some of the different tools and techniques that are available to SolidWorks users in assemblies. Most importantly, this chapter discusses the various purposes that you might have for creating assemblies. The second emphasis of this chapter is to help you understand various methods for using external references. More than anything, this chapter prepares you for important decisions that you will need to make relating to your modeling methods in SolidWorks found throughout this book.

If you take the SolidWorks training class from a SolidWorks reseller, all assemblies seem to take the same form and have the same function. You may then take this way of working back to your office and start applying it there. However, if you do this, you could be missing out on many other ways of using assemblies. While SolidWorks definitely seems to have a certain orthodoxy in mind for the assemblies functionality, there are actually an array of techniques that you can use to achieve a wide range of goals.

This chapter helps you identify some of the ways in which you can apply SolidWorks assemblies functionality to accommodate your goals and your workflow style. You are encouraged to experiment and evaluate some of these methods to find out what suits your needs best. You don't have to accept the established techniques. In fact, as you will see in this chapter, the established techniques tend to be less efficient, and especially less robust, than some alternative methods when you start making changes to your assemblies.

A lot of these alternative methods have been developed by many different users of other CAD packages over the years and have become universal to some extent. They have been adapted to SolidWorks use in different forms.

Understanding the Purpose of Assemblies

In the physical world, assemblies exist for several reasons:

• Separating materials

• Allowing relative motion

• Reducing material

• Allowing for different manufacturing techniques

• Allowing for disassembly or repair

In a CAD model, you need to follow these physical-world reasons for making individual parts and putting them together in assemblies, but CAD models can also have additional requirements. Independent of the reasons stemming from physical-world requirements, CAD assemblies might have some unique reasons for existing:

• Depicting an assembly process such as order of operations

• Specifying dimensional assembly relationships and tolerances

• Establishing clearances and limits of motion

• Visualizing motion and spatial relationships between parts

• Designing parts in-context

• Creating a parts list for assembly (Bill of Materials, or BOM)

• Creating a parts list for purchasing

• Automating data entry through PDM (product data management)

• Staging renderings

• Creating data for downstream applications such as animation or motion analysis

You can probably come up with a number of additional reasons for making CAD assemblies. In fact, almost as many reasons exist for making assemblies as there are people making those assemblies.

If you are trying to drive product development with a single top-level assembly, you might run into situations where the various functions of the assembly start conflicting with one another. For example, you might have an assembly where a part flexes. It is difficult or impossible to make flexible parts work effectively in SolidWorks with dynamic assembly motion. Another situation might be in-context relations where the parent and child components move relative to one another. Or maybe you need an assembly for a rendering and the assembly has to have multiple instances of in-context components, which can be tricky to manage. You get the picture. You can't always do everything with a single assembly.

It is certainly possible to have multiple assembly files for a single product. In fact, in some cases, it may be necessary. Rendering is probably one of the most common reasons for you to create a new assembly. Conflicts between external references and motion are another common reason to create a new assembly document.

Identifying types of assemblies

The average SolidWorks user thinks an assembly is a collection of parts put together with mates that position parts and may also allow motion. In this kind of assembly, you might use patterns, configurations, in-context techniques, and so on. The goal of the assembly is probably to simulate reality in the way it looks and moves.

Driving an assembly with base part and mates

This is considered “orthodox” SolidWorks assembly usage, and is the way the SolidWorks training materials describe creating assemblies. Insert a part or subassembly at the origin, which becomes fixed in place automatically, then start mating parts and subassemblies to the base component and add on from there.

This is the most frequently used assembly type in SolidWorks, but this type is also the most prone to failure, and the least likely to allow for relationships to exist between the parts. If you have been doing this kind of work already, and have made changes to the parts and watched the assembly update, you know that there are all sorts of things that can go wrong with this arrangement. Mates coming into conflict, flipping direction, or losing references are the most common errors that you might see when mating parts directly to one another in an assembly.

It is hard to imagine an assembly in real life where the parts don't depend to some extent on one another for their size or shape. So having a SolidWorks assembly where each part is modeled independently doesn't reflect real-world design intent very well, nor does it really use the advantages of parametrics and associativity that are touted so much in SolidWorks.

It is difficult to criticize an assembly modeling method that has been used for so long by so many people, but the high failure rate of mates attached to edges and faces speaks for itself. This is a problem that SolidWorks has tried to solve for many releases of the software, but the failure rate hasn't changed much, if at all. You may find that the software even tries to hide certain types of mate errors to make them easier to ignore.

The difficulty arises from the underlying methods built into the software. All of the faces and edges of parts are created using a history-based modeling system. Each feature is created in order, in a recipe for creating the final piece. The assembly, however, is generally not history-based. So mates attach to faces. If the faces change in such a way that the mate can't attach anymore, the mate fails. If the faces change in such a way that the way the mate works changes, parts can move in a way you don't expect. If you add fillets, or draft, or split a face to add color, or do any of a number of things that change the way the software internally identifies the faces or edges, then the mates you have applied will either fail or change the way it locates or allows parts to move.

The bottom line for the method of mating to base parts is that it is unreliable through changes. Of the methods that are presented in this book, this is the most common yet least reliable method. This is not the fault of the software, but of the method. The reason this faulty method is the most popular is because it is the easiest, and requires the least planning.

When SolidWorks first appeared on the market in the mid-1990s, it became very popular not only because it was inexpensive but also because it was much easier to use compared to products such as Pro/ENGINEER. Pro/ENGINEER taught methods for putting parts and assemblies together that were tedious but worked better through changes.

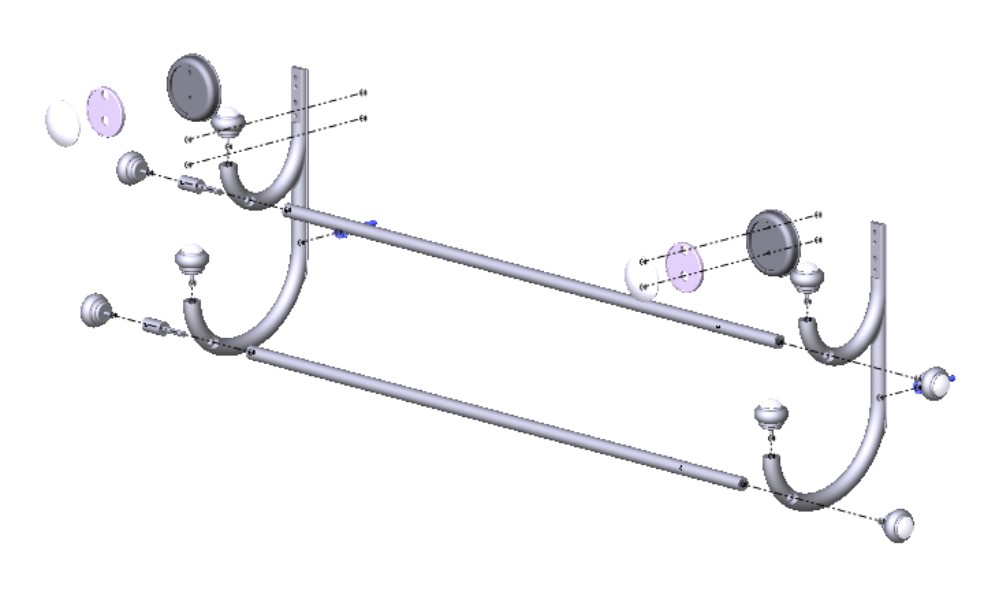

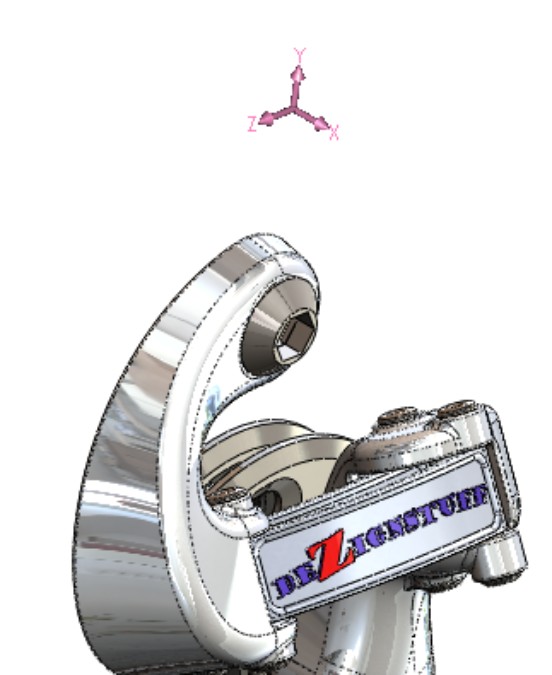

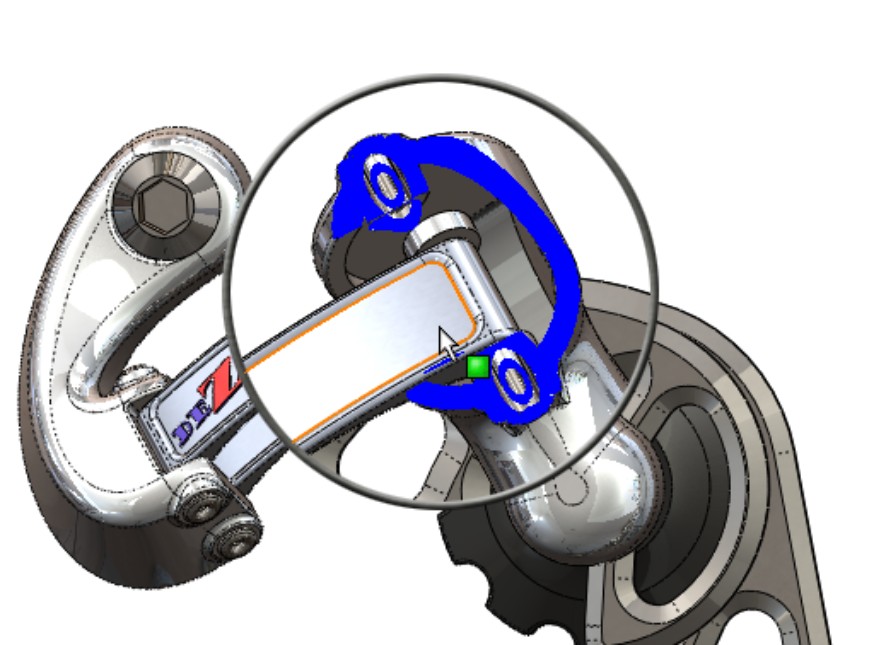

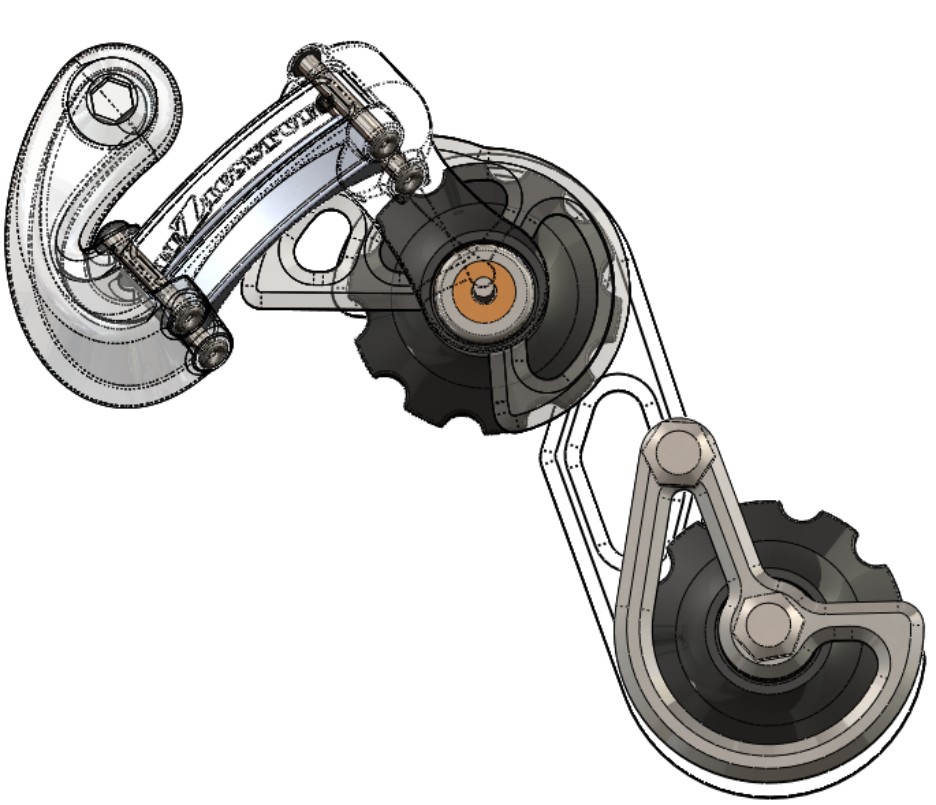

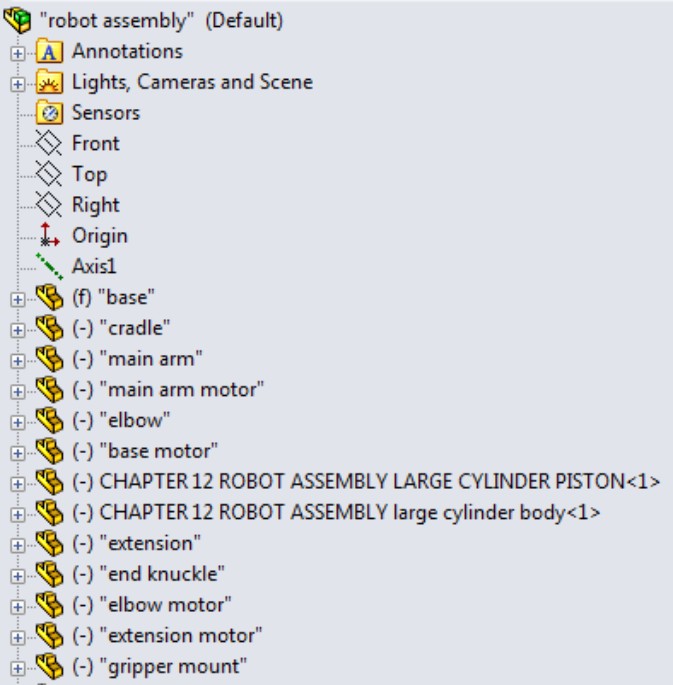

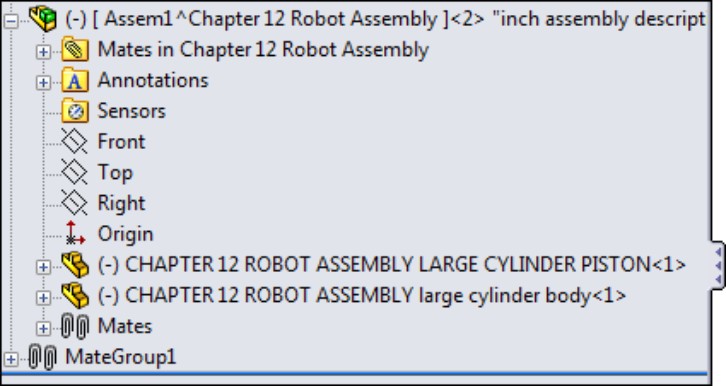

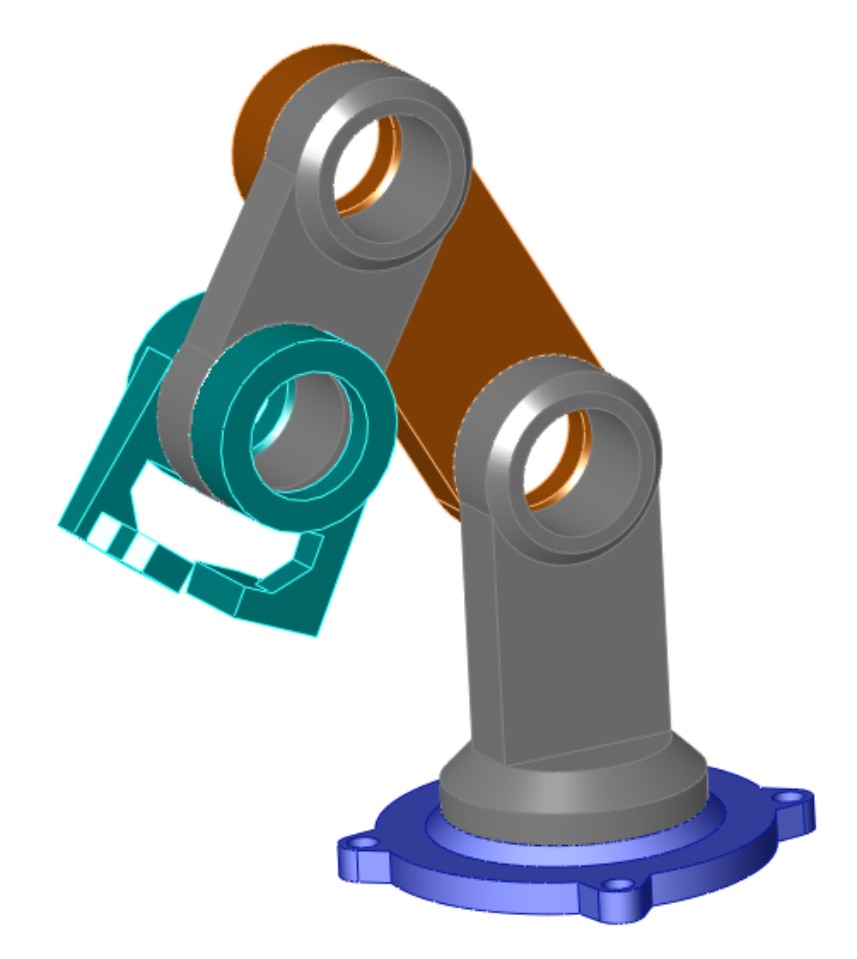

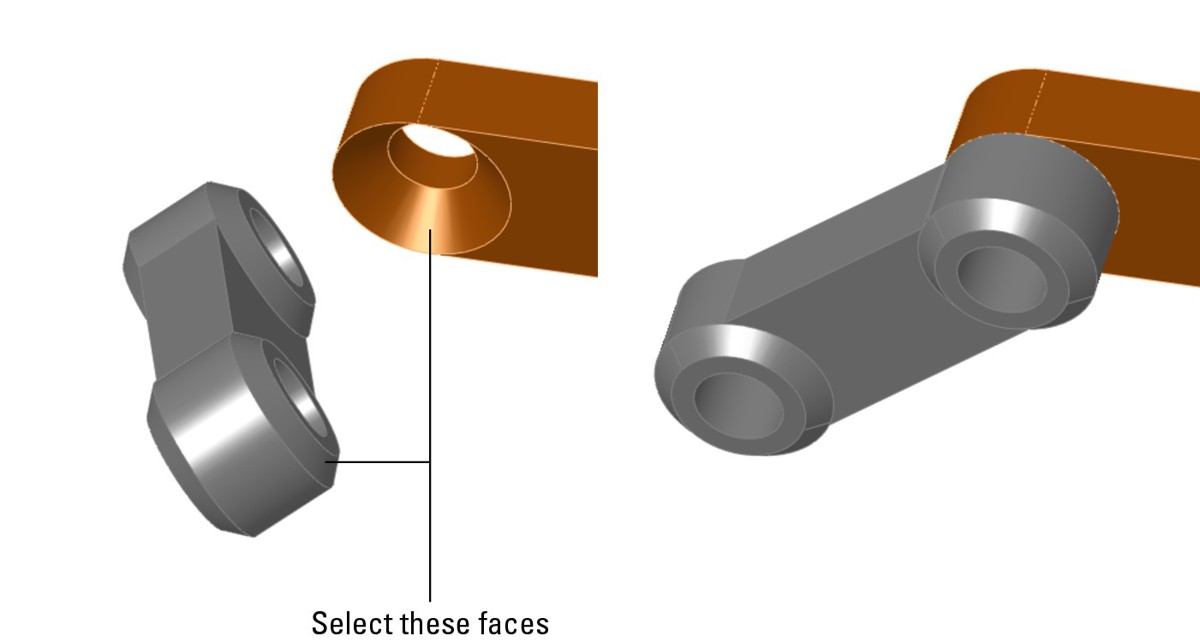

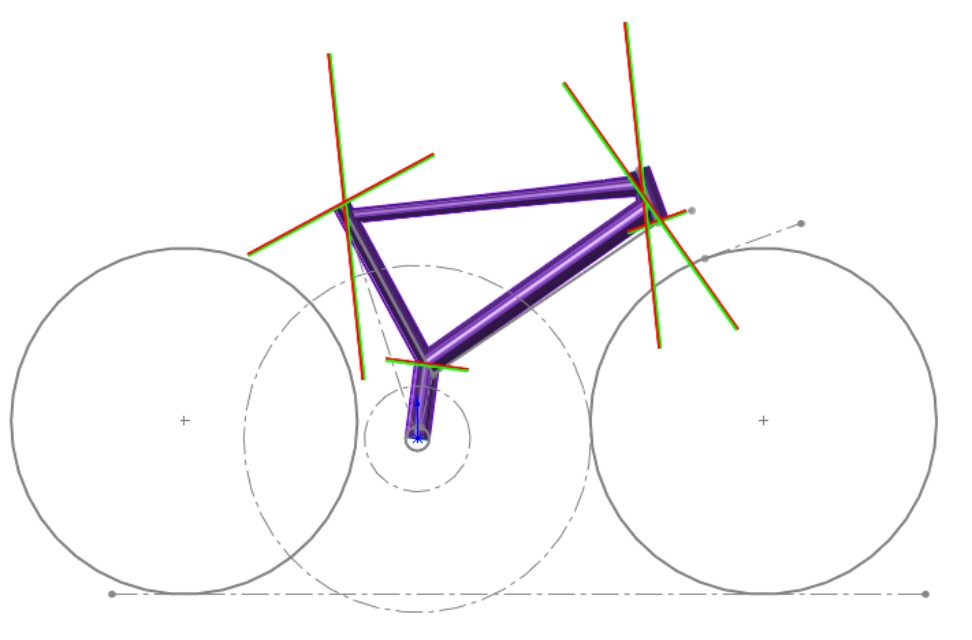

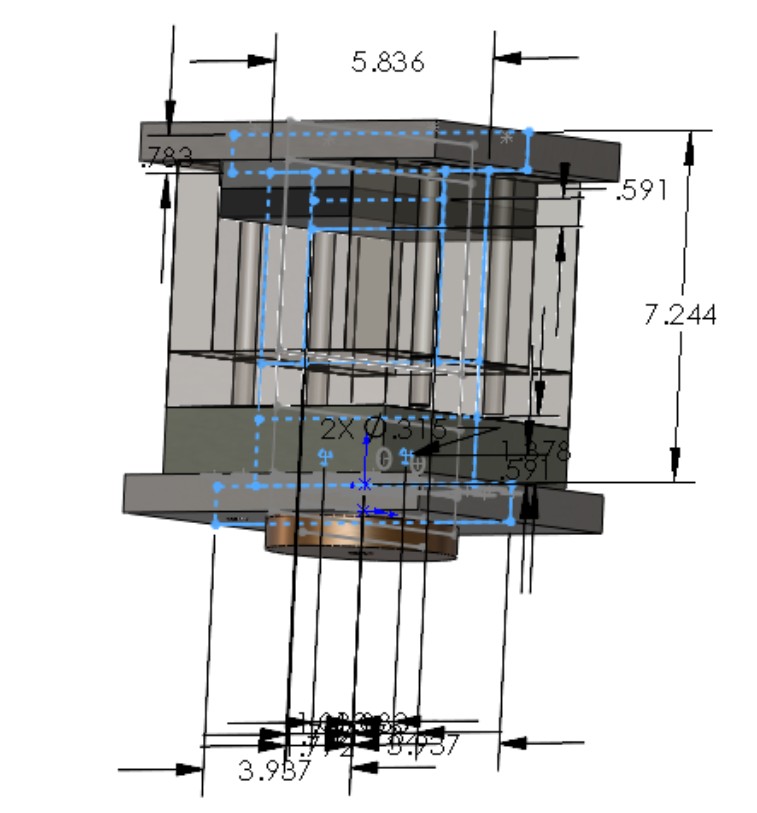

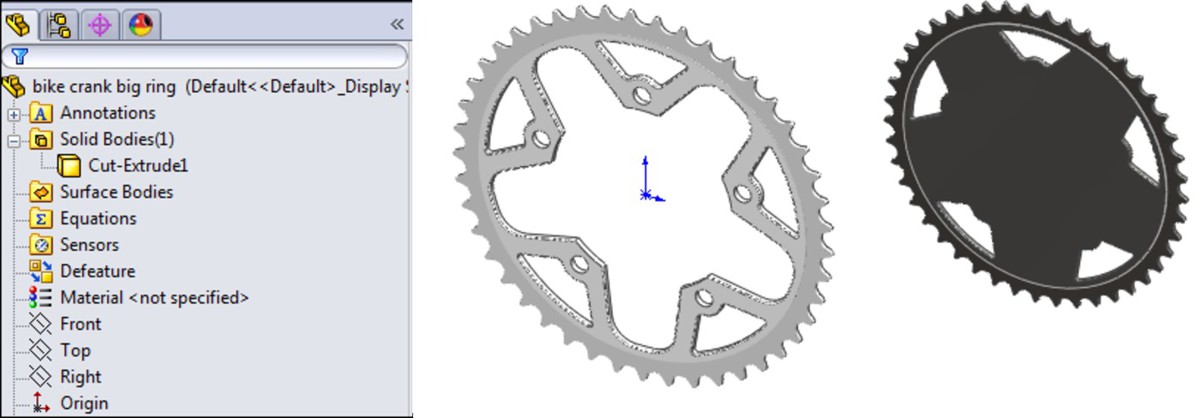

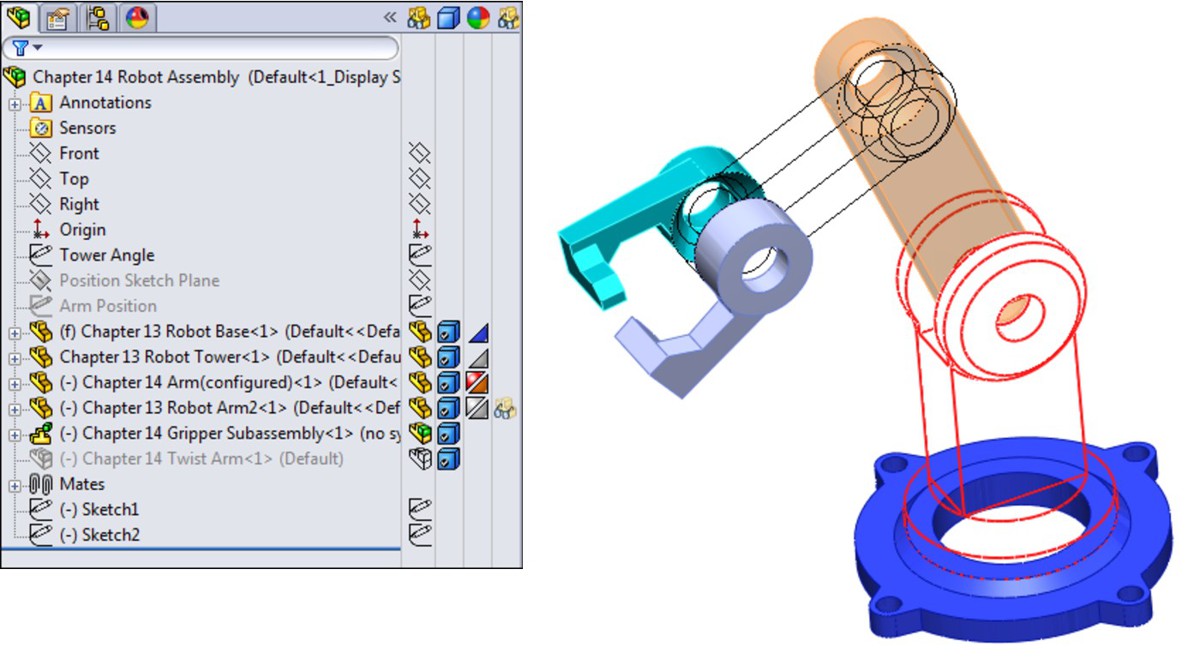

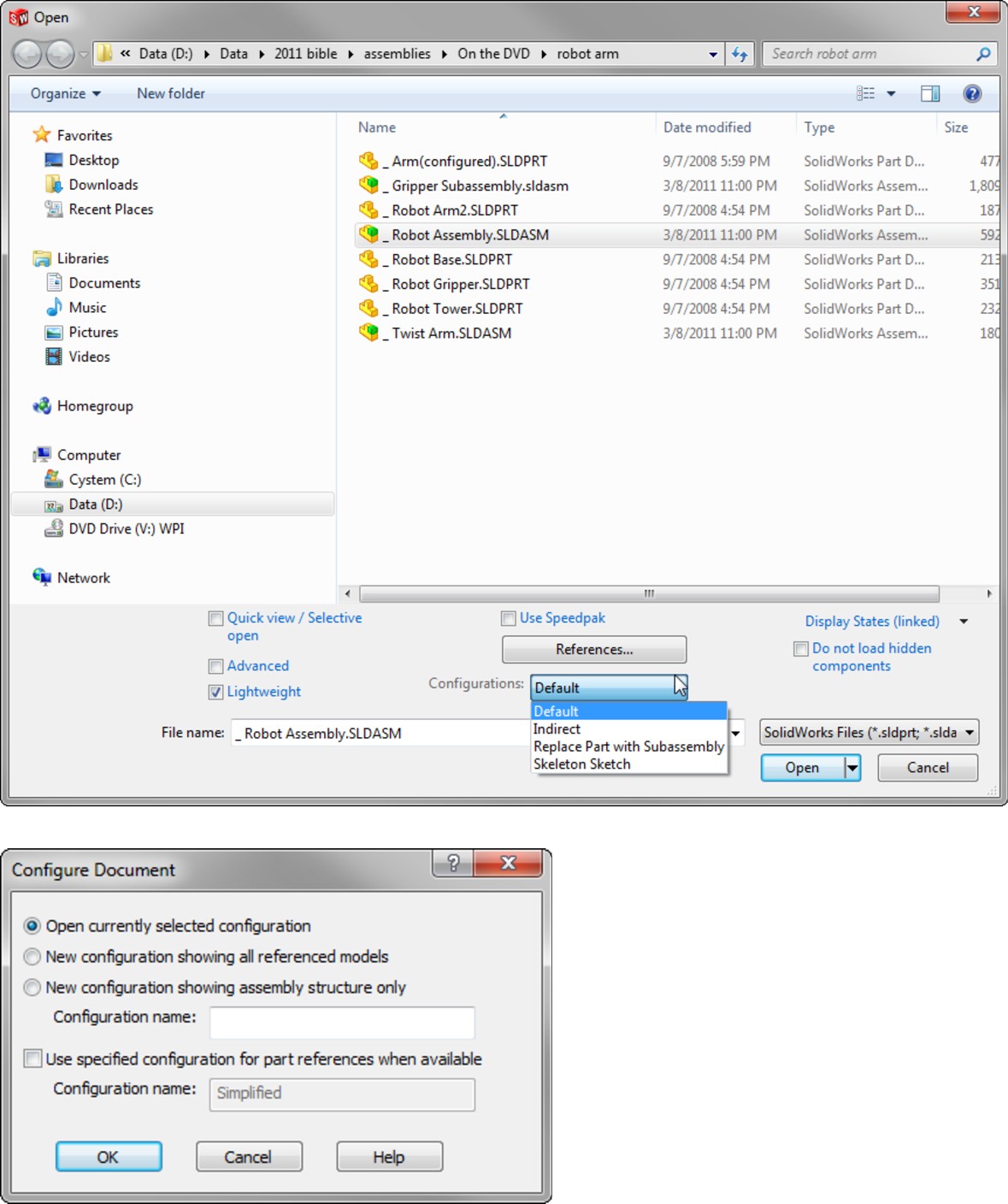

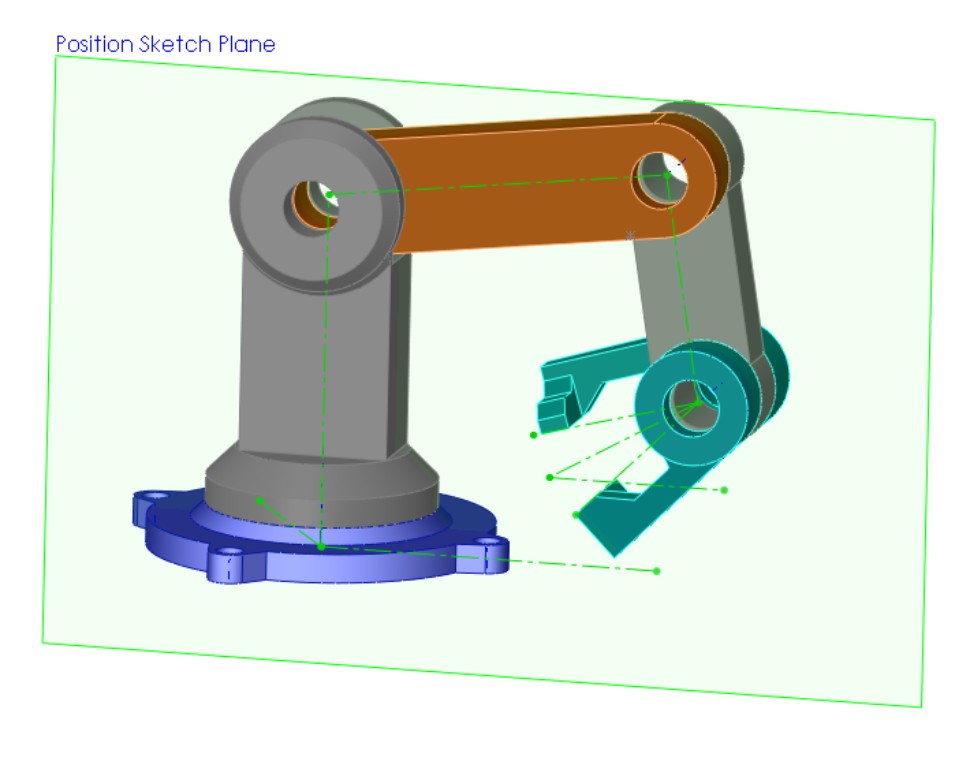

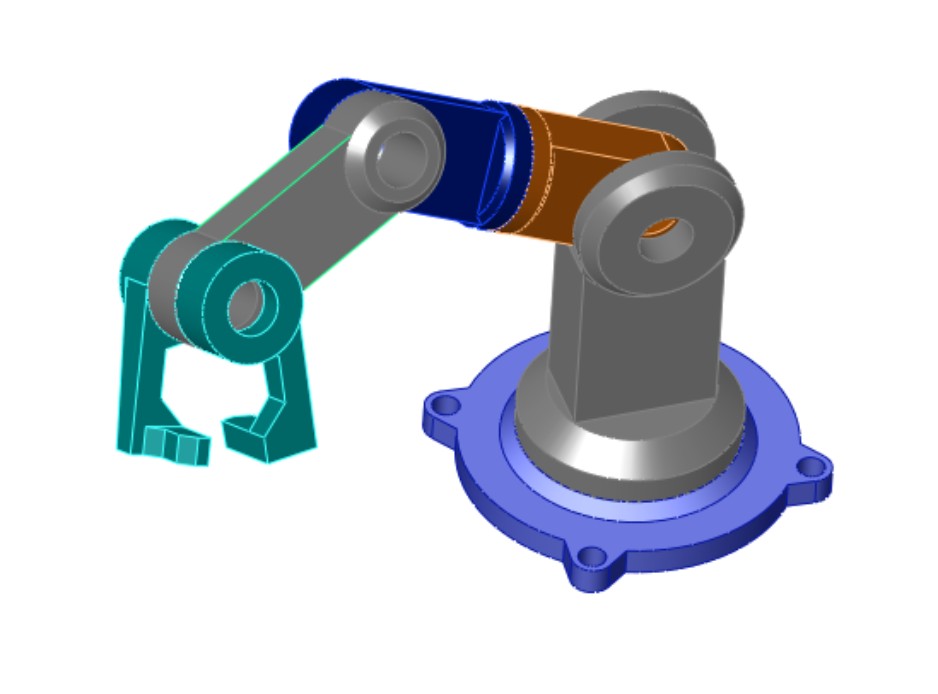

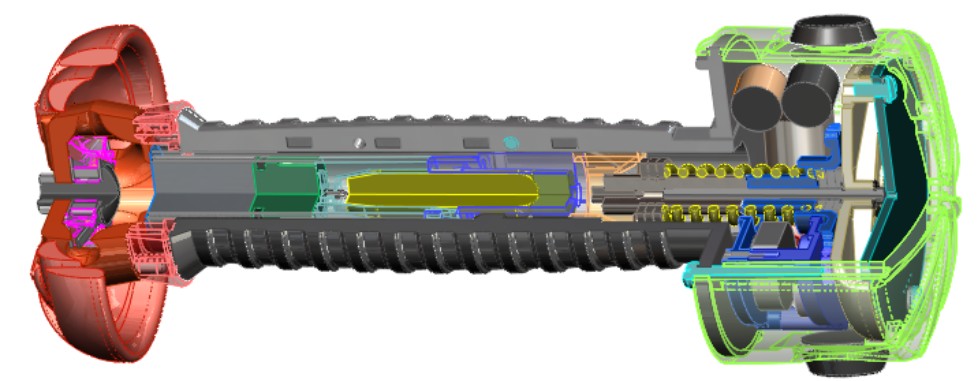

As an example of where you might use this kind of assembly, think of a robotic arm. Figure 1.1 shows an assembly that was created with bottom-up techniques and was assembled with face-to-face mates.

FIGURE 1.1

Mechanical parts using mates to locate and enable motion

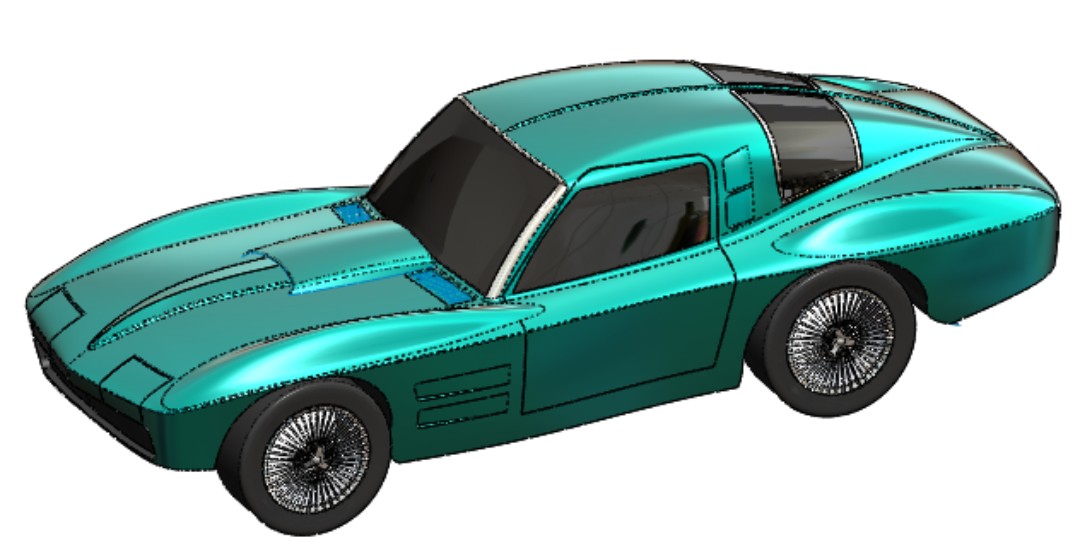

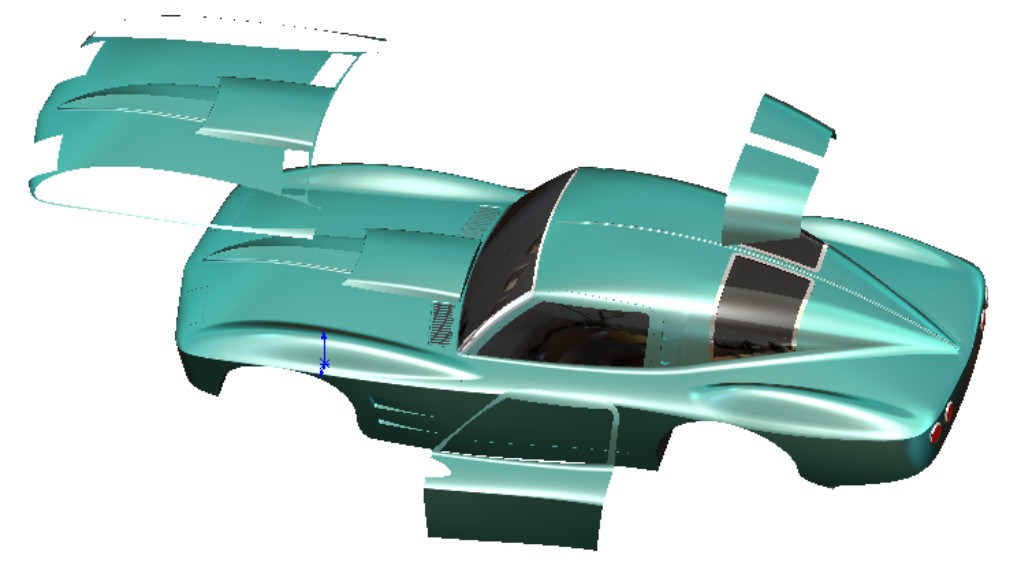

But if you were to create, say, a scale model of a car, as shown in Figure 1.2, the method of independently designing each component, especially something like body panels, and then mating them together wouldn't make much sense. Other methods in the other types of assemblies shown later in this chapter will help with this type of design.

FIGURE 1.2

Considering how you would design the parts of a scale model car

It would be difficult or impossible to design the body panels of the car such that they fit together well and looked smooth next to one another using the bottom-up with mates method.

Driving an assembly with sketches and planes

One way to avoid the potential pitfalls of mating to a base part is to replace the changeable faces and edges with items that are more stable. The stability hierarchy listing items from the most to the least stable looks like this:

• Assembly or part origin

• Assembly or part standard planes

• Reference geometry (plane, axis, point)

• Reference geometry from inserted parts (from using the Insert⇒Part command)

• Sketch lines and midpoints

• Sketch endpoints

• Surface model faces

• Solid model faces

• Edges and vertex points

• In-context items

• Reference geometry

• Faces

• Edges

An easier way to remember this without memorizing the list is that the more parents something has, the less reliable it is as a reference. This becomes more applicable if external references are involved, such as inserted parts or an in-context situation. Edges created by fillets or chamfers are lower on the list of stable references than other edges.

There is no clear answer to the question, “Is this reference stable enough?” It is entirely possible for you to be completely successful using in-context edges for all your model references. In order for that to happen, you would have to plan your model very well and avoid any big topological changes (changes to the number or function of faces) to the model.

Cross-Reference

Chapter 10 covers in-context modeling in more depth, and Chapter 19 covers inserted parts.

When you are building a part, selecting references from near the top of the previous list can be challenging, especially when faces and edges are so easy to use. You need to evaluate how much editing and rework you think you will generate when changes that you haven't necessarily planned on have to be made. Much of this ties into the design intent discussion from the SolidWorks 2011 Parts Bible.

Now consider the two examples mentioned in the last assembly modeling method — the robot arm and the model car. You could design the robot easily with the sketch layout, but simulating the motion in 3D would be difficult if you did it in conjunction with the sketch. The model car would still be difficult to assemble, and if you were just using sketches as the references between parts, it would be difficult to design the body panels such that they fit together smoothly.

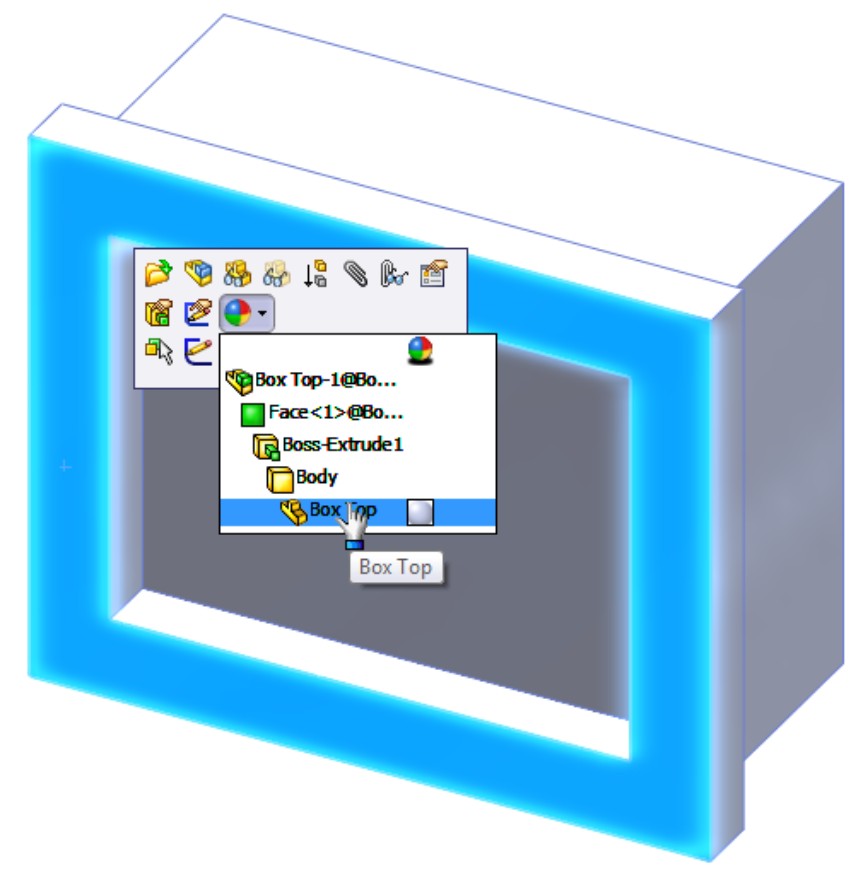

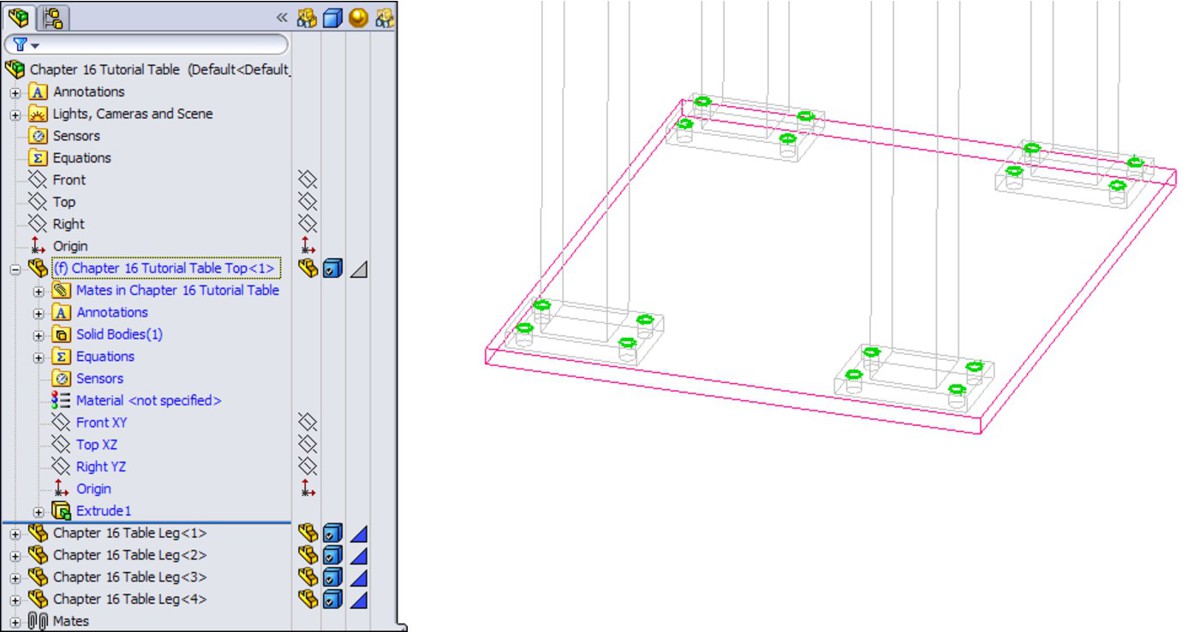

Modeling parts in place

In-context design is discussed in more detail in Chapter 10, but here you will get some idea of what to look forward to, and why this book isn't just about in-context design by itself. Modeling parts in the context of an assembly that contains other parts enables you to make relationships between the parts. Those relationships are managed by the assembly. The parts have to be arranged spatially with respect to one another, and the references to the files must also be managed.

When you see a sales demonstration, the technique of using edges of other parts from the assembly to make a new part looks very compelling, especially when you make a change to the other part and the new part updates as well. It's hard to argue with that kind of functionality. But the price you pay for that sort of associativity is that you have to manage the relationship between three files: the parent part, the child part, and the assembly. And further, within the assembly, the relationships are made between specific instances of the parts, so if you have multiple instances of each, you have to do something to remember which pair of parts is the driving pair.

Also, model history with parts does not work the same with assemblies. The relationship between the parts does not have any memory, so if you started the in-context relationships before the parent part was complete, and then put fillets over the edges that you had referenced, your in-context references would fail.

Take another look at the robot arm and the model car examples. Using in-context methods, you could certainly design the robot arm, but again you might run into some problems with getting it to move correctly while maintaining the references. However, with the model car, getting the parts in the right place wouldn't be any problem because you would be modeling the parts in-place. On the other hand, you might be able to get the shape to flow smoothly, but it is still doubtful. In-context modeling can copy 3D surfaces between parts, but for an improved workflow for this type of work, you will have to read further into this chapter.

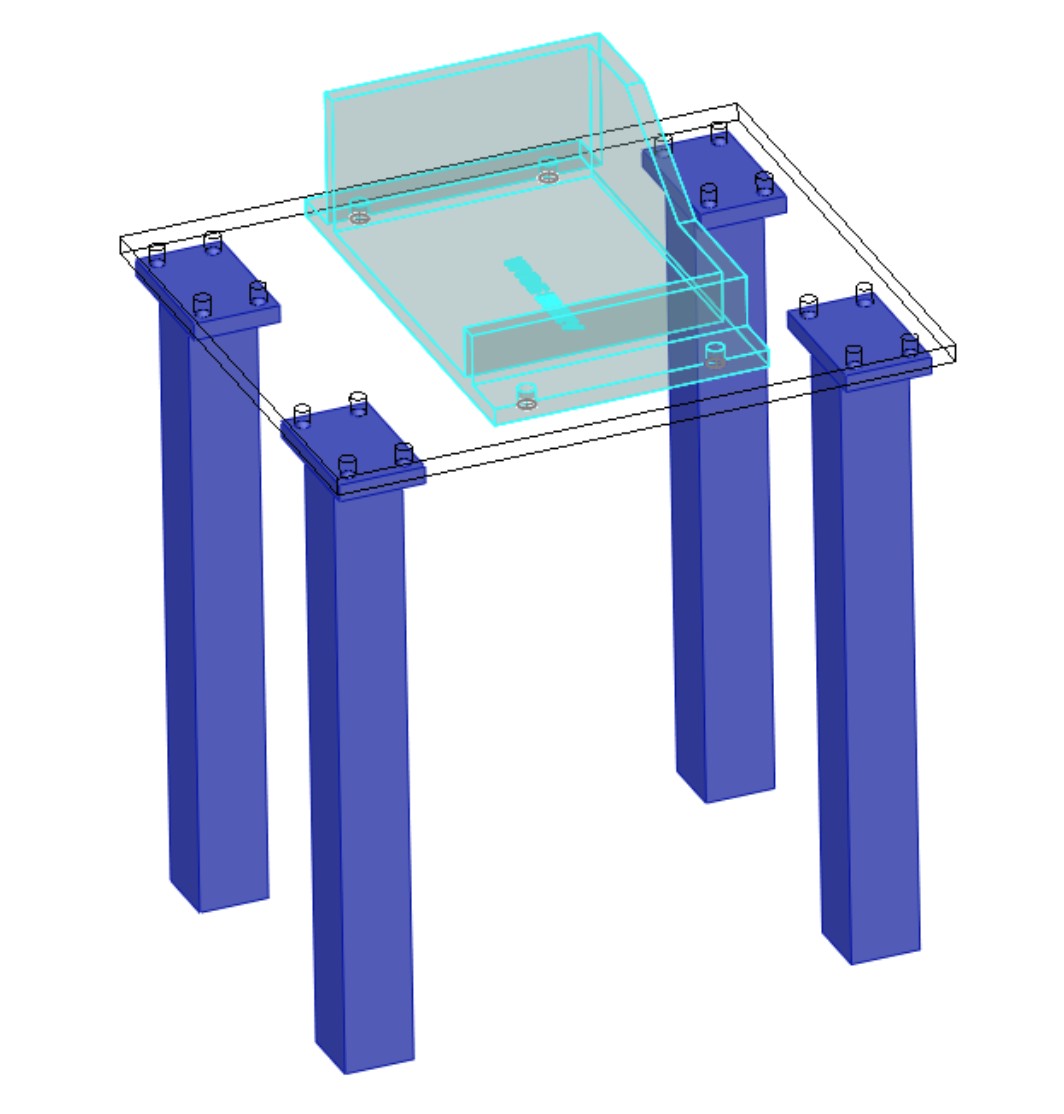

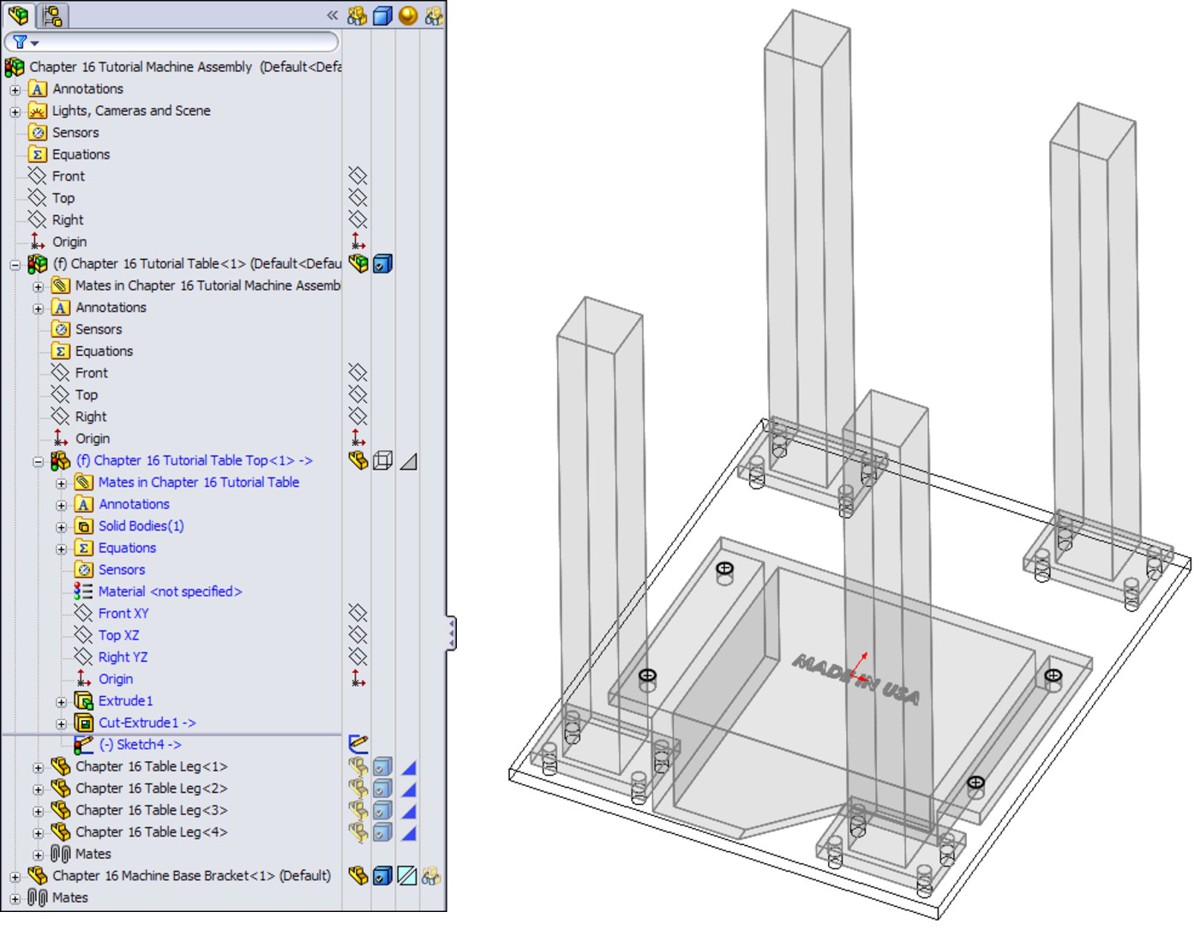

An example of a part where modeling in-context works well is a table with legs, as well as a fixture that sits on the table, as shown in Figure 1.3. The in-context work lines the holes up between the parts. There is no relative movement between the parts, and the individual parts are not likely to be used in other assemblies.

FIGURE 1.3

Using the in-context method to its best advantage

The ideal situation to use in-context techniques is when two parts are assembled face-on-face, the shape of the contact faces are the same or offset, and there is a set of holes used for fasteners. Complex shapes are generally not a good candidate for in-context methods. The main point is that there is no relative motion between the two parts.

Modeling parts as multi-bodies

Another method you can use to model parts is to start the models in a multi-body part. It is not recommended to use this method for creating finished parts as multi-bodies, but getting some of the major parts on an assembly started as a single part and then breaking them out into individual parts for details can be a very effective method.

Say you are modeling a riding lawn mower, and you need to create the plastic cowling on the front of the mower. The cowling is made up of multiple pieces because some of them are different colors, and some are transparent. The complex shapes of the cowling encompass multiple parts. If you were to model one part, and then try to model another part independently that shared some of the same shape, it would be very difficult or impossible to get the shapes to match acceptably.

One answer to this problem is to create the shape in a single part, then break the single part into individual bodies, and then save the bodies external to the original part. When you put these parts back together into the assembly, each part can be placed so that its origin matches with the assembly origin. Because the parts all started from the same part, they will all share the same origin. This makes putting the parts back together much simpler. It makes assembly for motion more difficult, but parts that have a shape in common are more likely to be fixed with respect to one another.

Multi-body modeling has advantages over in-context modeling in that it reduces external references (although saving bodies out as parts creates an external reference), but it also has some drawbacks. If you were to take all the features of individual parts and stack them into a single feature tree in a single part, you would probably be unhappy with the result. By making all of the features for all parts within a single part file, you make troubleshooting much more difficult, and rebuild times are dramatically increased. Add to this the inability to reuse parts, do individual revision management, or perform simple assembly operations such as dynamic motion, exploded views, or BOMs, and following the multi-body method through to finished parts becomes very unattractive.

The best option for using multi-bodies to create parts for an assembly is to start the parts in multi-body mode, and then as soon as the inter-body references are no longer needed, transition the bodies to separate parts.

Multi-body modeling may not do so well when parts are repeated, or where purchased components represent a large percentage of the total parts. While you do have mate-like functionality for placing bodies within a multi-body part, it is probably not the best use of this method. Figure 1.4 shows a product that is designed as a multi-body part but involves many difficulties because of reused parts and hardware.

FIGURE 1.4

Reusing parts is not a strength of multi-body methods.

Revisiting the test for each method, you would find that the robot arm is well suited to being designed as a multi-body part and then reassembled with mates in an assembly. In fact, the multi-body method is probably the best method for this type of work, maintaining references between parts, and then assembling the parts into an assembly mechanism with motion.

The model car, with its shape that flows between parts, would still be awkward, although it could be done as individual parts. You will now look at the last method to see if this helps with the car model.

Inserting a master model

You will learn about the master model technique in Chapter 19. In a nutshell, a master model is a single part where you place sketches, reference geometry, surfaces, and maybe some solids, and then insert that part into other parts to use a reference to build each individual part. Using this technique makes in-context work unnecessary, and eliminates some of the dangers of creating too many features in a multi-body part.

You assemble parts in this manner the same as with the multi-body part method. Take each part, and drop it into the FeatureManager of the assembly. This aligns the part origin with the assembly origin, and because each part was built from the same master model, all parts share the same origin.

Take another look at the robot arm and model car examples. The robot arm may be a little awkward using this method, but it works. The multi-body method is probably best for this type of design.

On the other hand, the master model method brings real power to projects such as the model car. You can design the entire outside of the car as if it were a single part, and then break it up into individual parts. In Figure 1.5, notice how some parts that will be manufactured as a single part can be easily pulled off of the master model. Sketches within the master model can help define breaks between parts and even if there is relative motion — for example, with the doors.

FIGURE 1.5

Pulling parts off of the master model

Excluding some parts

Methods such as those mentioned previously are great for any part that is unique to an assembly, but should not be used for library type parts. If you have a part that will be used in more than one assembly, it should not have any external references. To be clear, all of these methods create external references except bottom-up assembly (where parts are modeled individually, and then assembled to one another or to a skeleton).

Any library parts that you have, or standard hardware such as nuts, bolts, washers, and so on, should not be modeled with references, nor should you use them in multi-body parts.

Without sounding against multi-body modeling, several SolidWorks users think eliminating the distinction between assemblies and parts would be a good thing. That point of view works for only the simplest small assemblies with simple parts. It's easy to come up with situations in which the tree management tools required to maintain models built using that philosophy through changes do not even exist in the software.

Creating an alternative to multiple assemblies

It may seem very inefficient to re-create or copy assemblies for different uses. In Chapter 8, you will learn about another way: using assembly configurations. If you are already familiar with part configurations, assembly configurations work on a similar principle. Assembly configurations are a great tool with a lot of theoretical benefits and practical limitations. As with most other functions in SolidWorks, when you need to create assemblies for multiple purposes, you may find that assembly configurations meet your needs. Or you may find it easier to just save out a copy of the assembly, knowing that changes for the sake of rendering do not diminish the usefulness of the data for something like exploded views, or managing external in-context references.

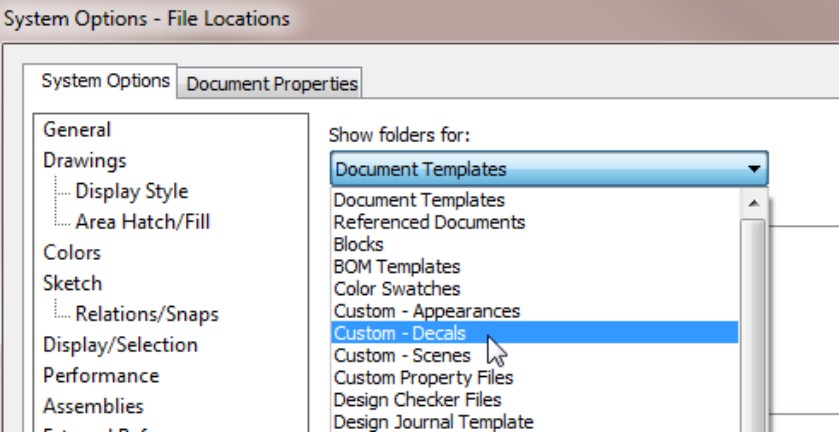

Creating Assembly Templates

When you have assemblies with different purposes, you may also need multiple assembly templates. One example of using assembly templates to help reuse work is saving an animation in a template. If you save an assembly template that contains a default turntable animation, then you can put other assemblies right into the turntable template and you've got an instant display animation. (Animation is covered in detail in Chapter 23.)

Another example of a useful assembly template would be a rendering setup with environment, background, and lighting. Putting a part or assembly into the template before doing a stock rendering can help you standardize renderings and work through them more quickly.

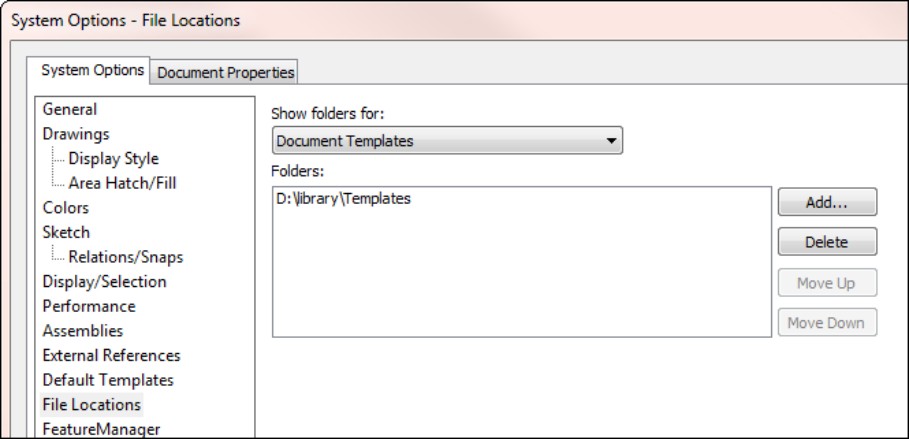

The steps to create an assembly template are similar to those for setting up a part template:

1. Specify a custom location for all your templates. You can do this at Tools⇒Options⇒File Locations⇒Document Templates. You should save it in a location such as D:/Library/Templates/. For a group of users, you may want to use a network location so you can share the templates.

2. Start with an assembly that has most of the settings you intend to use.

3. Add whatever animation, scene, or light settings you want. You may have to add a dummy assembly to get the settings right, and then delete it before saving it as a template.

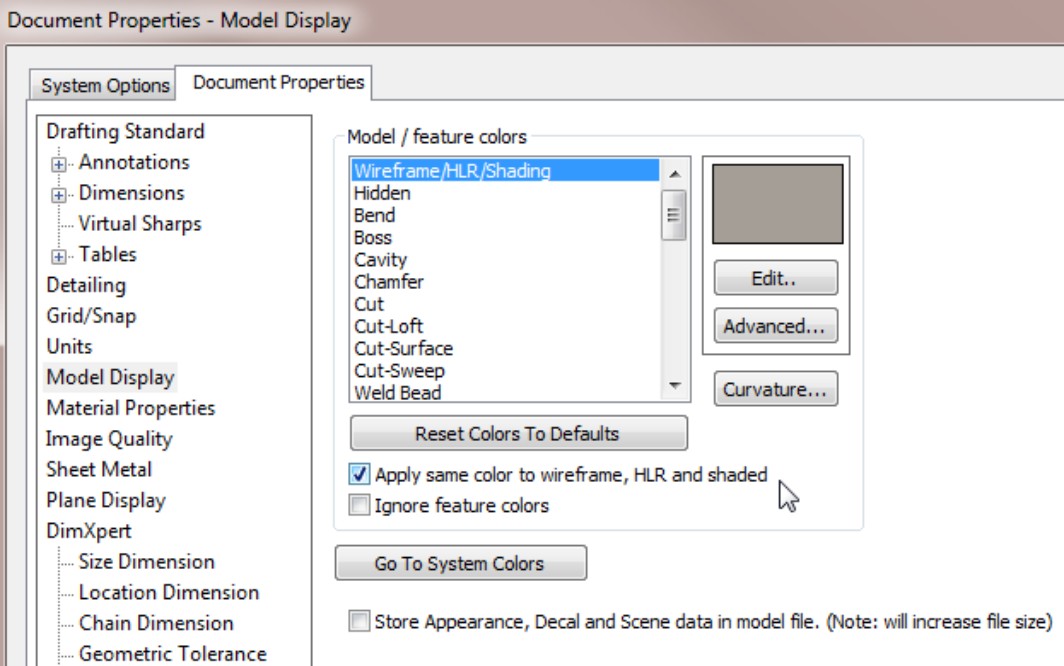

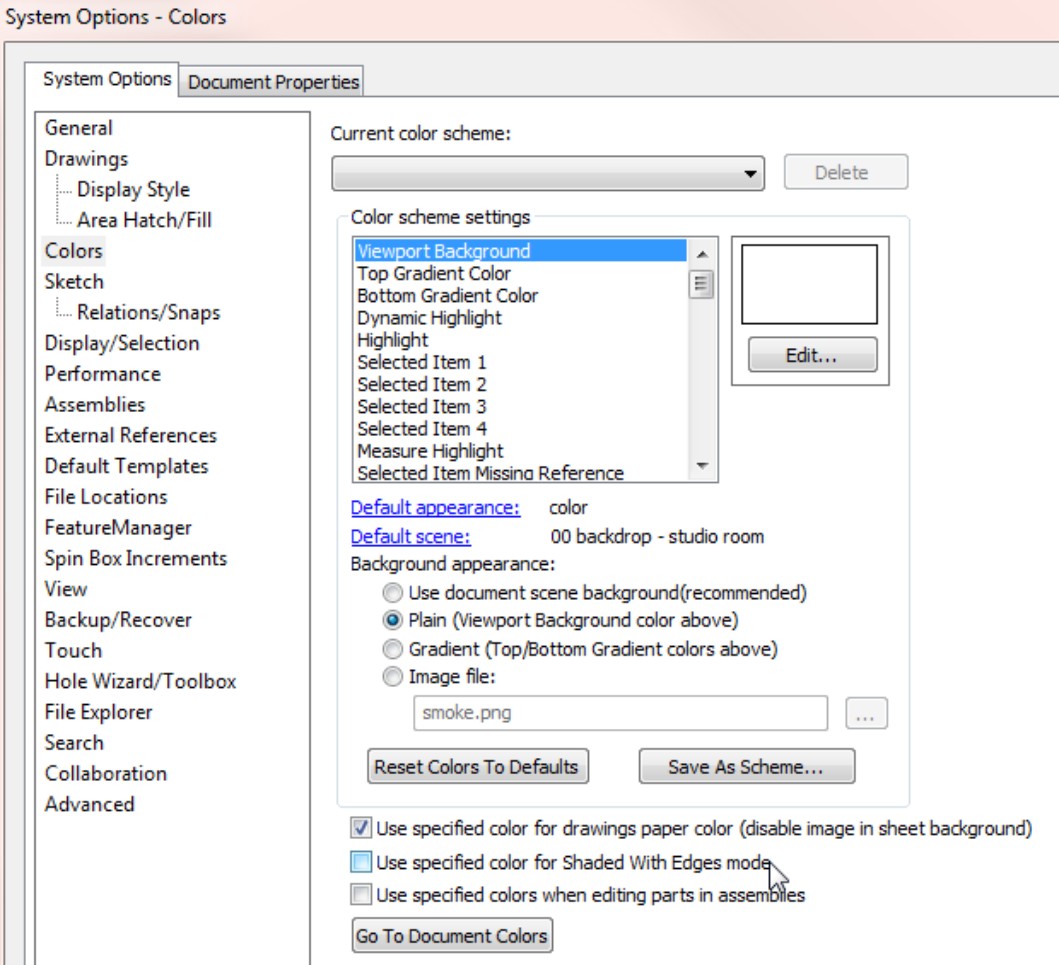

4. Set the options in Tools⇒Options⇒Document Properties the way you want them. Pay special attention to the Drafting Standard, Units, Model Display, and Image Quality settings.

5. Rename the standard planes as appropriate. If your assembly template is bound to be used for injection mold tooling, you may name planes to establish the Parting Plane. If you are creating architectural assemblies, you may have planes called Plan View, Side Elevation, and North Elevation.

6. Make sure the custom properties (found at File⇒Properties⇒Custom) for the assembly template are set the way you want them. Remember that you can use Tags in some ways like custom properties. In fact, custom property settings might be a reason for making separate assembly templates. You might have a different set of custom properties for a tooling assembly used in manufacturing as opposed to a product assembly that is shipped to customers. You may also choose to change the default settings for showing annotations such as cosmetic threads and shaded cosmetic threads (click the right mouse button (RMB) on the Annotations folder in the Feature Manager and select Details for these options)

7. When you have all of the document-specific settings the way you want them, save the assembly file as a template. Choose File⇒Save As, and SolidWorks directs you to the folder where you have specified that your templates will go.

Figure 1.6 shows the Tools⇒Options⇒File Locations interface where you should set your templates' locations.

FIGURE 1.6

Establishing the location of your templates

Using assembly templates is easier than creating them. To choose from a number of assembly templates, you have to use the Advanced interface on the New Document dialog box. If you use the Novice interface, you can only choose the default templates.

If you want to use only a single assembly template, and set that one as the default, first save the template to a location as described previously, and then set the default assembly template at Tools⇒Options⇒Default Templates.

If you would like to devote an entire tab of the New Document dialog box to just assemblies, then in Windows Explorer, in the folder specified in your template locations, create a new folder named Assemblies or something relevant. This folder name will show up as a tab in the Advanced interface for the New Document dialog box.

Note

The Novice interface displays a button that says Advanced, and the Advanced interface displays a button that says Novice.

Figure 1.7 shows the Novice and Advanced interfaces.

FIGURE 1.7

Starting a new assembly from the Novice and Advanced interfaces of the New Document dialog box

Putting Parts into Assemblies

When you are building an assembly, several ways exist to put parts into assemblies:

• Choose Insert⇒Component

• Drag and drop from Windows Explorer

• Drag and drop from other SolidWorks windows

• Drag and drop from the Design Library window

• Ctrl+drag to add a second instance of a part that is already in an assembly

• Create an assembly from a part

• Create a part in-context

The first part that you put into an assembly is always fixed (meaning locked into position). When parts are fixed automatically, the origin of the part is always located at the origin of the assembly, but parts may be manually fixed at any location in the assembly.

After the first part, any additional parts you put into the assembly will either fall where you drop them if you drop them in the graphics window or be positioned at the assembly origin if you drop them into the FeatureManager.

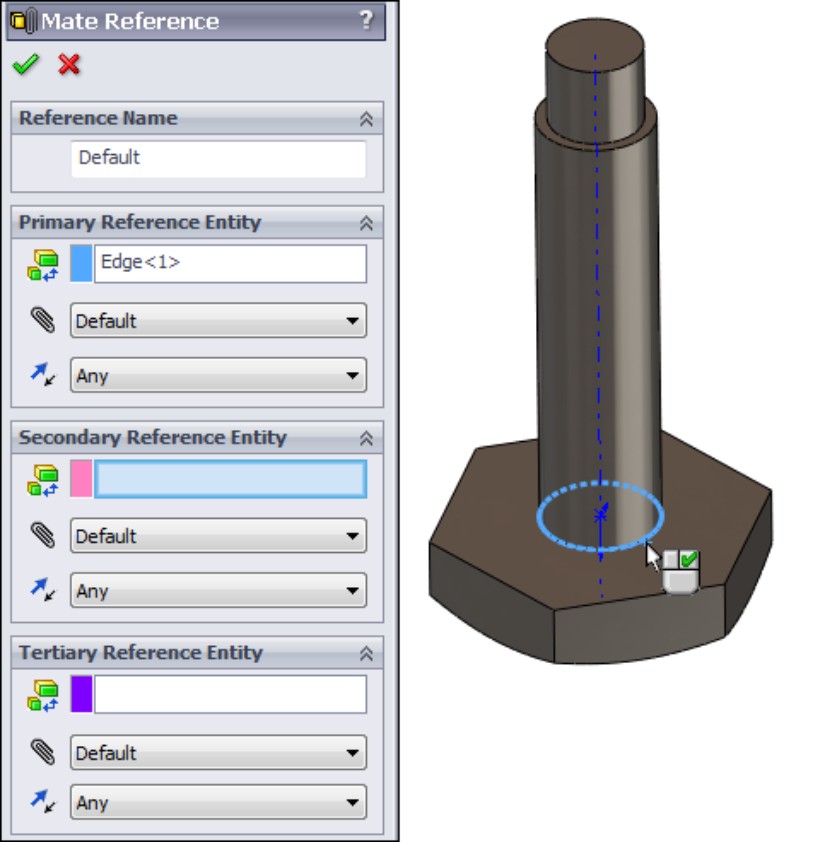

One of the most valuable methods is to use SmartMates and Mate References. SmartMates enable you to Alt+drag a part by specific geometry on the part and drop it onto specific geometry on another part; a mate is then automatically created between the parts. SmartMates do take some practice, but they help you save a lot of time and frustration when putting an assembly together from parts. Mate References are similar, except that you have to set them up beforehand (and so they work best on library type parts), and they enable a part to snap into place when you drag it into an assembly.

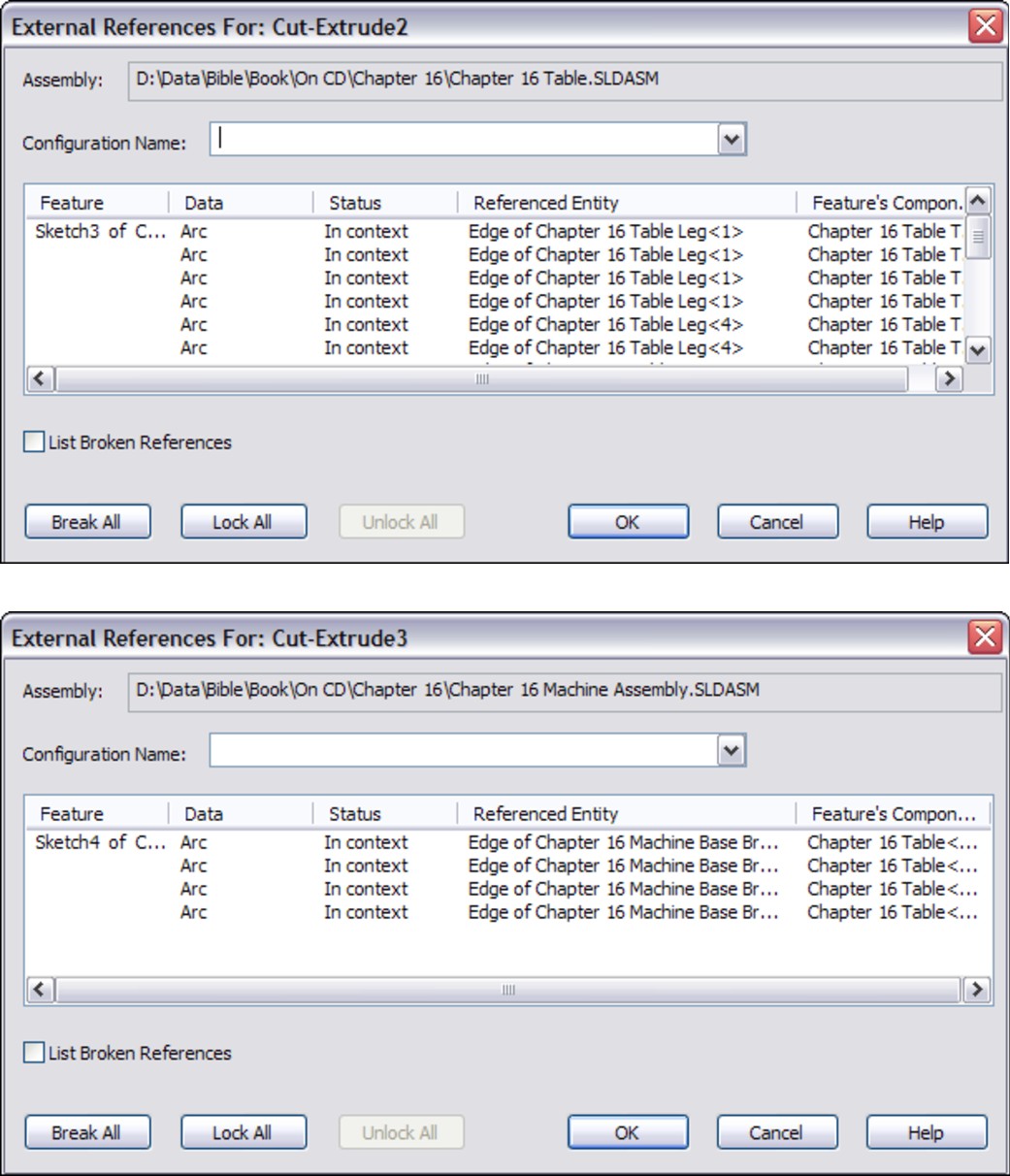

Understanding External References

External references are one of the most time-consuming aspects of assemblies, and all assemblies and assembly replacement techniques have them. An external reference is any reference to a file outside of the current file. So in its simplest form, part files in an assembly create external references, because the assembly references the parts.

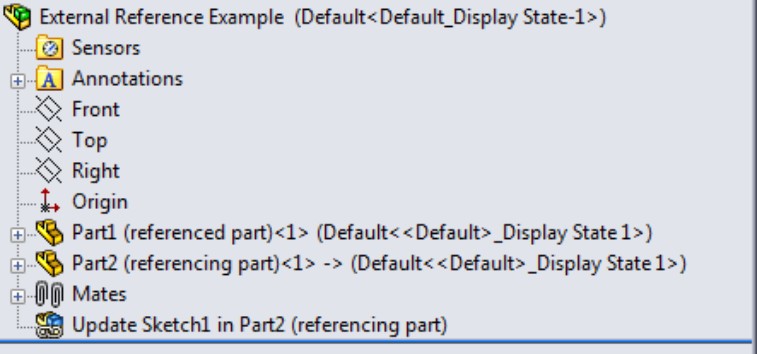

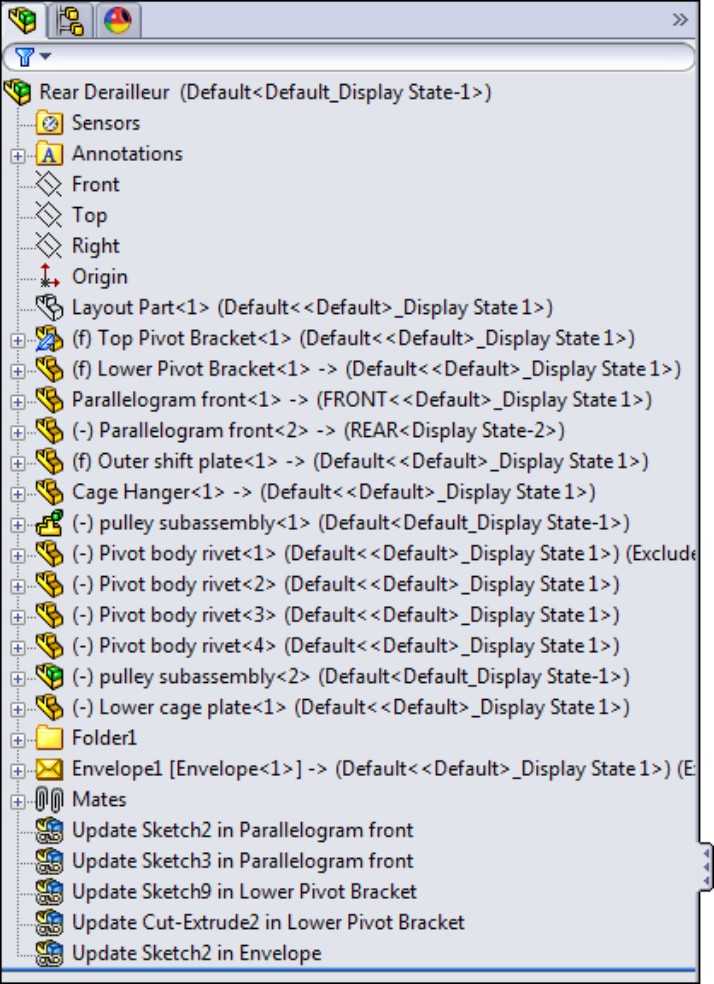

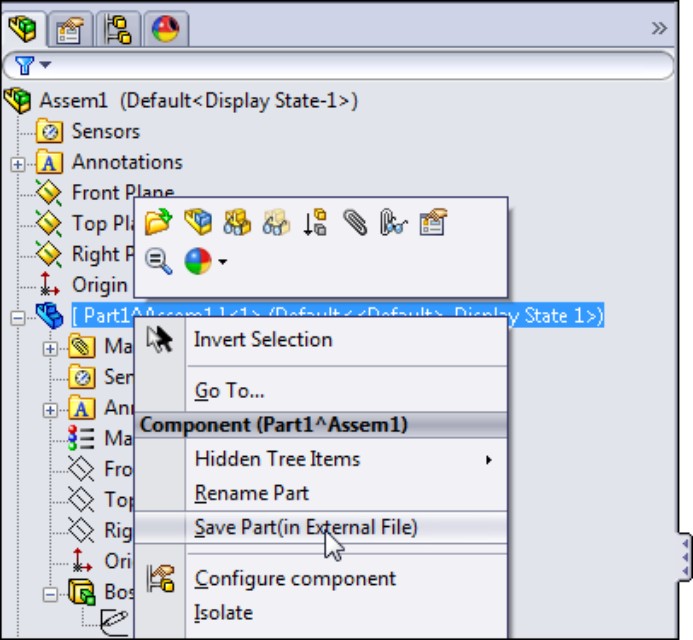

You can easily recognize external references of all kinds by the -> symbol following a feature in the FeatureManager. Figure 1.8 shows a portion of an assembly FeatureManager that contains the symbol. You can also find this symbol on externally referenced features within a part.

FIGURE 1.8

The external reference symbol on a sketch and a feature

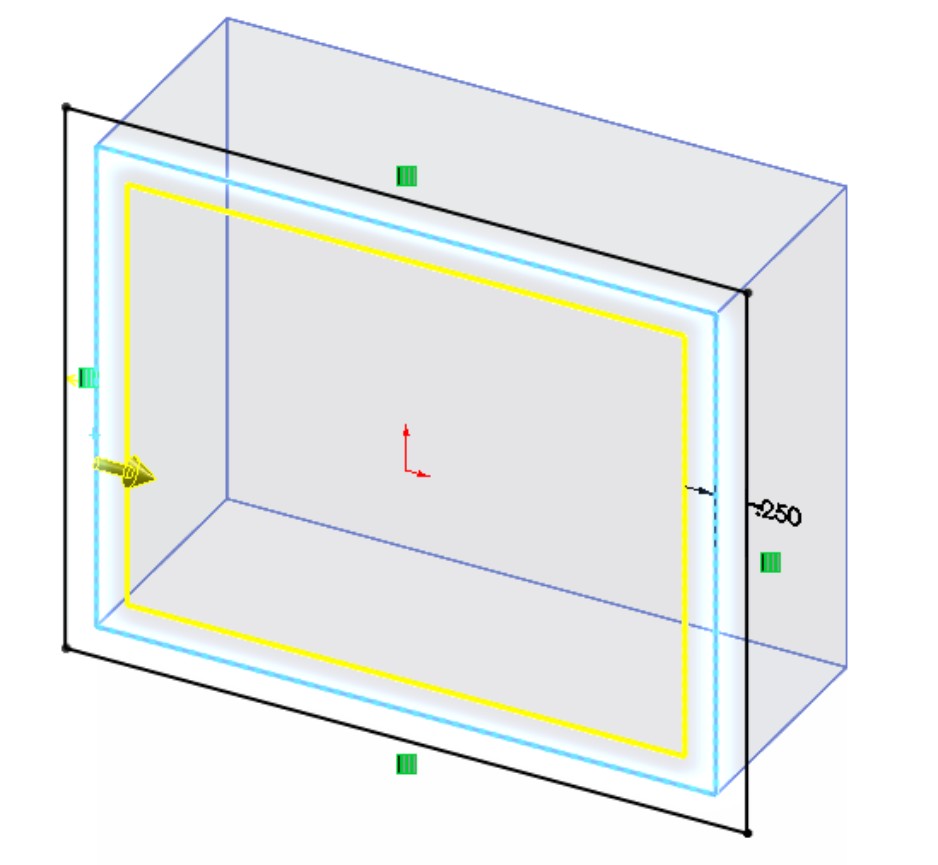

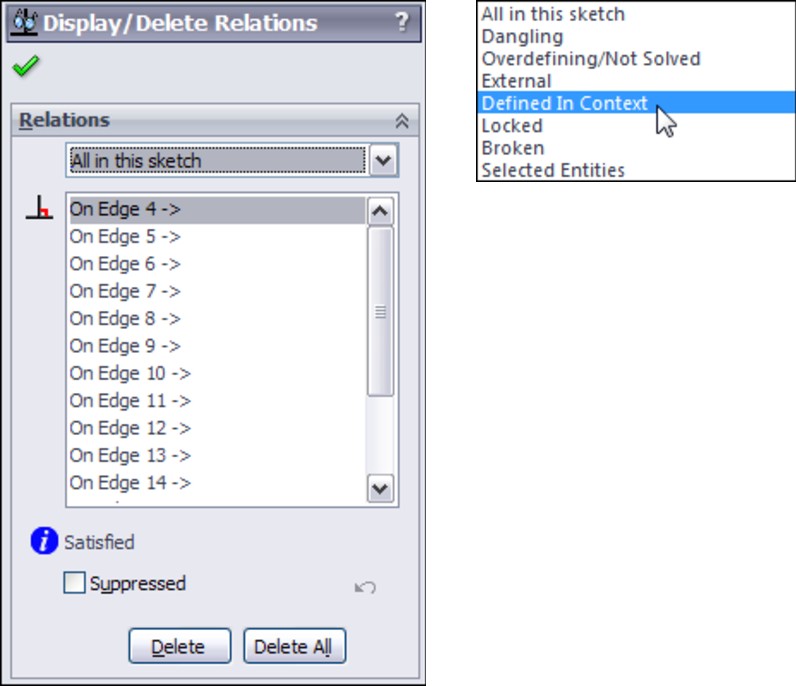

Referencing external files in-context

In-context techniques are all about external references. External in-context references in an assembly occur when one part in the assembly has some sort of geometrical reference to another, such as offsetting an edge of a part, using a vertex of a part with a coincident sketch relation, or using a face of another part as a sketch plane. All of these references are saved in Update Holders that reside in the assembly FeatureManager, but SolidWorks hides them by default. Figure 1.9 shows a simple assembly FeatureManager with a single Update Holder. You can show the Update Holders in an assembly by right-clicking the top level name of the assembly in the FeatureManager and selecting Show Update Holders.

FIGURE 1.9

Displaying an Update Holder that keeps external reference information

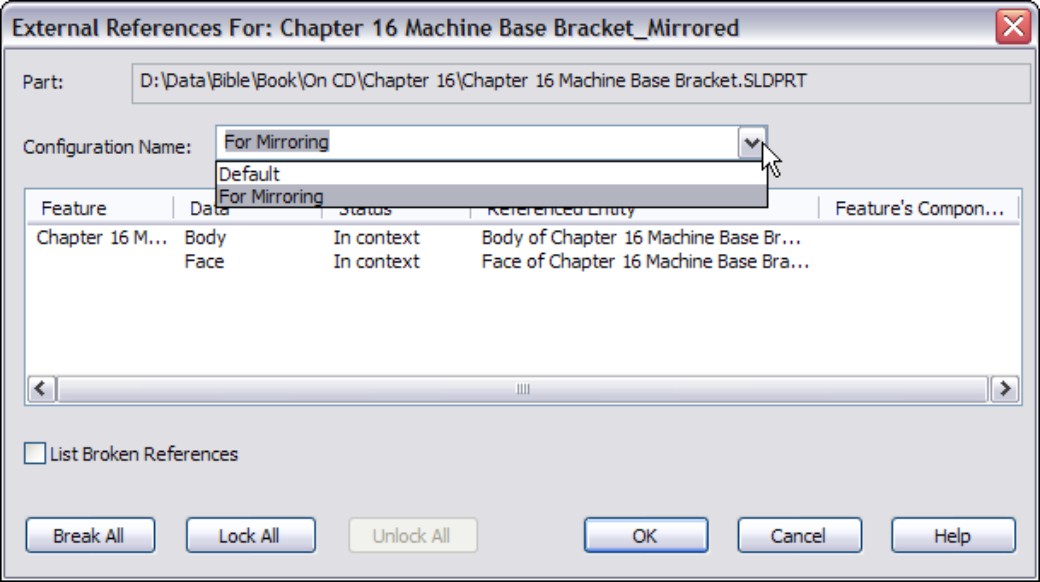

To view the contents of the Update Holder, right-click the Holder or any part or feature that contains external references, and select List External References from the menu. The information stored in the Update Holder shown in Figure 1.9 is shown in Figure 1.10.

FIGURE 1.10

Showing the contents of the Update Holder

In the example shown in Figure 1.9, four edges of Part1 are offset into Part2. Also, the Part2 sketch into which the edges are offset uses a face of Part1 as the sketch plane.

Note

The Insert the features of the original part(s) if references are broken option in the External References For dialog box does not apply to assembly in-context situations. It only applies to inserted parts (what the Help system calls “derived parts”). Inserted parts are also external references where references can be broken. You will find more information on this topic in the next section.

Each Update Holder holds the external reference information for a single feature. If a sketch and a feature have different external references (for example, the sketch might reference face edges, while the feature might reference a vertex in the other model for an Up To Vertex end condition), there will be a different Update Holder for each. The external reference information has several components:

• The name of the assembly where references are made

• The configuration of the assembly where references are made

• The feature where the reference was created

• The type of entity that was referenced, and which part it is in

• The part from which the reference was created

Referencing external files from a part

Chapter 19 is all about referencing external files from a part. As a preview of what you will see in that chapter, you can insert one part into another part to use in a number of ways, such as the following:

• A starting point, for example, adding secondary operations to a cast part

• A tool, for example, using the Indent feature to create a clearance for an interfering part

• A Boolean operator, for example, to subtract one part from another

• A set of reference geometry, for example, inserting the surface of a car door to create the outer skin of the door

To create these external references, SolidWorks provides four different features or functions:

• Insert Part

• Insert Into New Part

• Split

• Save Bodies

External references within parts can be broken in the same way that in-context relations can be broken. External references in parts have just one fewer component compared to assemblies — parts obviously do not list an assembly where the reference was created.

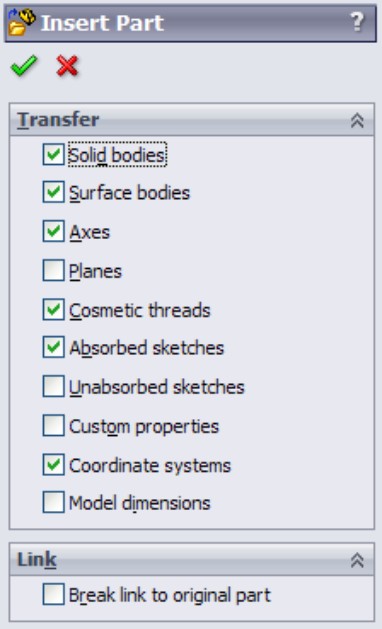

For parts, two different kinds of external references exist: inserted parts (on the left in Figure 1.11) and stock parts (on the right in Figure 1.11). Figure 1.11 shows these two types of references inserted at the top of different part FeatureManagers. Notice that they both have the in-context external reference symbol (->) after the first feature.

FIGURE 1.11

Two kinds of external references in SolidWorks parts

The inserted part allows you to bring across planes, sketches, features, and even the entire part if you want, but on the down side, it forces you to bring all bodies to the new part (you can select solid or surface, but you can't select which bodies). The stock feature enables you to select which bodies you bring to the new part, but it only allows you to bring solid bodies (not surfaces) and does not allow you to bring reference geometry, sketches, or features.

Summary

If you have taken the SolidWorks training classes, even the advanced training classes, you may not have seen the entire range of what you can do with SolidWorks assemblies. Keep an open mind about being able to accomplish more by using assemblies that are built for different purposes.

External references in assemblies tend to intimidate a lot of users, but if you know where to find the necessary information, and how to handle the data, you can have complete control over your assembly models, and you don't have to be afraid of techniques such as in-context or master model.

Chapter 2: Navigating the Assembly Interface

In This Chapter

Discovering elements of the SolidWorks interface

Exploring the interface

The SolidWorks interface for working with assemblies offers a wide range of tools. You will often find more than one way to do almost everything. Most of the tools are the same as those found in the general parts interface, but this chapter will show you special techniques for using these tools to make your job easier with assemblies.

Once you have mastered the various interface elements and customized your SolidWorks installation, working with assemblies becomes much more efficient and satisfying. Your command of the interface will come with practice and experience. Many existing users may discover features in this book of which they were not aware, even though they have used the software for years.

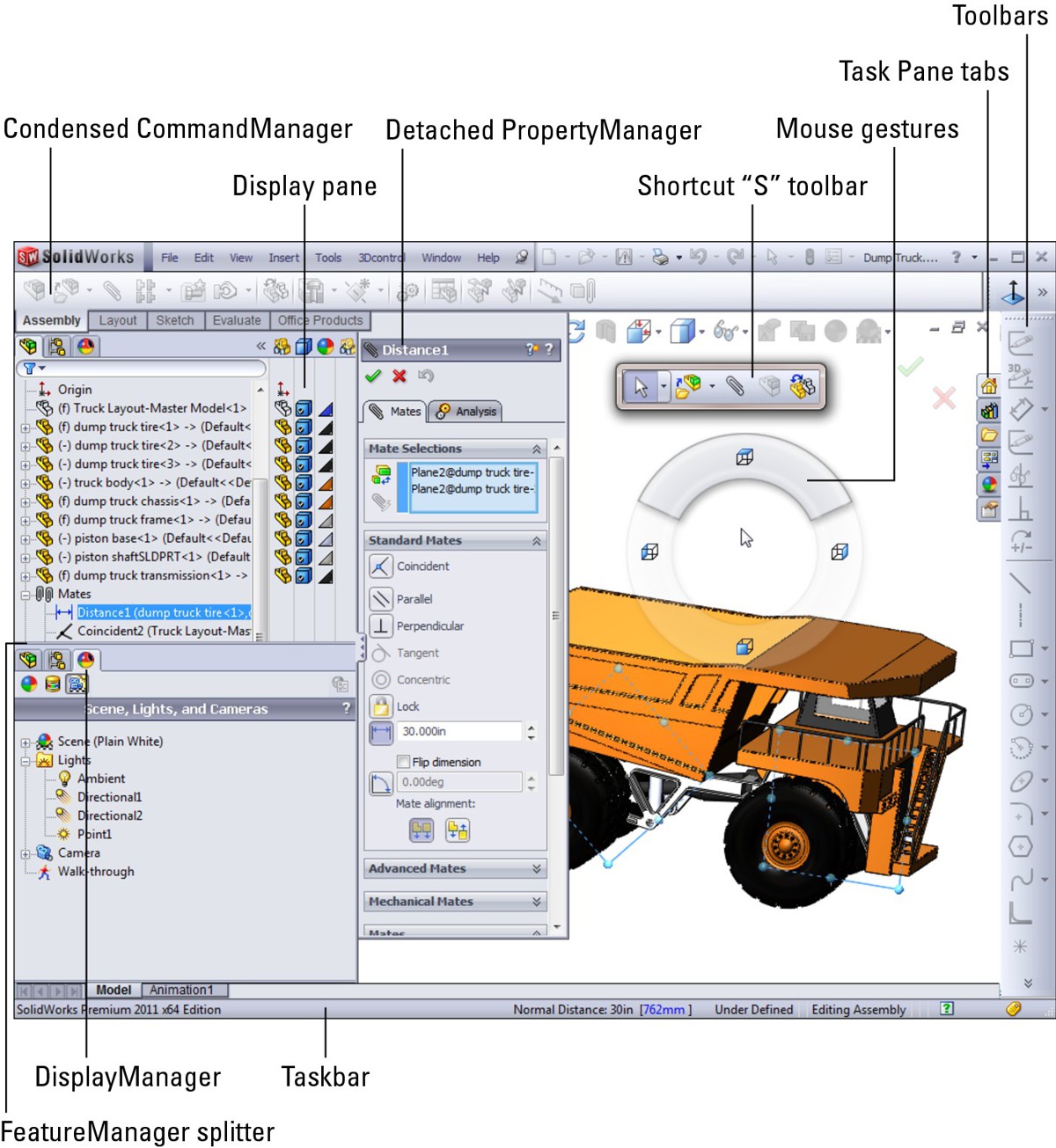

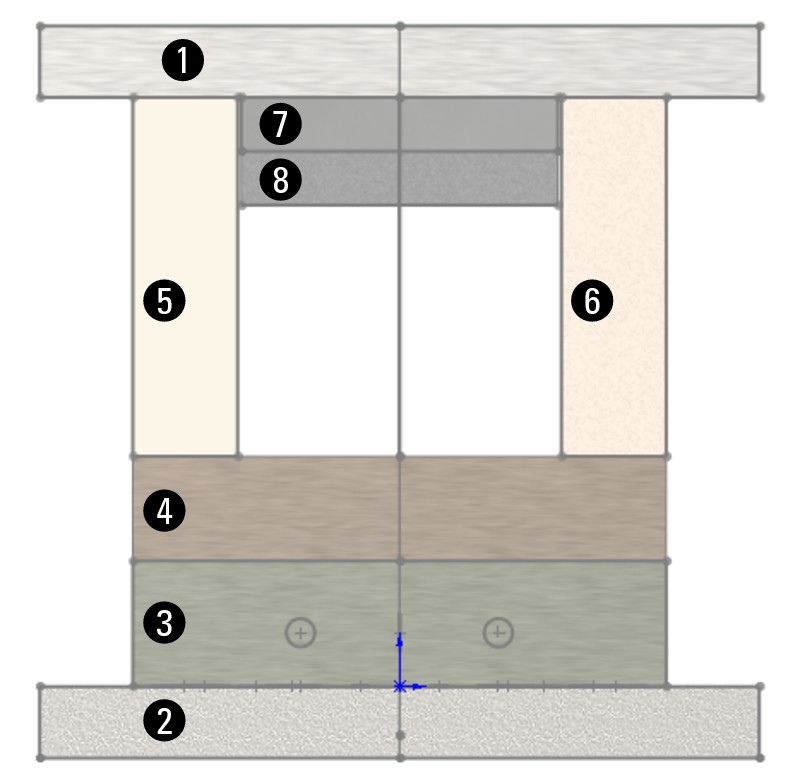

Each interface element identified in Figure 2.1 is explained in detail within this chapter. You won't see all of the elements shown in Figure 2.1 at the same time; the figure was assembled to show as many interface elements as possible.

FIGURE 2.1

Elements of the SolidWorks assembly interface

Identifying Elements of the SolidWorks Assembly Interface

Most of the elements of the assembly interface are the same as the part interface. (You can find a complete description in the SolidWorks 2011 Parts Bible.) This chapter describes the elements of the SolidWorks interface that are either unique to assemblies or vital to the assemblies' functionality.

Using the CommandManager and toolbars

Remember that the CommandManager saves settings for parts, assemblies, and drawings. This means that it may have different tabs when you are in each of these document types, and you can set each type to have the features and functions that you need.

The CommandManager is less useful in assemblies than it is in parts. Of course, everything depends on what you plan to do in assemblies, but most users generally use fewer tools in assemblies than they do in part documents. In parts, it is common to use the Features tab as well as Sheet Metal, Weldments, possibly Surfaces, and some other CommandManager tabs. In assemblies, the Assembly and Evaluate tabs are the most relevant.

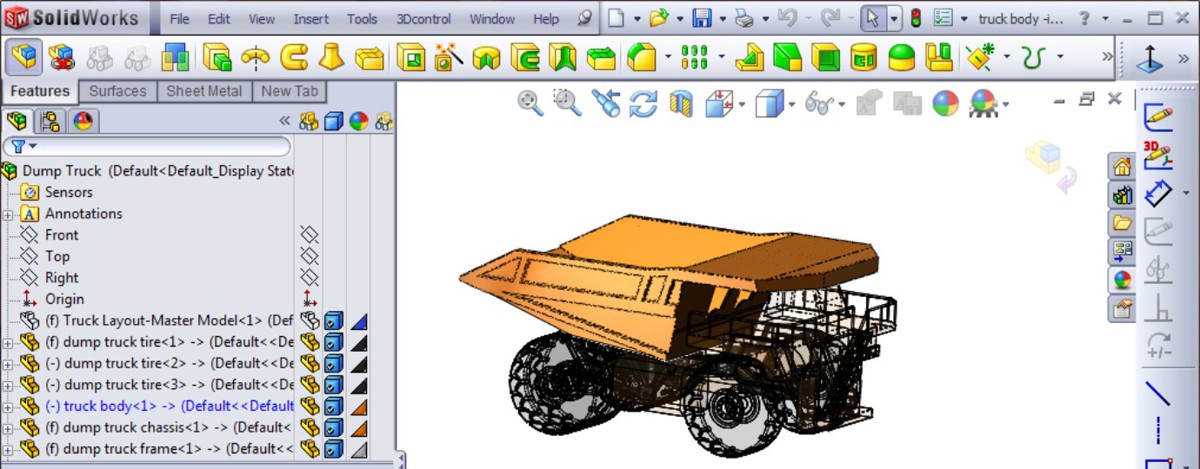

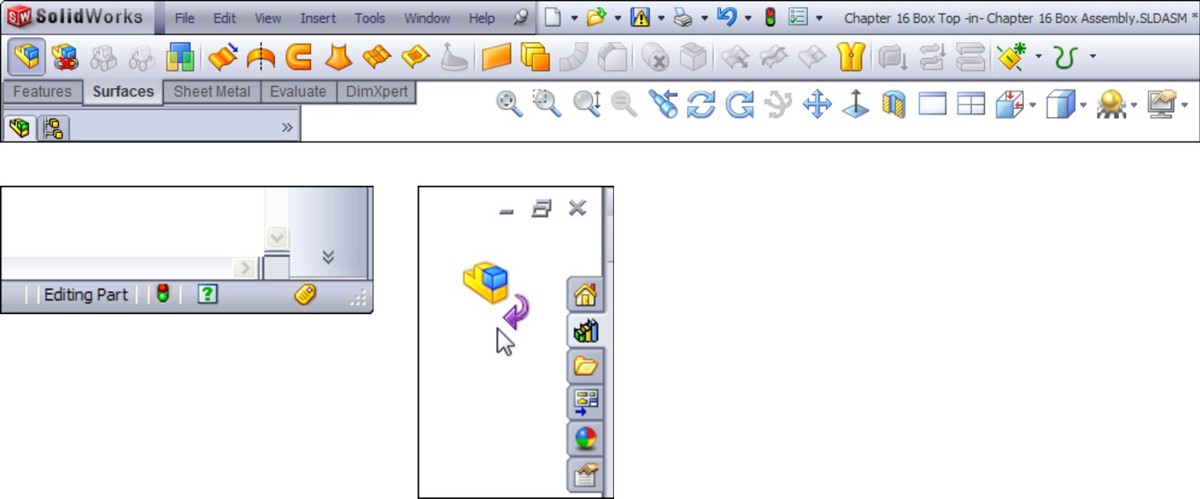

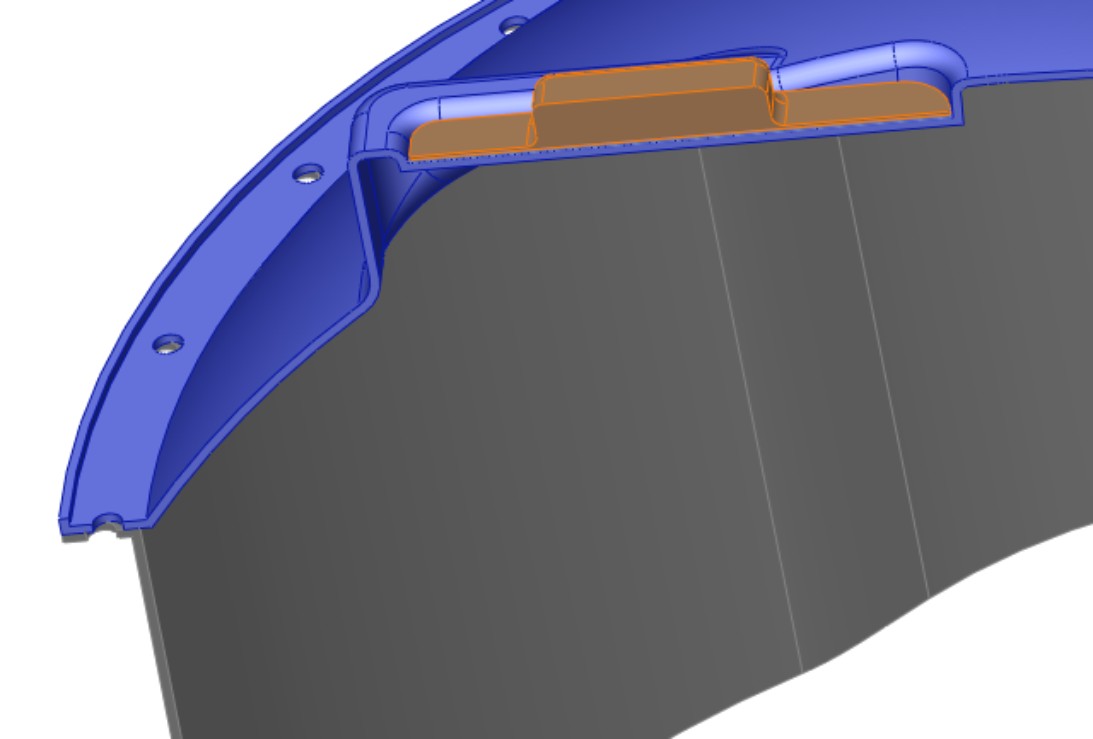

When you edit a part in the context of the assembly, the assembly CommandManager turns into the part CommandManager with some additional tools. Figure 2.2 shows the CommandManager in an assembly when editing a part (with large icons and text removed).

FIGURE 2.2

The CommandManager when editing a part in the context of an assembly

One of the most common mistakes when editing parts in an assembly is to forget which mode you are in — Edit Part or Edit Assembly. Notice the ghosted Edit Part icon where the sketch Confirmation Corner goes (upper-right corner). Also notice that the Edit Part icon in the Assembly toolbar appears depressed. If you have room in your interface, the name of the assembly or the part shows on the title bar. Figure 2.2 shows the interface at a low resolution (1024 x 768), and only part of the height. At this resolution and with the menus pinned along with the title bar toolbar, there is little room for the filename.

Notice that the first five icons on the left side of the CommandManager in Figure 2.2 are assembly tools. They are, respectively,

Edit Component

No External References

Hide/Show Components

Change Transparency

Assembly Transparency

Notice that the Hide/Show Components and Change Transparency icons are nearly indistinguishable. On the interface, the transparency icon is ghosted somewhat. Remember that tool tips can be a very effective way to remember what various icons in the interface signify until you have learned them thoroughly.

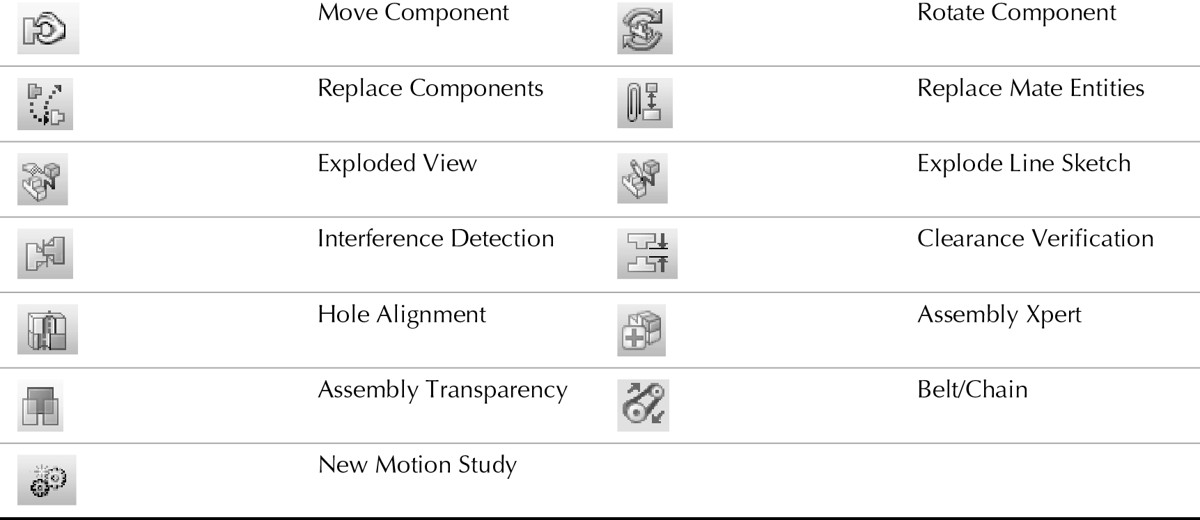

Introducing the assembly tools

The tools on the Assembly toolbar are not all available by default, and if you are new to SolidWorks, or are experienced with the software but only use assemblies superficially, you may not be familiar with all of the available tools. The names of the tools are listed in Table 2.1, as displayed in Tools⇒Customize for the Assembly toolbar.

Notice that the small New Part icon is different from the large icon; the small version looks very much like the Smart Fasteners icon. All of these tools are covered in depth throughout this book. You can use the index to find where each topic is covered in detail. Chapter 7 is devoted exclusively to using the Assembly tools.

Using the Heads-Up View toolbar

The Heads-Up View toolbar appears along the middle of the top edge of the graphics window. Figure 2.3 shows the default arrangement of the Heads-Up View toolbar, and it is shown in relation to the rest of the interface in Figure 2.1. This toolbar is not configurable for each document type. It is either on or off, and the icons on it remain the same for parts, assemblies, and drawings.

FIGURE 2.3

The Heads-Up View toolbar

You can customize the Heads-Up View toolbar by using the Toolbars dialog box (Tools⇒Customize⇒Toolbars). Customization includes turning the Heads-Up View toolbar on or off and adding or removing buttons. If you have multiple document windows or multiple viewports showing, the Heads-Up View toolbar only appears in the active window or viewport. This toolbar often overlaps with other interface elements when several windows are tiled or if the active window is not maximized. If it is pulled out of the FeatureManager, it can run into the PropertyManager, as well as the Confirmation Corner or the Task Pane.

Using the Shortcut “S” toolbar

The Shortcut toolbar is also known as the “S” toolbar because by default, you access it by pressing the S key. You can customize this toolbar for each document type and another toolbar for sketches, so it can have different content for sketches, parts, assemblies, and drawings. To customize the “S” toolbar, right-click it when it is active and click Customize from the right mouse button (RMB) menu, as shown in Figure 2.4.

FIGURE 2.4

Right-click the Shortcut “S” toolbar to customize it

Many people claim to have customized the “S” toolbar to such an extent that they have been able to remove the CommandManager and all other toolbars from their interface. This may be true if you use a limited number of sketch entities, sketch relations, and feature types, or if you make extensive use of flyouts on the “S” toolbar. However, if you work with a wide range of tools (say, surfacing, sheet metal, and plastic parts), you may need some additional toolbar space. It is completely possible to have access to most of the software's functions with the “S” toolbar and either the Menu Bar toolbar or the CommandManager. The CommandManager gives you the most flexibility, but it also requires the most space.

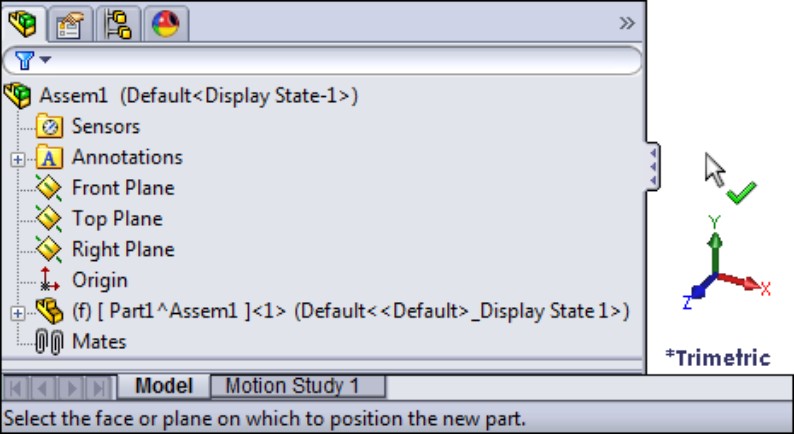

Working in the assembly FeatureManager

The FeatureManager in assemblies has some special working modes (see Figure 2.5). It does many of the same things that the part FeatureManager does, but because it manages parts rather than features, you can expect some differences.

You will also encounter some special icons in the assembly FeatureManager. Here is a list of some of these icons; they will all be explained in more detail throughout this book.

FIGURE 2.5

The FeatureManager for a simple model

• Lightweight and Hidden Lightweight. Lightweight components have data loaded from the assembly only. Hidden Lightweight have the data loaded but are not visible.

• Out-of-Date Lightweight and Hidden Out-of-Date Lightweight. Out-of-date lightweight parts exist when changes have been made to the original part, but it hasn't been reloaded yet into the assembly. The symbol notifies you that what you see in the assembly may not represent the current state of the part.

• SpeedPak. SpeedPaks are derived configurations that use only body or face geometry (no parametrics) to display parts and subassemblies within upper-level assemblies. You will learn more about all of these techniques later in this book.

• Envelope. An Envelope is a part in an assembly that is not counted toward the Bill of Materials (BOM) or mass properties. Its primary function is to designate an area for selection. It could designate the range of motion of an operator or piece of machinery, or an area where noise may be above a certain decibel level. Envelopes are intended to be used as part of the Advanced Component Selection that you can access through the menus at Tools⇒Component Selection⇒Advanced Select.

• Update Holders. Update Holders contain the information about external references in assemblies where in-context references have been made. They are hidden by default, but you can show them by right-clicking the name of the assembly and selecting Show Update Holders.

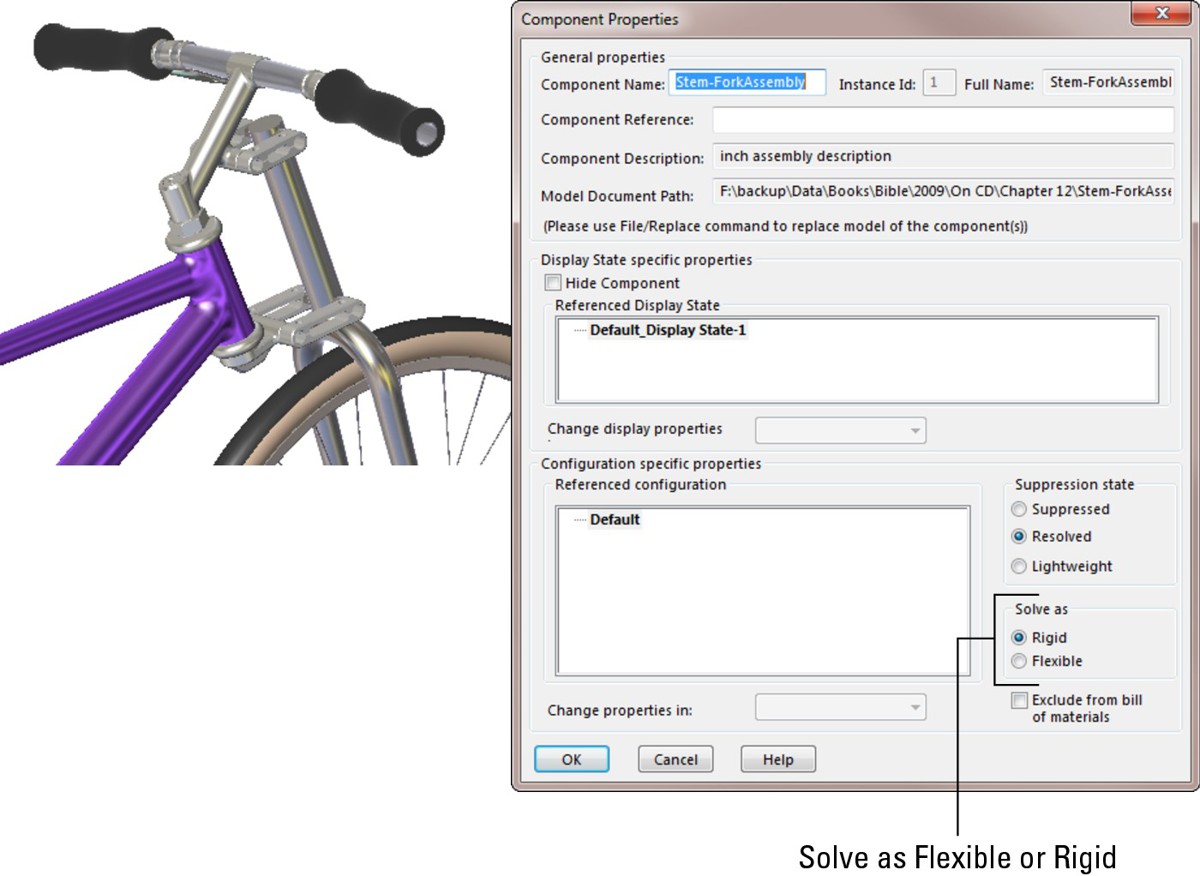

• Flexible Subassembly. SolidWorks solves assembly mates within the assembly document by default. This means that any mates (and motion) associated with a subassembly will not be solved in the upper-level assembly. If a joint is in a subassembly and you want it to move while displayed in the upper-level assembly, you must make the subassembly a flexible subassembly, using the Component Properties dialog box.

• Display Pane. You can open the Display Pane flyout from the FeatureManager by clicking the double arrows at the top-right corner of the FeatureManager. The Display Pane helps you to visualize where appearances, display styles, or hidden bodies have been applied in a part document and where appearances have been applied at various levels (overrides) in an assembly document. The Display Pane is helpful when you're looking for colors that are applied to the model at some level other than the part level.

• Rollback Bar. The Rollback bar at the bottom of the FeatureManager enables you to see the part in various states of history. You can add features while the Rollback bar is at any location. You can also save the model while it is rolled back.

• FeatureManager Filter. One of the most useful elements of the FeatureManager is the FeatureManager filter. The filter resides at the top of the FeatureManager. If you type text in the filter, SolidWorks searches part names, descriptions, tags, comments, document properties, mates, and configuration names for matching text, and only shows matching components in the window. The filter is very useful for quickly finding parts, features, mates, or anything else that shows up in the part or assembly FeatureManager.

Working with multiple document windows

You may sometimes have the luxury of working on a single part at a time, but more often you will have several documents open at once. Fortunately, SolidWorks has several methods for dealing with “information overload,” to help you sort through it all.

Managing open windows

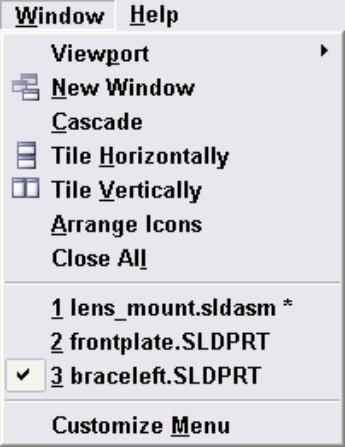

Like most Windows applications, SolidWorks can arrange the open document windows in one of several ways that are available through the Window menu (see Figure 2.6):

• Cascade. This is most useful for accessing documents that are to be edited one by one.

• Tile Horizontally. This is most useful for wide and short parts.

• Tile Vertically. This is most useful for tall, narrow parts, or documents where you want to compare items in the FeatureManager.

• Arrange Icons. When windows are minimized to icons, this menu selection arranges the icons neatly, starting in the lower-left corner of the window.

FIGURE 2.6

The Window menu

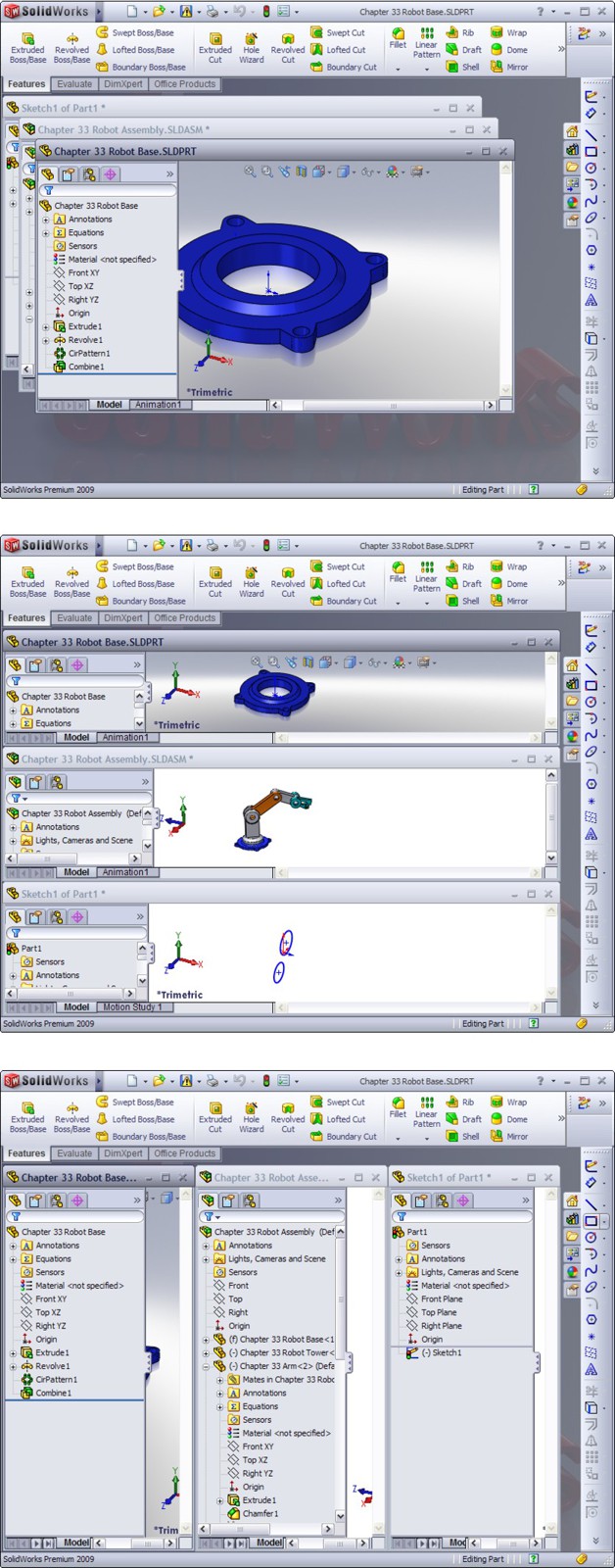

The images in Figure 2.7 are meant to show the arrangement of the windows, not the content of the windows. Also, remember that you can use the F9 key to close the FeatureManager; the F10 key to remove the toolbars to create extra interface space when arranging several windows in the graphics window; and the F11 key to remove portions of the interface and enable you to work full screen.

FIGURE 2.7

Window arrangements: Cascade, Tile Horizontally, and Tile Vertically

Understanding the Interface for Moving and Mating

Moving and Mating operations are exclusive to assembly documents and so have some unique interface elements. For the easiest type of moving parts that are set up for dynamic assembly motion, there is no interface at all. You just select the part and drag the cursor. This type of moving is not always as precise as you might need, so SolidWorks enables other types of moving with different interfaces.

You can prevent the motion of components while dragging by turning off the option found at Tools⇒Options⇒Assemblies⇒Move components by dragging. This option is turned on by default.

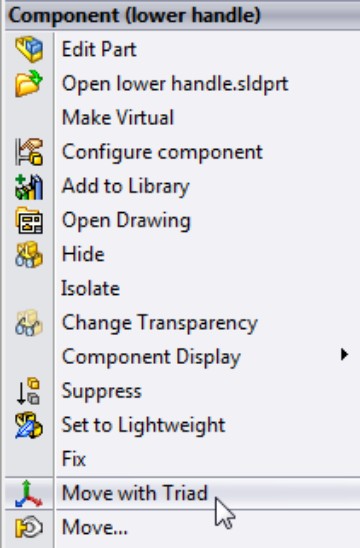

While moving a part with the default (select) cursor, you can choose some options from the RMB menu to help you move the component. Figure 2.8 shows a portion of this RMB menu.

FIGURE 2.8

Selecting other options for moving parts in an assembly

The Move option simply opens the Move Component PropertyManager, where you can access the options and controls shown later in this section.

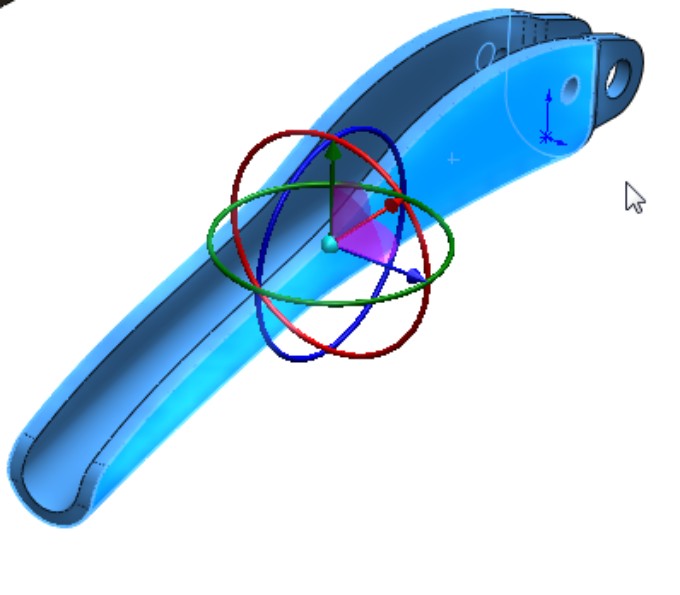

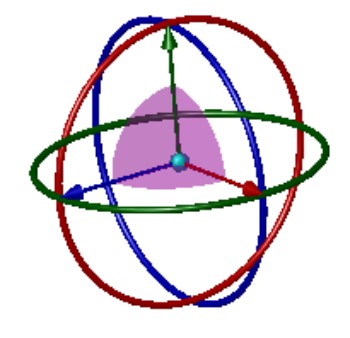

The Move With Triad option brings up a triad with wings and concentric rings, shown in Figure 2.9. This may seem confusing at first, but its function becomes clearer as you use it.

FIGURE 2.9

Using the triad to move components

The arrows enable you to move parts along that direction only. The rings enable you to rotate the part around that direction only. The flat “wings” between the arrows enable you to move the part in a plane parallel to the flat wing. To use these wings correctly, you must sometimes reposition the view so you can see the wing properly in order to select it.

The small, blue ball at the center of the triad enables you to move the triad to a more convenient location. It does not snap to any geometry. Moving it only gives you a better view or makes it easier to select parts of the triad without selecting something in the background.

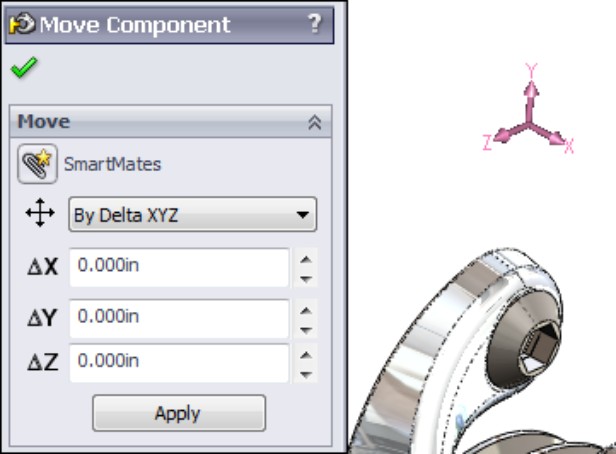

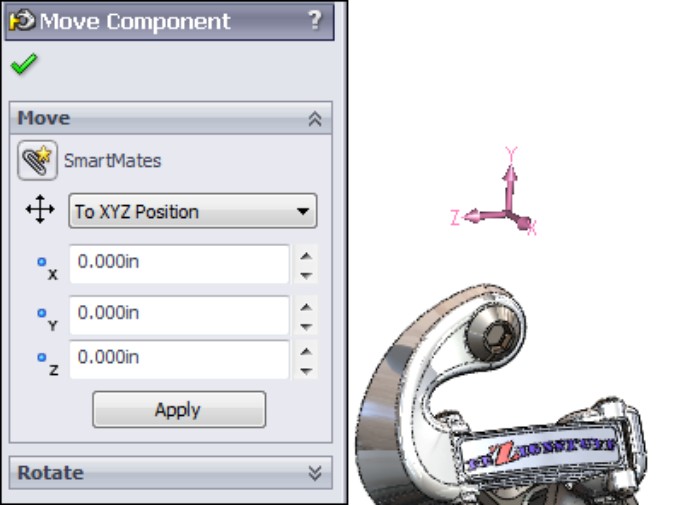

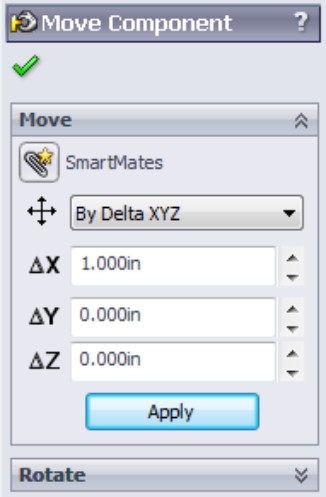

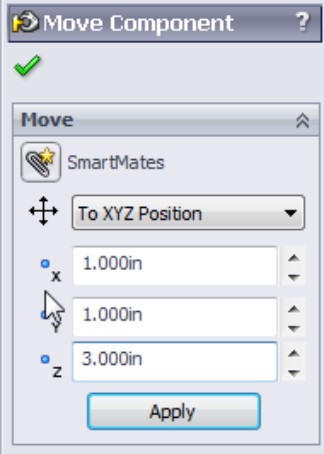

Using the Move Component interface

The Move Component tool enables you to move parts in an assembly using various methods. Figure 2.10 shows the interface for this tool.

SolidWorks allows you to move parts in assemblies using the following methods:

• Free Drag

• Along Assembly XYZ

• Along Entity

• By Delta XYZ

• To XYZ Position

All of the following movement options are available for both translation and rotation.

FIGURE 2.10

Available options in the Move Component interface

Free Drag